We need the Spindle Key for changing the bit

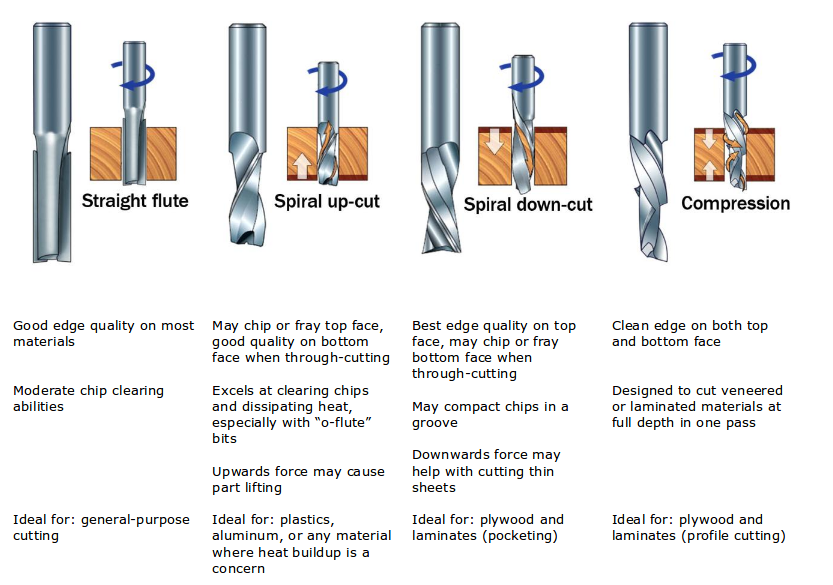

1.Flute type :

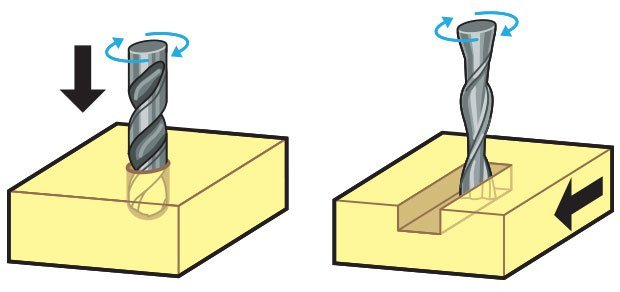

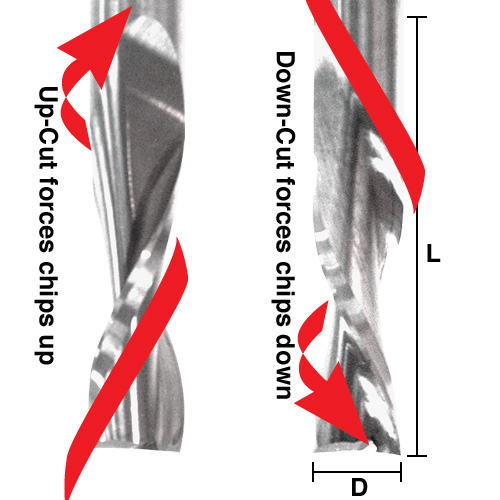

In an Upcut type end mill the teeth on the flute will point upwards. This means that the end mill is cutting and drawing out the wood through the flute.

This is good for cutting deep into the stock. But this leaves a bad surface finish on the top of the surface.

