Total Indicated Run-out (TIR)¶

Mill Test Traces¶

The fab academy test trace file above was use to create cam to test our X-Carve 500mm size milling machine. I purchased the smallest 500mm model of the X-Carve mill because it would be more rigid and so it would fit on a normal work bench top.

I had been told that it was impossible to micro-machine or mill a circuit board on a lower cost (sub $1000) milling machine like an x-carve. I suspected that this was not true, so I proceeded in the following way. It seemed to me the mass of the spindle, small cutting diameter, and rigidity of the machine was capable. I did know that vibration and concentricity of the tooling in the spindle may be important.

I wanted to make sure my x-carve spindle was ready for micro-machining. The first few times I tried to machine my circuit board on my x-carve it broke the 1/64” diameter end mill almost immediately. The bit also seemed to be vibrating a lot despite the fact that the spindle itself was runny vibration free and quietly. Being trained as a machinist years ago, I knew I should check the spindle and tooling run-out of the 400watt 48vdc quiet cut spindle we have installed on our x-carve mill. Below you can see photos where I am using a Mitutoyo 513-406-10E Dial Test Indicator to check the run-out. This specific Dial Test Indicator was suggested by Ron Reed at Precise Bits a micro machining supplier I called in the process of researching micro-machining.

After rotating the tooling, collet and spindle the Total Indicated Run-out (TIR) measures a max of .0015” which is OK for a 1/64” diameter bit, but could be improved. I am waiting for some new collets from Precise Bits and we will see if they can improve TIR. Also of note is that Ron suggests carefully tightening ER-11 Collets to 10 Nm (90 in/lbs or 7.5 ft/lbs), this is significantly less than the 40Nm suggested by ER-11 collet manufacturers suggest. These manufacturers may not be aware of how small diameter our end mills are.

The above test trace file was cut with the following parameters:

| Feedrate | Speed | Plunge Rate | Cut Depth | Tool | TIR |

|---|---|---|---|---|---|

| 10 ipm | 12000rpm | 4 in/min | .004 in | 1/64” 2FL CU 129974 | .0015 in |

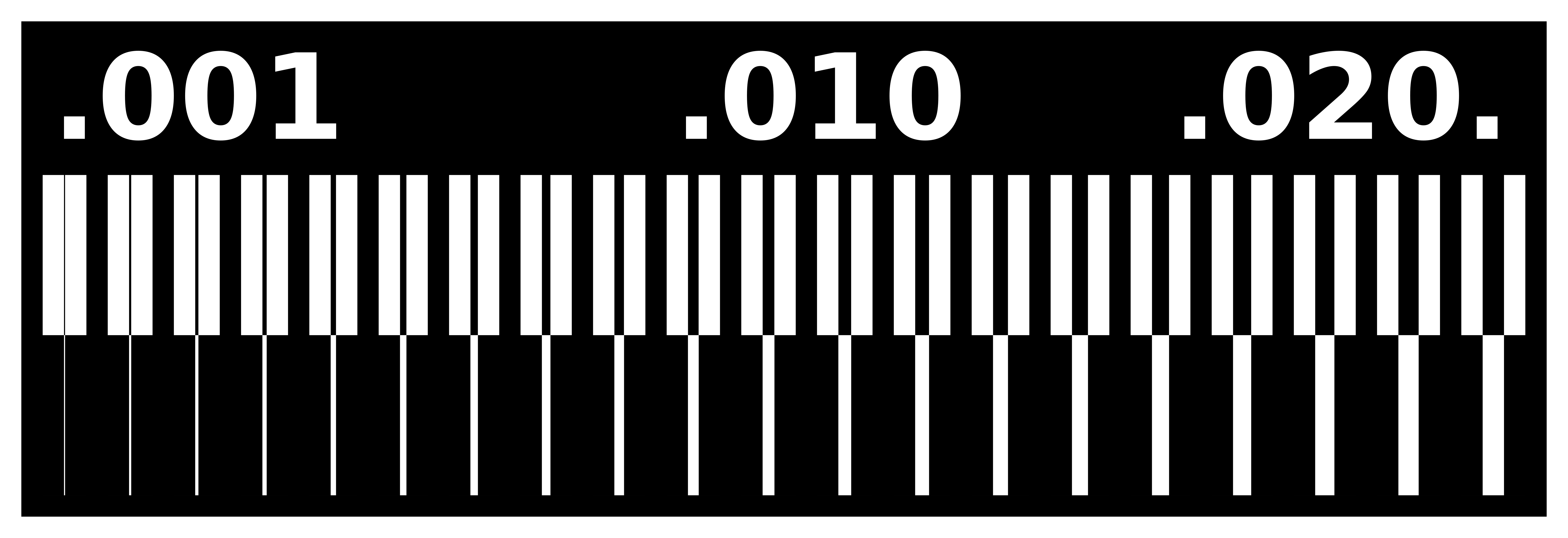

The test traces came out quite good for the purposes of the Fab Academy and matched the typical output of a Modela mill. The traces stayed in place into the 4th segment from the left, this means all typical trace widths will be easily machined on our x-carve. If I have time I will further optimize the x-carve with a focus on further reducing TIR.

To learn about the tapered stub end mills I use for circuit milling see my page on Tapered Stub End Mills are pretty Awesome!