The structure of the project was designed by using wood and by CNC.

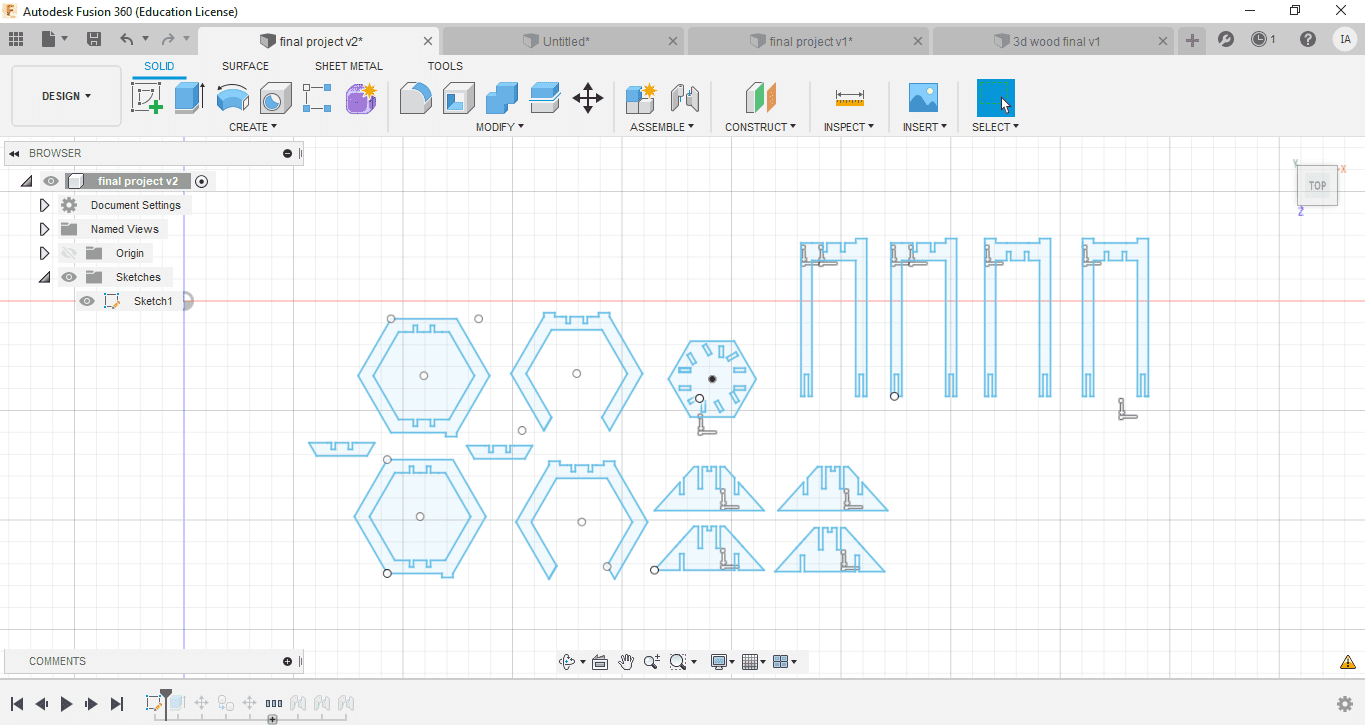

Initially I prepared the design on the fusion360 software and started

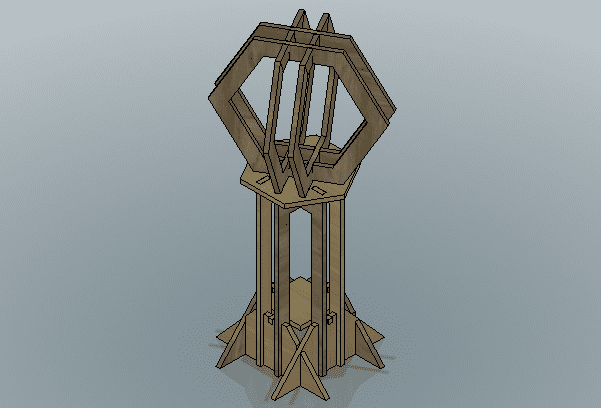

Then I simulated the design to make sure the design met expectations and to avoid errors

The result was great, compliant and free of any errors. Then I saved the design in DXF format and went to the wood drive to cut the design on CNC.

