Applications and Implications

Propose a final project masterpiece that integrates the range of units covered:

What will it do?

My idea is to build a sorting waste machine that can take up to 10 inputs at a time and sort

them item by item into 4 categories: metal,glass ,plastic & paper and organic waste.

Who's done what beforehand?

I searched a lot on the idea ,I found a student that made similar idea but the machine could only take one item at a time: https://www.youtube.com/watch?v=m22jhrKHFWo

also https://www.youtube.com/watch?v=2BHWQhaVk44 and https://www.youtube.com/watch?v=oSmBZKaOkpE

What will you design?

I shall design the mechanism , the PCB of control ,and the power board.

What materials and components will be used?

For the mechanism , it varies between wood and plastic.

There will be motors used like servo motor and stepper motor.

For the electronic part :The sensors are hall effect,capacitive sensor,IR sensor, methane sensor.

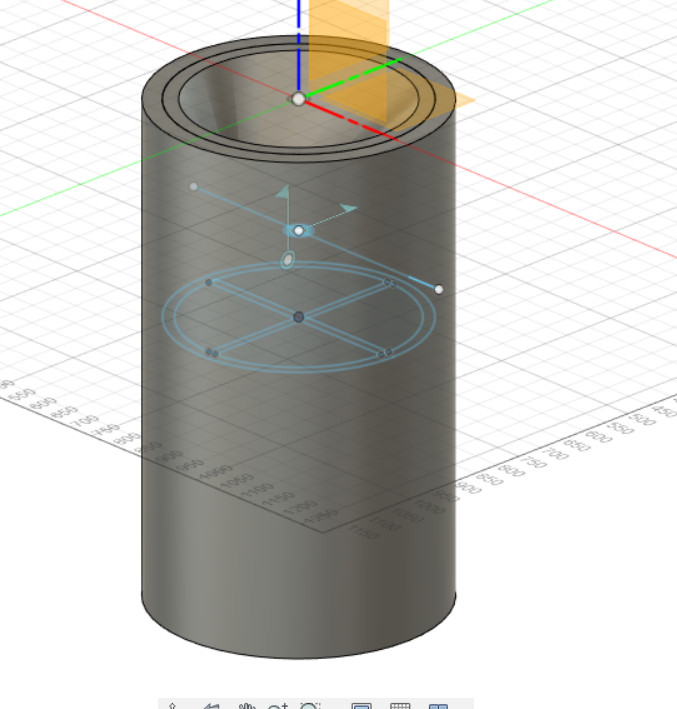

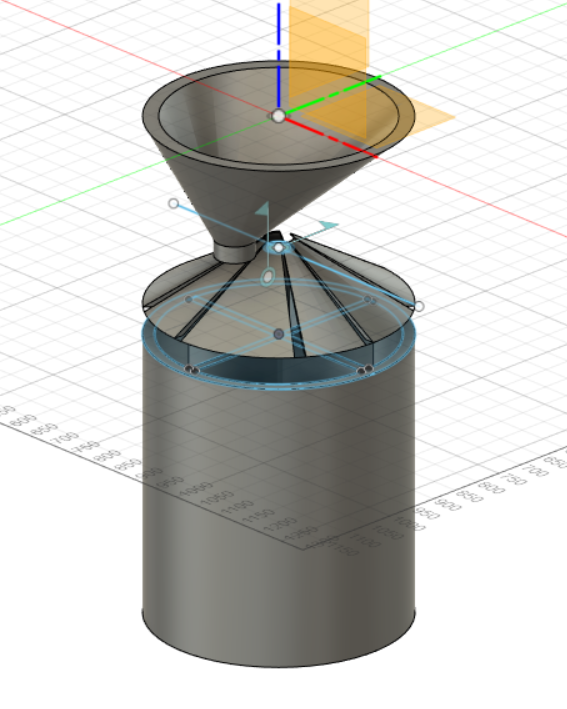

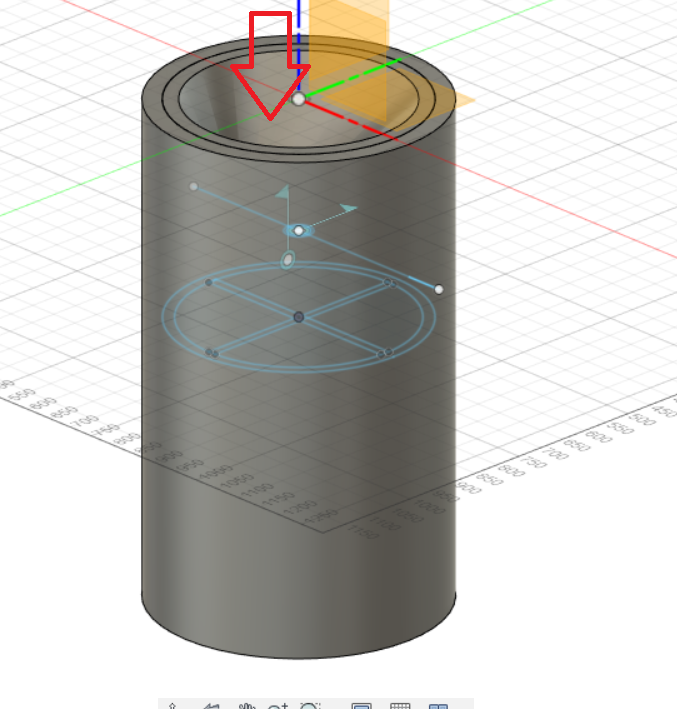

2D and 3D design

Questions that should be answered?

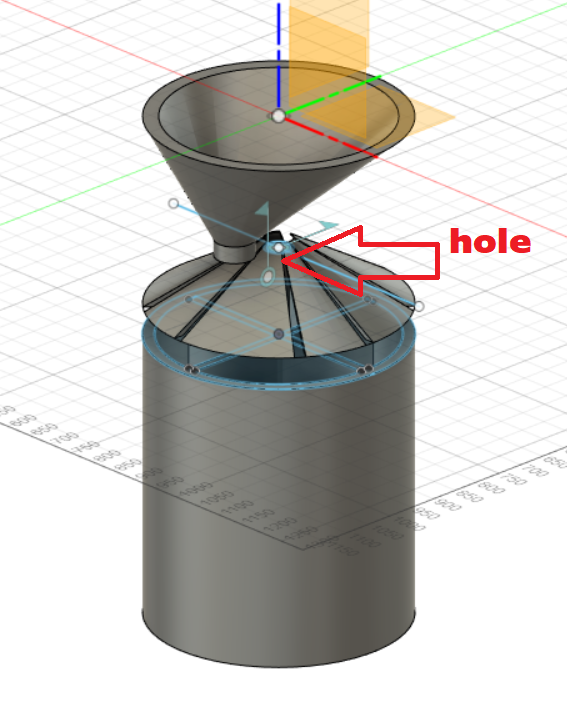

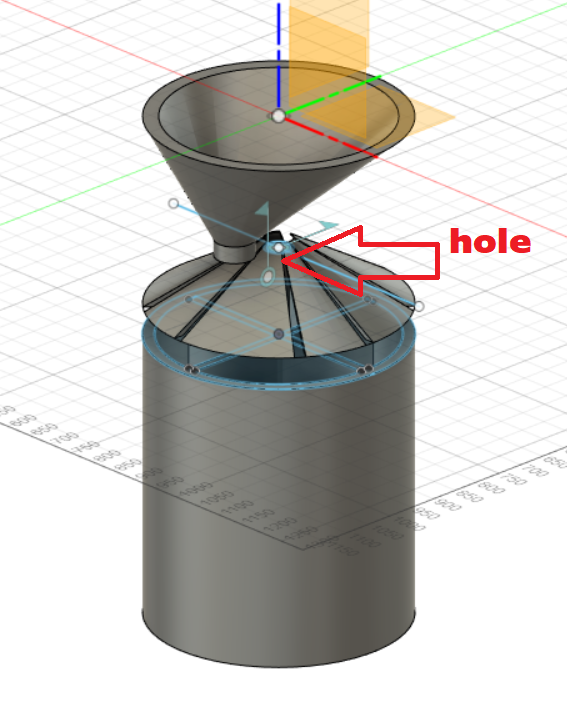

What is the exact size of the inner hole?

To determine this point I have to study the statistics of the size of average daily inputs(waste), for example : the plastic bottles, the metal cans, the glass inserted.So at first I can put a constraint for the average size of inputs processed.Then if the machine works properly,I shall make it more generic.

