Assignment

- Group assignment: Make lasercutter test parts, varying cutting settings and slot dimensions

- Individual assignment: cut something on the vinylcutter.

- Design, make, and document a parametric press-fit construction kit using lasercutter.

Introdcution of Laser cut and Vinyl Cut

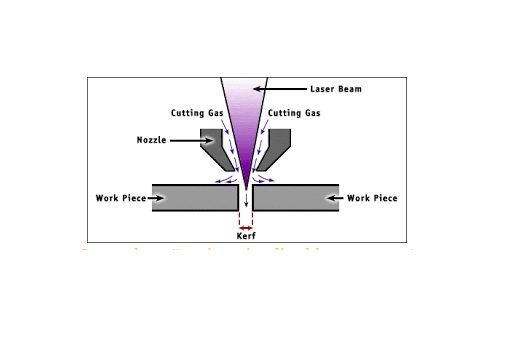

Laser CutLaser cutting is a technology that uses a laser to cut materials and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses and hobbyists. Laser cutting works by directing the output of a high-power laser, by computer at the material to be cut. The material then either melts, burns, vaporises or is blown away by a jet of gas leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat sheet material as well as structural and piping materials. Additionally, laser cutting easily adapts to ever-changing manufacturing demands, both in terms of production volume and market needs. The equipment used for laser cutting can be set up and repurposed for specific needs much faster than can the tools associated with traditional cutting processes. And since the materials cut with lasers typically do not require additional cleanup, the use of laser cutting increases throughput and eliminates other secondary operations, allowing the product to be made available to clients in less time.

Vinyl CutA vinyl cutter traces out shapes and graphics for precision cuts applicable to multiple facets of vinyl image transfers. These machines are used in the sign and t-shirt making industries and range from the small, portable desktop variant to large format machines used, amongst others, in the automobile and marine industries. Able to run on simple or complex design software, textile vinyl rolls of varying thickness, density and application can be cut with an adjustable rotator knife, mounted as per requirement. Vinyl cutters differ in cutting force and speed depending on individual machine specifications. With regards to stickers for the automobiles, lots of people might recommend using vinyl peel off stickers because they certainly look better than regular peel off stickers. In addition to that, the actual designs could be better maintained long-term using vinyl stickers. People buy shirts along with beautiful and different styles. Occasionally, they would like to have that option of making their very own designs, as well, and also have those designs printed on their shirts. That should make a truly superb company. Whenever prior to, it was a little tougher to finish in a short span of time, we can currently obtain wonderful outcomes with vinyl cutters. It could be examined just how much these vinyl cutters cost these days. Read with regard to truthful reviews of these types of publishing as well as graphic disciplines equipment.

