Computer-Controlled Cutting

Group assignment:

Characterize your lasercutter's focus, power, speed, rate,

kerf, and joint clearance

Individual assignment:

Cut something on the vinylcutter

design, lasercut, and document a parametric construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways,

and for extra credit include elements that aren't flat.

Group assignment

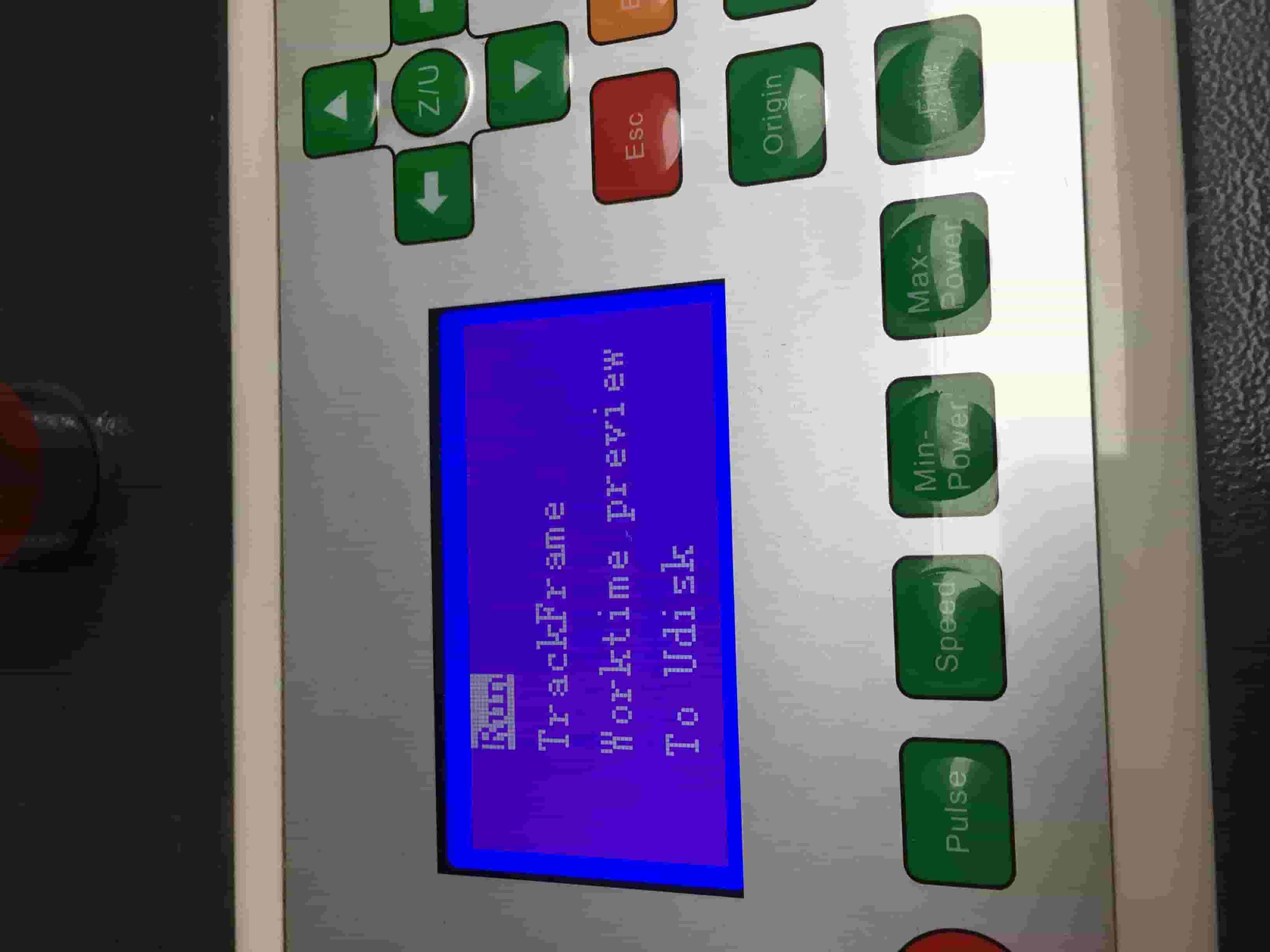

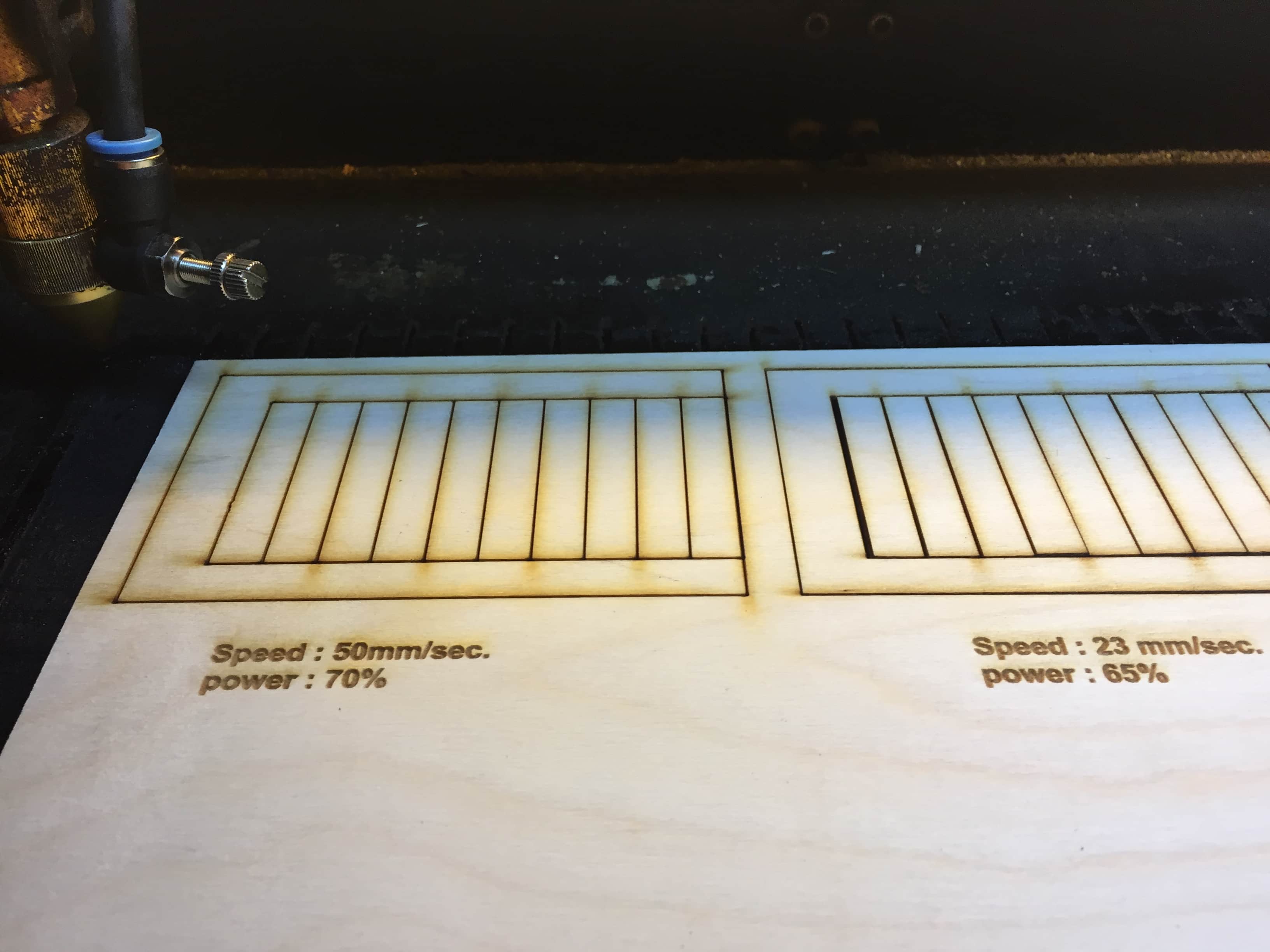

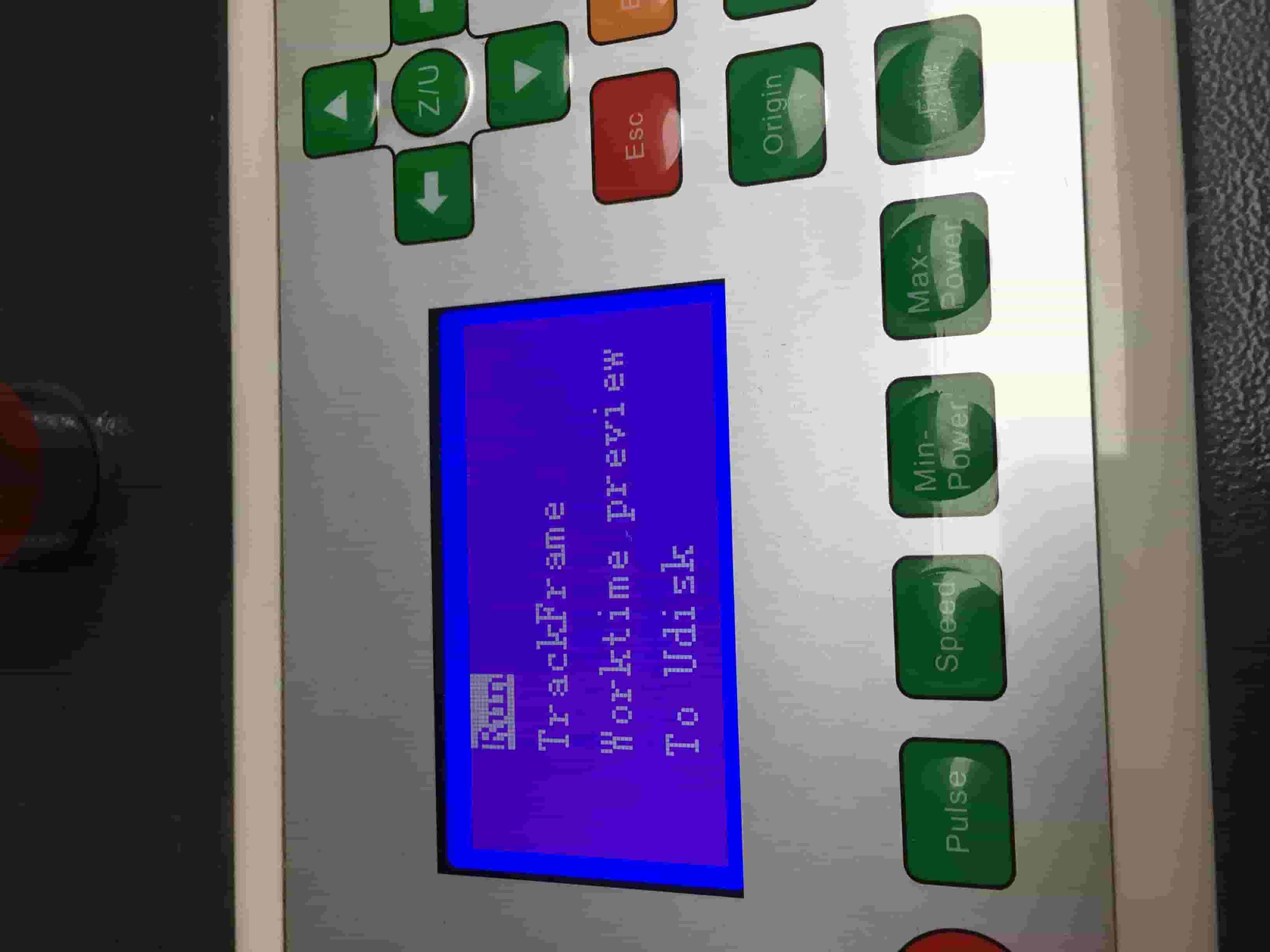

We use as laser machine "Morn MT3050D",up to 50 watt and 1000 mm/sec.