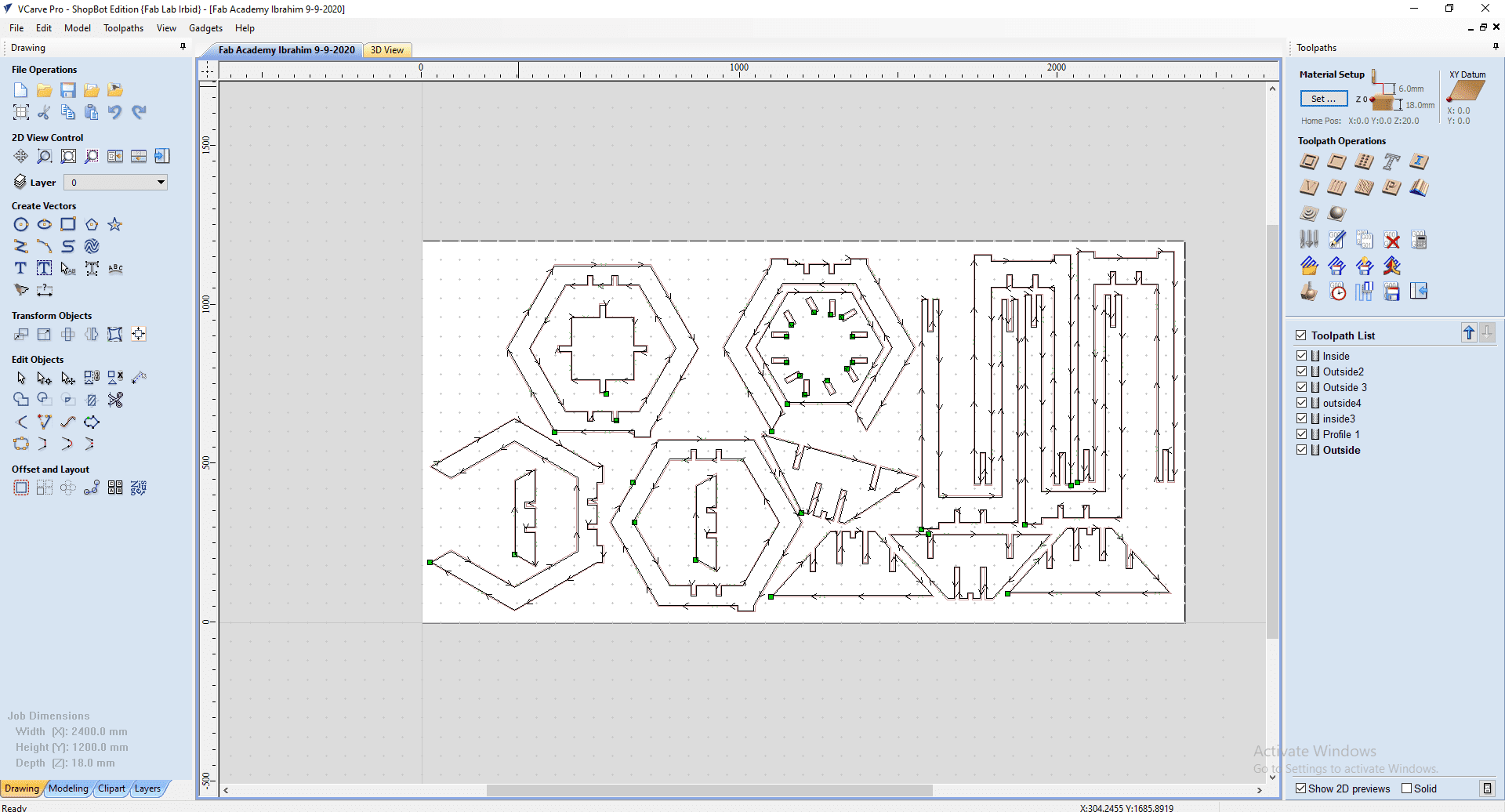

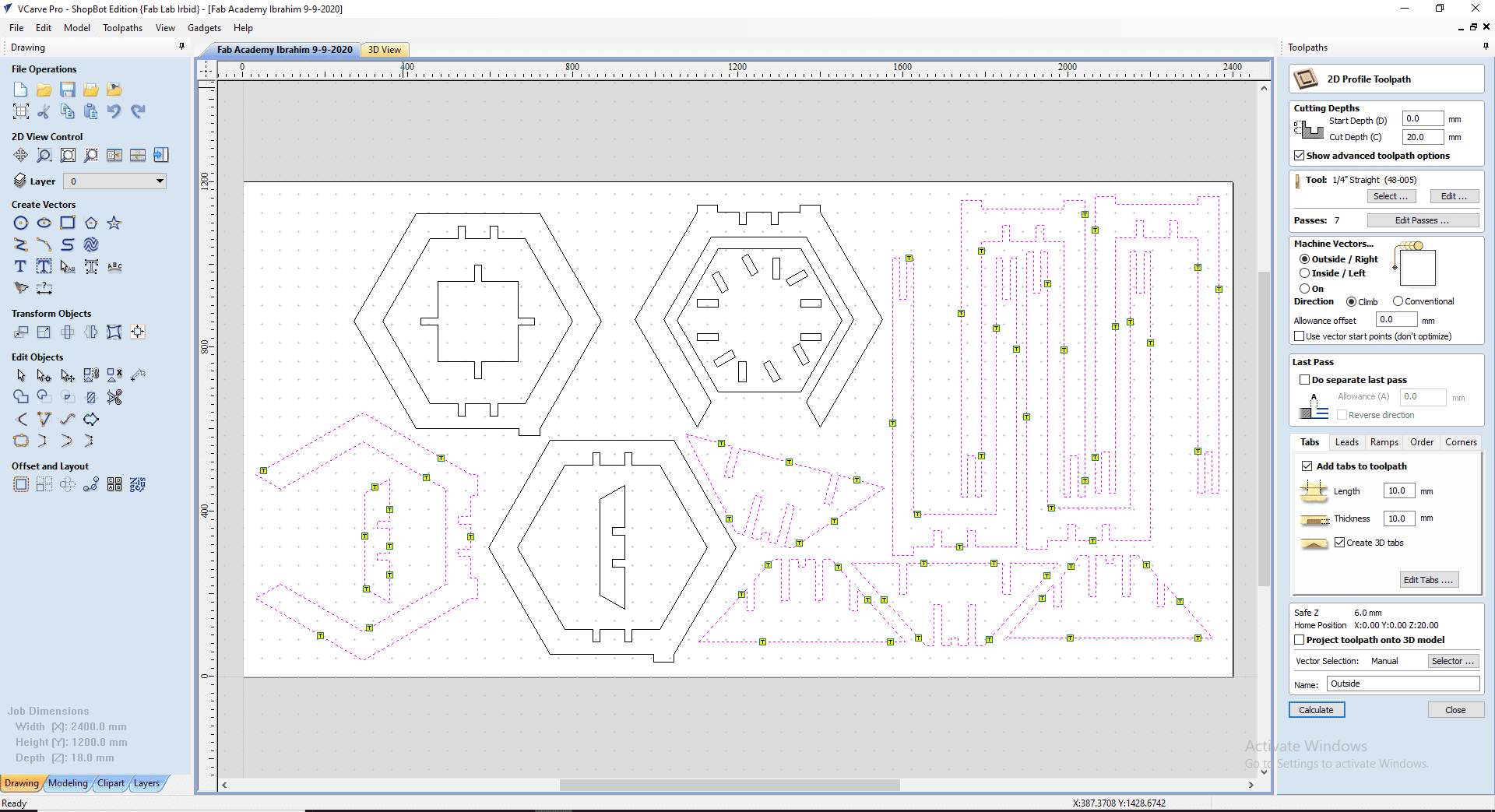

Open the design on shopBot and prepare the settings

Then I determined the cut from the inside and then the cut from the outside and arranged the cuts.