test runout, alignment, speeds, feeds, and toolpaths for your machine

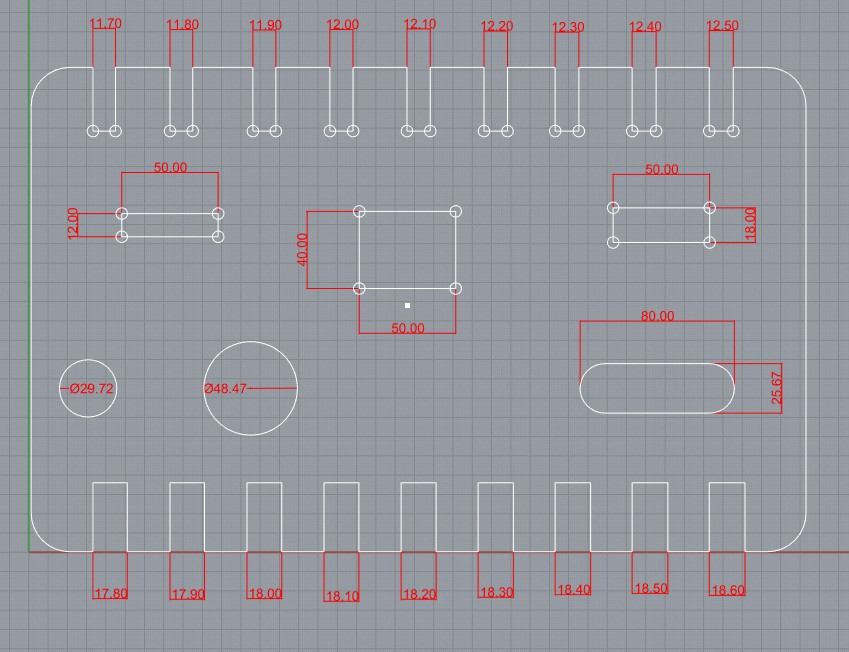

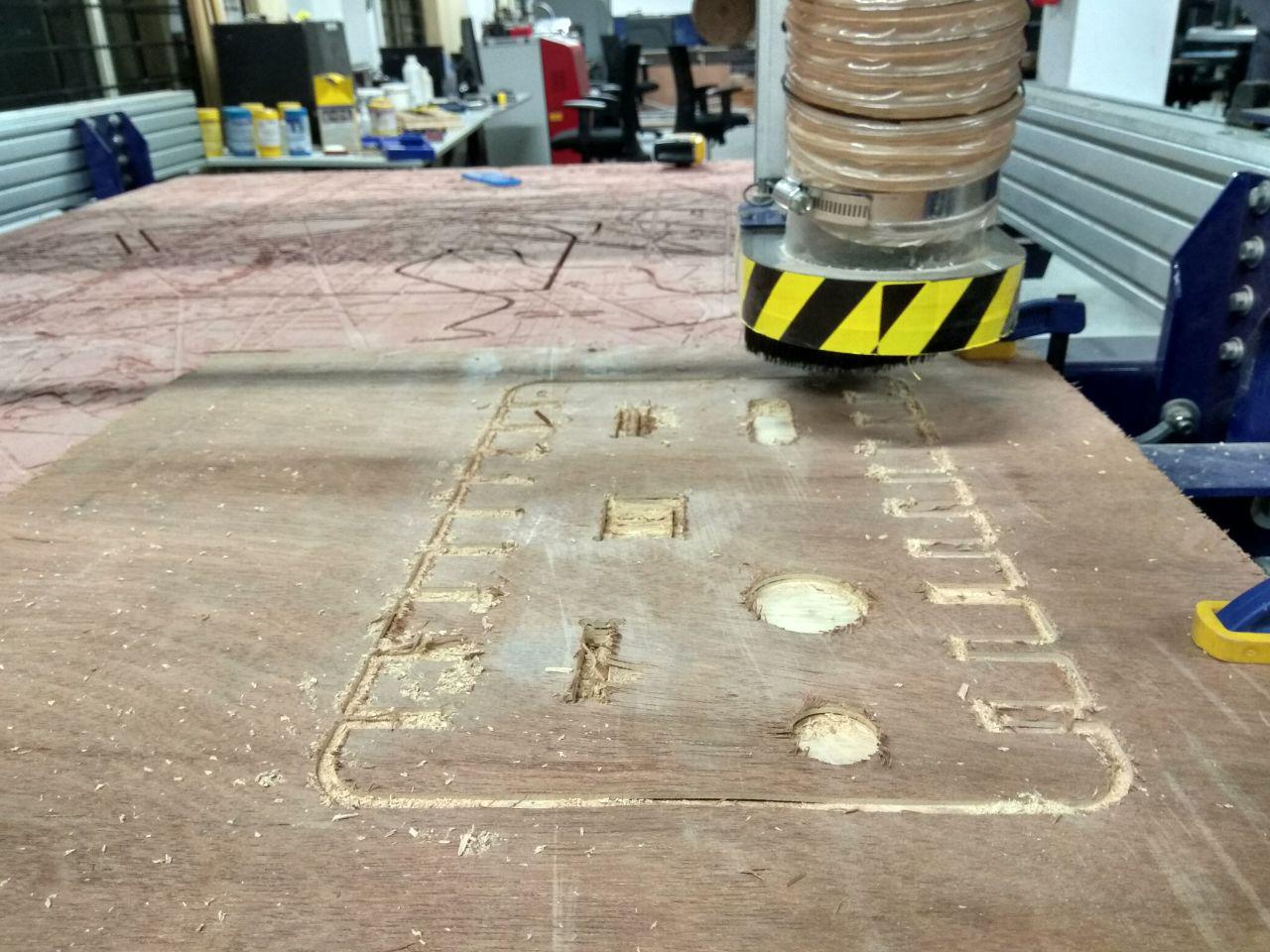