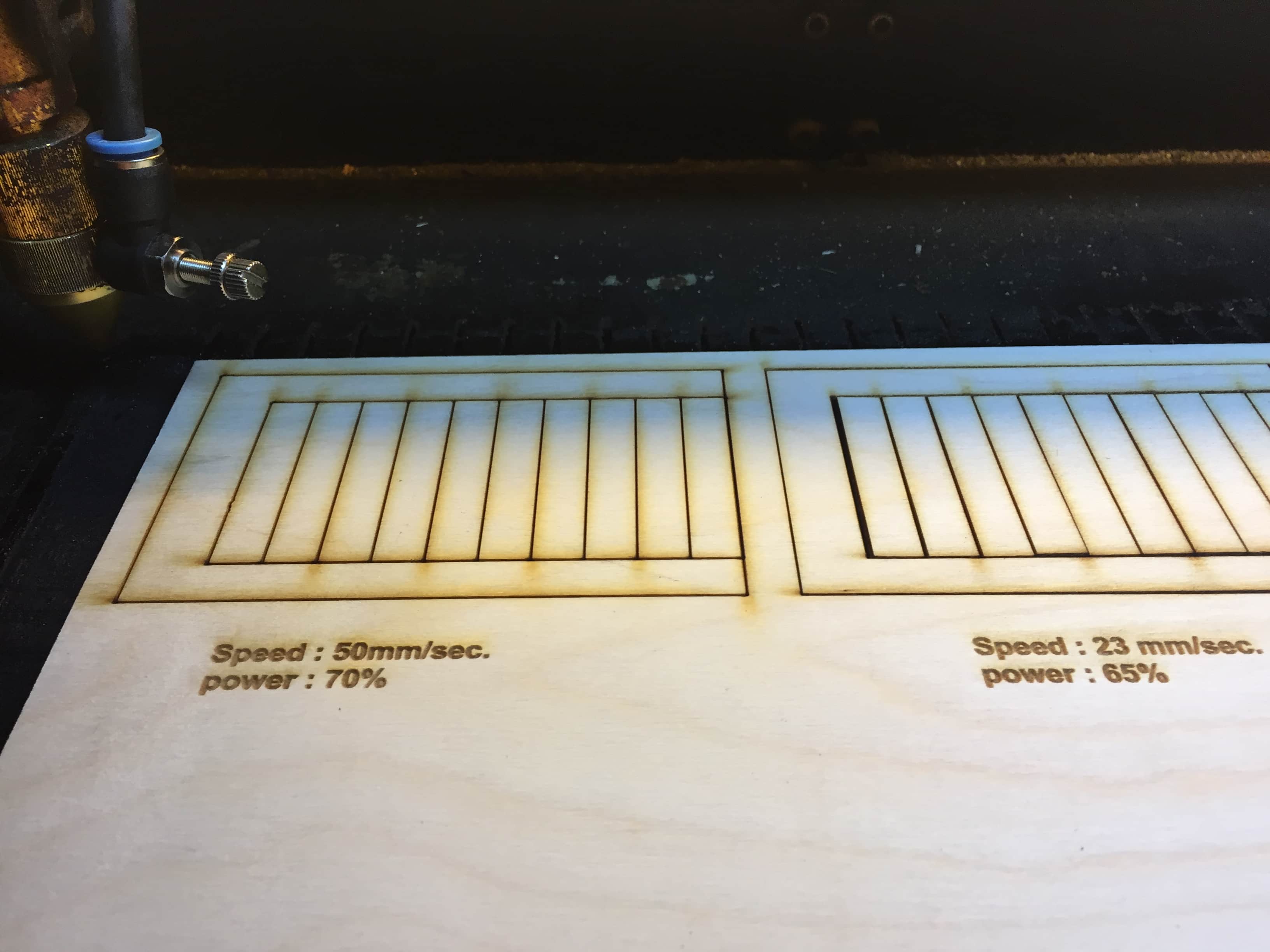

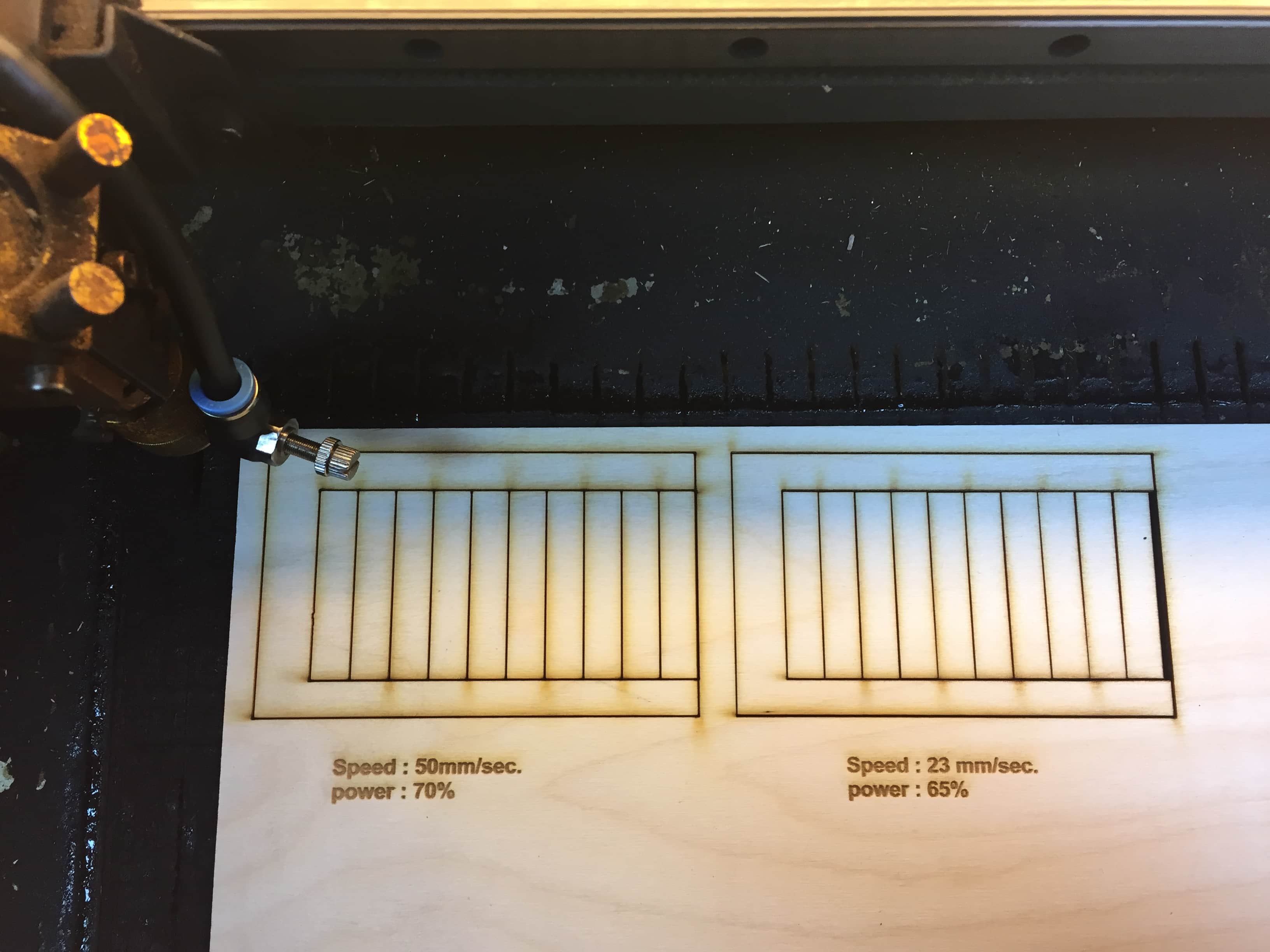

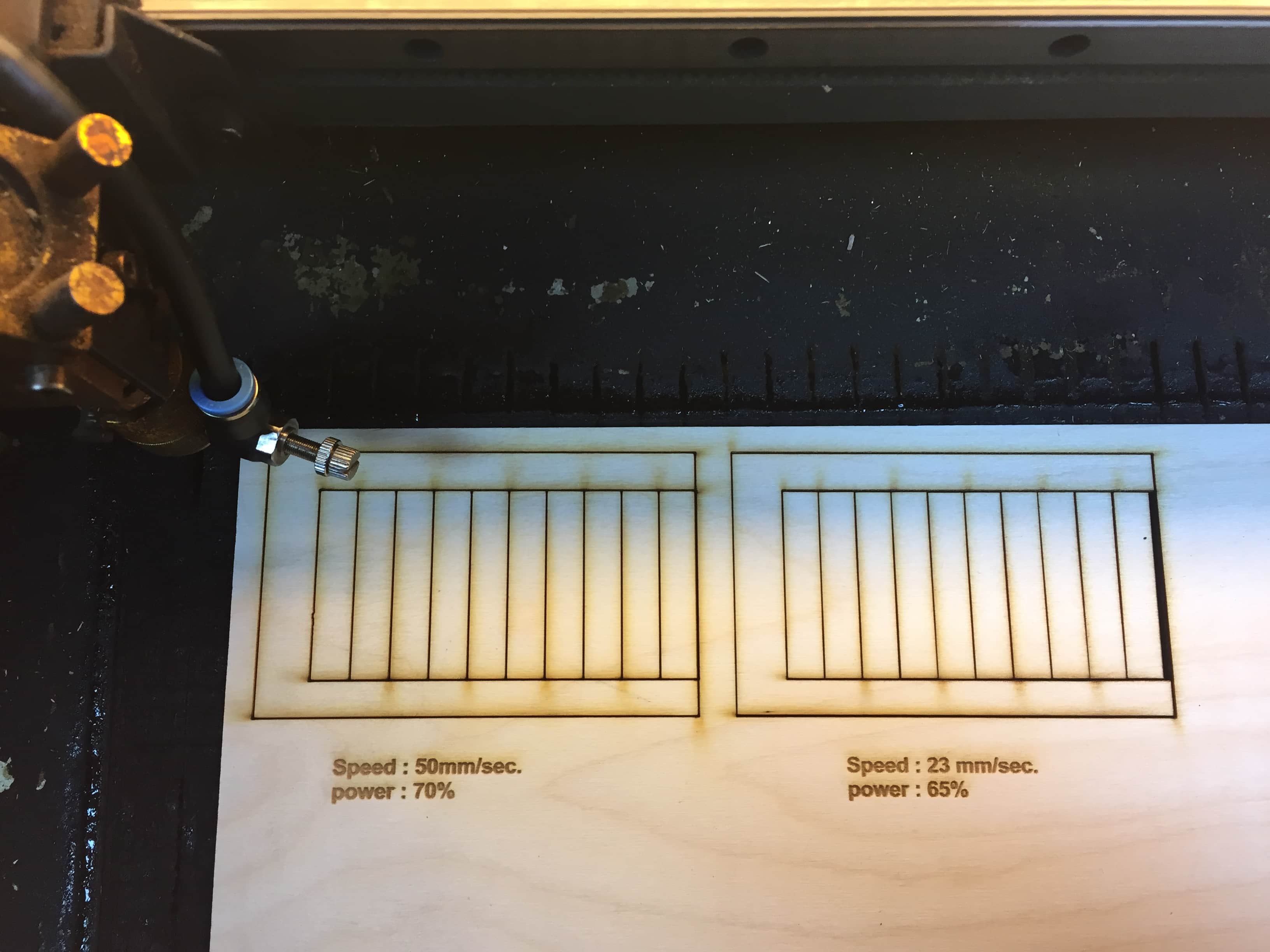

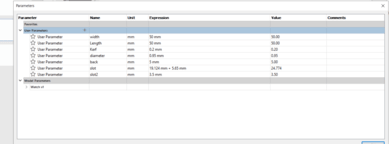

So to categorize the laser machine we made a drawing as follows:

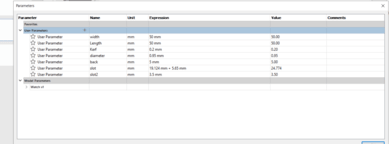

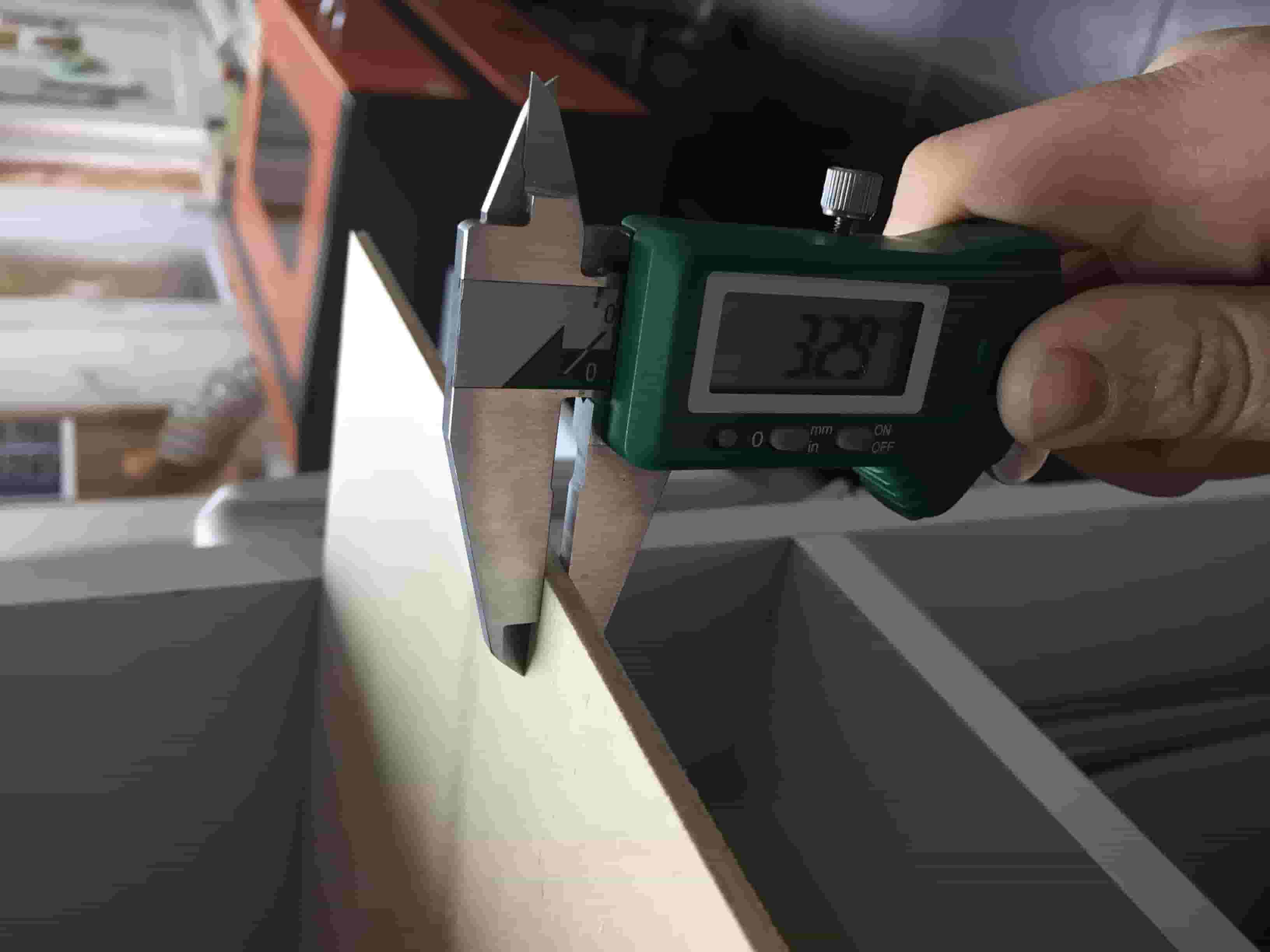

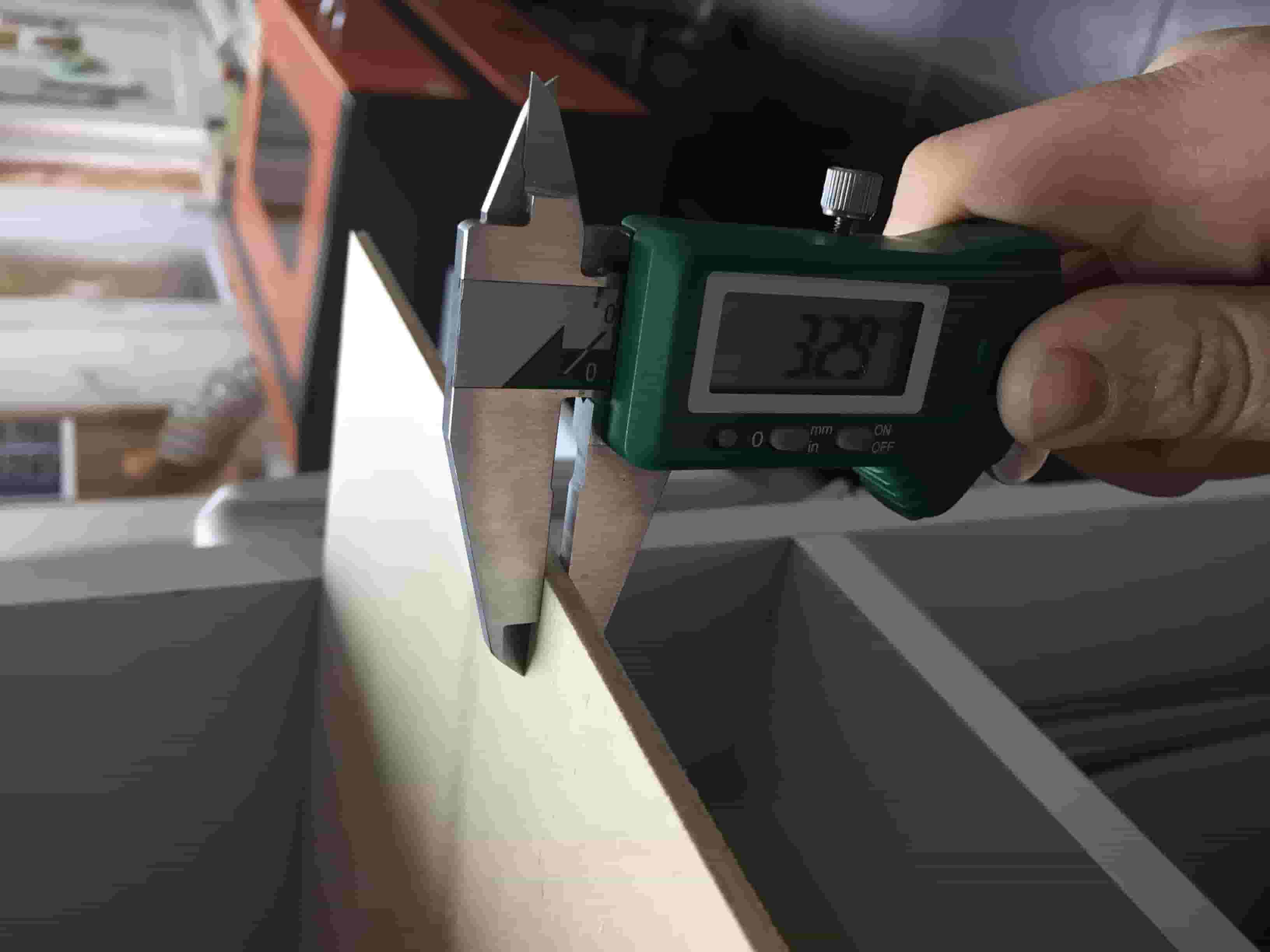

Then after cutting it, we measured the difference in width and divided it on the total number of strips , we made it with different power and speed:

The original width before cutting was 113.58mm but after cutting 111.26 mm the difference is 2 mm divided by the number of strips the Kerf is 0.2 mm.