Vinyl Cutting

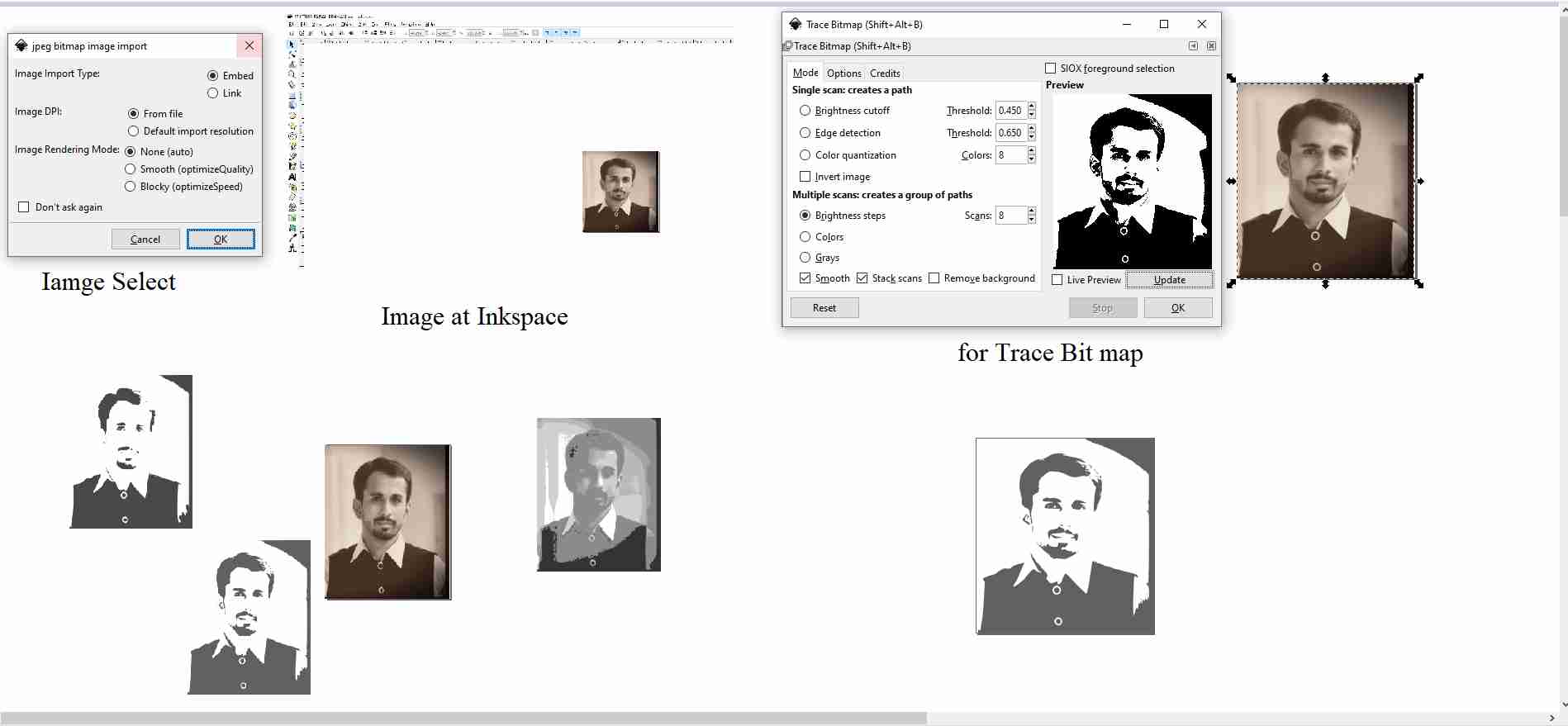

In this Week I want to cut my Gray picture by using Vinyl cutter. For Perfoeming this Task I want Use tha Inkspace Sotware for the Image conversion.

- Open the Inkspace Software and Select the Iamge for the Vinyl Cutter

- select the image and to the Path and Press the (shift+alt+B)for the trace bitmap

- Now a window while be open, from there select the "Gray image " at the window.

- Now ungroup the image and you while find many gray scale copies of your orignal image.

- Now to make it complete black and white from gray image just select the picture and change the colour to black

- Vinylcutter only cuts the Edges, so we need to get the outline of the image, we can get it easily with trace bitmap and then stoke in inkspace.

