Week 10 : Applications and Implications

the assignment for this week are:

-

We have to answer a bunch of question concerning our final projects:

- What will it do?

- Who's done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

- NOTE:

- Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production,

- microcontroller interfacing and programming,

- system integration and packaging.

- Where possible, you should make rather than buy the parts of your project

- Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

1.What will it do?>

What is a humidifier?

In general, Humidifiers add moisture to the air to prevent dryness that can cause irritation in many parts of the body.

I want to make a humidiefier that whenever there's low humidity in the air, it starts to work on it's own!

What is an ultrasonic humidifier?

An ultrasonic humidifier, however, uses a high-frequency vibrating diaphragm made from either ceramic or metal to produce an extra fine mist that is expelled into the room. This vibrating diaphragm sits on the water reservoir’s surface where it churns the water at a high frequency to create droplets that are then blown into the air by a fan.

2.Who's done what beforehand?

Technically in the Fabacademy no one has done it before, but what I know is that, Joe Zoulikian from Berytech Fab Lab made a De-humidifier which is the opposite to what I'm going to make!; He made a Dehumidifier for the 3D printer(for the filaments to keep them in a less humidity environment;It kind sucks the humidity out of ).

However, it’s widely so known and commercialized everywhere in the planet!

NOTE: I gotta say that this kind of thing ain’t that widely known here in Tunisia and no one knows its benefits..I suppose "^^

3.What will you design?

- A water tank and a box for the PCB and the sensors using the 3D printer!

- The outerbox using laser cutter; In fact I'm thinking about making a traditional Lamp design !

- The PCB board for the Input and output devices!

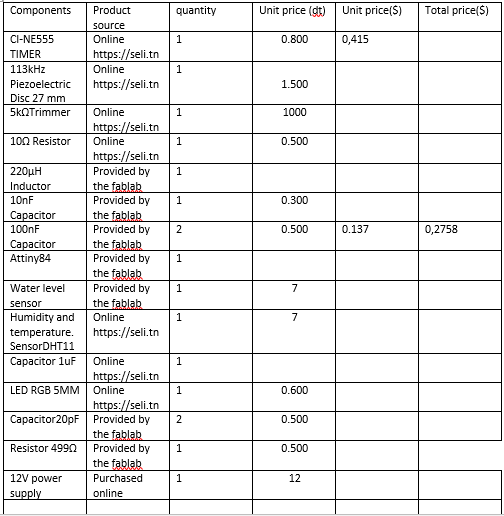

4.What materials and components will be used? 5.Where will come from? 6.How much will they cost?

Bills of materials

7.What parts will be made?

- The Ultrasonic mist maker:Since one of the central component “the Ultrasonic Mist maker” is nowhere to be found here in Tunisia, I decided to make a one using a piezo transductor and some other components for its board to work.

- I'm gonna design the entire model usinf Fusion 360, and then gonna print it using the 3D printer!

- I'm not too sure that I'm going to use the laser cutter here, but yeah(this part needs to be uploaded)

8.What processes will be used?

- 2D and 3D Modeling.

- Subtractive manufacturing: Laser Cutting for the outer box

- Additive manufacturing: 3D Printing for the pcb , sensors and the the water tank

- Electronics Designing.

- Electronics Production.

- Input & Output Device.

- Networking and Communications: I’m thinking about making an application to mentor the work of the humidifier!

9.What questions need to be answered?

Since I never really used a mist/fog maker before and I kinda don’t know how it really works, so the big challenge here is to make it really work on my terms!

I need to make a circuit drive for the piezo disc!

Note: I'm thinking about adding other things!

10.How will it be evaluated?

- The design as a whole has to be well made and good looking.

- Accurate communication between the input and output devices.

- No wirings shall be visible first of all. Overall the product has to be neat and tidy.