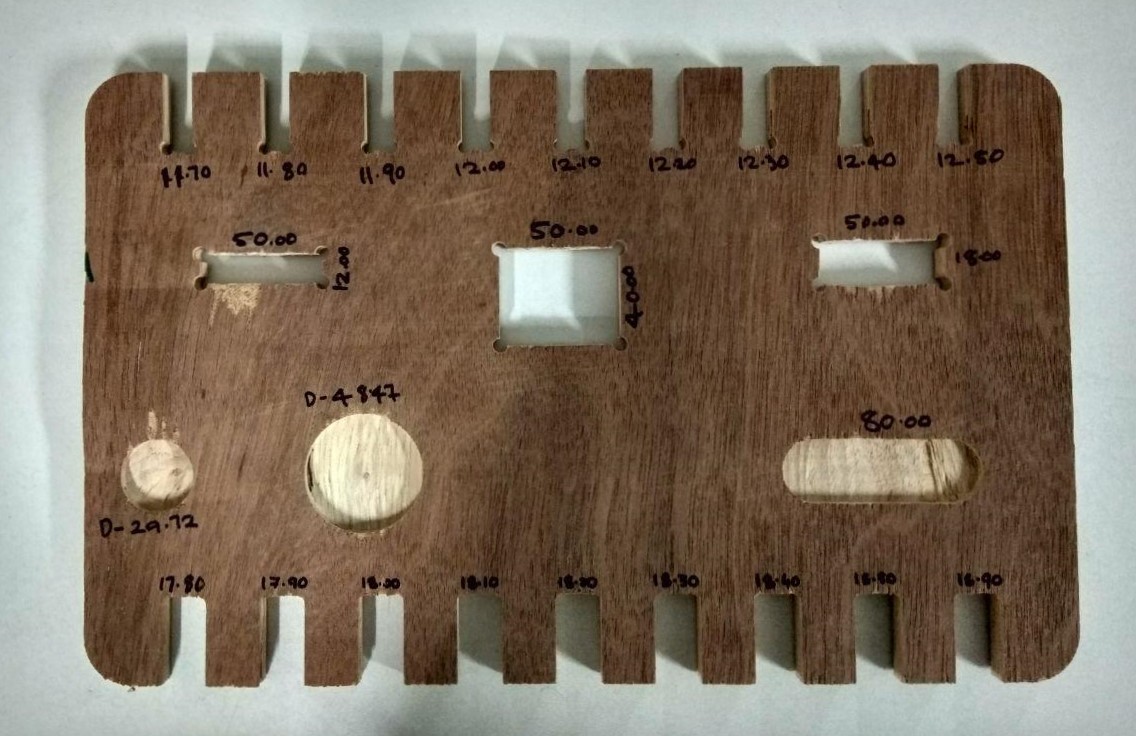

Deigned a test design to learn about the machine tolerances.

This week, we used a CNC mill to make something that's big and needs to be cut precisely.