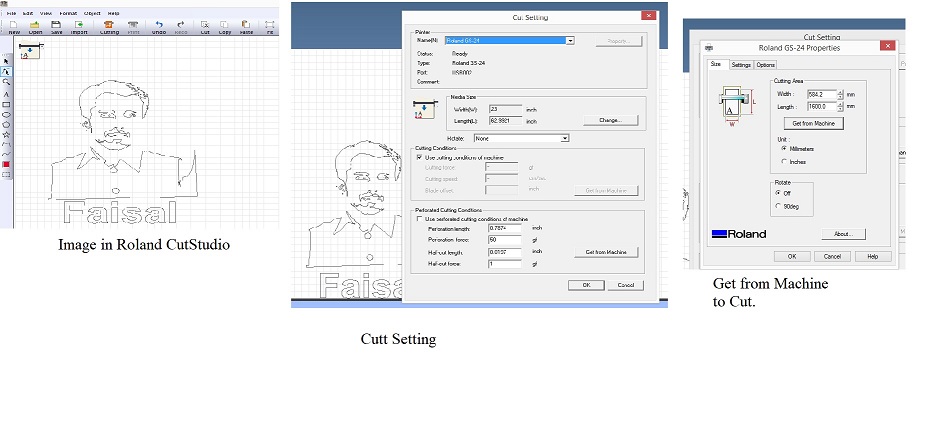

After all the Process, Now we have to convert the .svg file to PNG image for the Vinyl cutter that is given below.

Vinyl Cutter Machine.

This machine we will use to cut the Vinyl.