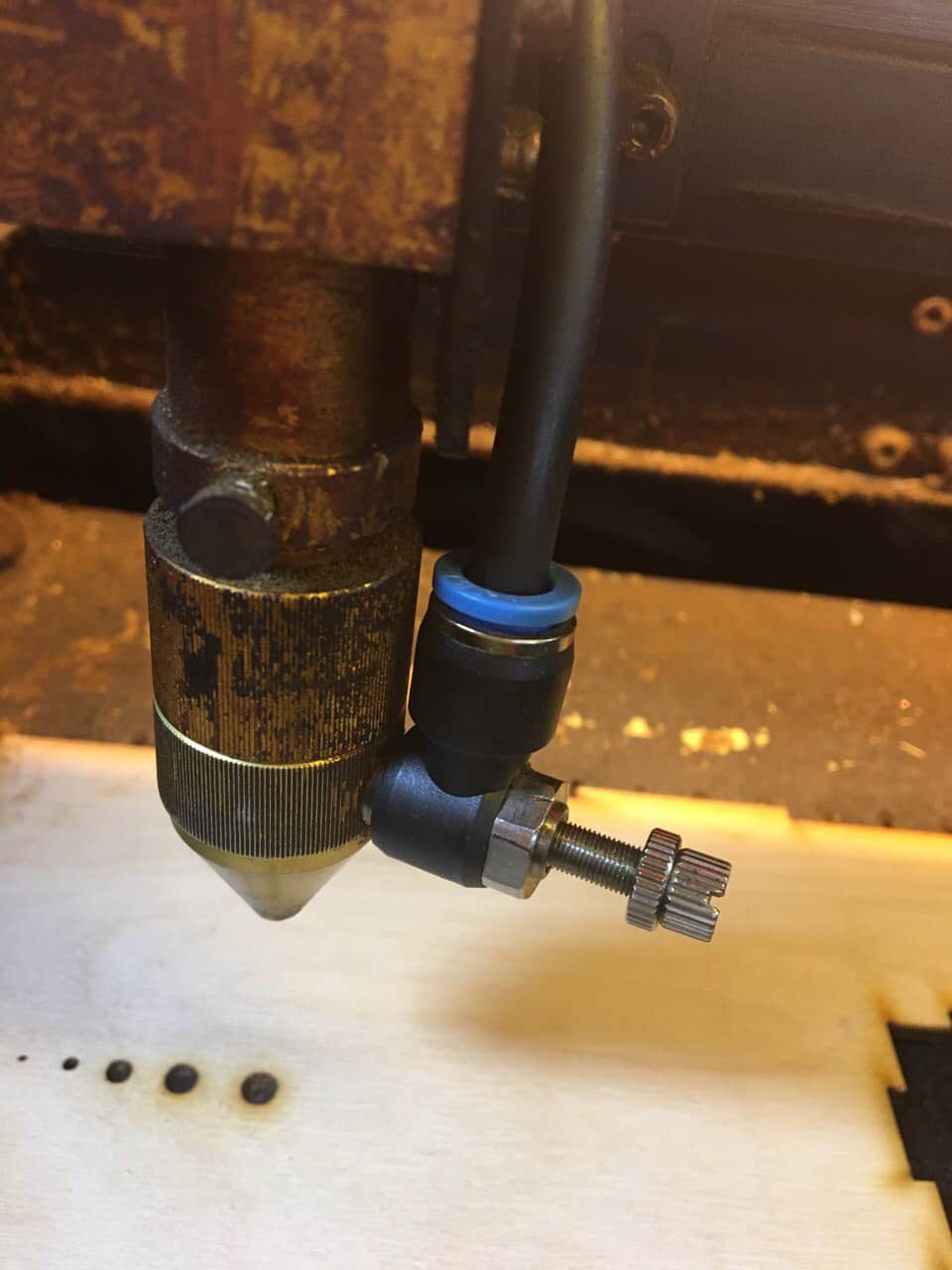

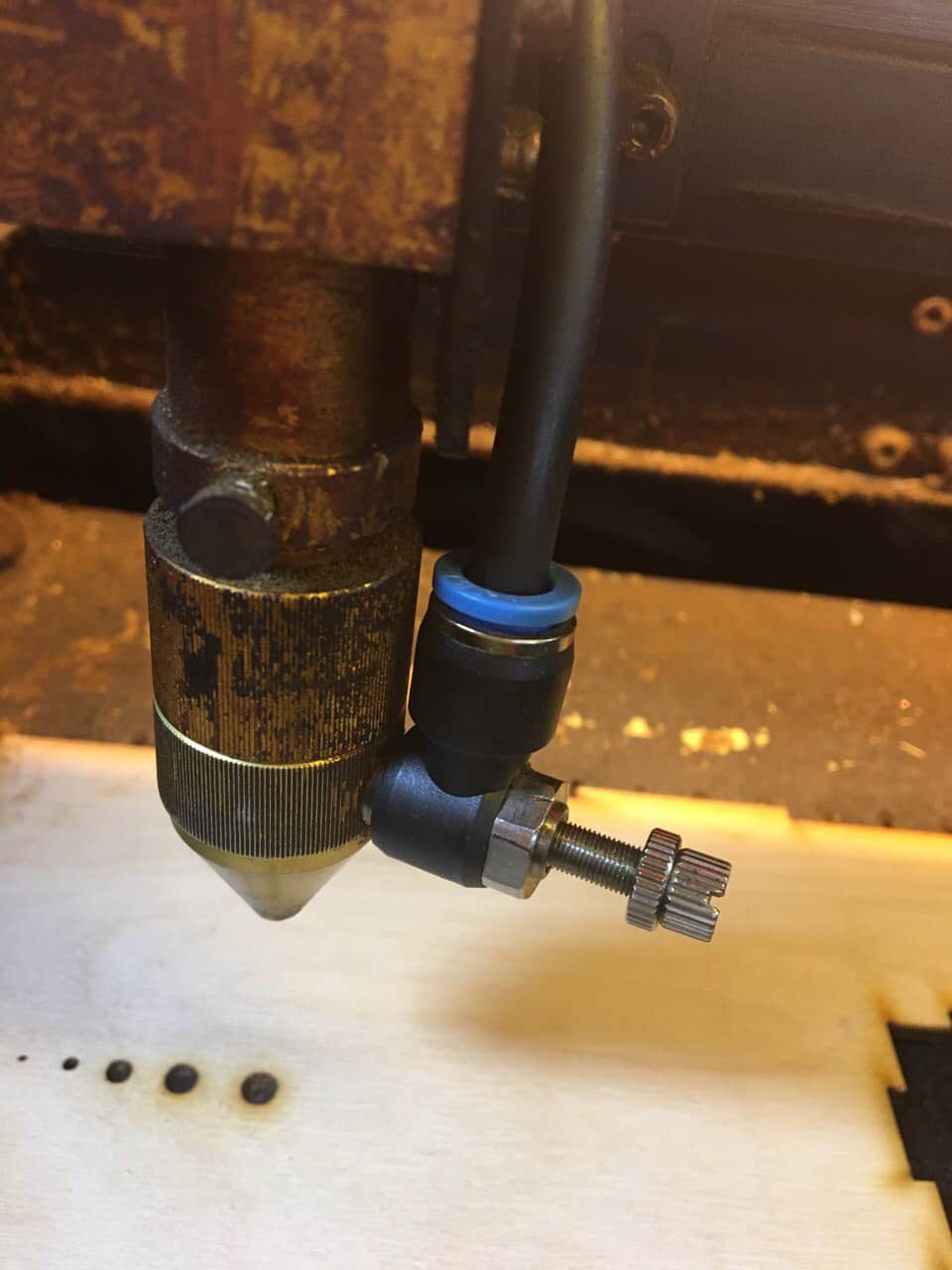

The focus is 5.91 mm.For plywood the right speed for cuting 23 mm/sec and for engraving 300 mm/sec, for the power for cutting 65% and for engraving 30%.My role in this group assignment is to document and take pictures.

Joints:

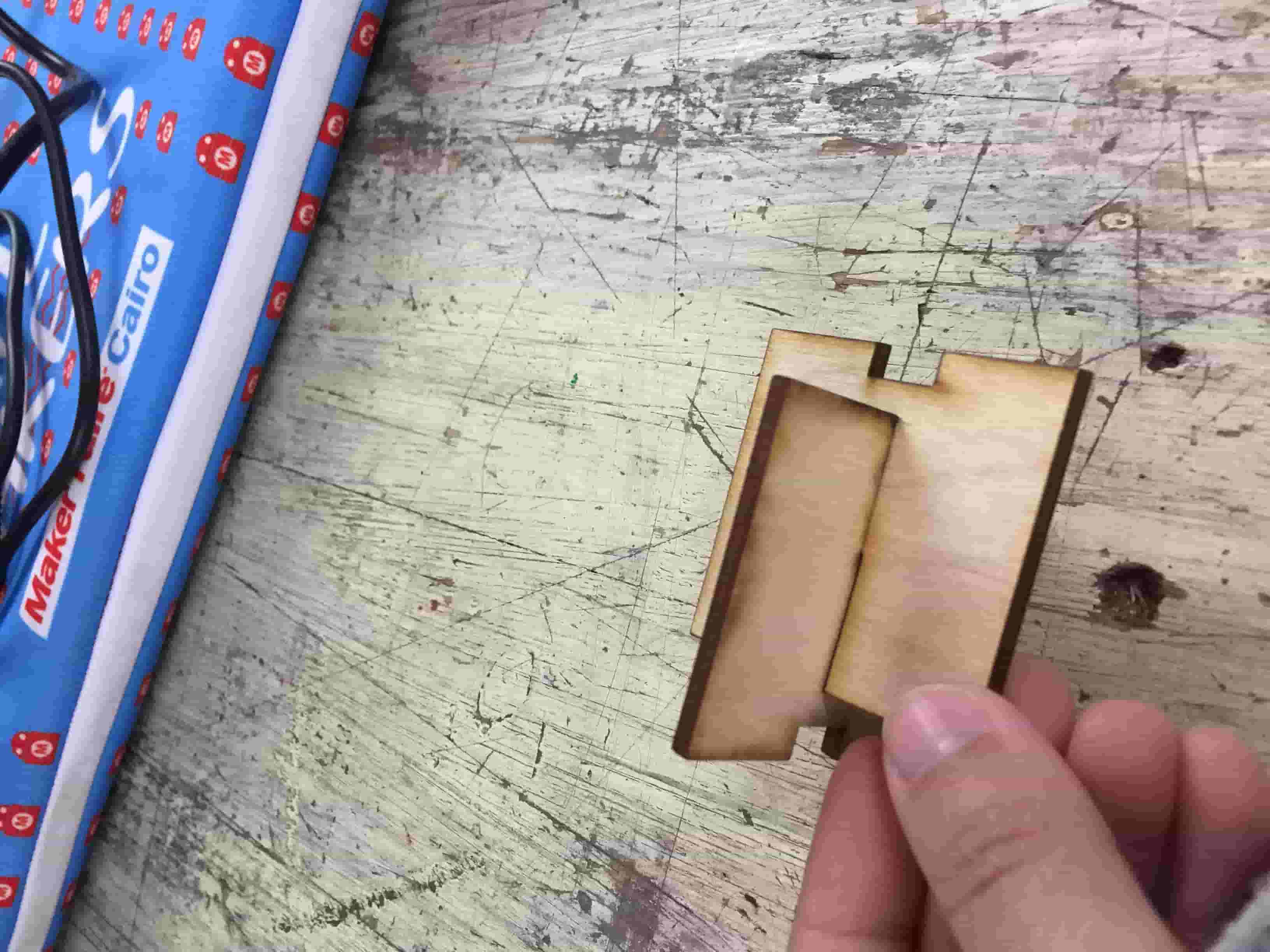

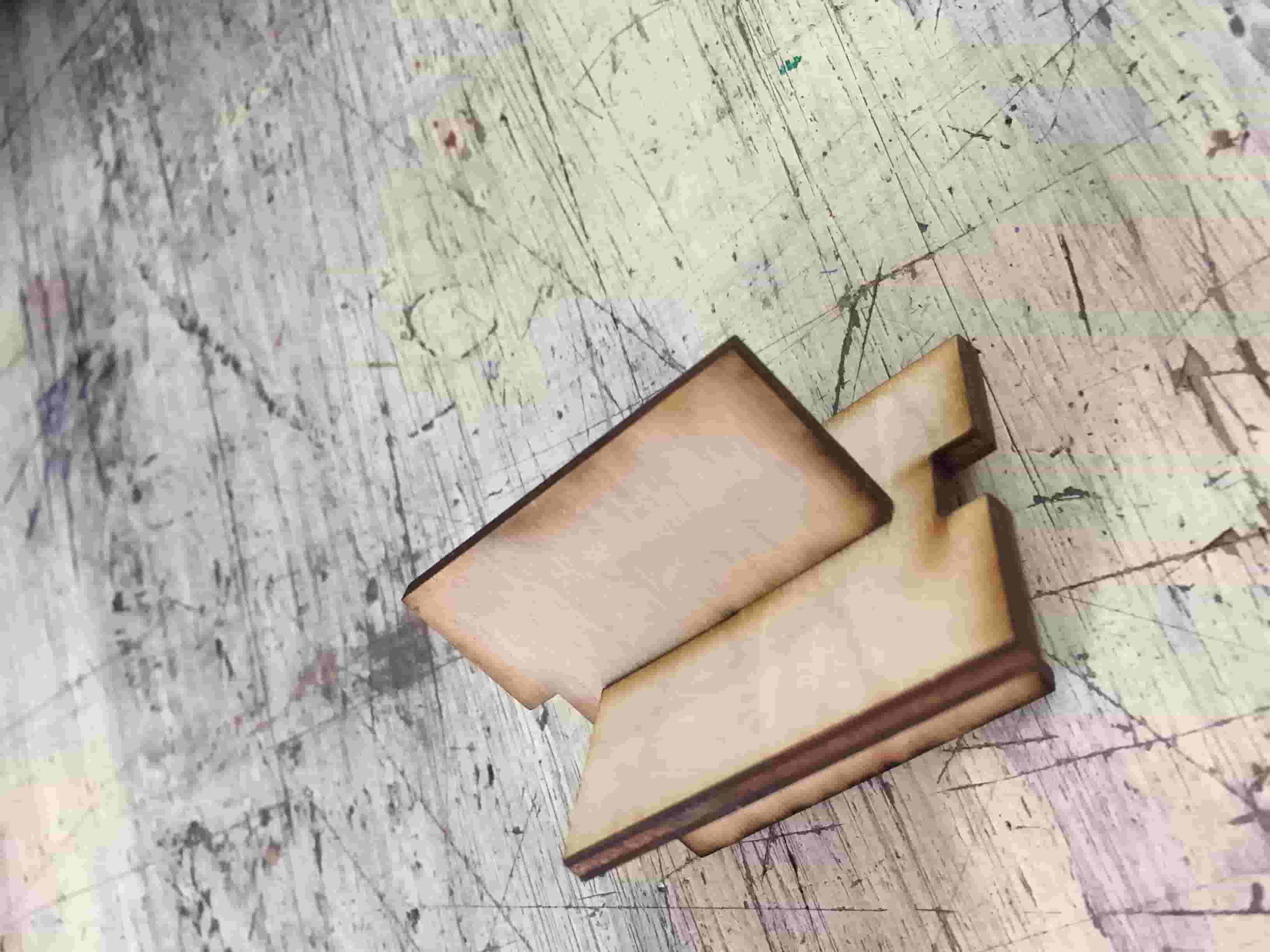

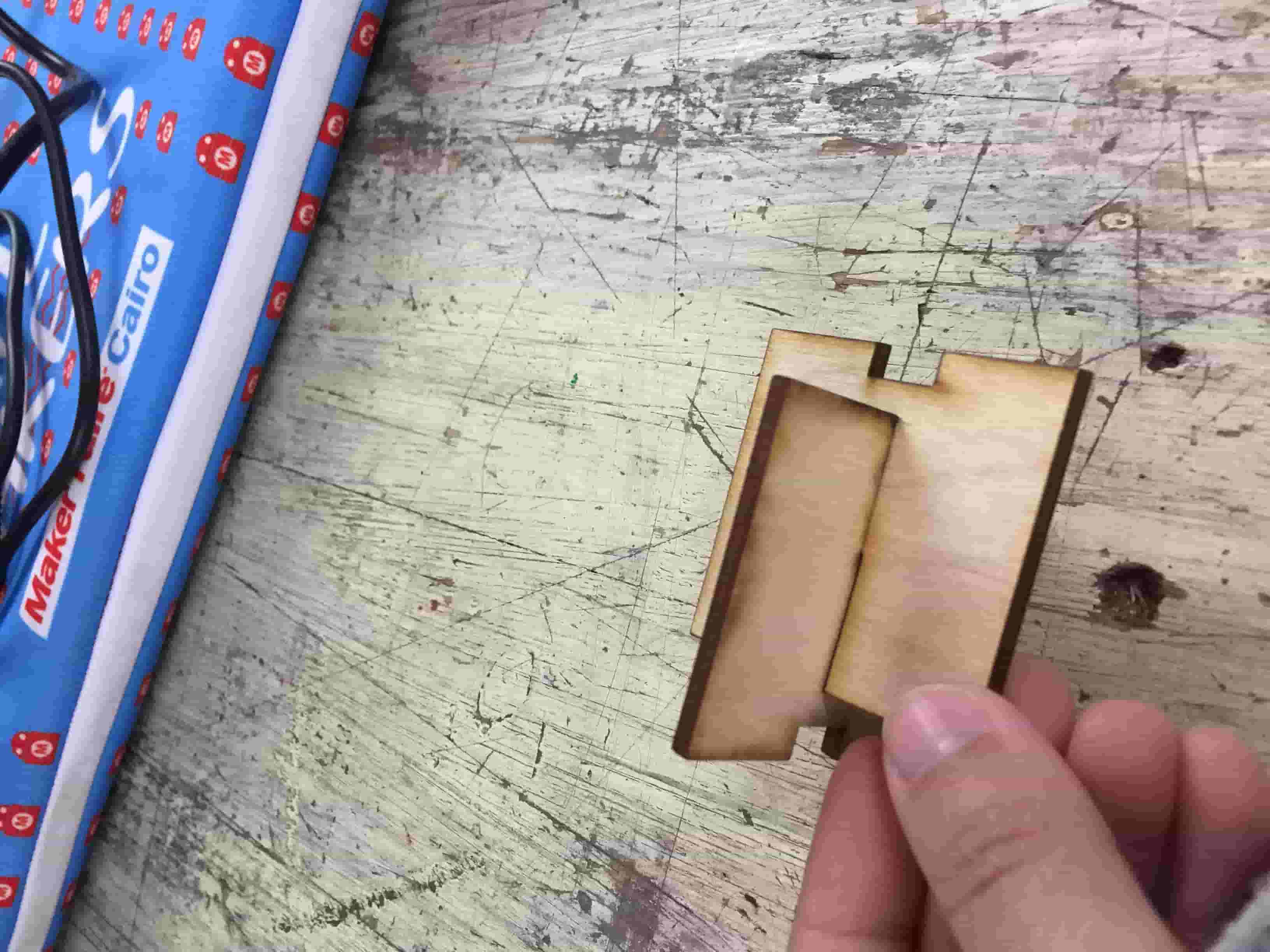

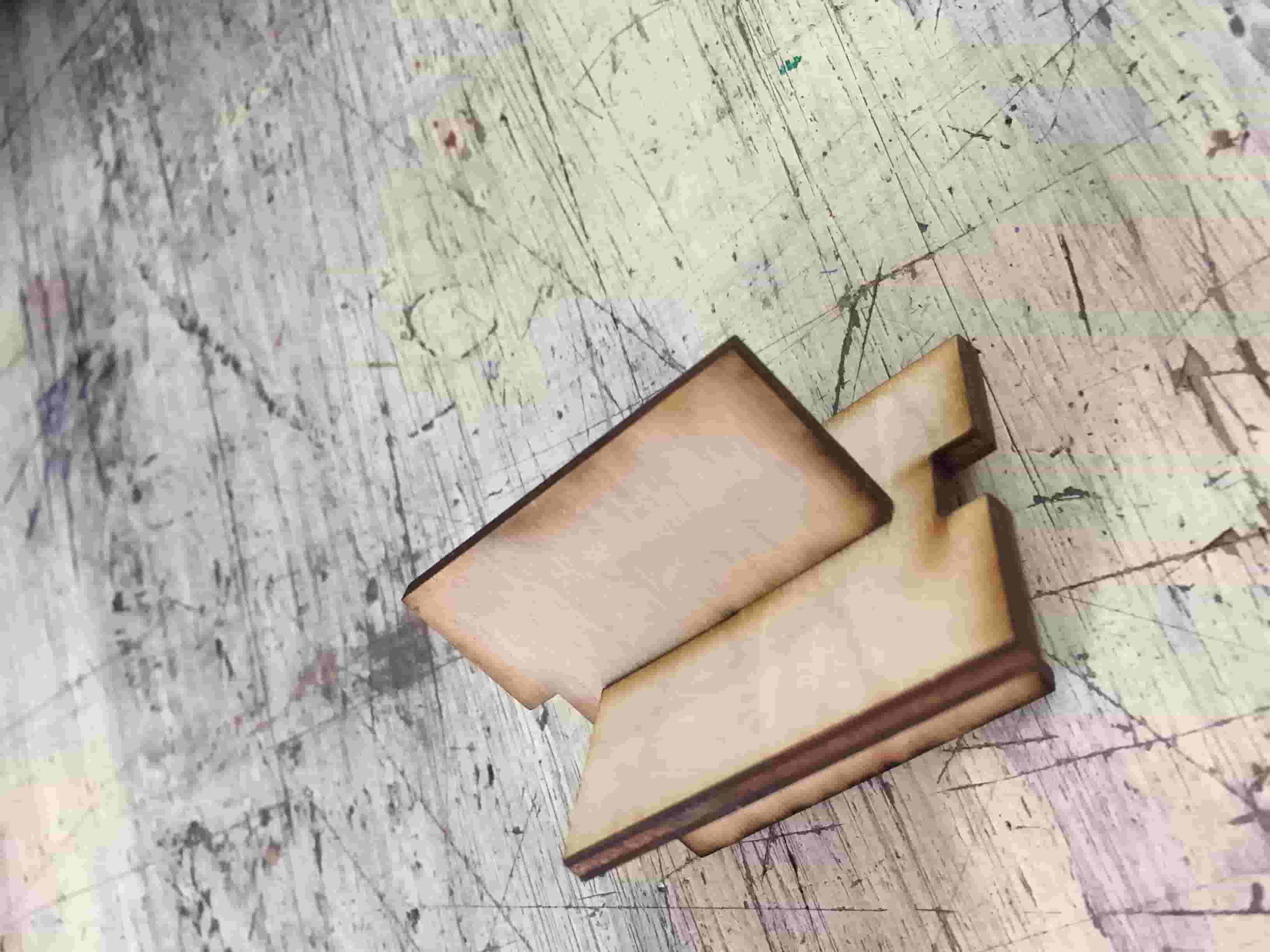

So I tried two joints ,I drew a parametric design for them and cut them.The first joint is "Snap Fit":

But it didn't come out right, so I adjusted the dimensions:

The second joint is "Wedge":

For this week assignment I decided to make Ramadan's Lantern in the laser cut assignment as it combines all the required features, and for the vinyl cutter I will make a logo and a cool design for my key card at Fab Lab Egypt.

So, I will start with the laser cut.

Laser cut

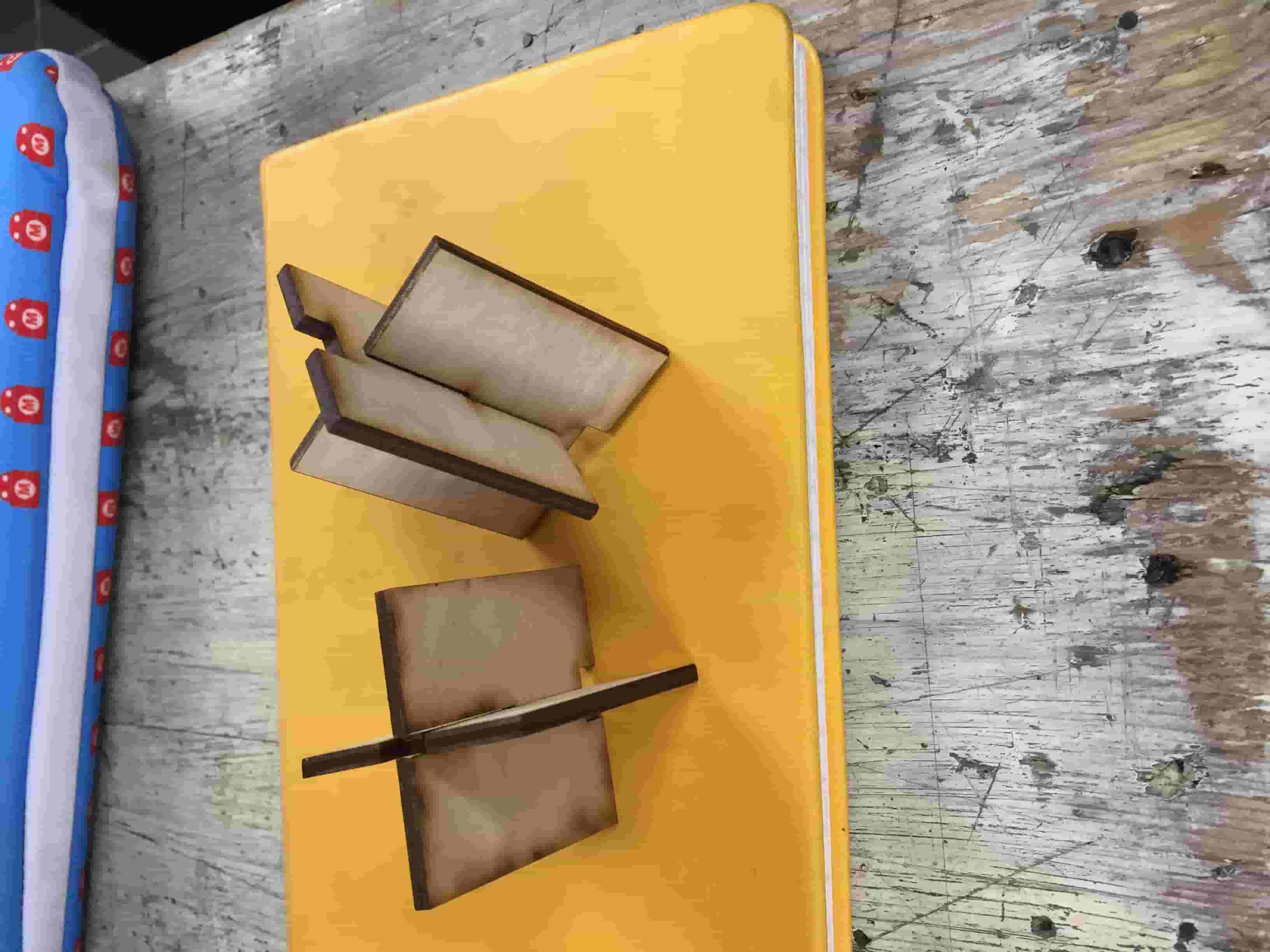

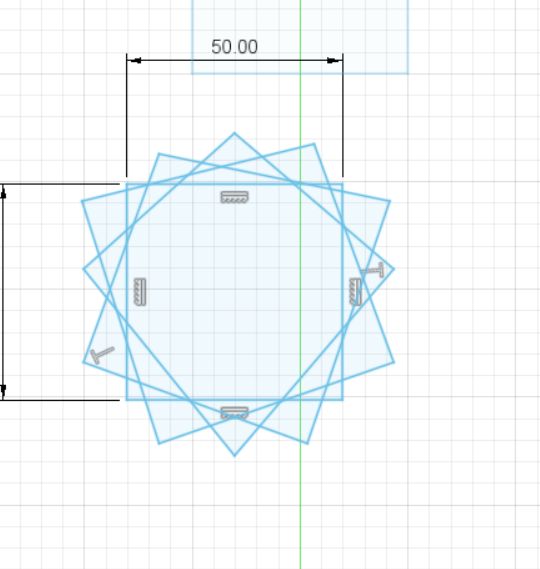

To make the base, I had this idea to make a parametric construction kit with shapes that I designed:

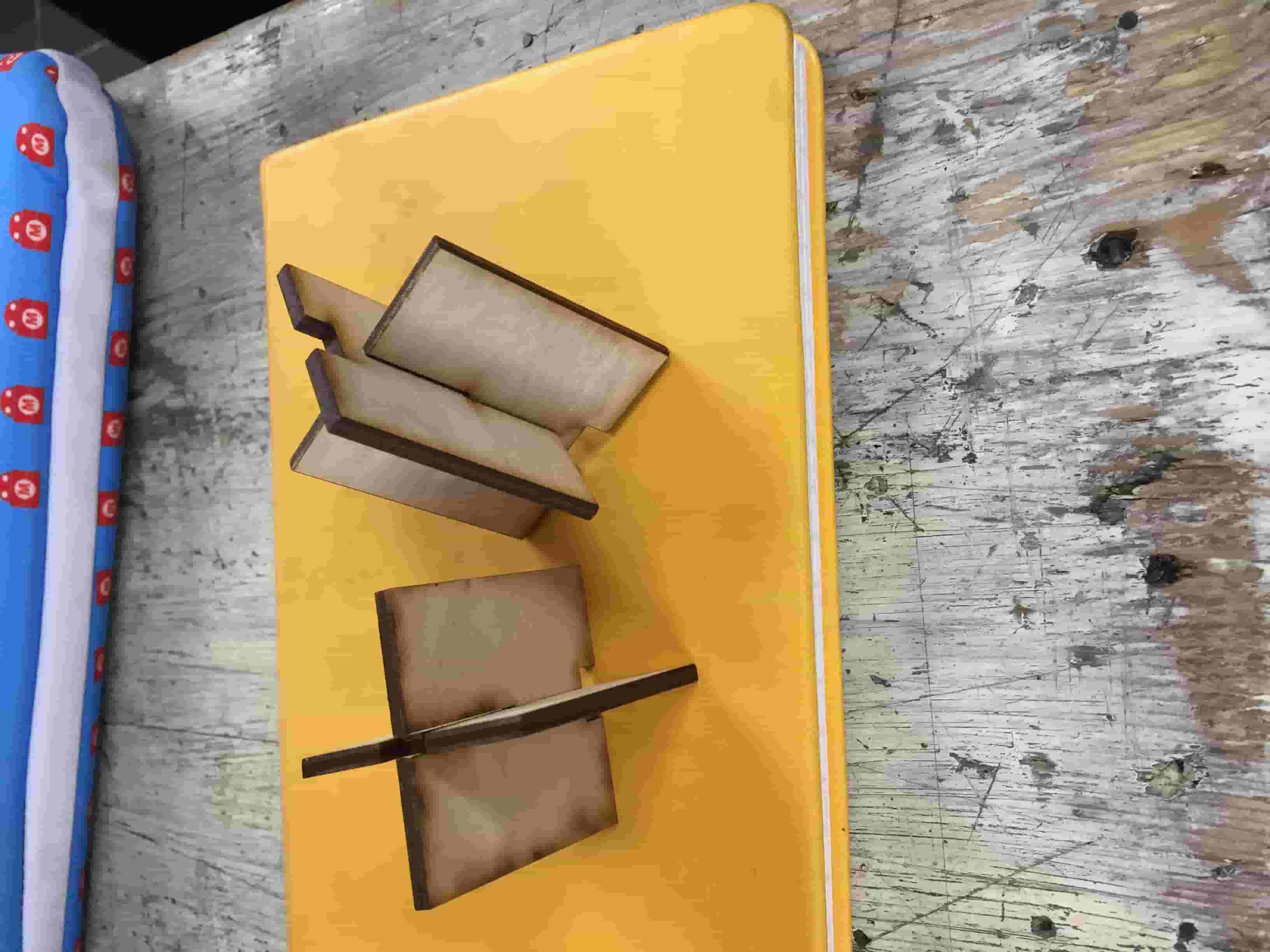

First I made th cubes :

Then I trimmed it and I added the grooves after mesuring the thickness of the plywood and taking in consideration the kerf :

It can be constructed as a base:

Or as other arrangements:

I engraved on it:

For the Laser cut assignment: Ramadan's Lantern with a twist!!!