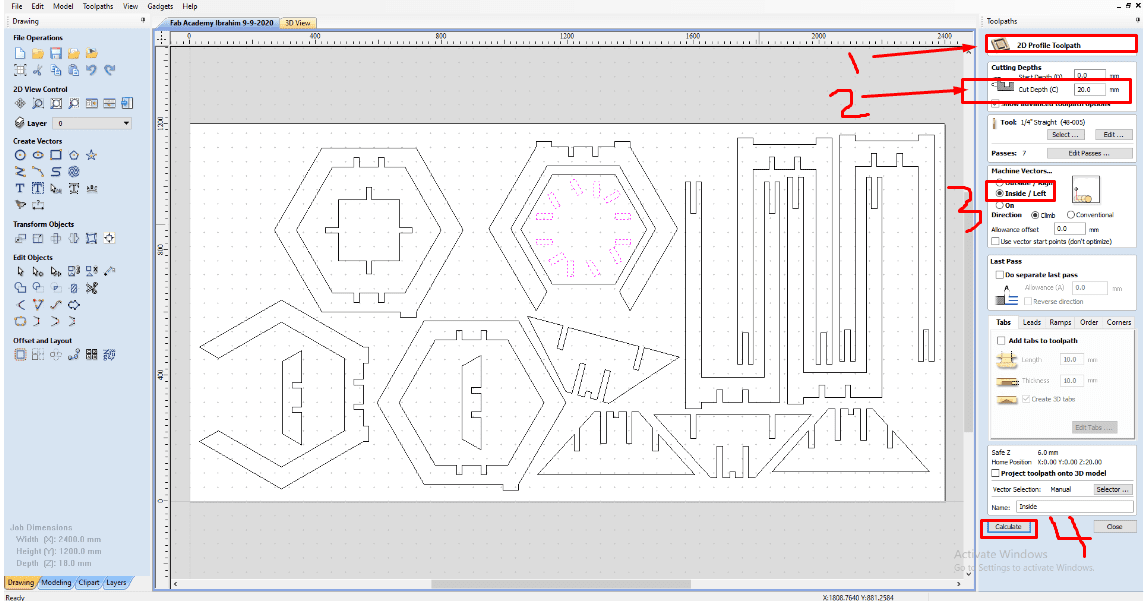

Through the toolpaths command, specify the thickness of the plank and then specify the type of cutting that is inside and here I do not need to add tabs so press calculate.

And adjust the settings with the rest of the pieces of the design, but specify the pieces outside

After finishing, I save the file in Gcod format

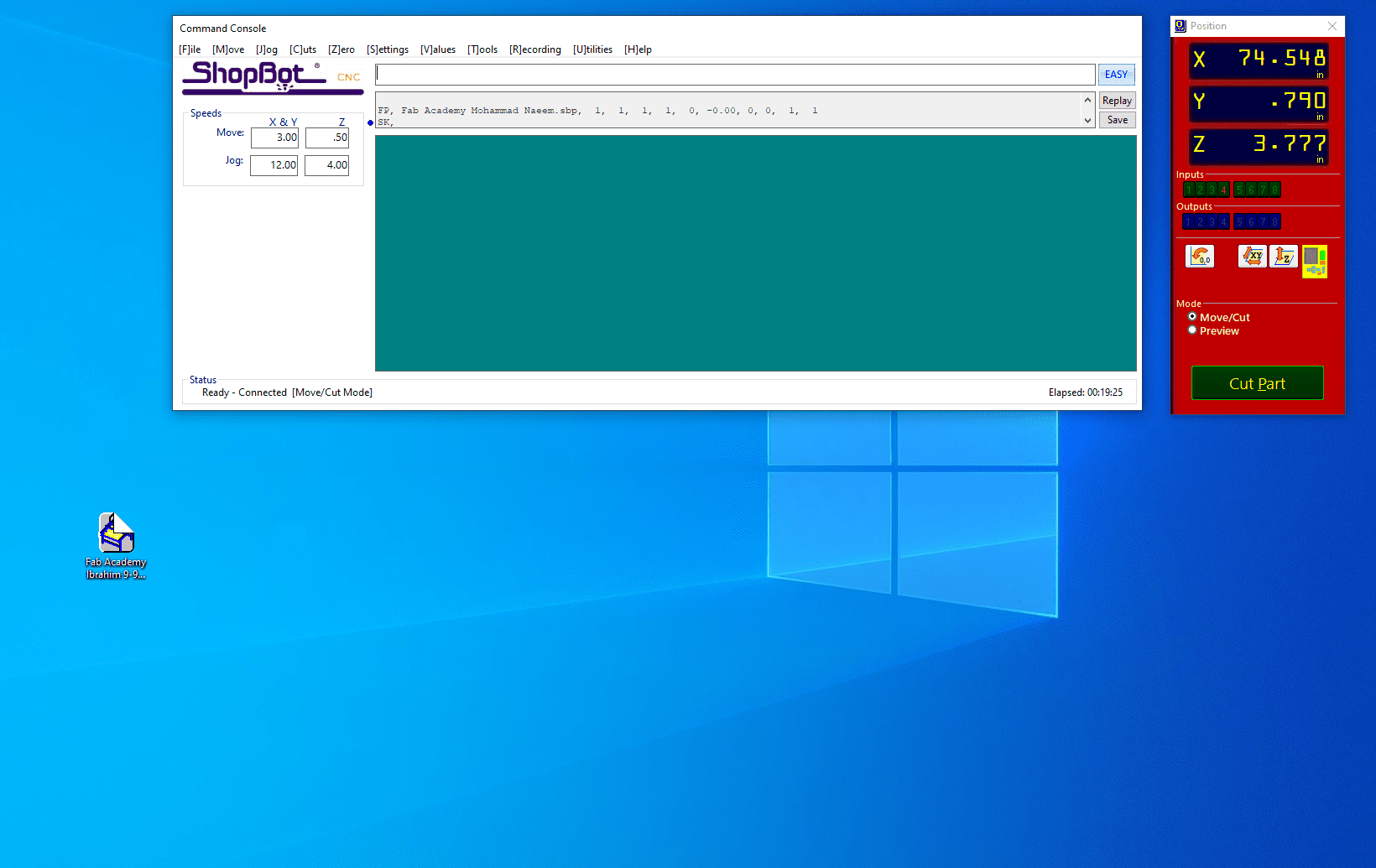

Now adjust the z-axis using the tweezers and the metal parts shown in the picture