Should I add shreders to minimize the size of the items?

This question is actually a solution for the previous question.

Does the organic waste need processing to emmit methane and if so how long does it take?

This question is also another constraint , to answer it I should answer what kind of organic waste will be processed.

What are the specific type of material that would be recognized by the sensor and how to generalize?

How I should insert the sensors in the mechanism in order to get the best result?

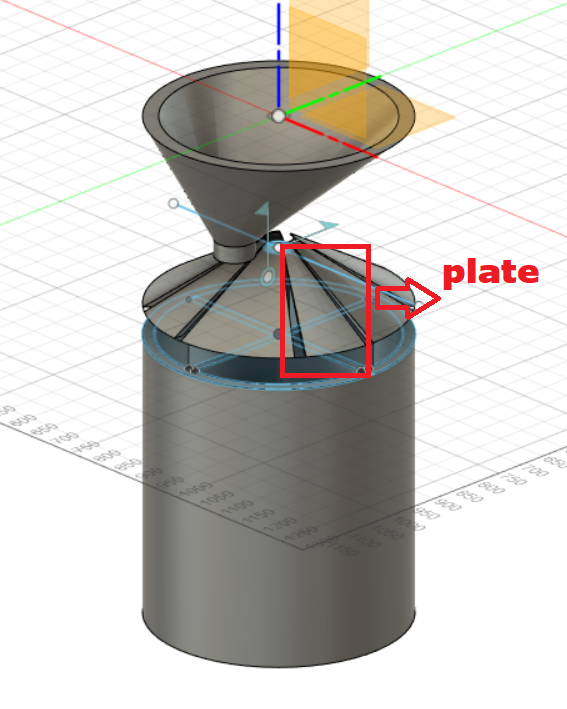

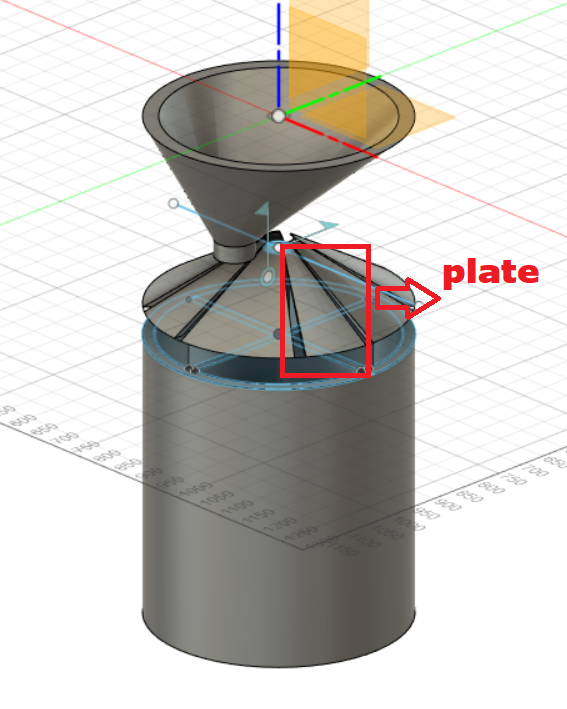

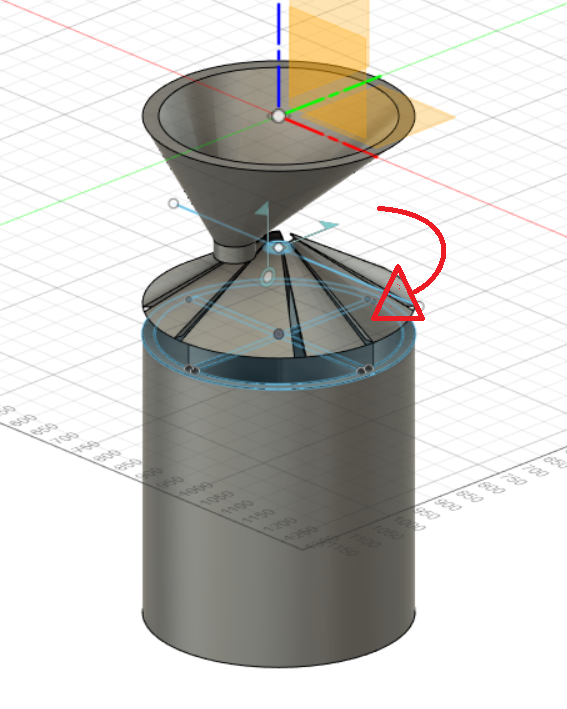

For the sorting phase in the machine ,the plates how should they open to drop the item in it's rightful categories?

