This page presents the assignments for week 4 of Fab Academy 2020: “Electronics production”.

To do list:

Group

- characterize the design rules for your PCB production process

- make an in-circuit programmer by milling and stuffing the PCB,

- test it,

- then optionally try other PCB processes

Week 4 "hero shot":

Table of Contents

1 Group assignment

I worked with

Serena, Benoit and Jonah (Fab Manager) to characterize the design rules

for the PCB production process with the laser cutter of the Lab.

1.1 Overview

1.2 Step by step PCB design process

Step 1

Import the .png file describing the PCB in corelDRAW as shown in figure 1.

Step 2

to open the print menu as shown in figure 2.

Step 3

Select the

appropriate parameters, reading the data sheet of the laser cutter, to

raster with the fiber laser, as shown in figure 3.

Step 4

At this step the PCB should look like as in figure 4.

Step 5

Be careful to put it inside the zone where copper have been removed, as laser isn't powerful enough to go through the copper.

Step 6

Step 7

Select the appropriate parameters, reading the data sheet of the laser cutter, to vector cut with laser.

Step 8

If everything worked fine remove the plate from the laser cutter as shown in figure 5

Step 9

If you have been to

impatient and didn't make enough pass of the laser, use a utility knife

to painfully cut the fiberglass as shown in figure 6.

Check PCB design

Use a microscope to check for hair as shown in figure 7.

Individual assignment

I have follow the tutorial of Brian on how to make a FabTinyISP.

Introduction

As stated in

Brian's tutorial: “The FabTinyStar is yet another version of an AVR ISP

programmer/board that can be produced in a fab lab using a milled PCB

and readily available components. The project is based on the efforts of

many people. For more history of the FabTinyStar and the people who

have contributed to it, please refer to Zaerc's FabTinyStar page”.

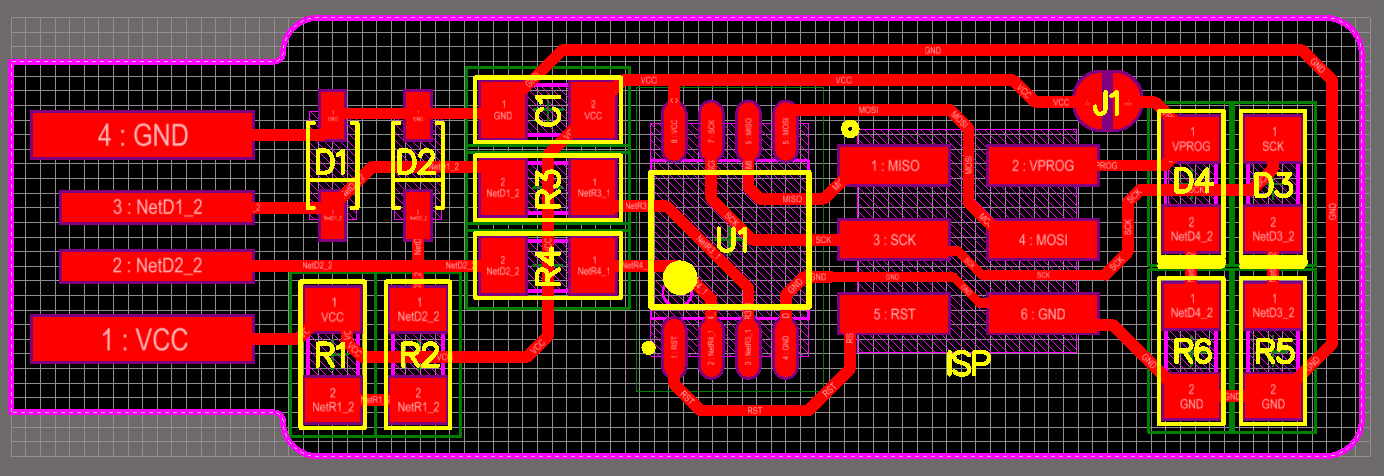

PCB Fabrication

Download the trace and the outline and use the step described in the group assignment section to obtain this PCB.

Figure 8 shows the PCB after the laser cutting steps

Assembling the PCB

Step 1

Wrote down all the name of the parts on a paper in one column and put a double sided tape right to it.Step 2

Pick up each piece on the inventory of your Lab.Step 3

Glue the piece near it corresponding name as shown in figure 9.Step 4

Step 5

Step 6

Figure 12 shows my PCB with all the soldered parts.

2.4 Improve USB connector

2.5 First checks for the PCB

As shown in figure 13, the red led is on when the PCB is connected to a computer.

2.6 Software installation

Step 1

sudo apt install avrdude gcc-avr avr-libc make

2.7 Get and build the Firmware

Step 1

Step 2

cd

Step 3

make

Step 4

ls

Figure 14 shows the terminal output after running the command:

make

2.8 Program the ATtiny45

Step 1

nano Makefile

PROGRAMMER ?= usbtiny

to the programmer name you are using as shown on figure 15.

Step 2

Connect the programmer to the ISP header on your board. Figure 16 shows a “atmelice_isp” programmer connected to the board.

Step 3

make flash

Terminal output should like the one in figure 17

Step 4

make fuses

Terminal output should like the one in figure 18

2.9 Test the USB functionality

Step 1

Step 2

Step 3

Step 4

lsusb

If you see a "Multiple Vendors USBtiny" device on the list as in figure19, then it worked!

2.10 Blow the reset fuse

Step 1

make rstdisbl

Step 2

2.11 Test your programmer

But programming was successful as shown in figure 20.