This page presents the assignments for week 15 of Fab Academy 2020: “Molding and Casting”.

To do list:

Group

- review the safety data sheets for each of your molding and casting materials,

- then make and compare test casts with each of them

- design a mold around the stock and tooling that you'll be using,

- mill it (rough cut + (at least) three-axis finish cut),

- and use it to cast parts

Week 15 CAD files:

main.scad (own work)

molds.scad (own work)

Naca4.scad (Rudolf Huttary work, details inside)

Parameters_Molds.scad (own work)

Week 15 "hero shot":

Table of Contents

Group assignment

Safety data sheets

Machinable Wax

The safety data sheet of standart BLUE formula and F-14 formula from machinablewax.com is available here.Machinable wax is not hazardous except after ingestion.

Mold Star 16 FAST (Silicone based material)

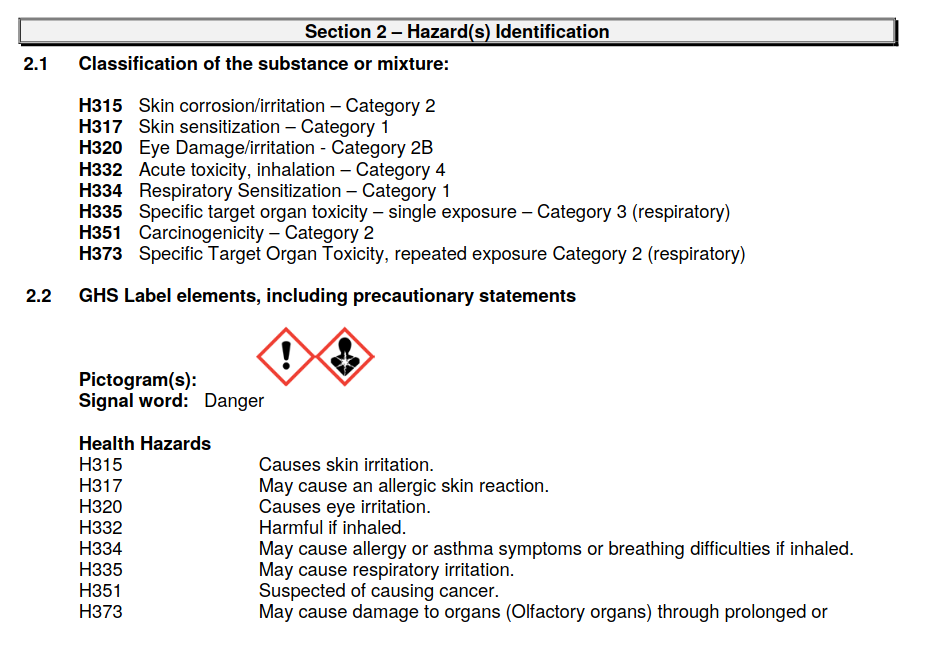

The safety data sheet of Mold Star 16 FAST from Smooth-on is available here .It is not hasardous as shown in the figure bellow.