Operting and loading the Material in Vinyl Cutter for the Cutting

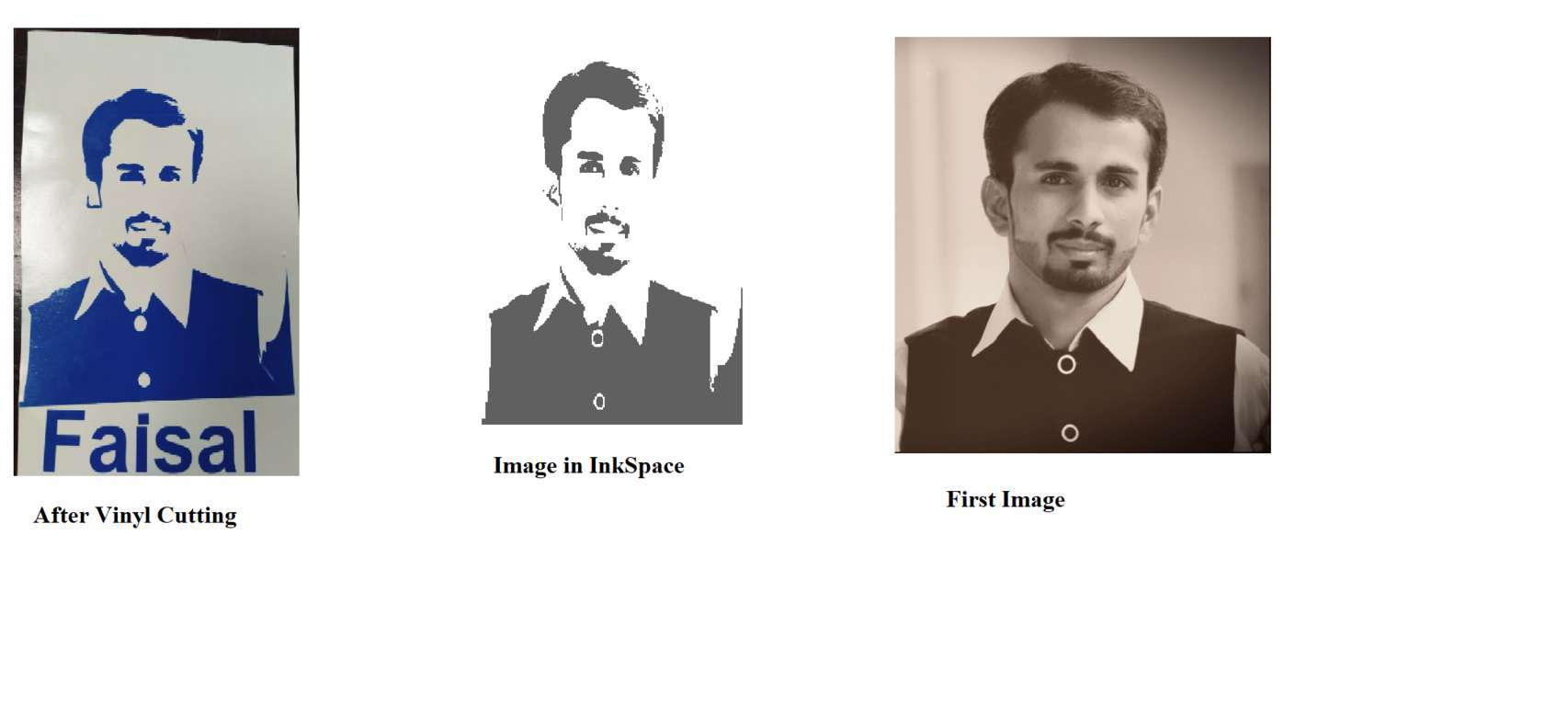

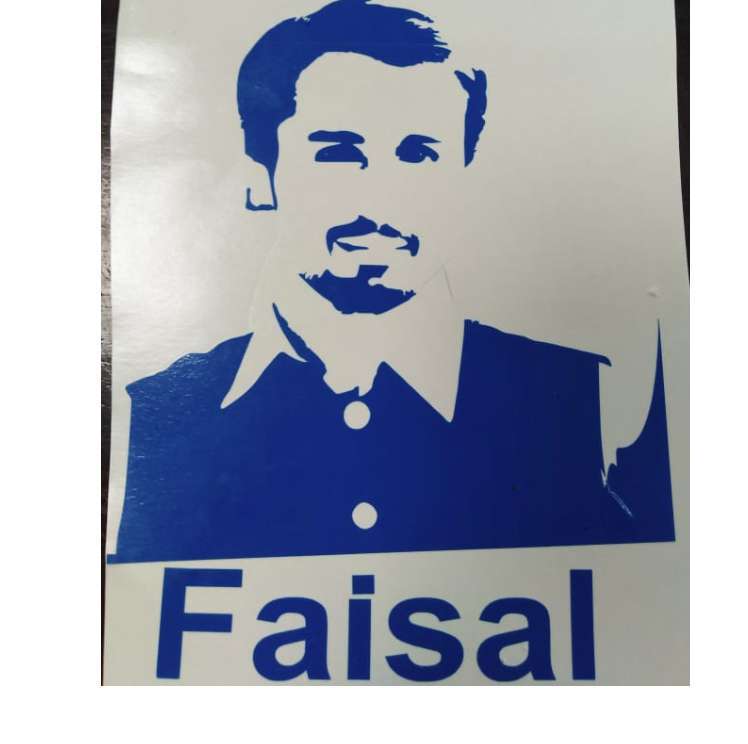

Result Compersion between the of Vinyl Cutter and Origional images

Result of Vinyl Cutter

GROUP ASSIGNMENT: CHARACTERIZE YOUR LASERCUTTER'S FOCUS, POWER, SPEED, RATE,KERF, AND JOINT CLEARANCE.