Actually this is a really important question,for the sorting phase as it wasn't clear in the first draft design.So to answer that I shall put 5 to 8 small servo motors each motor connected to a plate after the microcontroller process the input information from the sensors,and apply the the algorithm and the programming ,the microcontroller send an order to the servo and it opens up the plate to drop the item then close again.

What is the sorting operating sequence

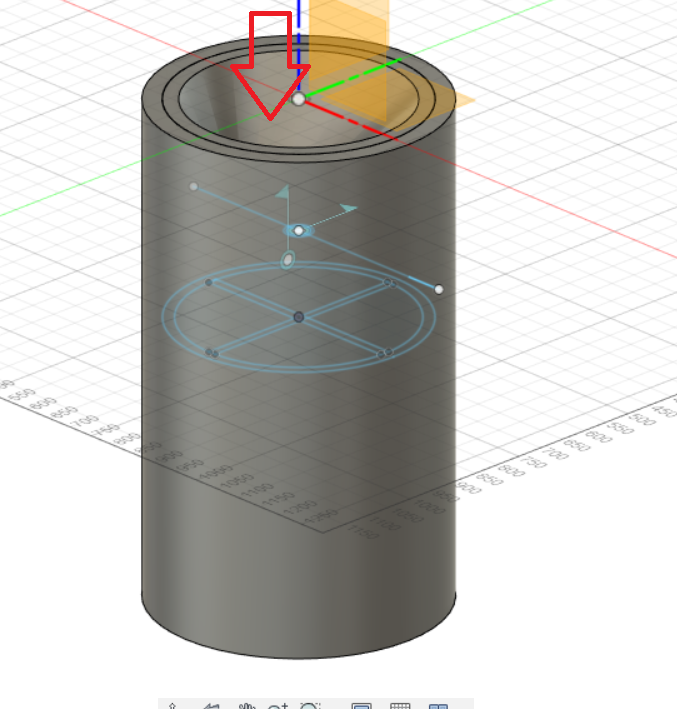

1)So First 10 items get placed from the top.

2) Then it falls throw the inner hole item per item.

3) After the first item drops on the plate there will be a sensor that detect it and gives an order to the stepper motor conncted to the plates to revolve in order for the second item to drop.

4) The sensors should be placed near the plates,after all the items get a plate ,the stepper motor revolve a complete cycle so that each plate get read by the sensors.

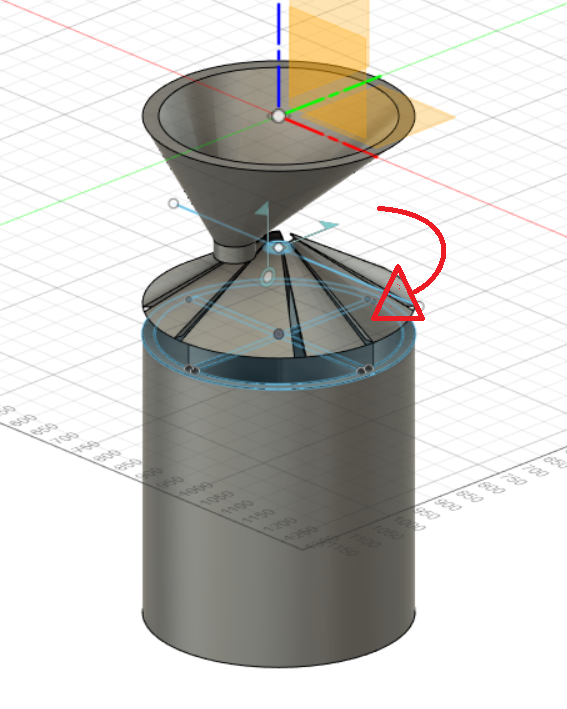

5)The microcontroller gets the readings of each plate that has a number .For example plate 1 trigerd the hall effect sensor so this is metal.

6)Then the stepper motor revolve to a calculated angle to place the plate right above the metal categorie.

7)Then the servo motor connected to the plate release the item.

8) Then proceed to the next item.