The Design

Pellet Extruding

Our pellet extruder was developed in house following several sources online. Particularly, we looked at

Bartlett's RC4 video.

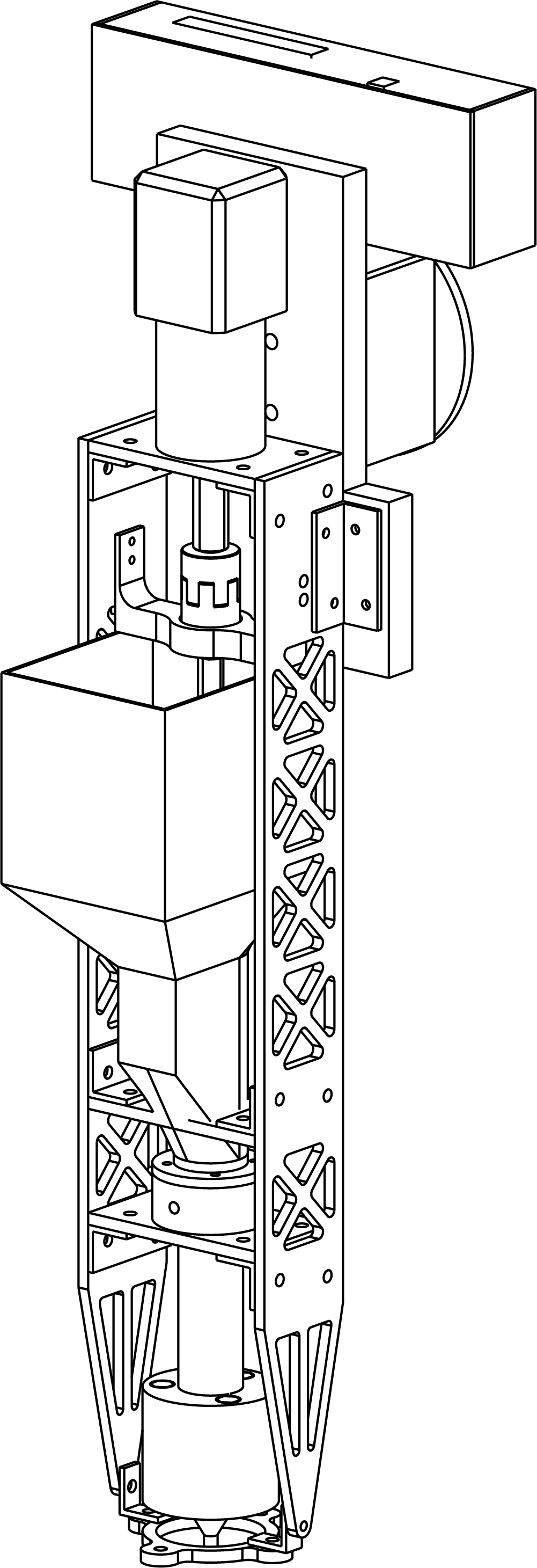

The design features a 1" auger in a tube, with a 3d printed tumbler, and a NEMA23 motor with a planetary gearbox. The heat block is made of three 75 watt heat elements, that are controlled using a REX C100 PID controller. We are also using a heated bed using 15m of low temp nichrome coil-wire. The whole thing is held together with an aluminium chasis and attached to a KR30 or KR10 Robot. We are printing ABS and PLA. In the case of PLA, it is printed from reclaimed suppert material and reused plastic, ABS is store-bought,

back to top