jchhfggou# MDEF - FABACADEMY COURSE INFORMATION

Evaluation criteria¶

2on Term¶

3rt Term¶

Grading and Final Evaluation process¶

Weekly assignments¶

Week 01 - Principles and practices¶

Individual assignment

Plan and sketch a potential final project and describe what it will be and who you can integrate it with Fabacademy (for instance, mapping it with the weekly assignments).

Week 02 - Computer aided design¶

Individual assignment

Model (raster, vector, 2D, 3D, render, animate, simulate, …) a possible final project, and post it on your class page.

Learning outcomes

- Evaluate and select 2D and 3D software, preferable one that you haven´t used before.( get out of your comfort zone)

- Demonstrate and describe processes used in modelling with 2D and 3D software(what you understand between raster-vector- 3d modelling- voxel modelling,etc)

Student should have

- Modelled experimental objects/part of a possible project in 2D and 3D software

- Shown how you did it with words/images/screenshots

- Included your original design files

FAQ¶

Is it compulsory to do parametric design this week? - No, but it is in computer controlled cutting. So it is a good idea to start learning now.

Week 03 - Computer controlled cutting¶

Materials and machines¶

- EACH STUDENT HAS A PIECE OF CARDBOARD AND PLYWOOD OF 3MM X 1200 X600 MM

- LASERCUTTERS Trotec100 - Trotec400 and Multicam Lasercutter

- VINYLCUTTER Silhouette Cameo - RolandGX24

Individual assignment

- Cut something on the vinylcutter

- Design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways (first try out in cardboard and after test other materials)

Learning outcomes

- Demonstrate and describe parametric 2D modelling processes.

- Identify and explain processes involved in using the laser cutter.

- Develop, evaluate and construct the final prototype.

Student should have

- Explained how you parametrically designed your files.

- Shown how you made your press-fit kit.

- Included your design files and photos of your finished project.

Vinyl Cutting

There is no specific project that is focused on this very useful tool. There are a range of ways you might utilise it throughout the programme, or your local instructor may set a specific project. You might make:

- stickers

- flexible circuit boards

- a textured surface/relief pattern

- screenprint resists/stencils

Ensure that you have used it in some way during this time and met the objectives below.

Learning outcomes

- Identify and explain processes involved in using this machine.

- Design and create the final object.

Student should have

- Explained how you drew your files.

- Shown how you made your vinyl project

- Included your design files and photos of your finished project

FAQ¶

What does ‘characterise’ mean?

- describe/understand the nature and features (of your particular laser cutter)

Can I use the Inkscape clone tool for my pressfit kit?

- No. The clone tool is not a real parametric software.

Is it compulsory to design my own file in Vinyl cutting?

- Yes. Or modify existing one, and acknowledge where you found it.