In my case, I built study table out of a MDF that will be assembled with screws or glue.

The bench is about 120x45x40cm

1.CNC mill (I used Velocity Cnc router machine wich is computerrised).

2.wood (I had2440 x 1220 x 30mm MDF).

3.Files and Sanding paper

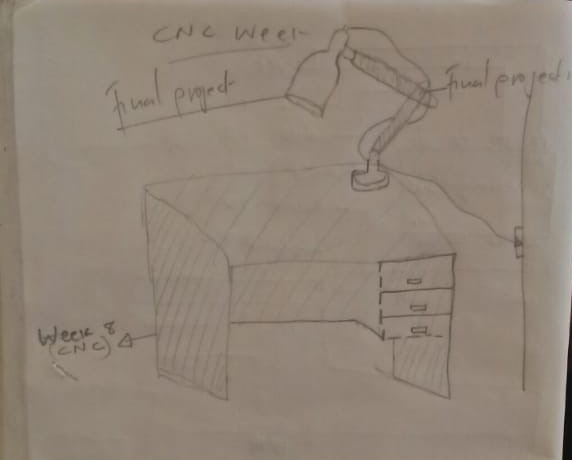

This is the sketch part of my week eight assignment and it is also part of my final project

I made the design in 123D AUTODESK DESIGN, an open source CAD software.

I started with the top part, it is basically a plain rectangle.

then i went ahead with extrusion

copy paste the other part and i used the snapping tool to snap

another rectangle for both sides

extrusion and snaping

after snapping both sides i tried to change the appearance depending with the colour of my material

drawing a sketch for the drowers

i went ahead with extrusion again

changed the appearance

another sketch for drower partition

i went ahead with extruding making a space for my locable drower

extruding the drower

i wanted two drowers

Finally i desided to change the appearance of my drowers to make it apealing

I found some metal tube in the store and desided tochange my design

Finaly after i have chamfer

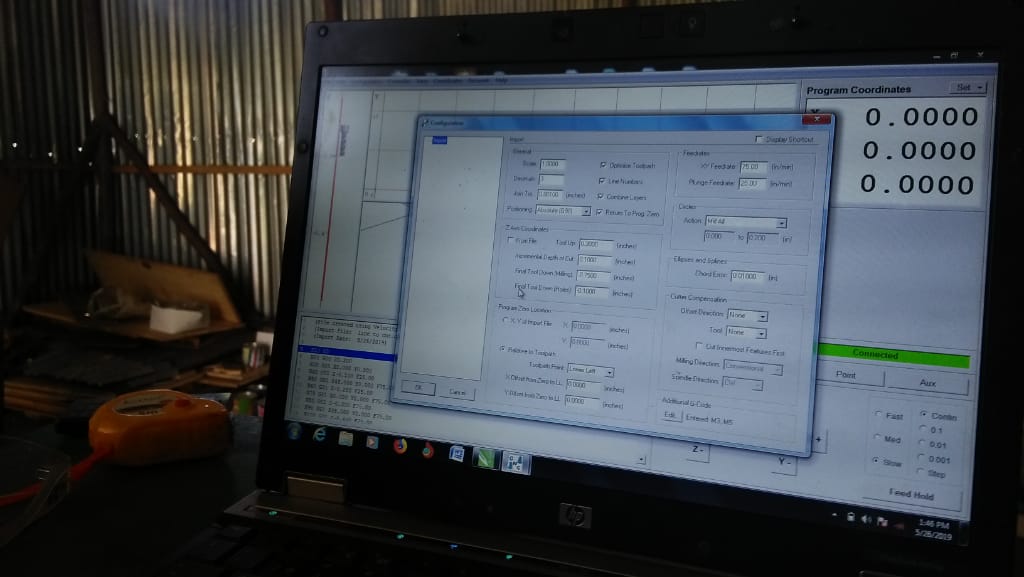

i imported the design to the cnc software and later did my settings

i forgot to take pictures wile i was sticking the edge below is the material i used

N|B With the welding part i hired somebody to do the welding part and it costed me 500ksh

Download files First Designe Here