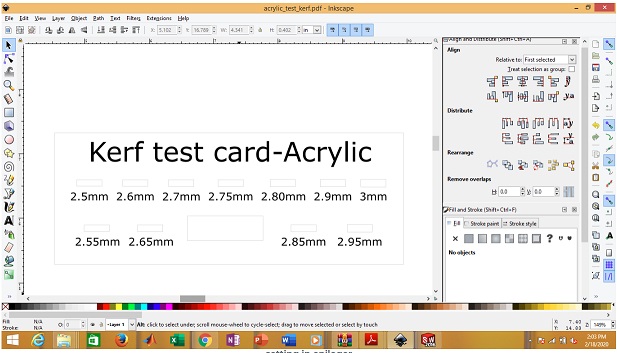

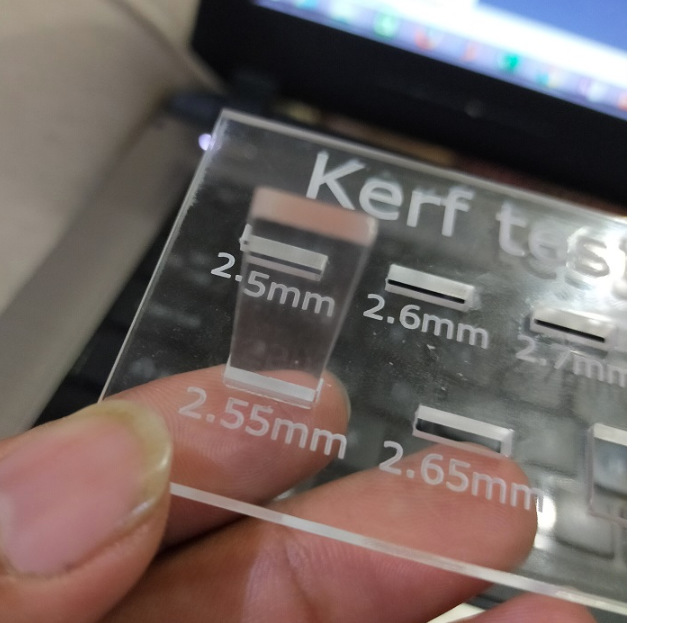

In this week we have to work on laser cutters. So first of all we need to charatarize the few things of laser cutter. One number is Kurf. When laser burn the material, the thickness or area of material which burn away are called kerf. The area(thickness)vary in order to measure the kurf of our laser cutter, we have design file in INKSPACE. First we measured the thickness of our material and then we have made rectangular boxes of different thickness with 0.05mm difference around the actual thickness of material. and also cutted the one long slit of same height. Idea is that which whole is perfect fit for that slit.