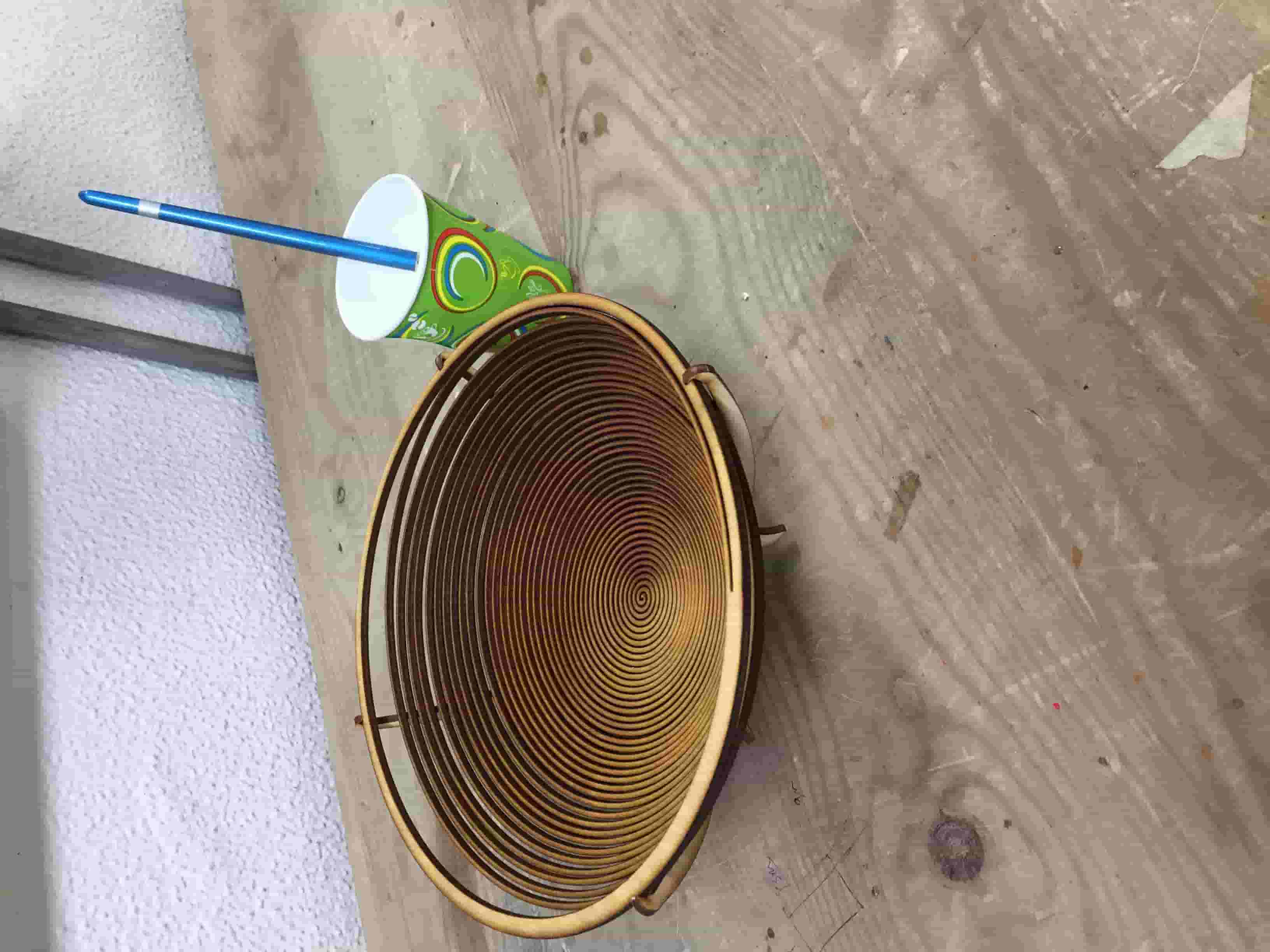

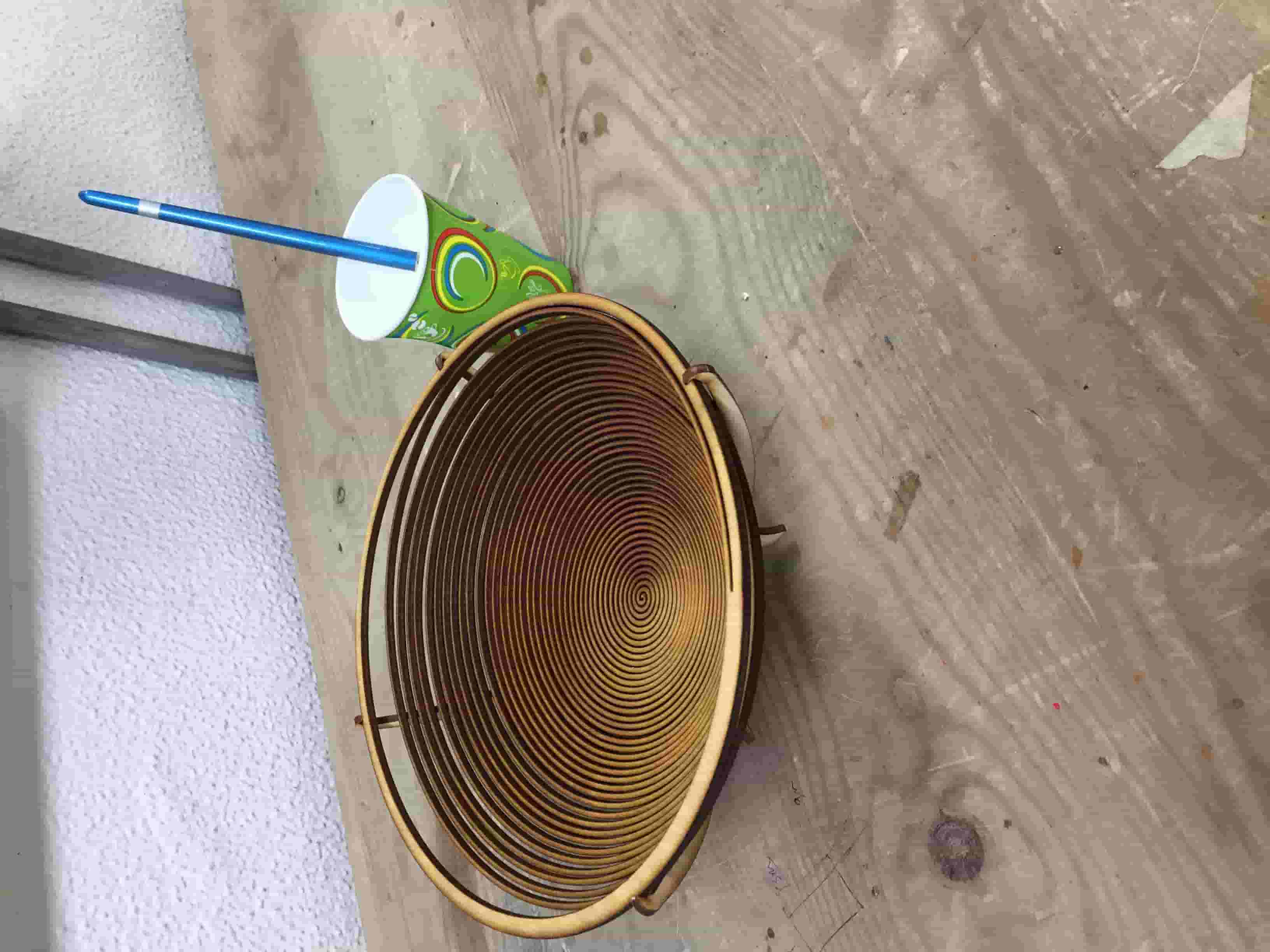

I started with the body as I wanted it elliptical. While searching for ideas I found a bowel made out of laser cut plywood.

Luckily,I found the open source file ,so I took it and I worked with it.

https://www.youtube.com/watch?v=s3BrBtG0FHM

So I decided to take the design and construct my lantern.

I made the top part:

Glued it :

Then the other half:

The lower part should be loose to let the lamp in easily.

And here is the Lantern:

Vinyl Cut

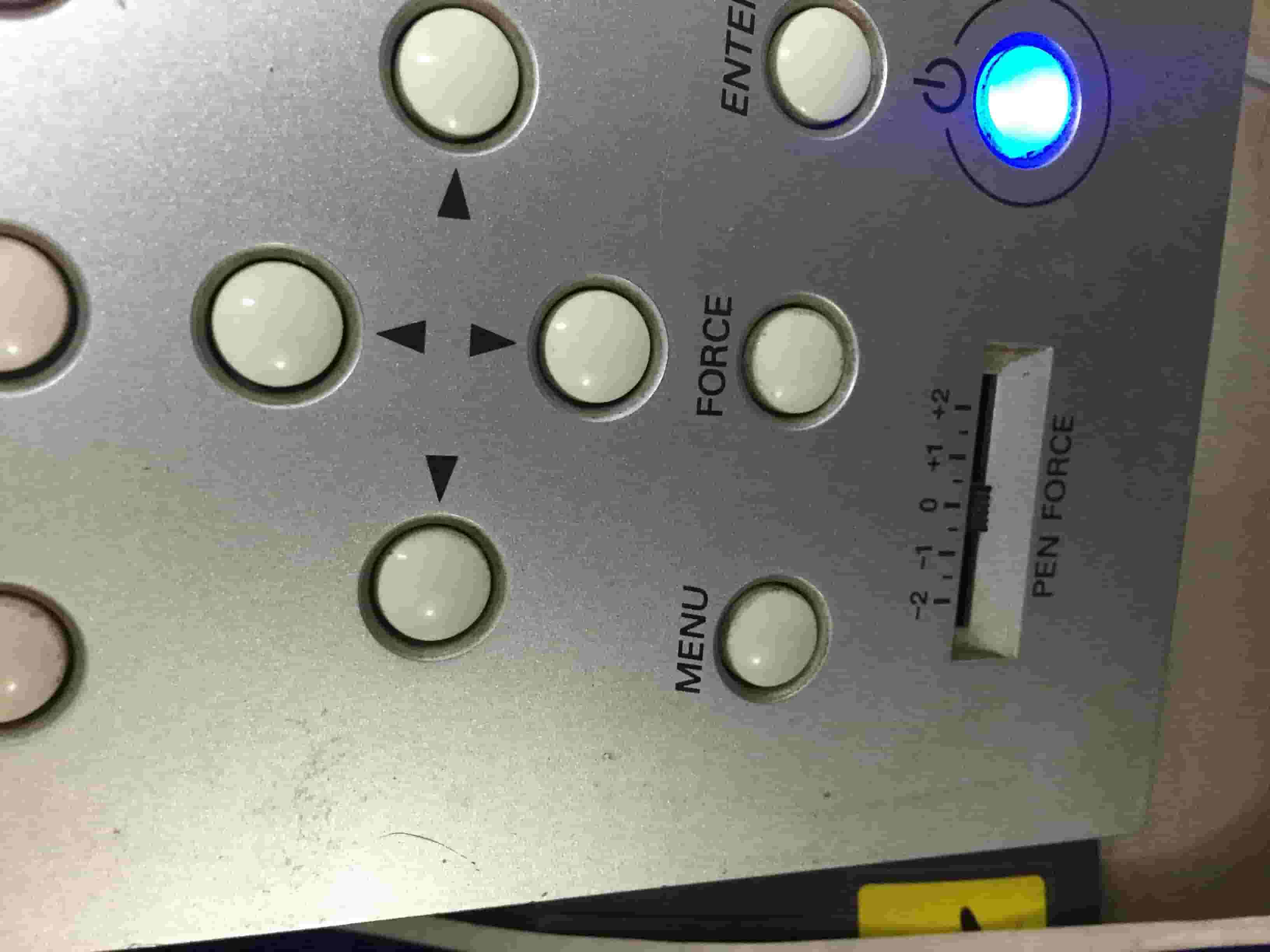

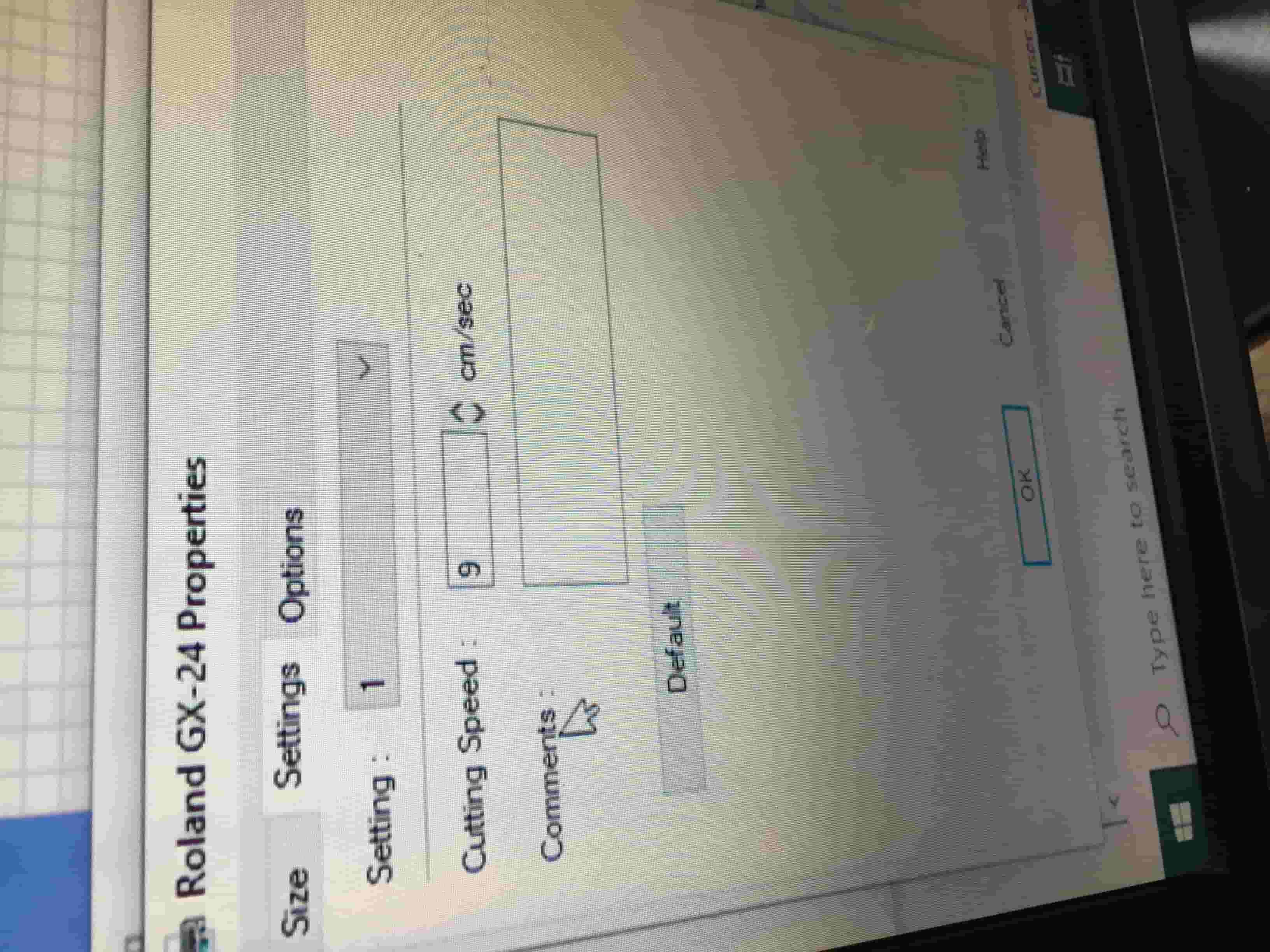

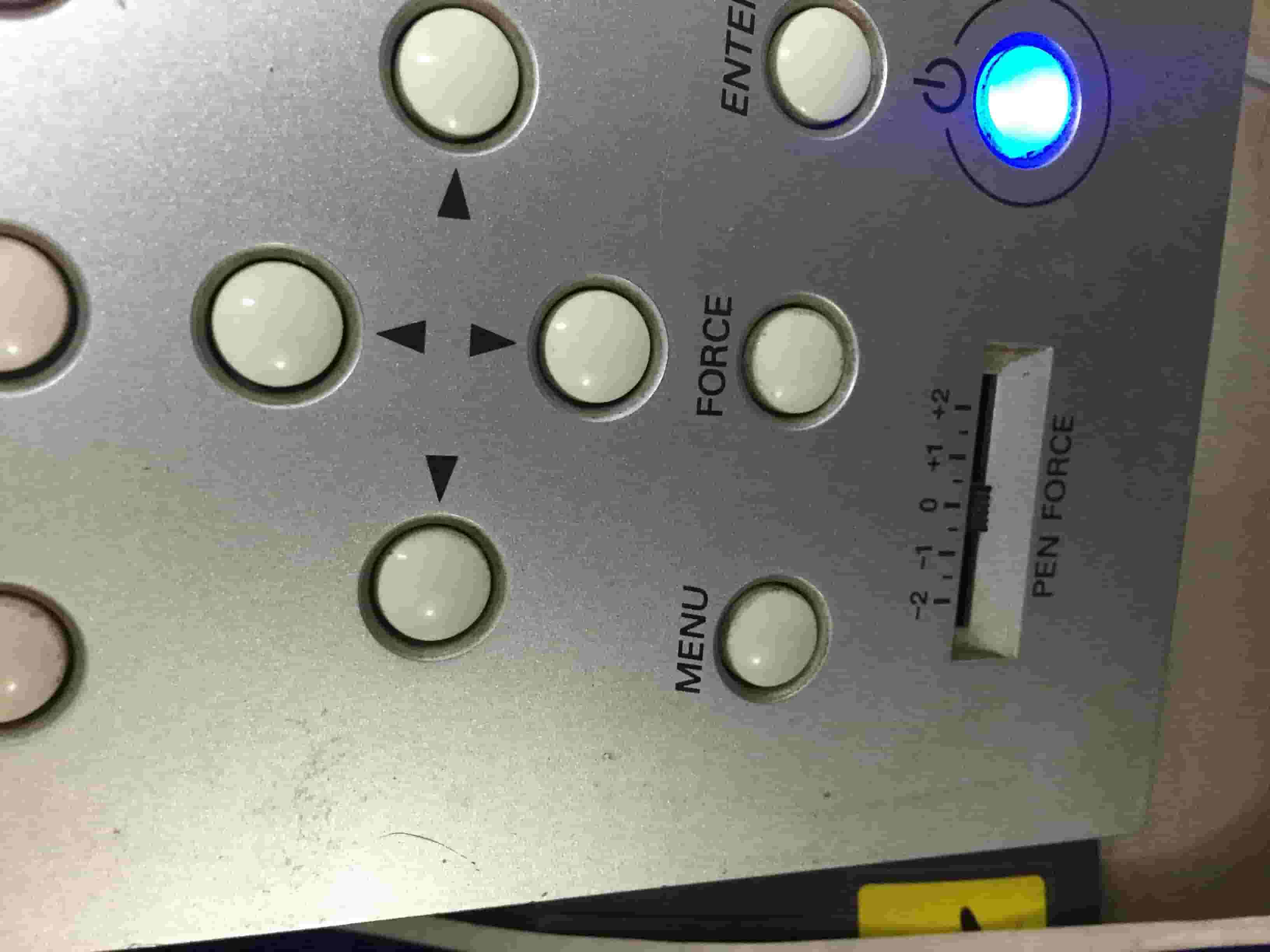

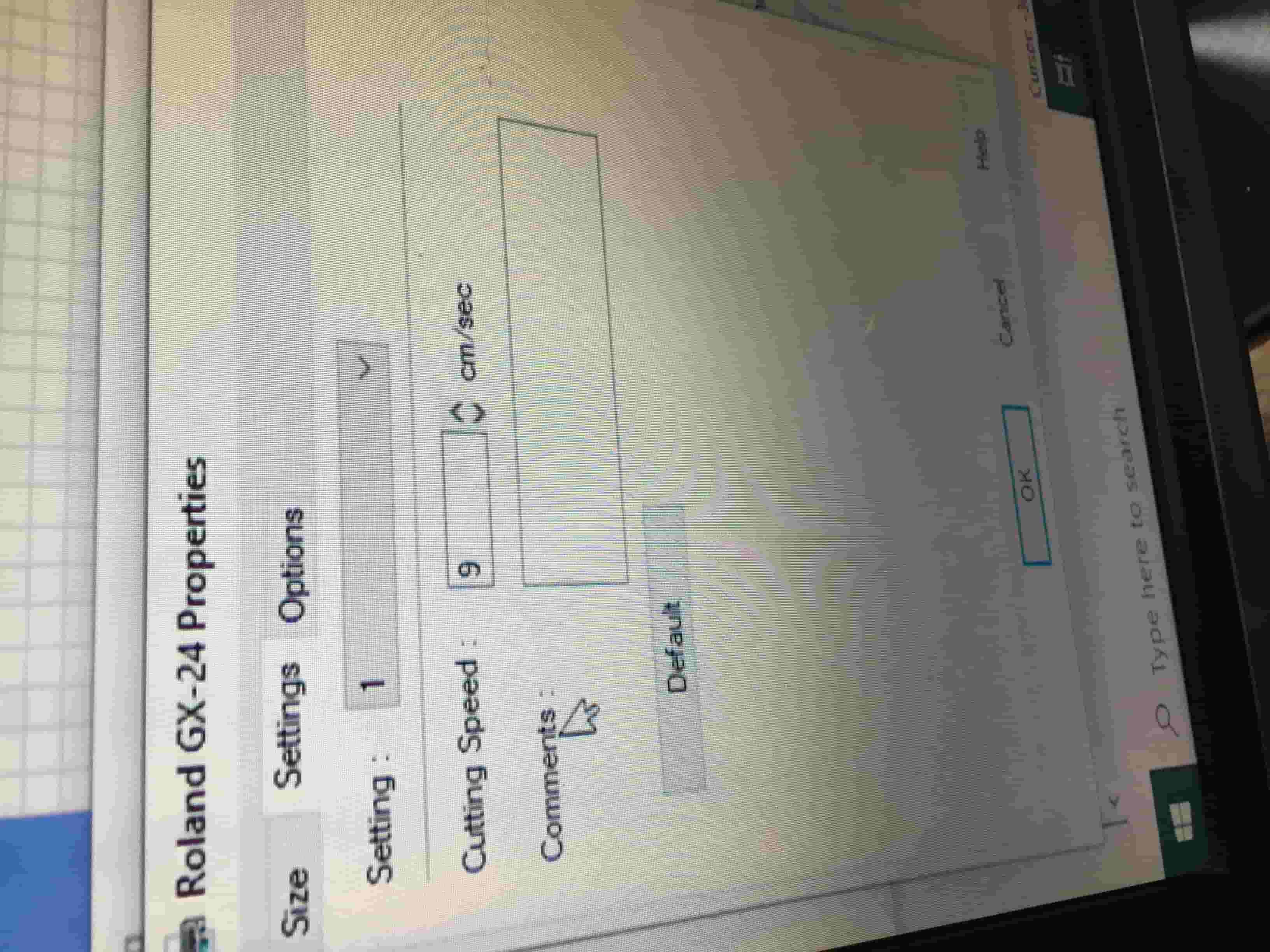

I chose the design and I want to make it colourful,I uploaded it as png.Then I began calibrating the machine :The force ,the speed and the pen force.

