Design a machine (mechanism + actuation + automation)

build the mechanical parts and operate it manually.

Actuate and automate your machine.

Document the group project and your individual contribution.

1.BRAMWEL OLELA - DOCCUMENTATION

2.DERICK WERE - ELECTRIC AND EMBEDDED

3.KIOKO MUTHUI - ELECTRC

4.CEDRIC DIUR - ASSEMBLY and FABRICATION

Caton

glue stic

bottle tops

scissor

straw

sticks

Geared Mortor

Bench power supply

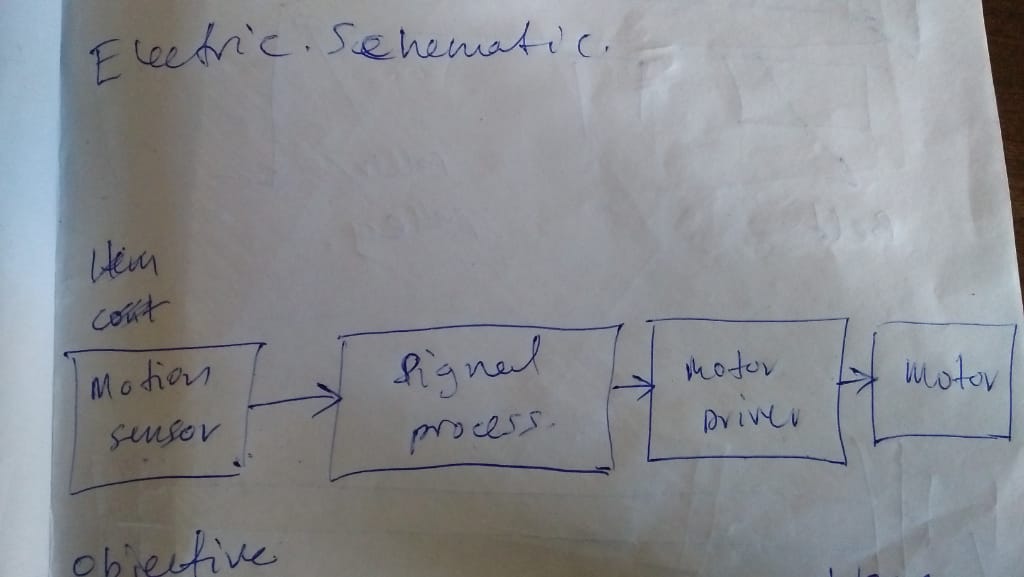

Count specific amount of item by moving them to a specific collection point,

if count achieved stop conveyor

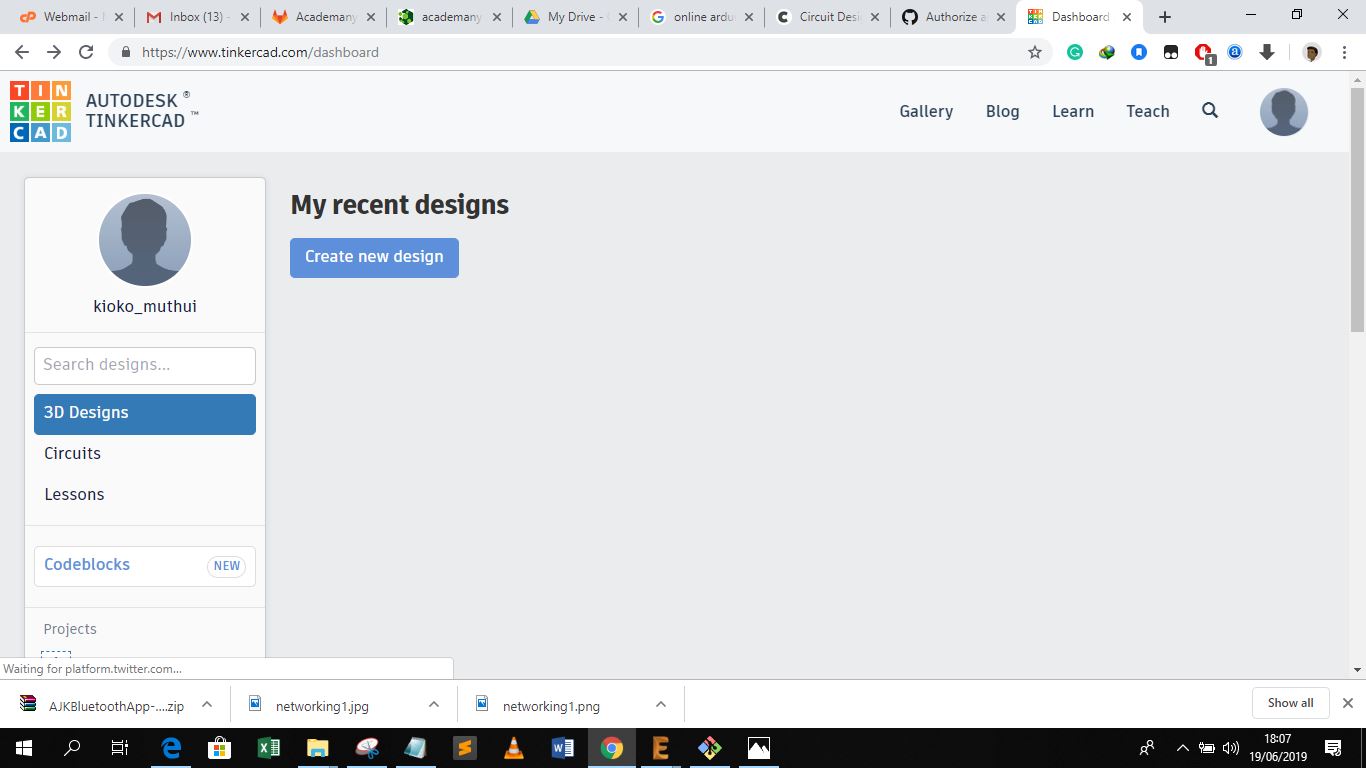

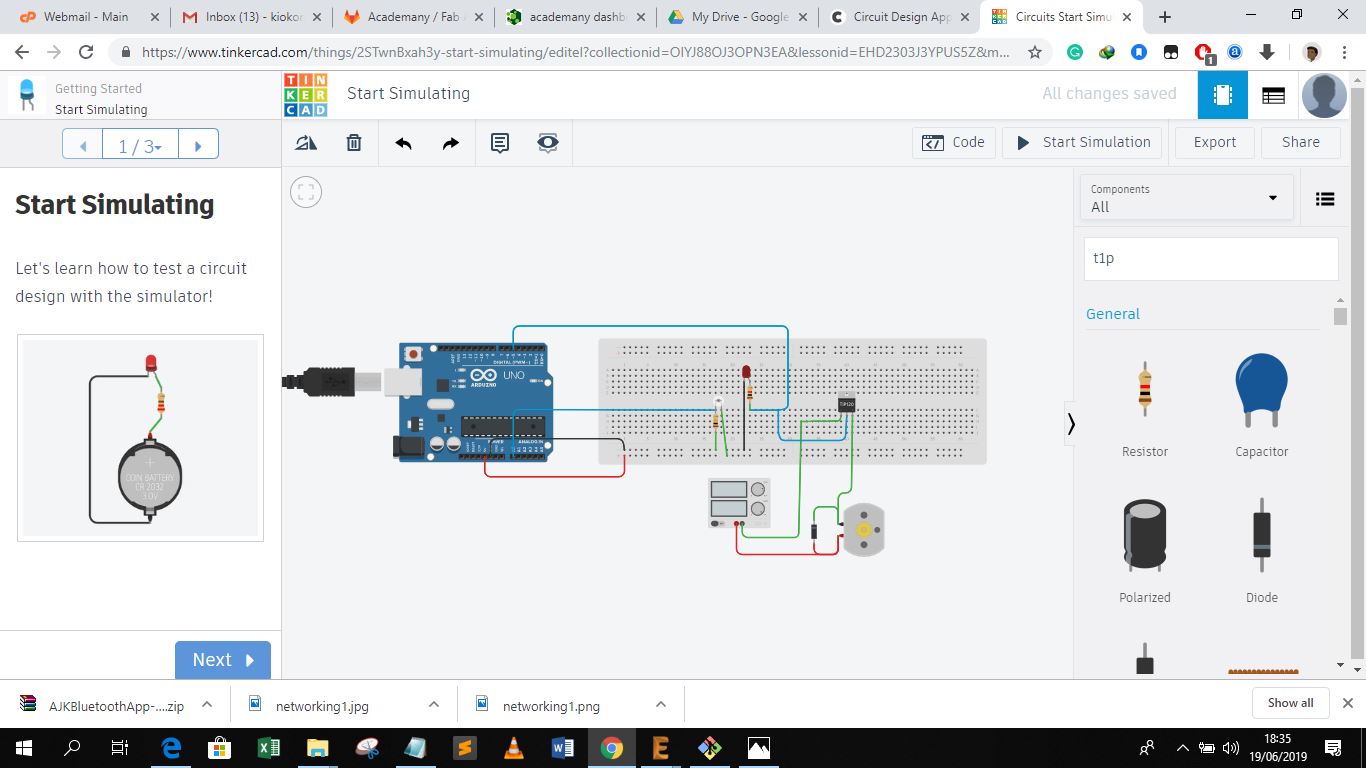

Kioko was incharge of creating the electric design and schematic. we decided to try out tinker CAD for this project compaired to Eagle which i am quite used to,

The Component List for the electrical circuit is as follows

DC Motor

1. LDR

2. Diode 1N4001

3. Transistor pnp TP130

4. LED

5. 10k Resistor

6. 1K resistor

7. Arduino UNO

8. Bench power supply

The first step was selecting all the components needed nand inserting them in the work area one by one

The next step involved joining the components one by one and colour coding the connections to avoid confusion. I later uploaded the code developed and simulated the circuit

.jpg)

.jpg)

