Group Assignment:

This week we are supposed to build the mechanical

parts to be operated manually for the prototype.

Inspiration – This idea was developed to address the

problems faced by the farmers in large farms. The day to day

activities like, tilling, sowing, watering, weeding and harvesting are

labor oriented and time consuming. Hence we thought on the grounds of

the Skycam principle.

Farm Bot Idea: https://youtu.be/wor4BFjbIyI

Spider Cam: https://youtu.be/8r0CiLBM1o8

Farm Bot Idea: https://youtu.be/wor4BFjbIyI

Spider Cam: https://youtu.be/8r0CiLBM1o8

The Group has decided to Design and Make a CABLEBOT. The details are as

follows –

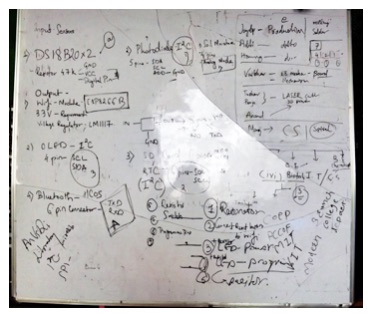

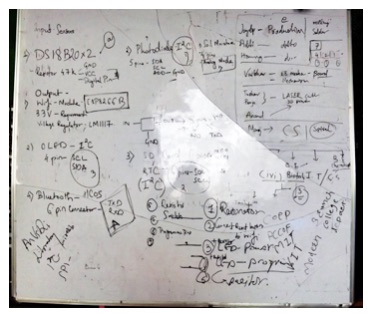

Ideation and Brainstorming the Design – As inspired by

the Farmbot and Skycam as shown in the pictures above, we moved ahead.

Planning

– We thought that the end Effector will use 4 cables, 4 step

up motors with winch, motor controllers and serial bus to get the actual

movements as planned.

Tools used in Fab Lab for this project –

Tools used in Fab Lab for this project –

Laser Cutting - SIL

3D Printing – Fractal Works

PCB milling – SRM Monofab

Procedure adopted The mechanism we are using is based on the “SKYCAM”

principle having 2 End Effectors.

One for the Seed Injector and the other for the Water Sprayer.

We will be using 4 Cables, 4 Stepper Motors, flexible wires for more

power and Motor Controllers in serial bus.

A winch to achieve the motion of the End Effectors.

Initial Prototype

Project Plan

Project Plan

Division of Tasks

Division of Tasks

We have divided the group into 4 Teams as,

Mechanical Design Task - Tushar Khukreja, Pooja Jadhav & Vaibhav

Saxsena – Pulley and 3D design and printing PCB Design and Milling Task

– Aditi and Jaydeep End Effector – System 2 groups - Task 3 groups

Hemang Vellore & Anand Verma. Control System Programming – Manoj

Shahukar worked on the Math developing a tool which controls it from

anywhere. Parts to be made in 3D print

1. Nema-17 case

2. Winch

3. Pulley with rotational support

4. End effector

Parts available in the Fab Lab

Plywood 3*3 sq.ft Parts to be bought

We finalized and purchased Nema-17, model- BH42 SH 47-1504 AF with the

specifications mentioned above.

Connecting the Parts for the Machine

Nut n bolts, Flanges and Metal pipes.

Research for the Machine ideated

First Prototype

First Prototype

Betterment of the design and idea

Betterment of the design and idea

The initial pulley dint work, so they have made this as shown below.

Final outcome as seen in the assignment machine design link

Final outcome as seen in the assignment machine design link

https://www.youtube.com/watch?v=rgBFXc8YP7c

Individual Contribution –

https://www.youtube.com/watch?v=rgBFXc8YP7c

Individual Contribution – My role was to research about the Cable Bot material procurement –

End Effector – System 2 groups - Task 3 groups Hemang Vellore & Anand Verma.

Review of literature for the Cable Bot - Make a Machine Project.

Brainstorming to arrive at the correct decision for the vendors list.

We have reviewed and discussed to finalize the procurement of the material to be used for the End Effector part of the Cable Bot.

Can check this video -

https://youtu.be/t5EWMiDjIhs

Learning Outcome – My team mate and I have extensively researched about our group assignment, Make a Machine Project. I have learnt to be a part of the Big Group Assignment which worked on effective communication on large farms to contribute from my side by creating an impact.

https://www.youtube.com/watch?v=rgBFXc8YP7c

References and Credits -

https://vamam2019.web.app/

http://fab.academany.org/2019/labs/vigyanashram/machine/mam.html