Smooth Cast ONYX FAST

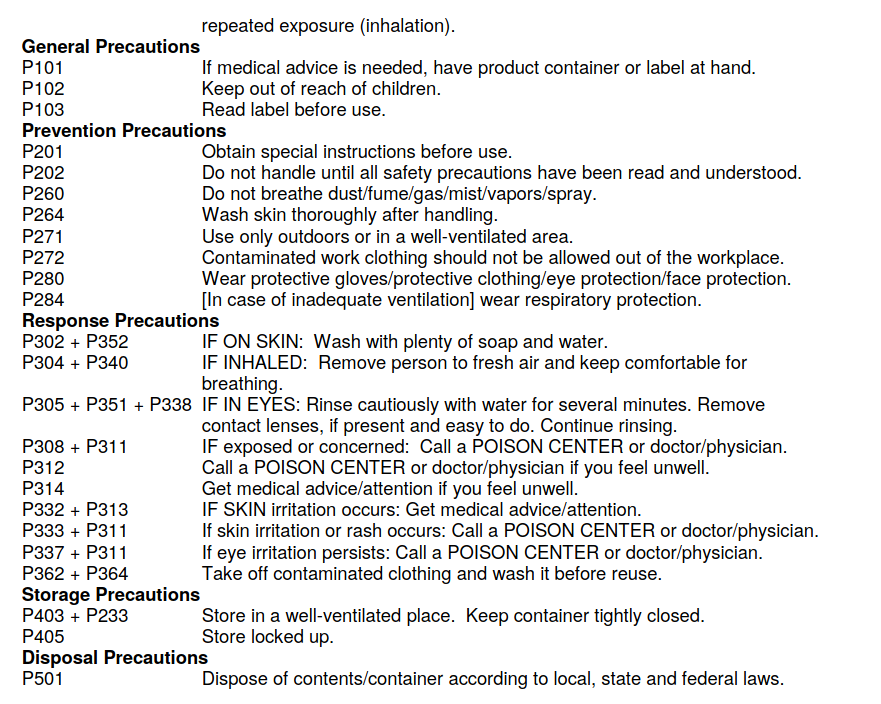

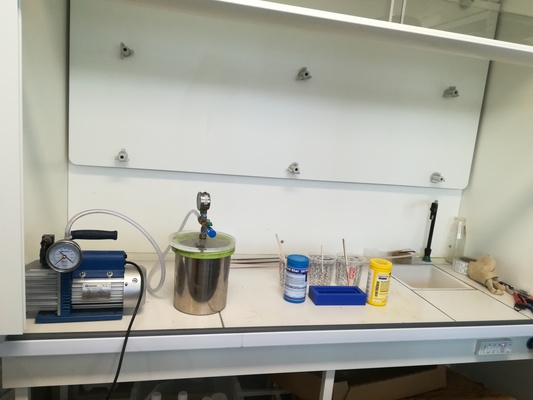

The safety data sheet of Smooth Cast ONYX FAST from Smooth-on is available here .It is very hazardous if inhaled as shown in the figures bellow. I used the fume hood of the Lab, a mask and gloves to make the pourring and casting.

Individual assignment

Wing section molding and casting

For this week assignment I wanted to cast a small wing section.Machinable wax mold

CAD

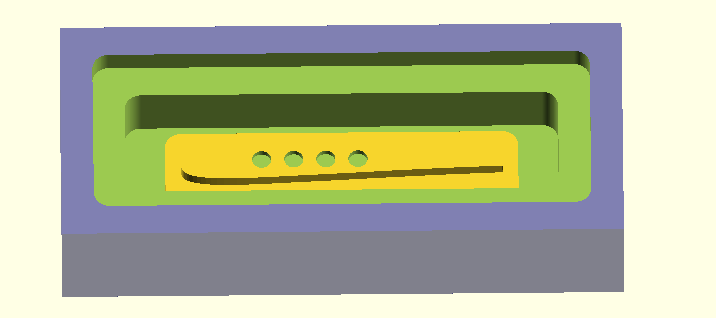

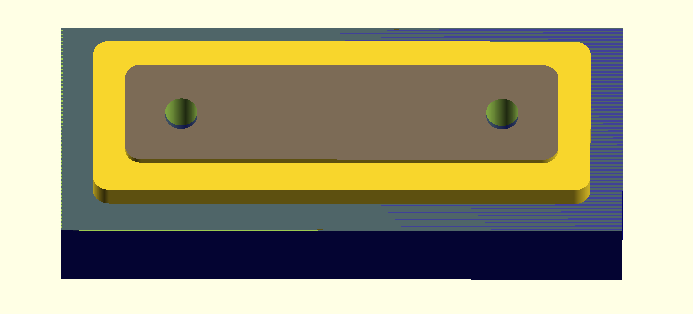

I used OpenSCAD to design the mold.I started with a two parts molds design.