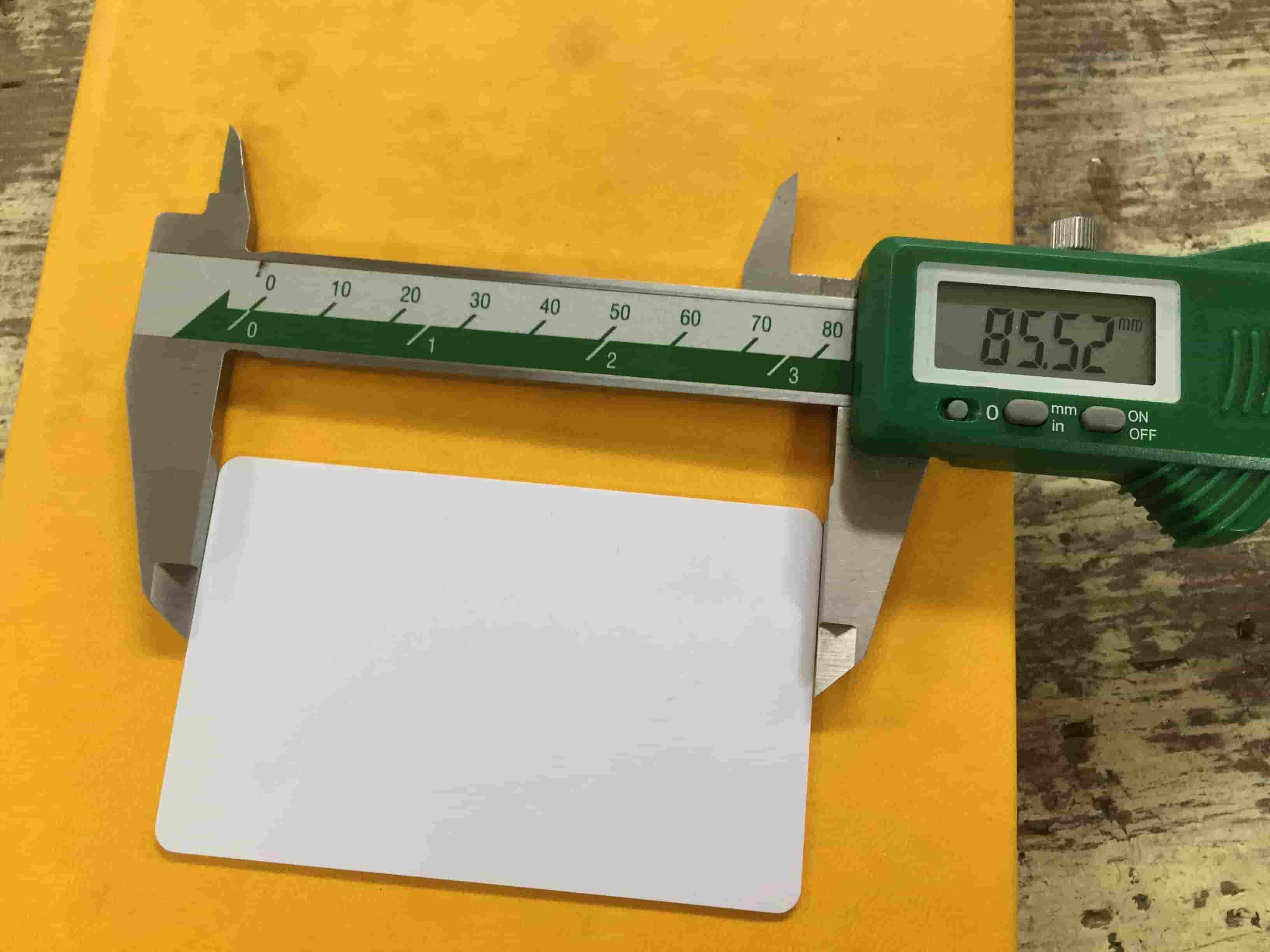

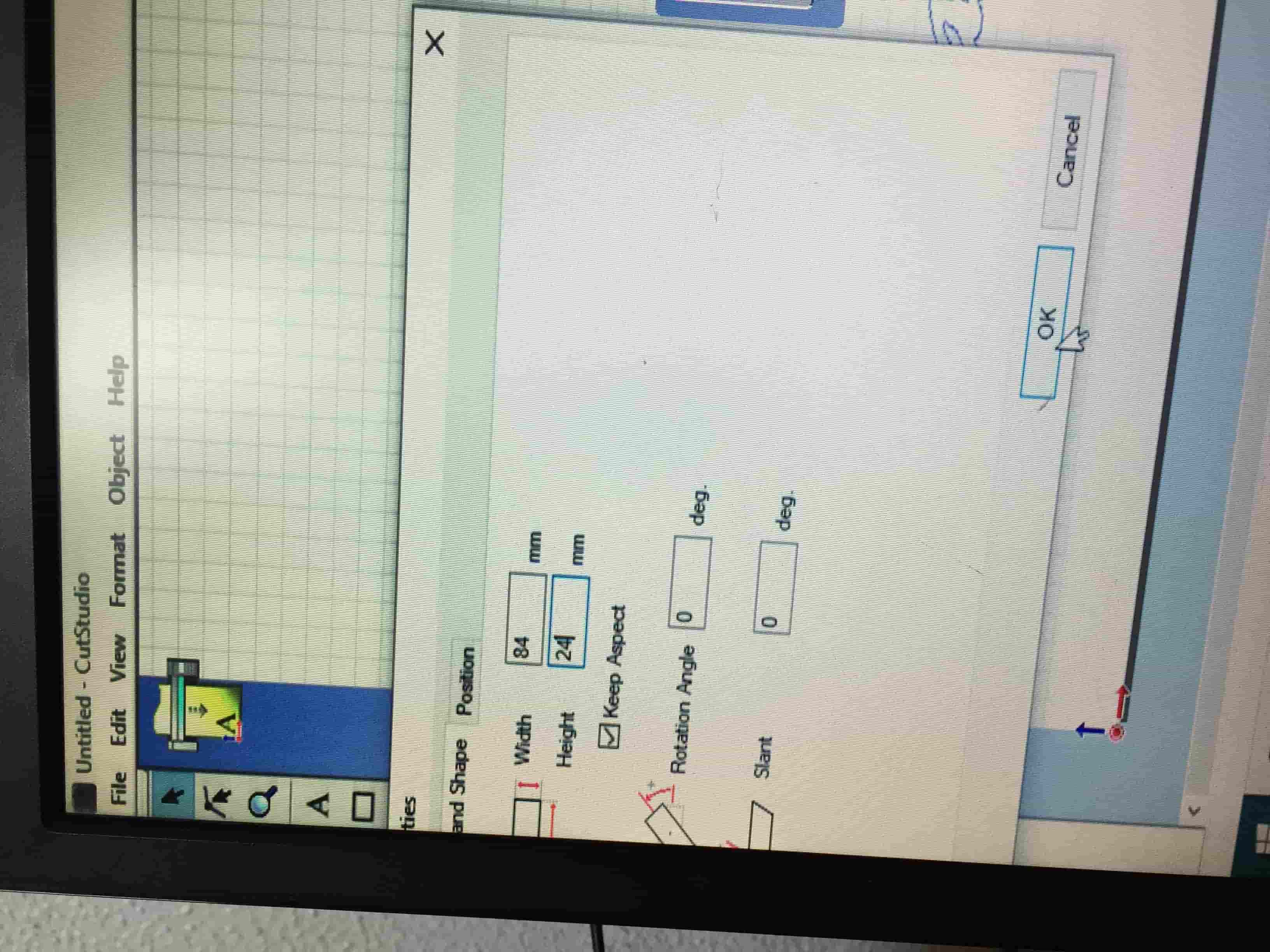

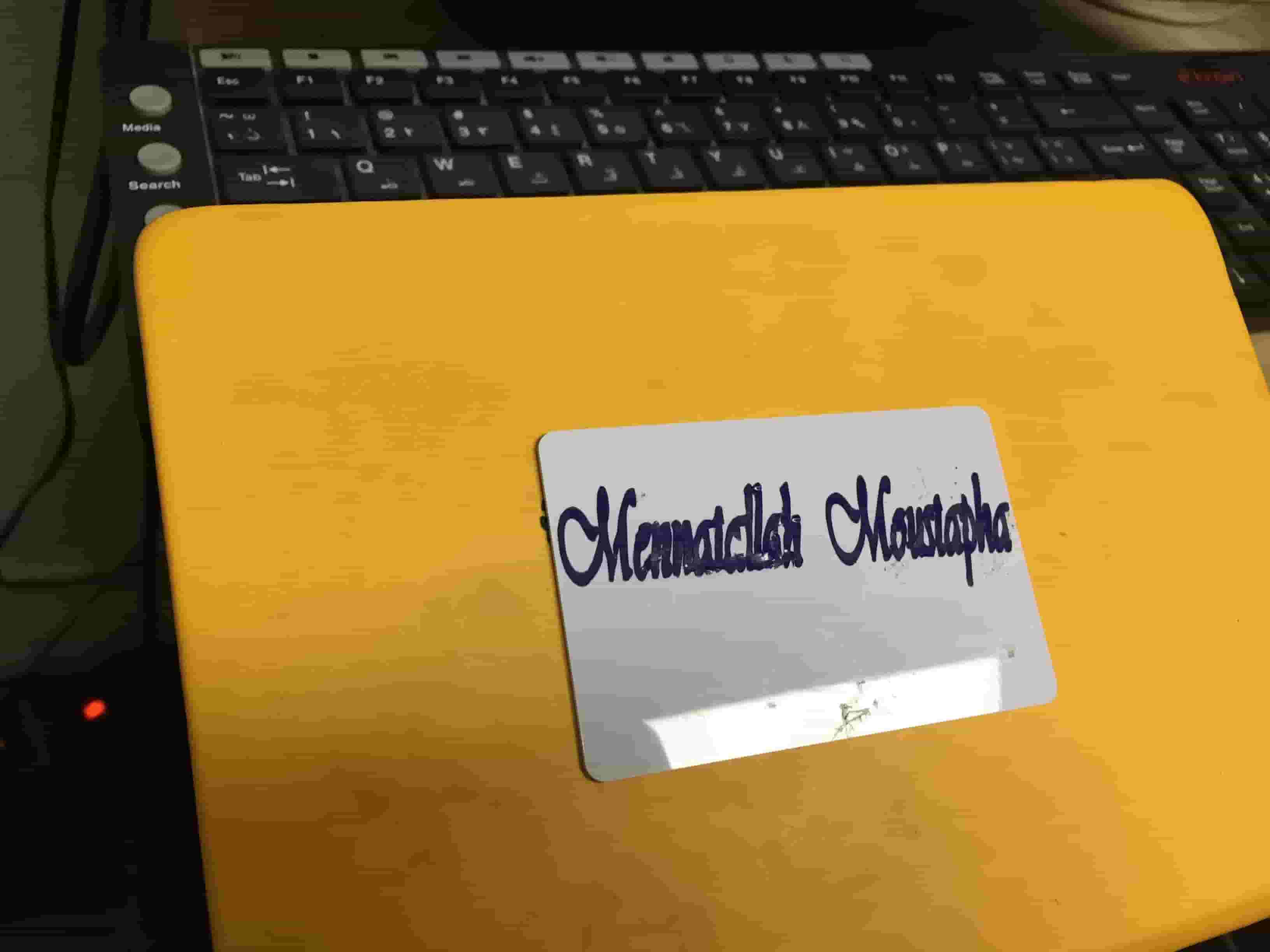

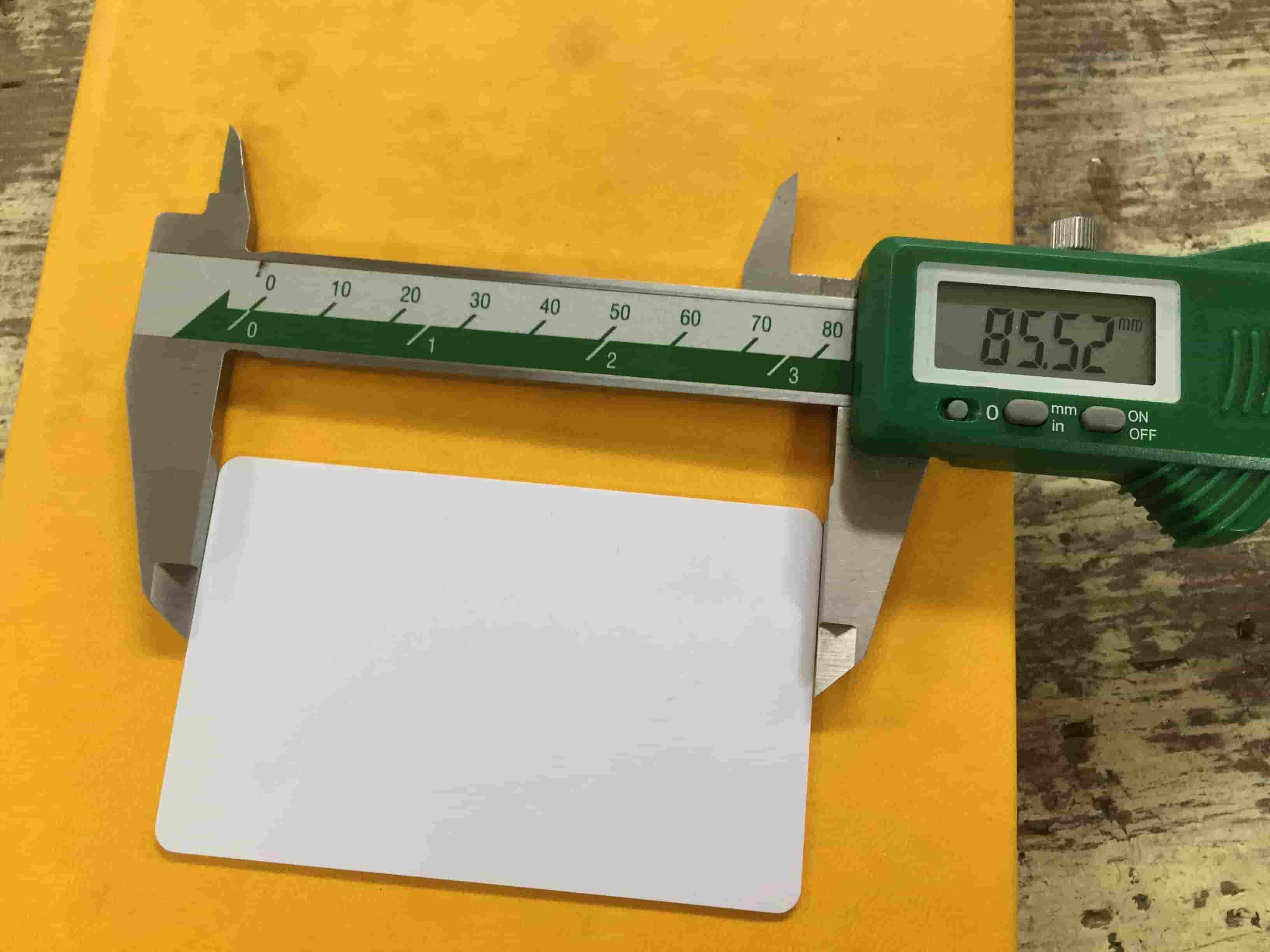

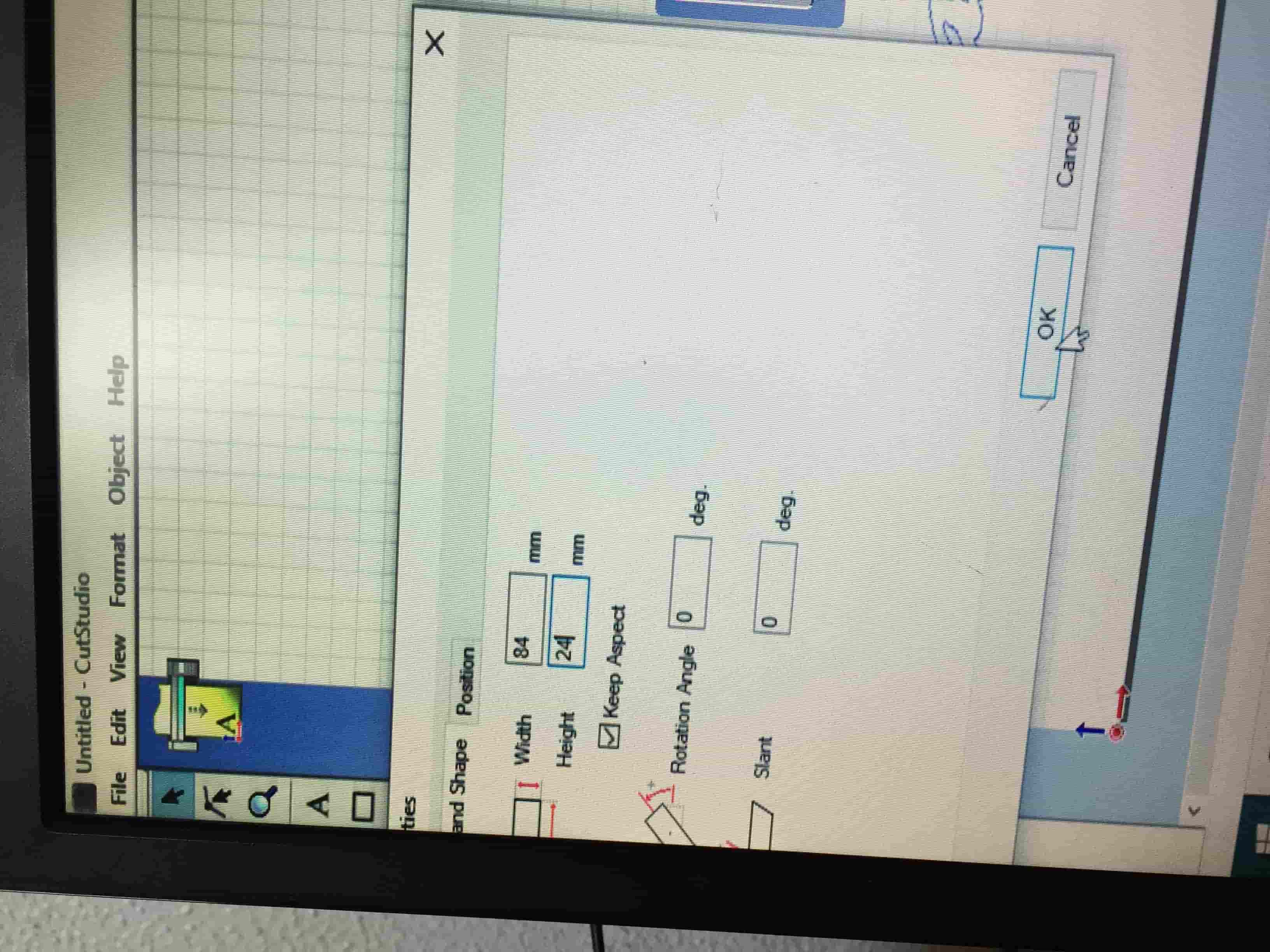

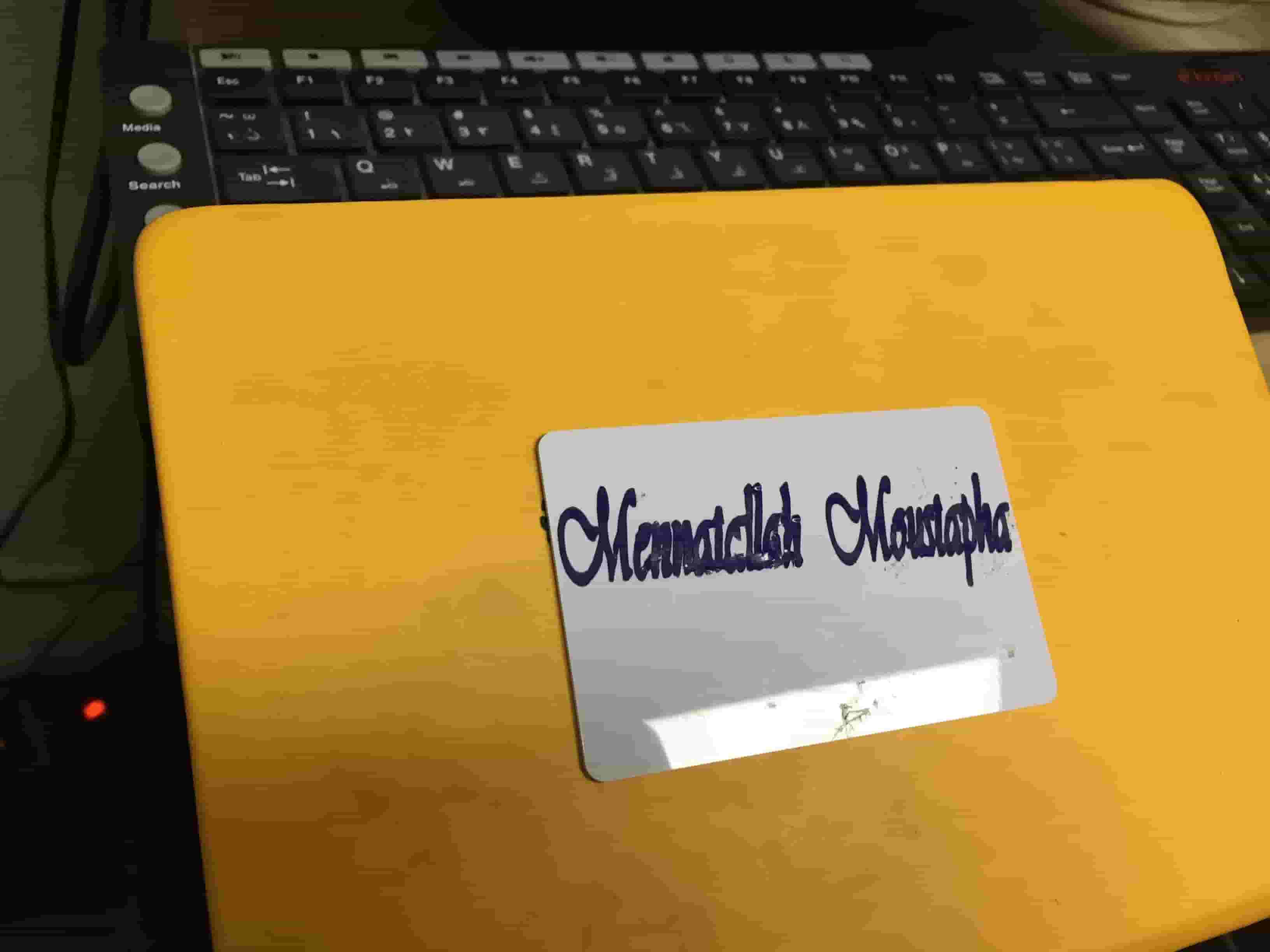

I took the dimensions of the card:

