This page presents the first and second ideas for my final project.

Table of Contents

First idea

Second idea

Goals

Achievable in a Fab lab

(by a non specialist member)

Modifiable

Transportable

Reparable

Reproducible

(to create a fleet of drones)

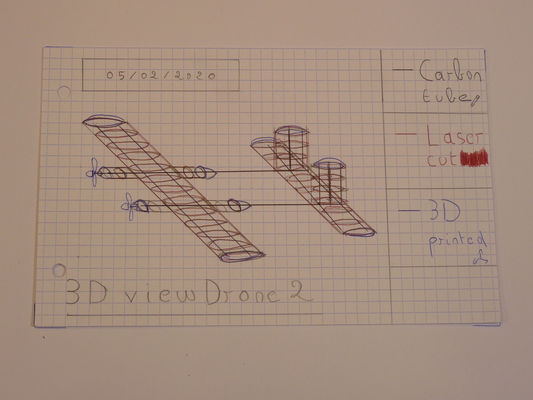

The figure 1 shows a hand sketch for a modular drone.

For more information on this design and other modular designs check the Hand sketches page.

Aims

Design and construction of drones for big conservation projects are currently done by either

Universities

Companies

International NGO

and seldom by local communities. The drones, made or bought, are usually transported to the place where the conservation mission take place.

Universities

Companies

International NGO

and seldom by local communities. The drones, made or bought, are usually transported to the place where the conservation mission take place.

Example: the Air Shepherd project

In the Air Shepered project, drones are used by trained pilots to spot poachers by night in National Parks protected areas.

The operators then transmit the information to rangers that deploy in the area and prevent the poaching.

This approach is efficient as the sole presence of a drone in the sky act as a deterrent for poachers (which might get killed in combat with rangers).

The drone are produced and operated by trained pilots of UDS, which “work with locals to identify threats to elephants and rhinos”.

What are this threats? According to Air Shepered website poaching generate an estimated 70 billion dollars benefice a year on black market. One pound of Rhino horn, which is associated to medical myths, is estimated to be worth 30 000 dollar on Asian black market.

Why?

I believe that the implantation of a Fab lab could create an ecosystem which benefit both the conservation effort and the local communities.

Example: the Air Shepherd project

In Fab lab, members could create simple to build, yet functional, fixed wing drones. Add training for local pilots, and the community could make a fleet of remotely controlled drones to fight again poachers at night.

This surveillance drones could also be used by day for FPV (First Person View) tourism. The advantages are the following:

- medium altitude flight could allow for stunning aerial view and video of wildlife and local flora (for tourists, bloggers, documentaries), with less impact then traditional safari using cars.

- Sharing publicly the video could help researchers monitor biology status (i.e. abnormal changes in fauna or flora).

- Locally trained pilot and ranger could provide dual controls for remote or on the spot tourists that could choose the zone to explore.

- Locally trained pilot could enforce local law on drones and assure safety for the flight.

How?

First idea

With a website teaching Fab lab members “How to build a modular drone for a conservation mission from scratch”.

Specification for the website

- The first page should allow the user to specify the machines that are available in her/his Fab lab. The minimum vital machine required for this project is a laser cutter.

- Each page should teach a significant step in the process of drone design. I will follow the structure of the book [1] to design a small unnamed fixed wing aircraft. Example for the process of drone design:

- The parameter chosen by the users should automatically start parametric CAD files.

- The last page should allow the user to download:

Second idea

Design a parametric drone using opensource softwares and document its conception, construction and then operation.Specification for the drone airframe

Modularity

Ease to build for the whole drone by assembling simple modules

Fast building by allowing parallel builds of modules

Ease to transport by stacking the modules in boxes

Isn't this project (way) too ambitious for fab Academy time frame?

Rational answer

- I am planning to adapt a design of a fixed wings drone to a modular fixed wing drone.

- I have some technical background with drones:

- Outside of this gap semester I am a PhD student working on how to develop a strategy for searching and tracking multiples moving targets using a fleet of cooperative drones. More info in this page.

- I am a member of a club for model aircraft making and flying. I have already make and fly drone from kit. I can also use the knowledge and advice from expert pilots (one is a professional fixed wing drone pilot for the army) and expert builders (some of them build and fly radio controlled jet aircraft, with working replica of a turbojet engine).

- I will follow the steps of the book [1] to design a small fixed wing drone and will adapt them to meet the assignments of Fab Academy 2020. See this page for my planning.

Less rational answer

Modified citations

Figure 2: In space no one can hear you scream [after two hours trying to solve a bug in your code]

(Card from the excellent board game Galaxy Trucker)

(Card from the excellent board game Galaxy Trucker)

Original citations

- “Shoot for the moon. Even if you miss, you'll land among the stars”, attributed to Oscar Wild

- “In space, no one can hear you scream”, tagline for the movie Alien, Ridley Scott's 1979.

Covid 19 lockdown

The Digiscope Fab Lab was closed for 3 months due to Covid lockdown here in France.

I was planning to make several drones versions and test them at the club location.

But the club was also close during lockdown.

So I ended with 2 days, instead of a full week, for each assignment from week 7 to 18 and then keep one week for the final project.

Note: the design I made during Covid lockdown needed adjustements that can only be checked after the part is produced with the machine of the Fab Lab.

List of possible and probable failures

Too heavy

Too fragile

Too unstable

A pain in the assembly ^^

Fallback

Build a hovercraf like this one

No fly tests, focus on the concepts and the build