Molding and casting

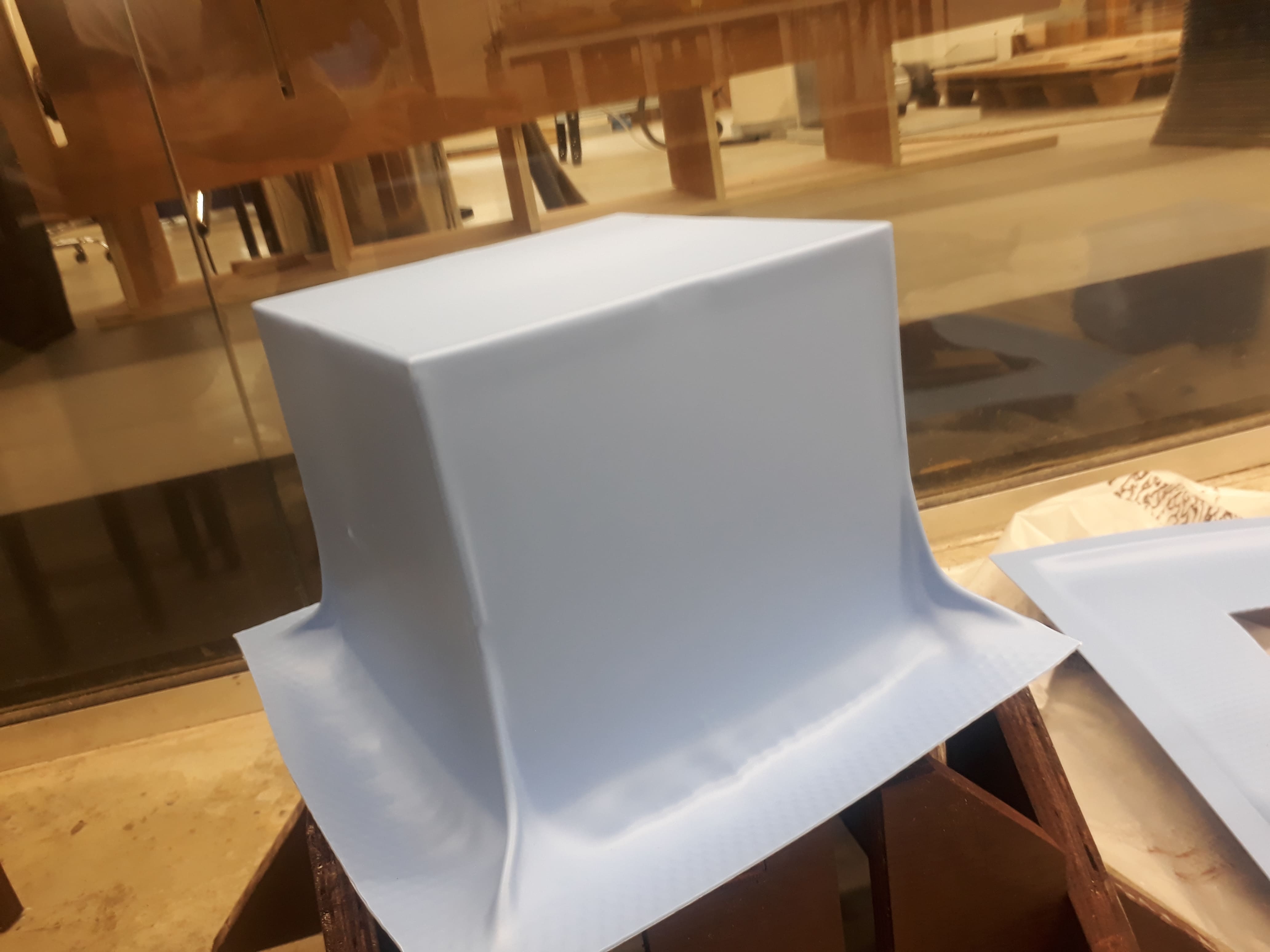

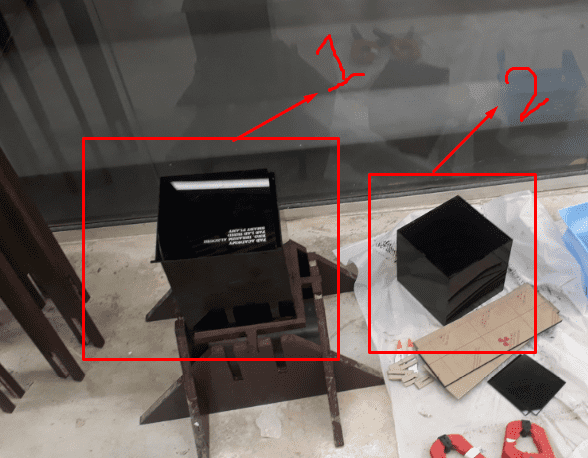

It is used Molding and casting to make an internal tank inside the acrylic tank in order for it to be waterproof and not leakage, so I made a box smaller than the water tank and put it inside the tank to form the tank together as a template for pouring the tank