Measuring the thickness

Making boxes in Inkspace

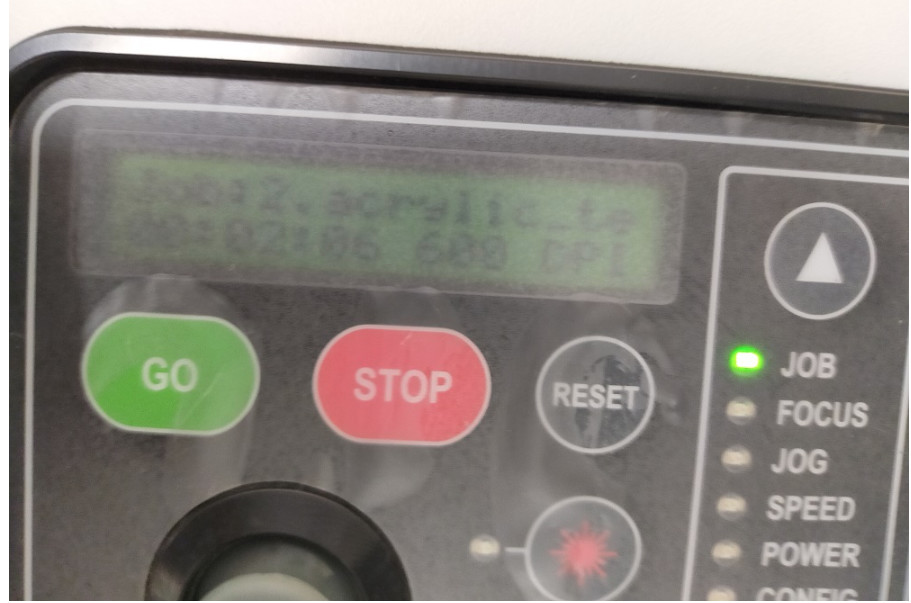

Resetiing the Machine

Testing kerf in different slots. 2.55mm suit best for 2.77-2.75mm

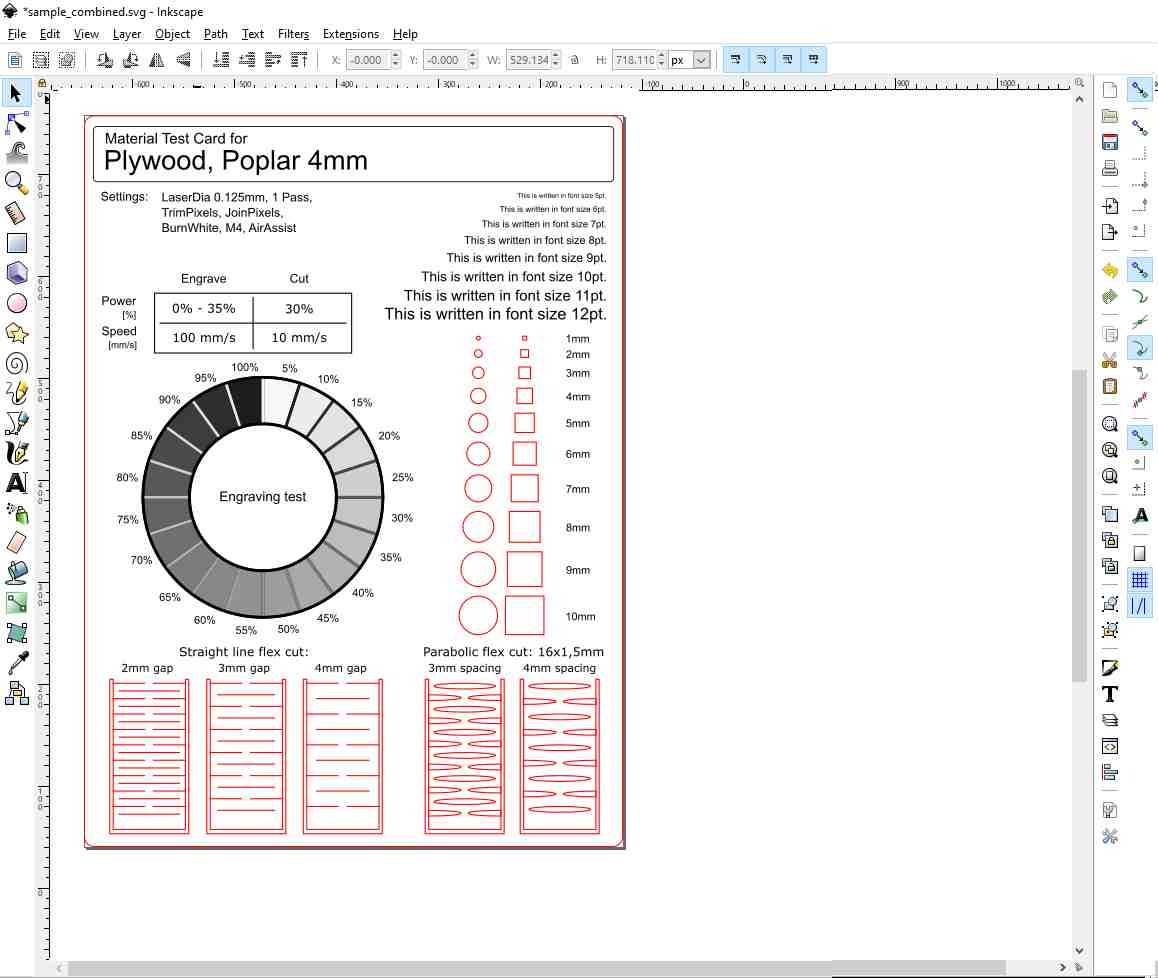

TEST CARD FOR POWER,SPEED,FOCUS,RATE

This File Downlaod by the Fab Acadmey 2020 course Week 5th Group Assignments

this is the final look of the group assignment.

Last Task Laser Cut.

In this week I have design the box that based on the press fit kit, for this task I have used the Inkscape software to design the box. so all step are mentioned below.

First I have open the Inkscape software and draw the black box for the bottom.