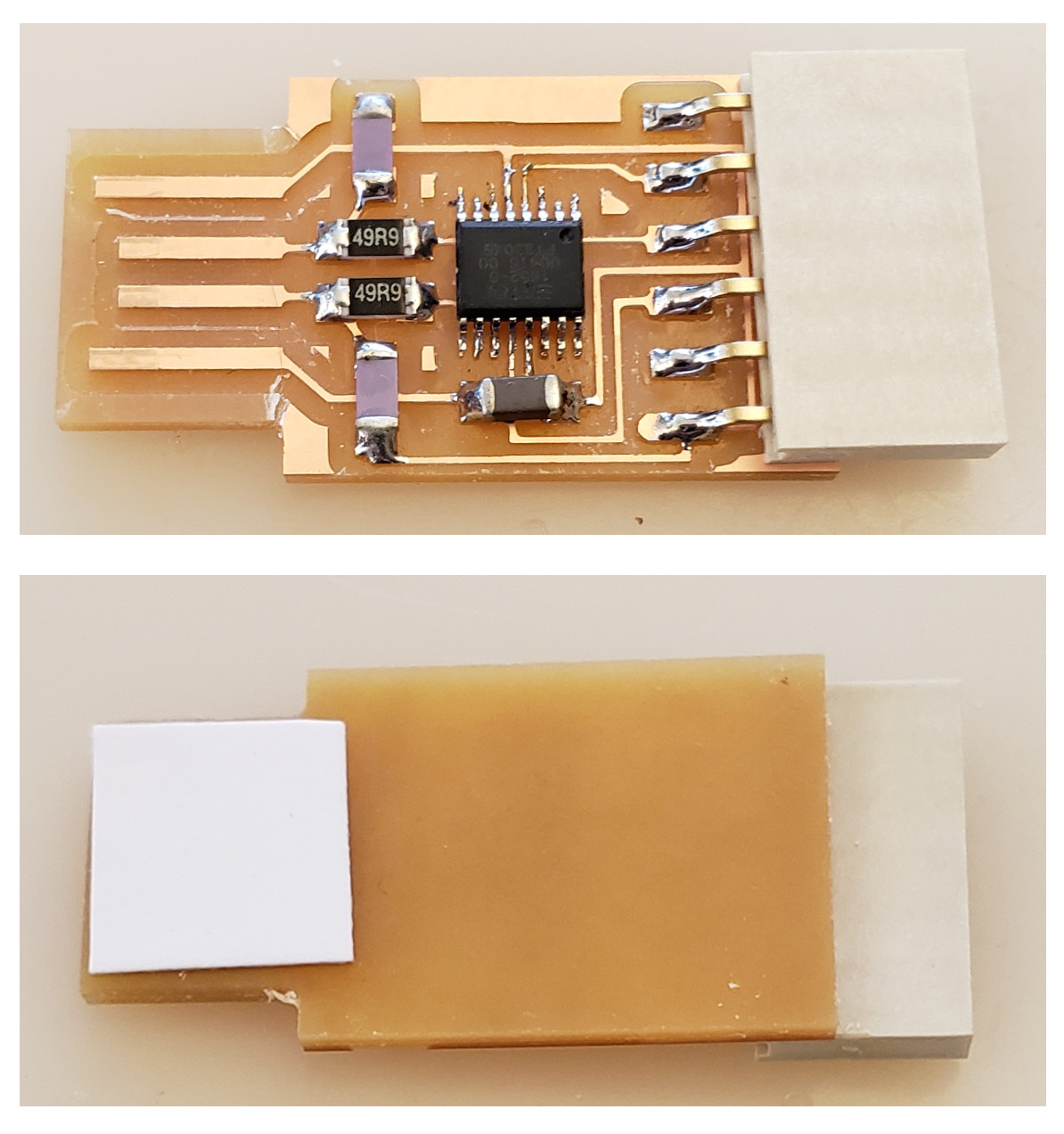

Week 04 - Electronics production¶

Individual assignment

TASK-1:

Fabricate your own LED BADGE using a desktop CNC and test it(make the led light up with the power supply):

TASK-2:

Fabricate your own USB to FTDI using a desktop CNC and test it(DRIVERSmake it be recognized by the computer):

Learning outcomes

- Described the process of milling and stuffing

- Demonstrate correct workflows and identify areas for improvement if required

- Be able to produce a board that doesn´t “smoke”

Student should have

- Shown how you made the board

- Explained any problems and how you fixed them

- Included a ‘hero shot’ of your board

- Light up the soldering led test board

- Connect the FTDI board to the computer and getting it recognized by the computer (how to install the drivers)

Week 05 - 3d printing and 3d scanning¶

Individual assignment

- Design and 3D print an object (small, few cm) that could not be made subtractively.

- 3D scan an object (and optionally print it, you could also 3d scan yourself or your 3dprinted part)

Learning outcomes

- Identify the advantages and limitations of 3D printing and scanning technology

- Apply design methods and production processes to show your understanding.

Student should have

- Described what you learned by testing the 3D printers

- Shown how you designed and made your object and explained why it could not be made subtractively(laser-mold-etc)

- Scanned an object

- Outlined problems and how you fixed them

- Included your design files and ‘hero shot’ photos of the scan and the final object

Week 06 - Electronics design¶

Individual assignment

Modify the Barduino (Eduino ESP32) with at least an LED and a button. Some extra credit could be: - You can also add the FTDI chip into the board, so that you can use directly USB - You can add a micro/mini USB female connector and the FTDI chip so that you can power it with a normal cable - You can modify and reshape the board to be however you want. Put the header connector vertically, horirontally… But always use female connectors (like an arduino)

Learning outcomes

- Select and use software for circuit board design

- Demonstrate workflows used in circuit board design

Student should have

- Shown your process using words/images/screenshots

- Explained problems and how you fixed them, including how you worked with design rules for milling (DRC in Eagle and KiCad)

- Included original design files (Eagle, KiCad, Inkscape, .cad - whatever)

Note: Also, if you make a board and it doesn’t work; franken-hack that board (with jumper wires etc) until it does work, then make a new one with the knowledge you have gained.

Week 07 - Computer controlled machining¶

Individual assignment

TASK: - Make (design+mill+assemble) something big.

