WELCOME TO MY

WELCOME TO MY  WEEK 9

WEEK 9

RETURN TO HOMEPAGE

Molding and Casting

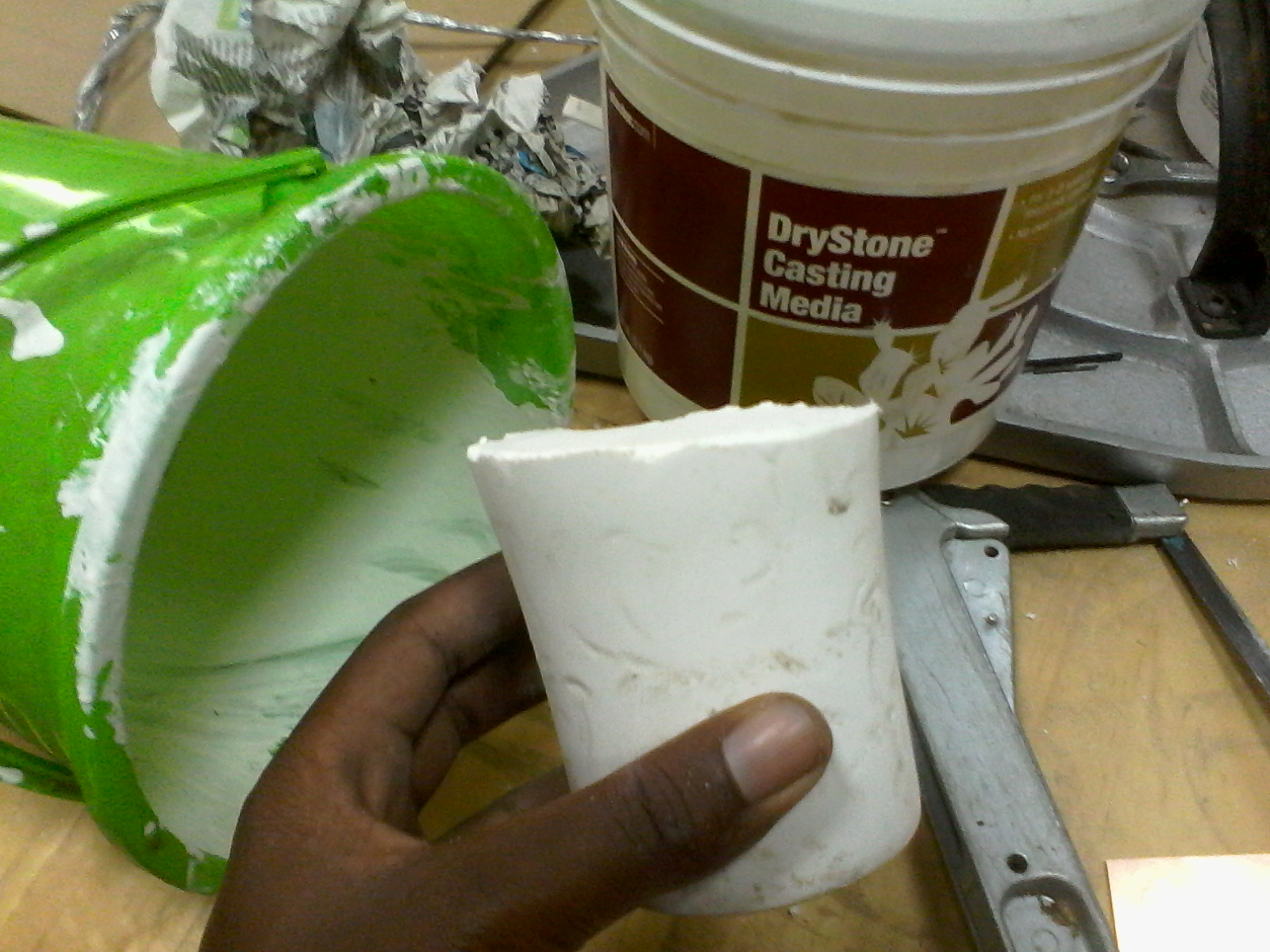

Hi pals?..this is week 9..and its a fun week involving molding and casting of materials..basically what molding and casting entails is similar to the working of 3D printing but here you have to machine a mold/source through: Injections(Sprue,runner,gate,vent,parting line,flashing),Insertion,vacuum,Blowing,Rotational or parts.. in which you cast a material such as:machineable wax low-temp wax rigid foam gesso alginate gel urethane rubber, plastic silicone PDMS

(polydimethylsiloxane) latex thermoplastic, thermoset polymers calcium sulfate desicant, coagulant, plaster, gypsum, drywall DryStone

Portland cement calcium silicate, aluminum/iron oxide, calcium sulfate Hydro-Stone metal glass ceramic food

testing mixing deairing pouring ,starting filling vent location curing polymerization cross-linking hydration endothermic, exothermic demolding taper release agents deformation storage shelf life

ShopBot VCarvePro fab modules image, mold .stl, .png, toolpath, mold tippy.cad, bottom, top, mold, video

Ok here we are,,I personally chose the rotational casting after molding a conical shape in which I used Drystone material in casting...