After that I have set the teeth of the bottom box

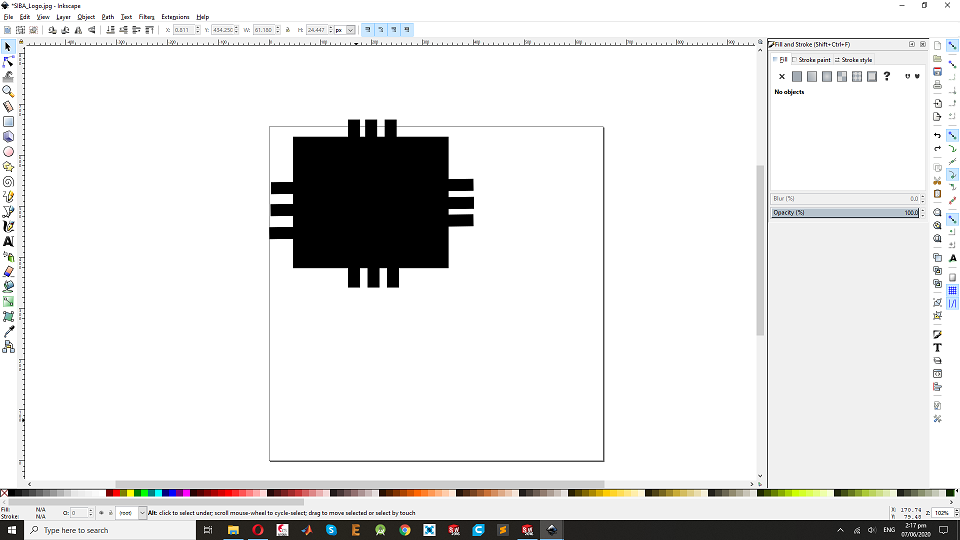

After that I have design the teeth all four sides with 5mm.

Remove the black back ground of the design just draw as this.

Now design the side of the box that has also whole which is used to fixed the uper side of the box.

Add some flower design in side of box to look better. and this for the engrave.

Now design frint side of the box and remove the black background.

Add some flower design in side of box to look better. and it is engrave.

Now I have design the box top , and add two teeths on the sides for the fixing . and this design will cut on the acrylic sheet of 5mm.

Now remove the black background from the top , and add logo of sukkur iba and one flower. that are engrave.