But I realized I could use only the lower part to cast the rubber mold as the bottom of the rubber mold is flat. I also was on a really tight schedule to finish all the assignments and the final project after the Covid lockdown. So I milled the lower part only.

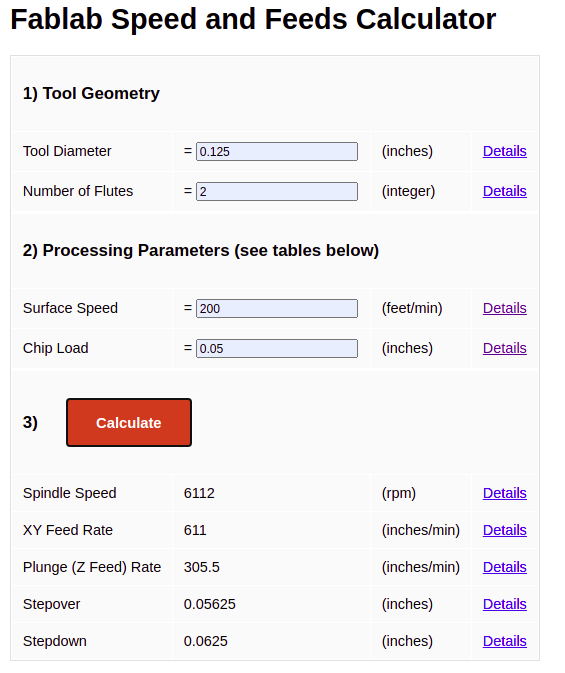

Milling

Result

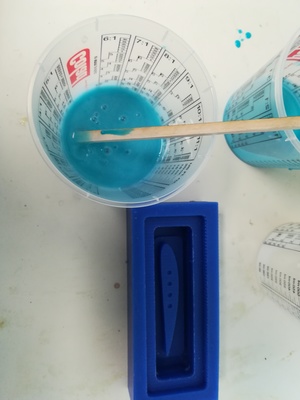

Silicone mold

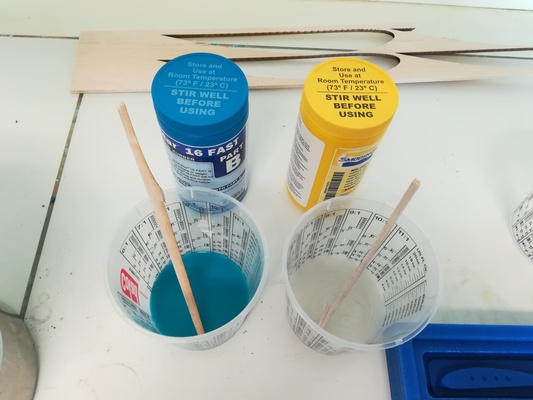

Casting

The mixture has a 6 minutes pot life, this let time to prepare the Silicone and pour it without too much haste.

It then have a 30 minutes cure time before one can remove it from the wax mold.

Result

Casting Urethane part

Casting

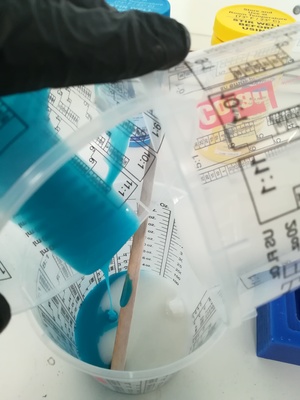

I mixed part A and part B with the ratio 1A:1B by volume. The mixture has a 2.5 minutes pot life, this let little time to prepare the mixture and pour it.One need to be ready and fast, or the casting will fail.

This one produce significant heat when mixed.

It then have a 10 minutes cure time before one can remove it from the Silicone mold.

The Silicone mold make it really easy to remove from the part.

With the quick cure time, this could allow to make a lot of parts easily.