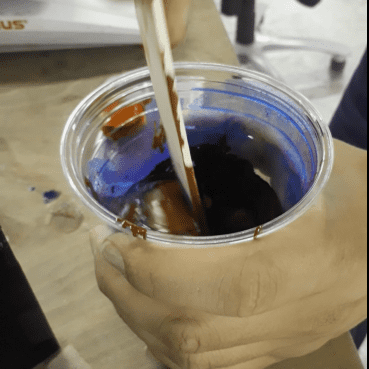

Important; you must weigh Part A & B components using a gram scale to be successful with Mold Max™ 60

As the mixing ratio is 100 A: 3b

Then I mixed the two materials quickly before pouring

But the result was disappointing, as the box needed a large amount of materials and due to the high density of the materials, it hardened before it reached the bottom and was distributed, and this result was

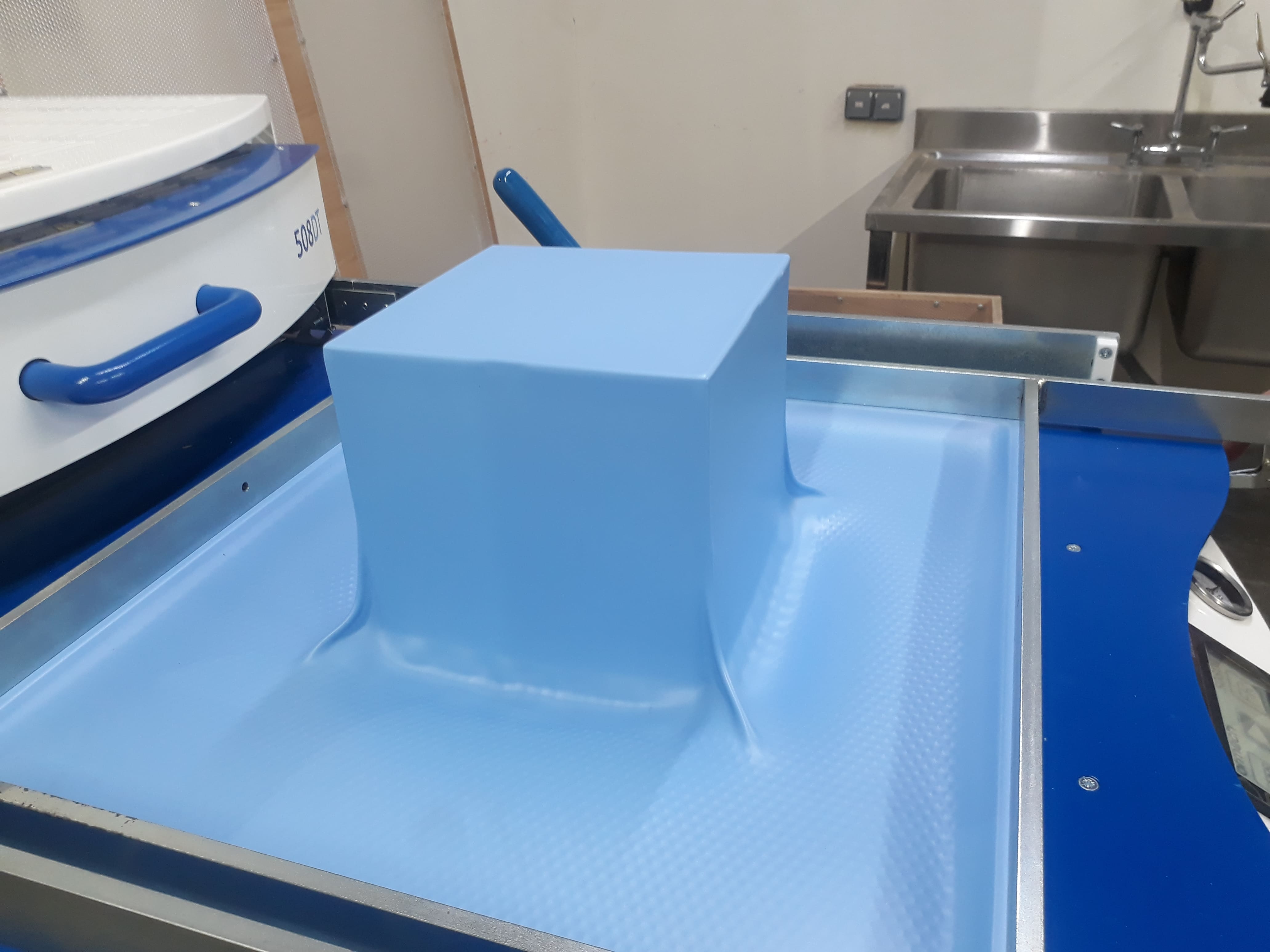

After this, another method was used to make an in-house non-leaking tank via a 508 TD formech You can also work on this machine as shown in the video below

I put an acrylic box in the machine and the result was great

Then I cut the excess and put it in the acrylic tank