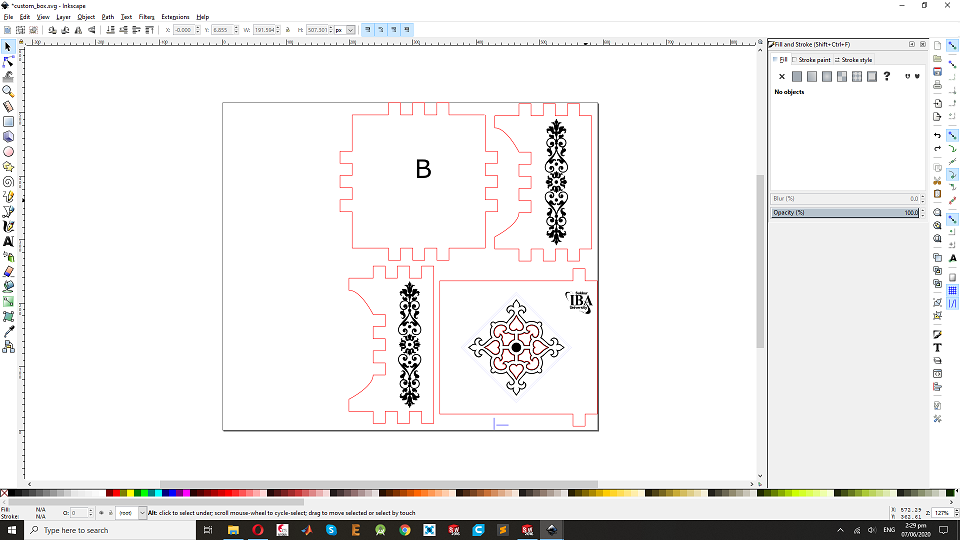

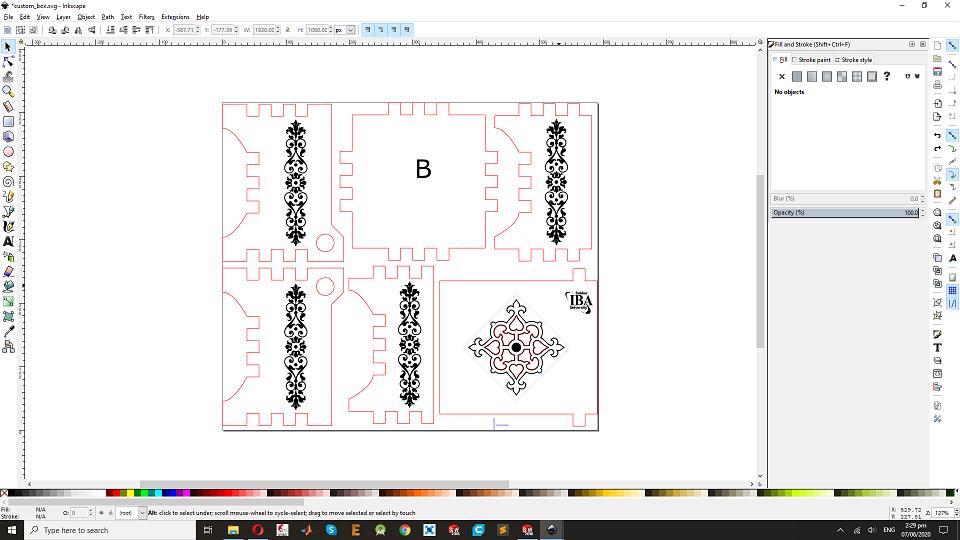

Now phase to combine the all designed box part in to one page for the furthermore process.

this is the final design of box for the laser cut.

This file is ready for the cutting so i will set some changing in this file then goes to cut the design, First set the Stroke pint color is black and stroke style is 0.001ich. and Now Now save file as a .pdf , while saving file as a pdf it system will open a dialog window, asking for dpi (dots per inch) you need to set it to 600 and click ok..

laser Cutting :

To do this job we will use the Laser cut machine that is Epilog Laser Cutters and this software Epilog job manager.first open the pdf file in pdf set the design parameter mean where we have to cut the design and then press the print option. then design will shift on the Epilog sofware.

First step to open the Laser cut machine and put the 5mm acrylic sheet.

Second step Now we open PDF file and press Ctrl+P to open printing properties, Select Epilog Engraver WinX64 Fusion in Printer Tab and click Properties.

We set Raster power to 100% and speed to 100%. and Cutting power to 30% and speed to 10%, after setting up parameters click OK and the job transfer to Epilog Job Manager. Now check the file that it is posible for the engrave.yes this file is valid for engrave.

After check the vector of file.

We select our job and check the preview by clicking on "preview".Select the location of job by dragging the image in preview menu and set where we need it on Laser machine bed, and click "Save",

After selecting the location click Save and click on print to transfer job to laser cutting machine.

Design is ready after the cutting.

Now my design is ready after the cutting and I ahve assembled the prees fit and its look like this.

This is the view of the Design .

This is the an other view of the of the Design .

Conclusion

In this week I have Learned to design parametric CAD design and software, Learned that how to run 'Vinyl cutter machine' and 'Epilog laser cut machine', Laser cutting machine is the effective way to engrave and make designs on plywood, cardboard, and other materials too.Vinyl cutting is the effective method of making stickers.and also this week is more use ful of the CAD design.

Download all files from Here

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License