Week 5

Electronics Production

Objectives

Individual Assignment

Group Assignment

Learning Outcomes

Individual Assignment

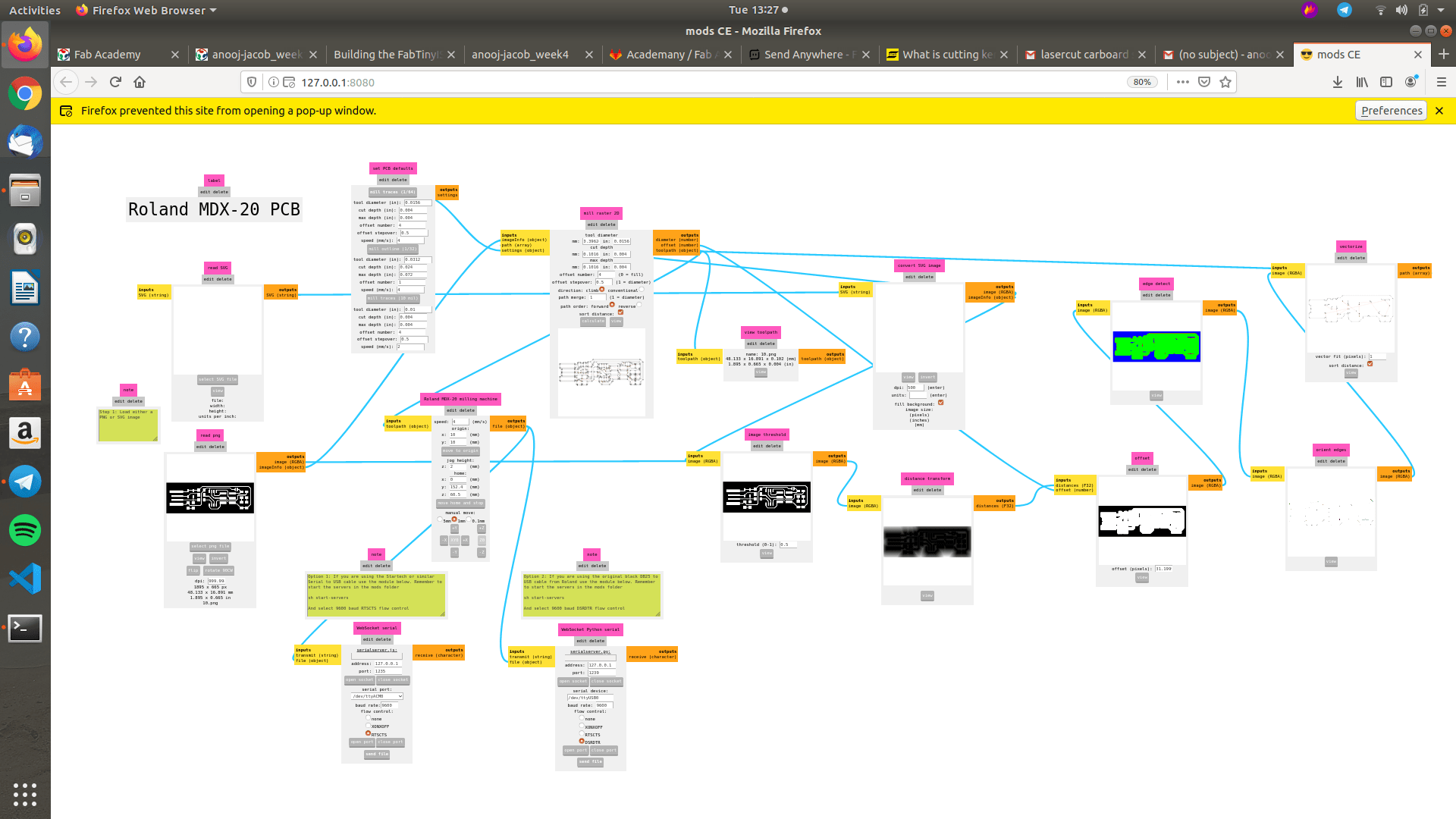

Milling Machine

Milling Tool

1) 1/64 tip - It is used for milling traces on the PCB, The tip size is 0.00156in or 1/64 of an inch

2) 1/32 tip - It is used for milling profiles and to cut holes, The tip size is 0.003125in or 1/32 of an inch

Both these tools have carbide tips.

Setting the Tool on Modella

- Raise the Z axis to the top

- Release the chuck using the L-key

- Insert the 1/64 inch milling bit a little more in to the chuck

- tight the screw

- Down the z axis close as possible to the bed

- Unscrew the chuck and release the bit

- Slightly press the bit close to the bed and tight the chuck screw

- Done

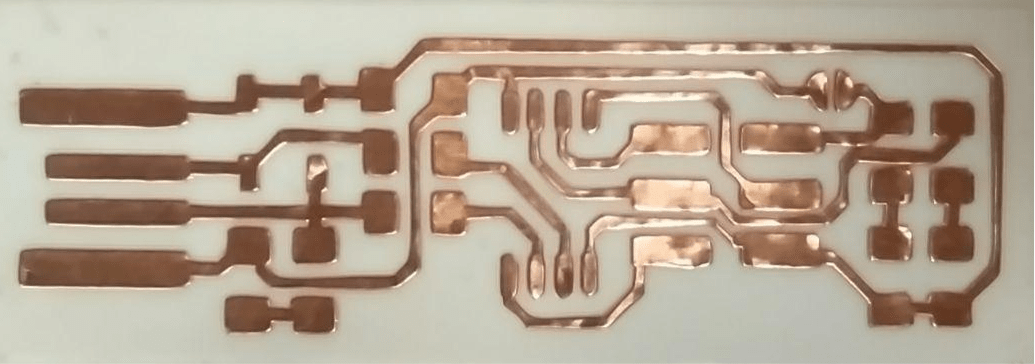

Making the PCB

MISTAKE

Soldering the Circuit

Programming the Micro-Controller

Vinyl cutting of PCB

Laser cutting of PCB