Aspiring Mindfully-Never Give Up!

We Can Make Almost Anything and Everything - From Design to Reality. Designing is actually making what the communities need. So, let’s “Make Dreams Real” to reach out. Background- I’m 11 year unschooled boy, currently in the 9th Grade. I was fascinated by the FAB ACADEMY concept of "Learn How to Make Almost Anything and Everything". Being an experiential learner I have understood that the best ideas come from a cross disciplinary team. Hence, I have been equipping my skills since 2 years to be a part of this amazing Makers cohort. Finally, I'm FA19-338 @FAB LAB 0.

Introduction to the FAB ACADEMY Digital Fabrication Diploma Program.

Internet / FAB ACADEMY videos.

My Final Project Ideation.

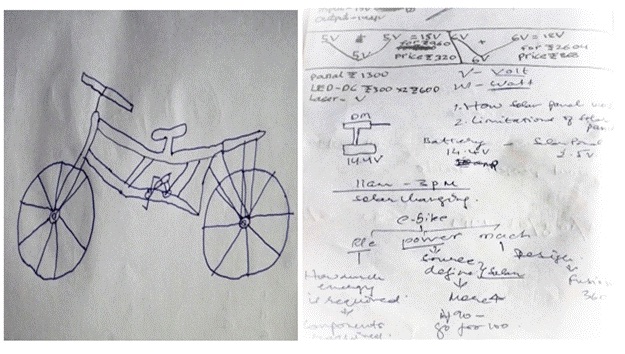

My Final Project Idea is to make an eBYKE. I’ve researched on this idea.

Then my FAB LAB Director - Yogesh Kulkarni said that a Smart Air Cooler would do for spiral development. He opined that this direction would help me finish the final project in a smooth way and can later go ahead with the pumps and other stuff. Hence I moved ahead with this idea.

Communicating an initial project proposal -

Ideation: I started researching on this Idea online and headed towards the Mind Mapping.

The Energy demand worldwide for buildings cooling has increased sharply in the last few decades, which has raised concerns over depletion of energy resources and contributing to global warming.

Current energy demand estimates stands at between 40 and 50% of total primary power consumption. In hot climate countries, the highest share of building energy use is mainly due to space air conditioning using traditional HVAC systems.

For example, in the Middle East, it accounts for 70% of building energy consumption and approximately 30% of total consumption. Nowadays, buildings air conditioning has become a necessity for people life and plays a vital role in ensuring indoor comfort levels. Hence, improving the efficiency of cooling technologies are essential, particularly ones that have the potential, i.e. high performance, low power consumption.

Currently, mechanical vapor compression coolers (MVC) are commercially dominant despite their intensive energy use and low performance in hot climate. In contrast, evaporative cooling systems are more environmentally friendly as they consume less energy and their performance improves as air temperature increases and humidity decreases.

EVAPORATIVE COOLING TECHNOLOGY Evaporative cooling is a heat and mass transfer process that uses water evaporation for air cooling, in which large amount of heat is transferred from air to water, and consequently the air temperature decreases.

Evaporative coolers could be classified into:

DIRECT EVAPORATIVE COOLING (DEC) This system is the oldest and the simplest type of evaporative cooling in which the outdoor air is brought into direct contact with water, i.e. cooling the air by converting sensible heat to latent heat. Ingenious techniques were used thousands of years ago by ancient civilizations in variety of configurations, some of it by using earthenware jar water contained, wetted pads/canvas located in the passages of the air. Direct evaporative coolers in buildings vary in terms of operational power consumption from zero power to high power consumption systems.

DEC systems could be divided into: Described what it will do -

The active direct evaporative coolers are electricity-driven systems, however, it use a fraction of power for air and water circulation. So, it is considered much less energy intensive than other traditional cooling technologies, with energy saving up to 90%. A typical direct evaporative cooler comprises of evaporative media – the wettable and porous pads, the fan blows air through the wetted medium, water tank, recirculation pump and water distribution system, as illustrated schematically in the figure shown below.

The direct evaporative cooling is an adiabatic cooling process, i.e. the total enthalpy of the air is constant throughout the process.

The water absorbs the sensible heat from the supply air and evaporates causing the air temperature decreases and its humidity to increase. Theoretically, the supply air could be cooled to 100% effectiveness, but in such process a wet-bulb effectiveness of 70%-80% only is achievable because of short contact time between the two fluids, insufficient wettability of the pads and due to the fact that the circulated water and the supply air will reach an equilibrium point that is equal to the wet-bulb temperature of the supply air.

Eventually the system would not be able to cool down the incoming air lower than its wet-bulb temperature. The wet-bulb effectiveness could reach range between 70-95% in most current commercial DEC coolers and mainly as a function of the type and thickness of evaporative media, working climate, and supply air flow-rate. However, active DEC coolers can be classified in terms of water distribution system type:

However, I chose to use the above picturized system of cooling for my final project.

Passive cooling techniques use natural phenomena, energies, and heat sinks for cooling buildings without the use of mechanical apparatus consume electrical energy. However, small fans and pumps could be required. Passive DEC is relied on the climate which means the techniques applied for hot and humid regions are different from those for hot and arid areas. This technology is able to reduce indoor air temperature by about 9 °C.

To sum up, the main drawback of the evaporative cooling is their high dependency on the ambient air conditions. Since the temperature difference between the dry- and wet-bulb temperatures of the ambient air is the driving force of evaporative cooling. For mild and/or humid climate this difference is small, therefore, leads to limited cooling capacity

Mind Mapping

My Final Project Idea of a Smart FAB Air Cooler

2. Sketch of how My Smart Air Cooler will look like.

Need –An air cooler works by evaporating the water. It lowers the temperature of the air using evaporative cooling. It is the addition of vapor in the air to reduce the heat. The energy needed to evaporate the water is taken from the air in the form of sensible heat, which affects the temperature of the air. Since it is very hot here in the FAB LAB 0, now after discussion with the Director I need to build a Desktop Low Cost Super Smart FAB Air Cooler to relieve me of sweat and heat, so that I can work in an amicable surrounding.

Aim – Make it pocket friendly. There are many air coolers available in the market today. But the whole idea is to design and make a Smart FAB Air Cooler using the Digital Fabrication techniques learnt during this Diploma Program of “Learn to make almost anything and everything”. So, my Final Project will be costing less than 100$ as specified; probably will try to make it around 60$.

Use – The proposed Smart FAB Air Cooler will have the following properties:

Digital Fabrication tools and Techniques to be used–

| SL.No | Tools | Techniques |

|---|---|---|

| 1 | Laser Cutter | 2D & 3D Design |

| 2 | Temperature Sensor Holder | 3D Design |

| 3 | PCB Design | Eagle Software |

| 3 | PCB Design | Eagle Software |

| 4 | AutoDesk Fusion 360 | 3D Design |

| 6 | Maker Case | Chamfer Design |

| 7 | Vinyl Cutting | Gimp Design |

Learning Outcome - This week I’ve ideated to work upon My Final Project of the Fab Academy Diploma in Digital Fabrication. I’m happy that I’ve communicated the initial proposal through research and sketches about the Smart Fab Air Cooler, its features, use and purpose of makery.

Reference – Fab Modules and Internet.

https://www.researchgate.net/profile/R_Boukhanouf

https://www.researchgate.net/figure/Structure-working-principle-and-psychometric-chart-of-a-direct-evaporative-cooler-4_fig2_265890843

https://www.researchgate.net/publication/265890843_A_Review_of_Evaporative_Cooling_Technologies#pf2