And don't forget the general safety equipment like glasses and headphones

Then tap the green start button

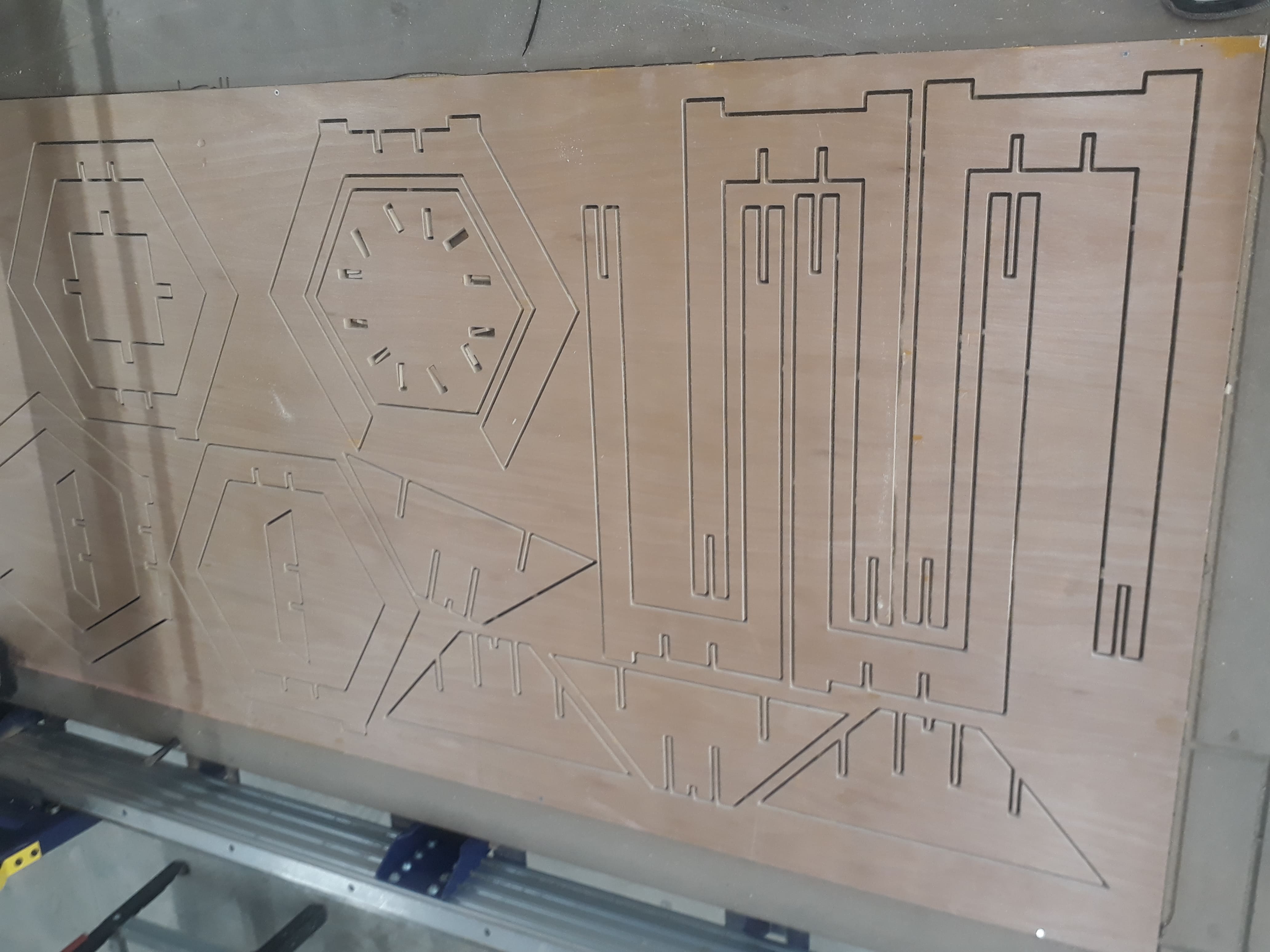

And this is how the mowing process begins

Now is the time to paint

you can download my design click here