Week 16 (Wildcard)

Week 16

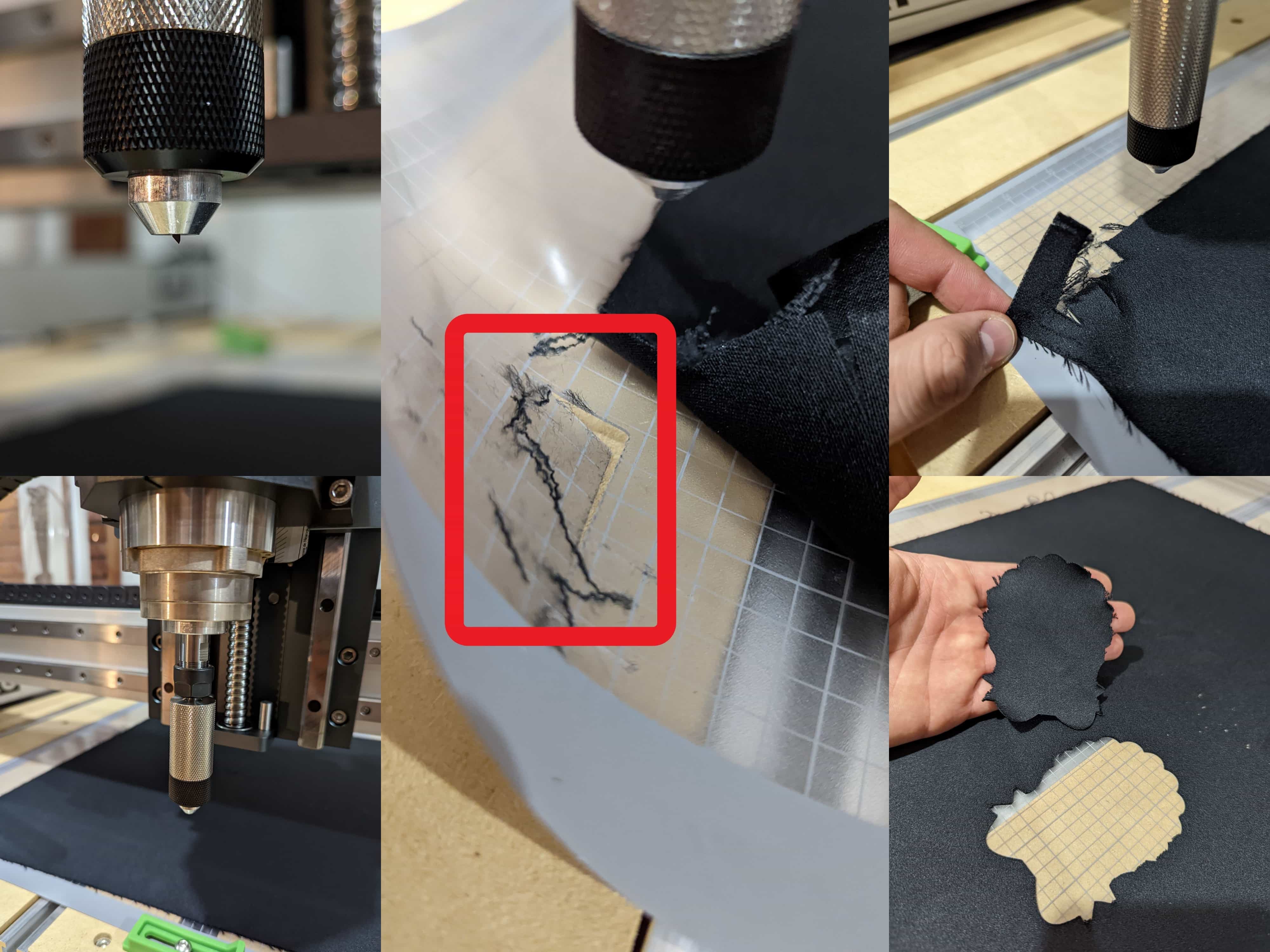

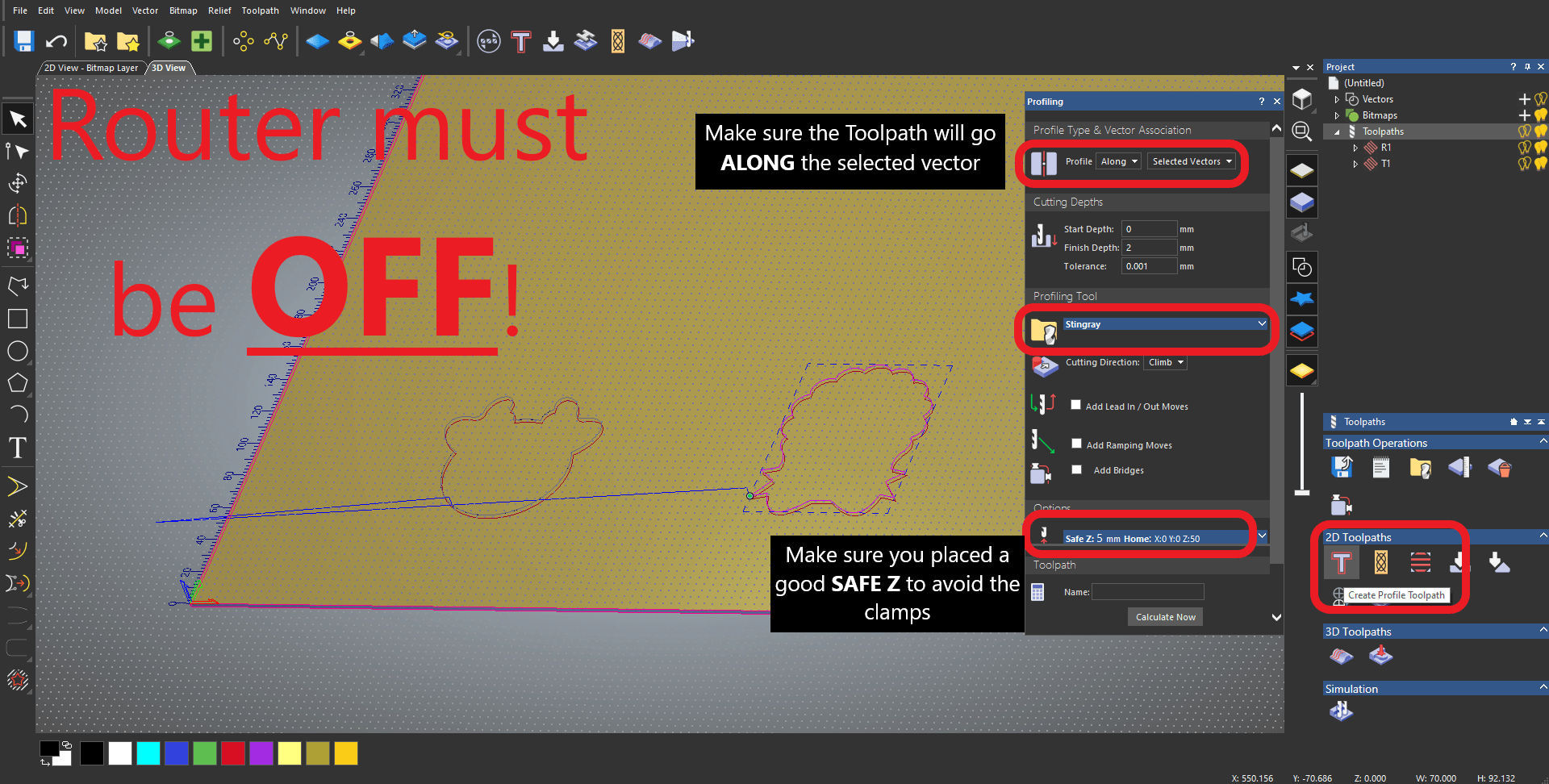

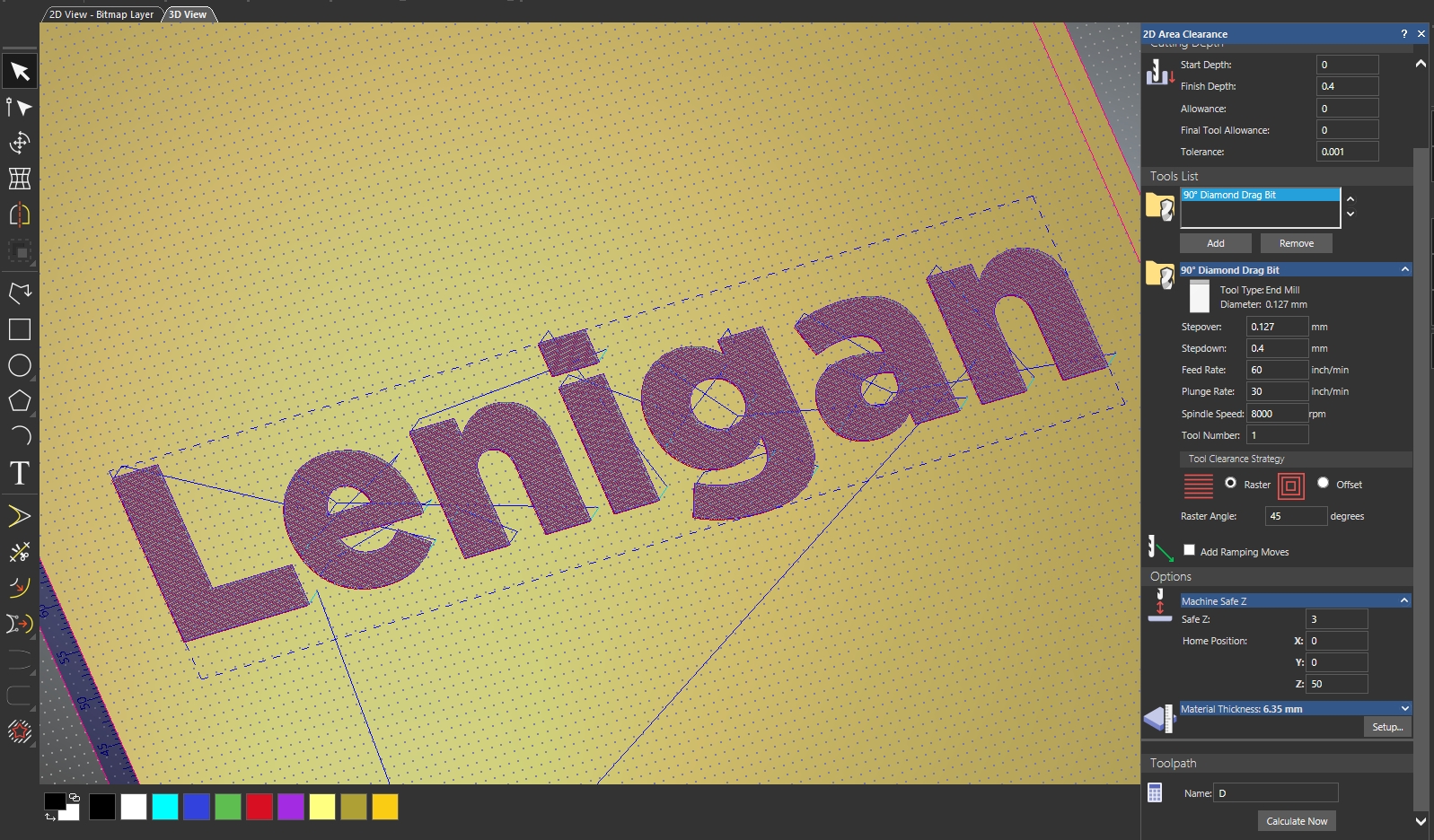

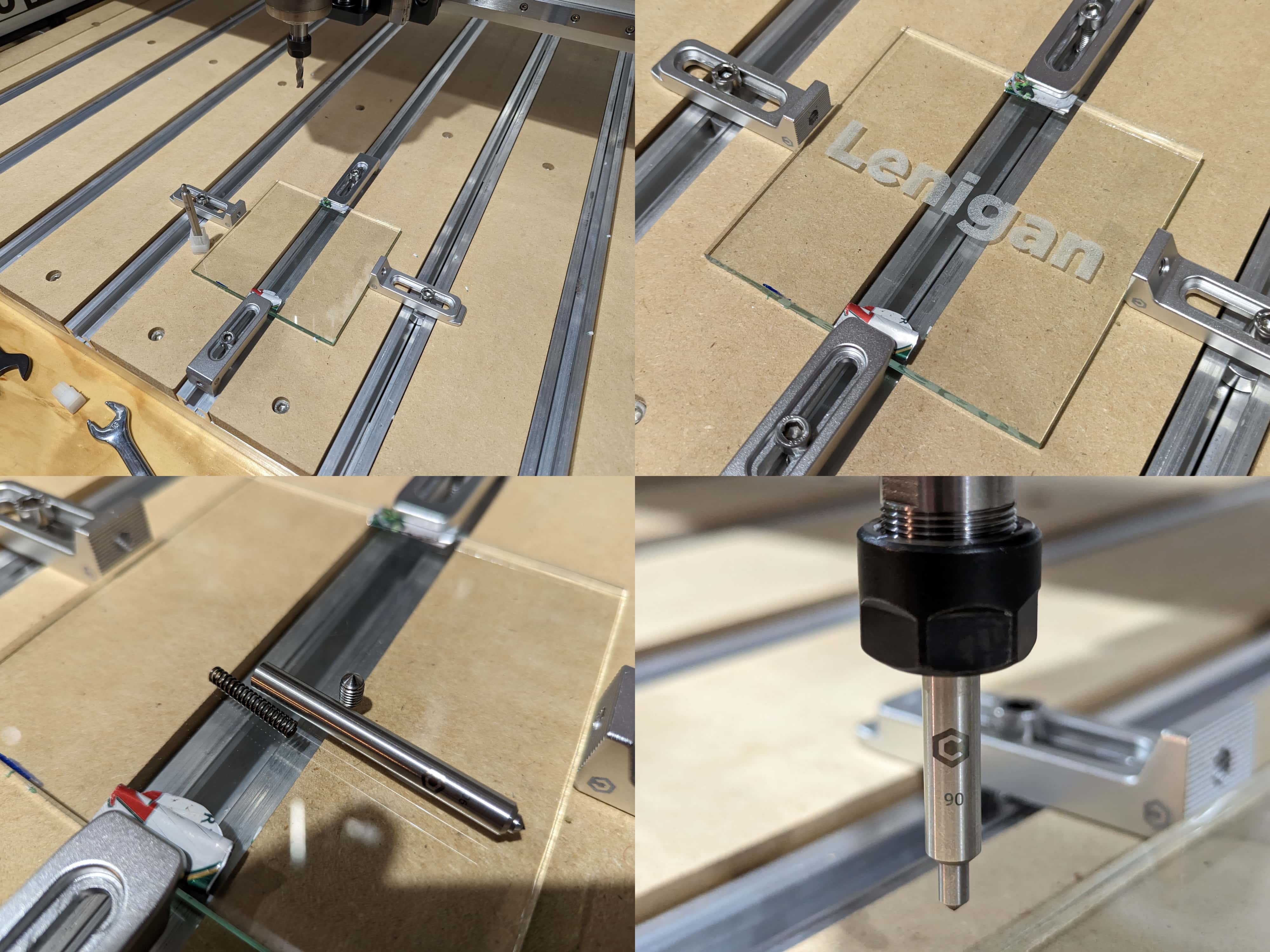

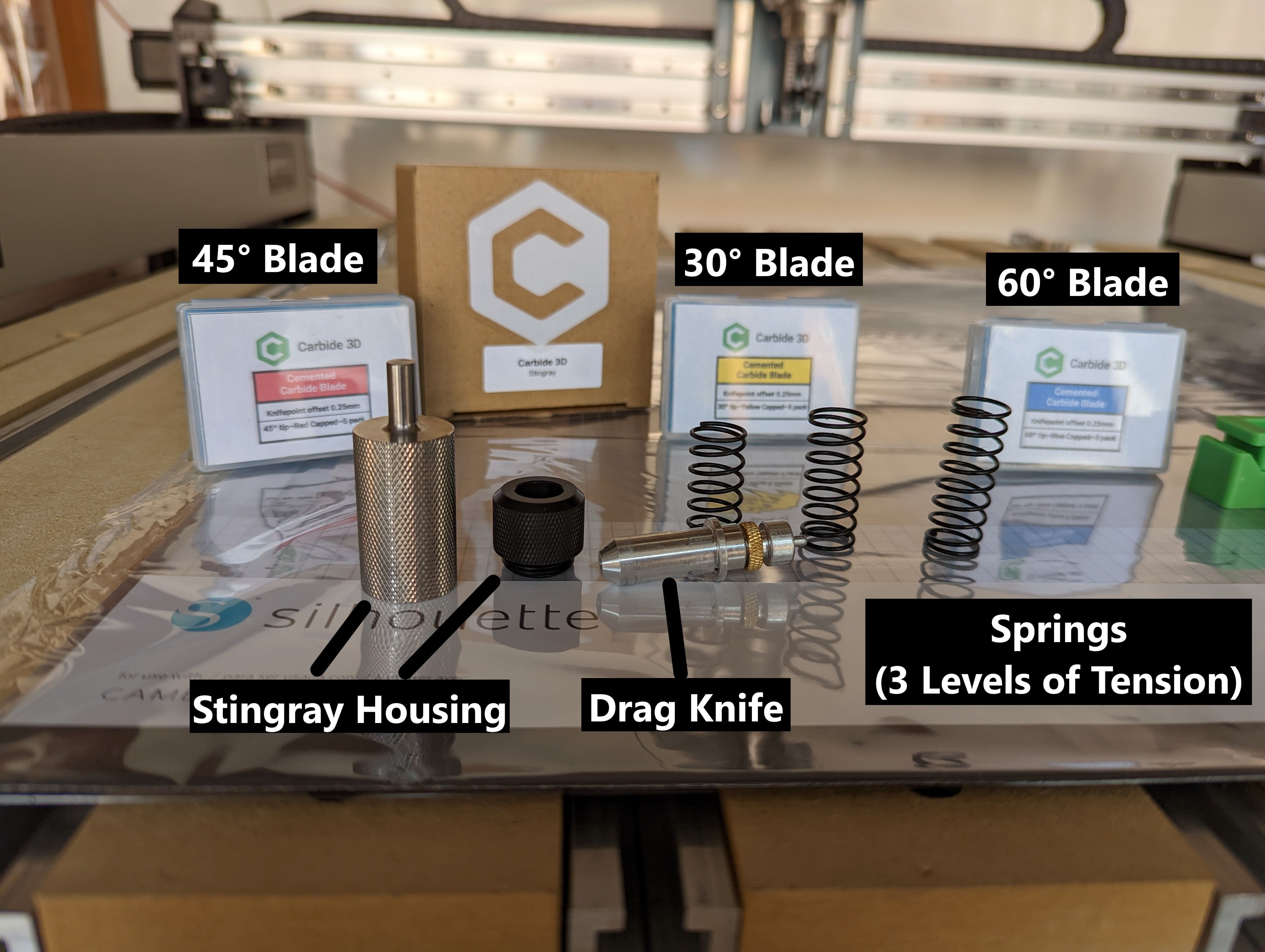

I don’t have a lot of access to a variety of machines but y can turn my CNC router into a flatbed cutter. A flatbed cutter is part of the CNC family (Computer Numerical Control) and the biggest difference these machines have are the tools they use. Another possible difference is the bed each machine has to secure the material in place. My Shapeoko Pro has a VFD spindle and by keeping it off the spindle wont turn. The next step would be to add a Drag Knife. Luckily Carbide 3d has a first party solution… The Stingray. To create a better cutting surface for the Stingray I you need a cutting mat. Normally people buy one with a really big cutting area and us DIY methods to make the surface sticky to be used as a work holding method. Instead of doing this I had a great idea to repurpose the catting mats the Silhouette Cameo Pro uses. This machine has a mate with light and strong adhesion.

Using the T tracks and my CNC claps I secured the strong adhesion mat because the black cloth I’m using is about .574 mm thick. Then I decided to use the 45° blade because it’s considered the workhorse of drag knife. The best of both worlds (thin and thick materials). The final parameter that’s really important is selecting the correct tension for the vertical force of the material you’re trying to cut. Thank God I did my tests on a corner because y selected the wrong blade height and spring tension hahaha. I manage to cut the mat too.