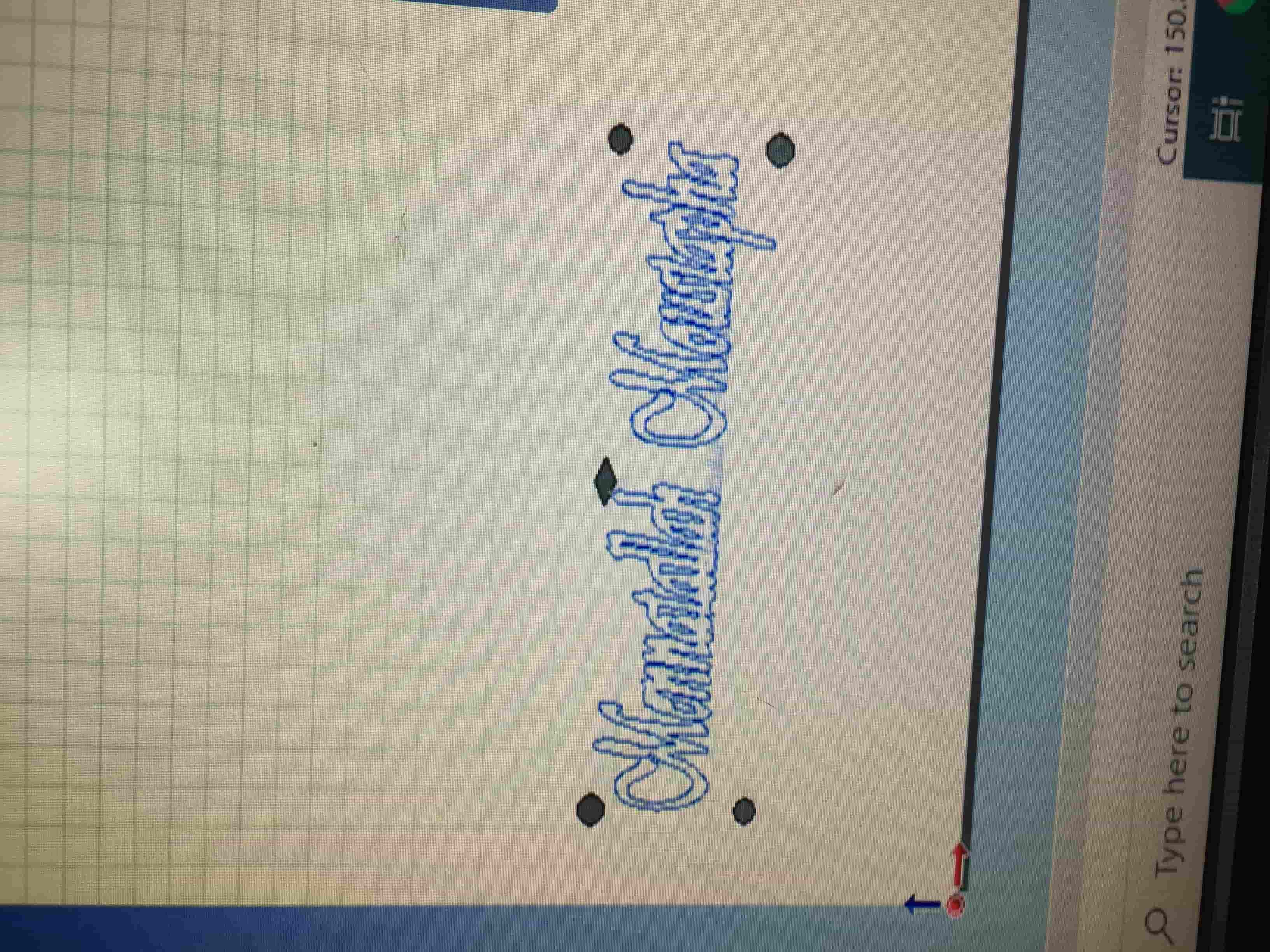

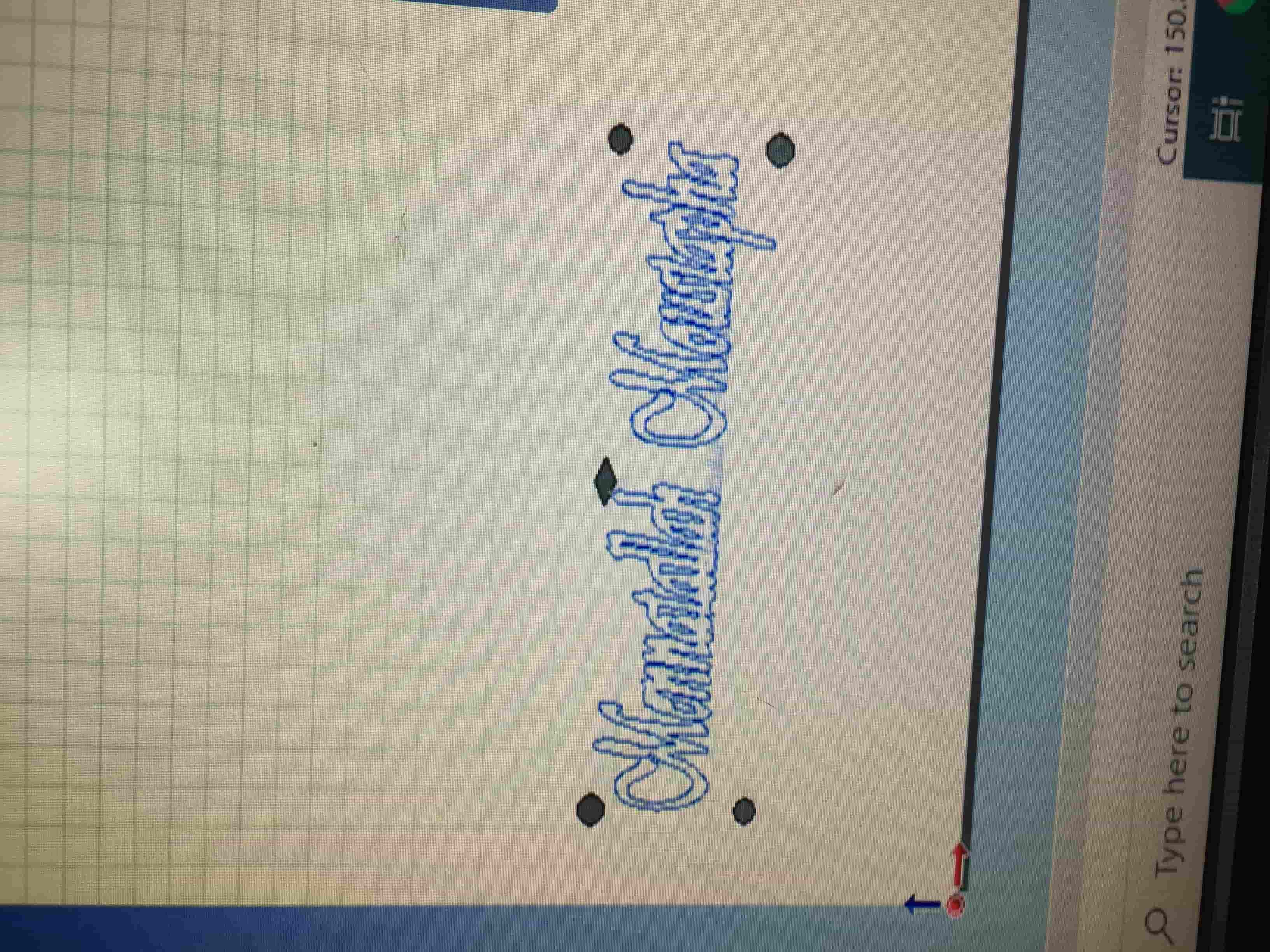

I adjusted the design's length and width:

After a few missed trials:

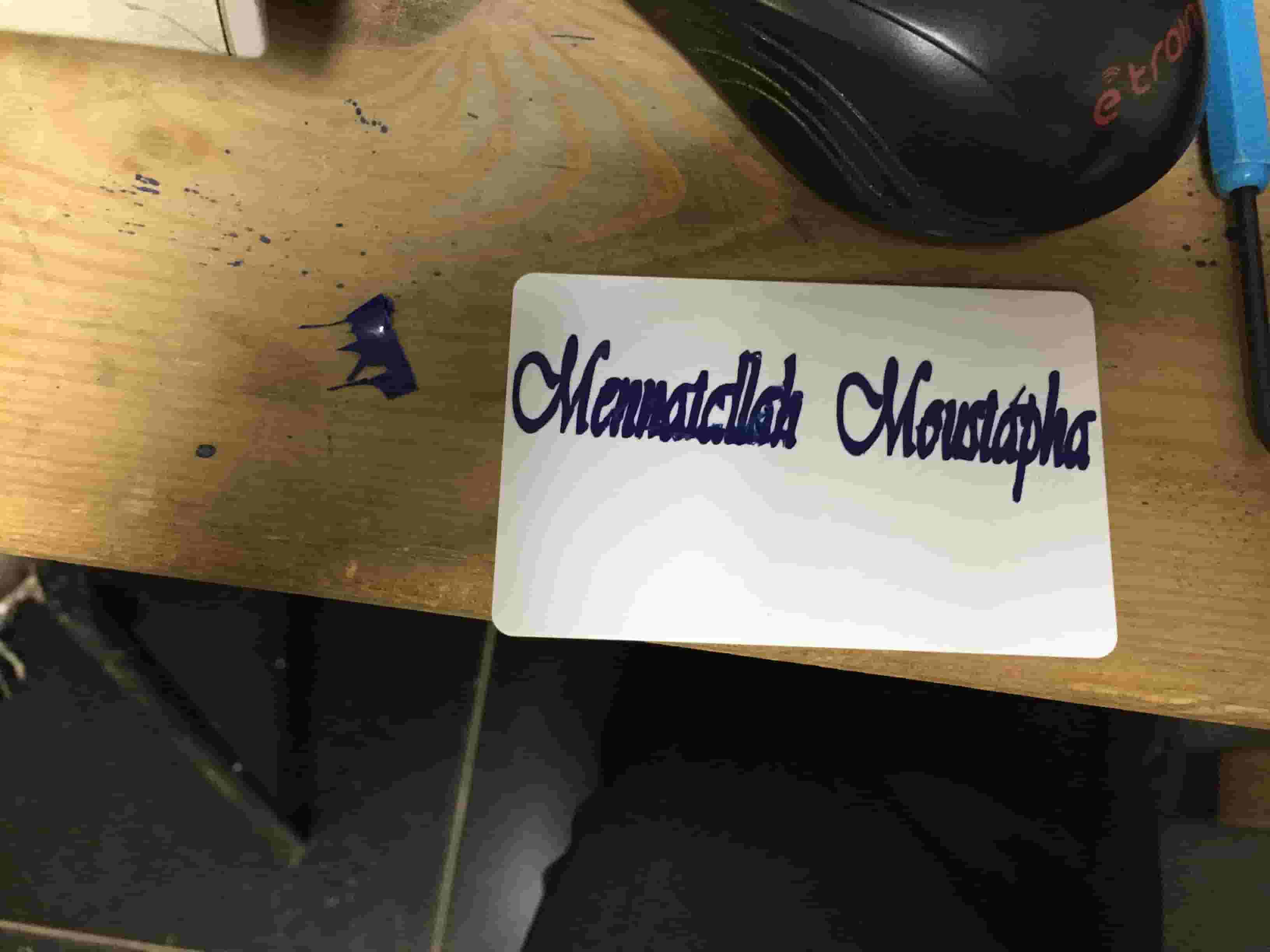

I figured out the right calibration ,uploaded the first design:

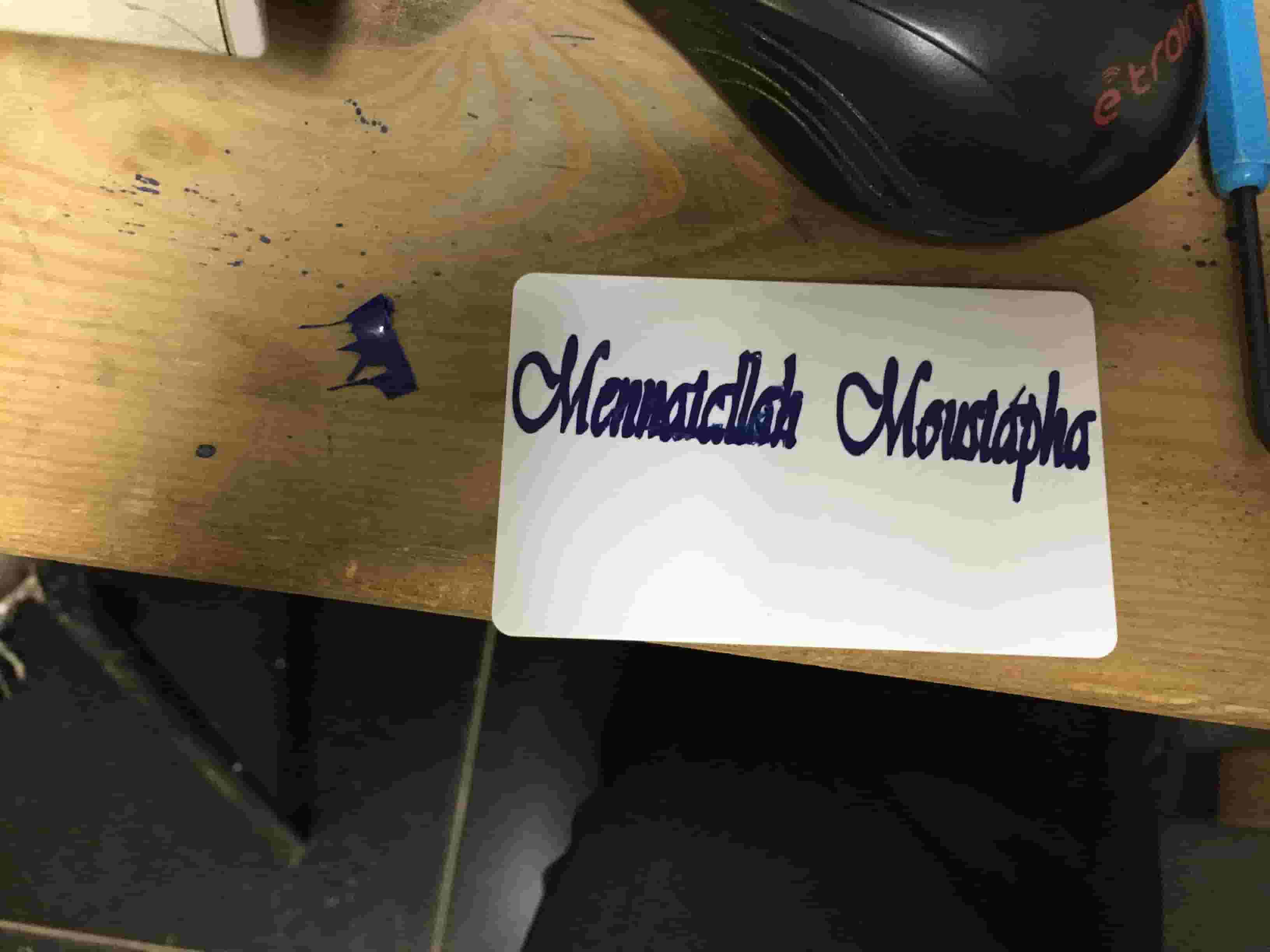

And Voila:

Then the second design which I wanted it to be colorful:to do so I divided the design on many colored sheets and !!:

Files