we used arduino IDE to design most of my projects because of its Global support and most codes are easy to find

we came across a code that could run a dc motor, change directions and even vary its speeds

we adjusted a the code to only include one run and in the event of the number of count is less than ten and stop if the count reaches ten.

This function is called the conveyor

// set pin numbers:

const int buttonPin = 2;

// the number of the pushbutton pin

const int motor = 13;

// the number of the LED pinv

const int led = 8;

const int sensor = A0;

// variables will change:

int buttonState = 0;

// variable for reading the pushbutton status

int sensorState = 0;

int threshold = 120;

void setup() {

// initialize the LED pin as an output:

pinMode(motor, OUTPUT);

pinMode(led, OUTPUT);

pinMode(sensor, INPUT);

// initialize the pushbutton pin as an input:

pinMode(buttonPin, INPUT);

}

void loop() {

// read the state of the pushbutton value:

buttonState = digitalRead(buttonPin);

// check if the pushbutton is pressed.

// if it is, the buttonState is HIGH:

if (buttonState == HIGH) {

digitalWrite(motor, HIGH);

int i = 0;

while (i < 10){

sensorState = analogRead(sensor);

if (sensorState > threshold){

digitalWrite(led, HIGH);

delay (2000);

digitalWrite(led, LOW);

i++;

}

}

}

else {

// turn LED off:

digitalWrite(motor, LOW);

}

}