Learning outcomes

- Demonstrate 2D design development for CNC production

- Demonstrate how to design for cnc(tolerances-joints-etc)

- Describe workflows for CNC production (how to use the machine safely)

Student should have

- Explained how you made your files for machining (2D or 3D)

- Shown how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)

- Described problems and how you fixed them

- Included your design files and ‘hero shot’ photos of final object

#### FAQ

How big is big?

- Answer: Big enough to show you understand many of the possibilities of CNC machining - drill, pocket, dogbones, nesting, etc.

What material I can use

- Each student has half of a fullboard (1220x1220x15 veneer plywood) medium quality

Can I join with a teammate to do something bigger

- You can join with one person to do something bigger and combine your pieces of wood. Also you can use all the scraps leftover that other students left.

You should try to avoid glue - nails - screw in your design, that means used wood joinery with proper tolerances

Week 08 - embedded programming¶

Individual assignment

TASK - 1:

- Program your led with arduino - analogwrite/digitalwrite

- Program with arduino (libraries) and also with registers

TASK - 2:

- Program with Platformio

TASK - 3 extra credit:

- BLINK WITHOUT DELAY:

Learning outcomes

- Identify relevant information in a microcontroller data sheet.

- Implement programming protocols.

Student should have

- Documented what you learned from reading a microcontroller datasheet.

- What questions do you have? What would you like to learn more about?

- Programmed your board.

- Described the programming process/es you used.

- Included your code.

FAQ¶

What board can I use?

- Answer: Programm your board (barduino, if you don´t have it program your arduino board or nodemcu)

Can I just program a blink

- Come on!, try harder, this week is for exploring alternatives and save you time in inputs,outputs, networking weeks..

Do I need to understand what I am doing

- For sure, it is better to try simple things but understand everything, this is the base to build your programming skills that you will use along all the programming weeks of the academy.

Week 09 - Input Devices¶

Individual assignment

TASK - 1 Mandatory:

- Program your board(arduino/nodemcu/attiny/barduino) to read a sensor - analogread/digitalread

- Program in whatever language you consider and read the data in at least serial monitor.

- Program it you board to change the led intensity based on the input sensor data

TASK - 2 Mandatory:

- DSP - make sensor of what you read and detect an event

- Filter the data and clean up noisy values, detect peaks, maxs, mins

TASK - 3 extra credit:

- Fabricate you own sensor!There are multiple ways to make DIY SENSORS to sense the world

Learning outcomes

- Identify and learn the difference between digital and analog sensor data

- Implement programming protocols.

Student should have

- Programmed your board.

- Explained the programming process/es you used and how the microcontroller datasheet helped you.

- Included your original code and tutorials references that you used.

FAQ¶

I don´t have arduino(or others) and neither sensors

What board can I use?

- Answer: Programm your board (barduino, if you don´t have it program your arduino board or nodemcu)

Can I just program a blink

- Come on!, try harder, this week is for exploring alternatives we recommend you to try the sensors you plan to use in your final project.

Do I need to understand what I am doing

- For sure, it is better to try simple things but understand everything, this is the base to build your programming skills that you will use along all the programming weeks of the academy.

Week 10 - Applications/Implications¶

Individual assignment

TASK - 1 Mandatory:

- Propose a final project masterpiece that integrates the range of units covered.

- Your project should incorporate 2D and 3D design,

- additive and subtractive fabrication processes,

- electronics design and production,

- microcontroller interfacing and programming,

- system integration and packaging

- Where possible, you should make rather than buy the parts of your project

- Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Learning outcomes

- Define the scope of a project

- Develop a project plan

Student should have defined

- who has done what beforehand?

- What will you design?

- what materials and components will be used?

- where will they come from?

- how much will they cost?

- what parts and systems will be made?

- what processes will be used?

- what questions need to be answered?

- how will it be evaluated?

The answers to the questions above will allow you to create your BOM (Bill Of Materials).

FAQ¶

Why do I have to answer these questions?

- Answer: These are questions to help you plan your final project. Answer these and any other questions you think will help you do this

Week 11 - Output Devices¶

Individual assignment

TASK - 1 Mandatory: - Program your board(arduino/nodemcu/attiny/barduino) to activate an output - analogread/digitalwrite - Program in whatever language you consider and try to activate different outputs with the same code.

TASK - 2 Mandatory:

- Program it you board to change the output based on a input sensor data

TASK - 2 extra credit:

- Fabricate you own output!There are multiple ways to make DIY Outputs to sense the world

Learning outcomes

- Identify and learn how to active an output with digital and analog signals

- Implement programming protocols.

Student should have defined

- Explained the programming process/es you used and how the microcontroller datasheet helped you.

- Outlined problems and how you fixed them

- Included original design files and code

Week 12 - Interface and application programming¶

Individual assignment

TASK - 1 Mandatory: - Write an application that interfaces a user with an input and/or output. That means, make an interface to visualize data or to activate outputs

TASK - 2 Mandatory:

- Try at least 2 diferent interfaces

TASK - 3 extra credit:

- Try coding in diferent apps example(processing-appinventor,etc)

Learning outcomes

- Interpret and implement design and programming protocols to create a Graphic User Interface (GUI).

Student should have defined

- Documented your process

- Explained the UI that you made and how you did it

- Outlined problems and how you fixed them

- Included original code (or a screenshot of the app code if that’s not possible)

- Included a ‘hero shot/video’ of your application running with your board

Week 13 - Invention,intellectual property and income¶

Individual assignment

TASK - 1 Mandatory:

- Choose a license for your work, explain why and put it in your repository

TASK - 2 extra credit:

- Add how others can contribute to your project and how you expect to disseminate it

Learning outcomes

- Formulate future opportunities

- License types and dissemination possibilities

Student should have

- A license type chosen and in the project site

- Explained why you picked it

- Explained how you would disseminate your project and allow others (or not and why), to contribute

Week 14 - Networking¶

By The Opte Project - Originally from the English Wikipedia; description page is/was here., CC BY 2.5, Link

Individual assignment

Read a sensor value and send it remotely to another chip. For instance:

- Another arduino via UART/I2C/SPI, etc

- Over RF with antennas

- Or to a remote server as in Friday’s session

Learning outcome

- Demonstrate workflows used in network design

- Implement and interpret networking protocols

Student should have

- Described your project using words/images/diagrams/schematic screenshots.

- Explained the programming process/es you used.

- Outlined problems and how you fixed them

- Included your code files

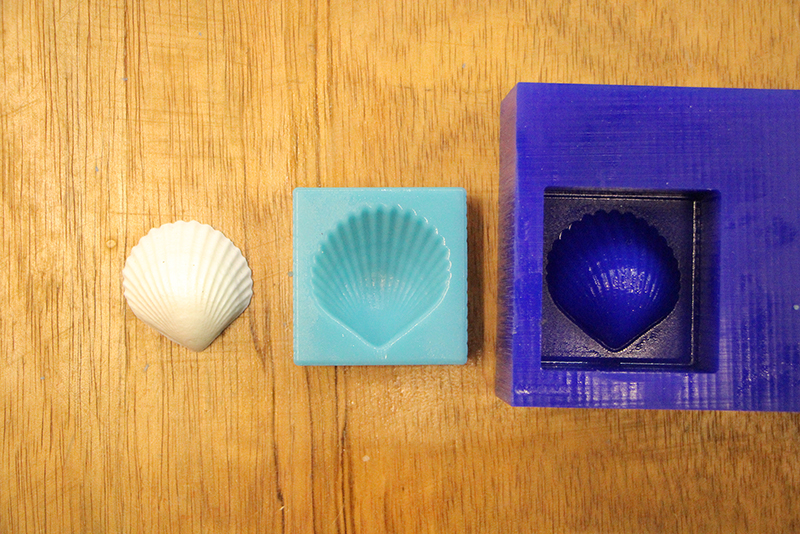

Week 15 - Molding and Casting¶

Individual assignment

- Design a 3D mould around the stock and tooling that you’ll be using, machine it, and use it to cast parts from it.

Learning outcome

- Design appropriate objects within the limitations of 3 axis machining.

- Demonstrate workflows used in mould design

- Demonstrate workflows used in construction and casting. (OPTIONAL)

Student should have

- Explained how you designed your 3D mould and created your rough and finish toolpaths for machining.

- Shown how you made your mould and cast the parts. (OPTIONAL)

- Described problems and how you fixed them.

- Included your design files and ‘hero shot’ photos of final object.

Week 16 - Wildcard week¶

Individual assignment

- Contribute to a distributed digital fabrication experiment, with the design of a “piece of art” made (draw) remotely from home.

Learning outcome

- Demonstrate workflows used in remotely control fabrication

- Design and generate the CAM file

Student should have

- Explained process involved in using the machine remotely.

- Described problems and how you fixed them

- Included your design files and ‘hero shot’ screenshot of you “art pice”