The Printed Circuit Board is mechanically

supports and electrically connects electronic components or electrical

components using conductive tracks, pads and other features etched

from one or more sheet layers of copper laminated onto and/or between

sheet layers of a non-conductive substrate. The Components are

generally soldered onto the PCB to both electrically connect and

mechanically fasten them to it.

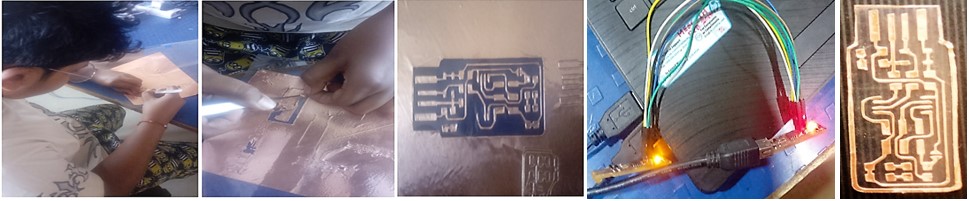

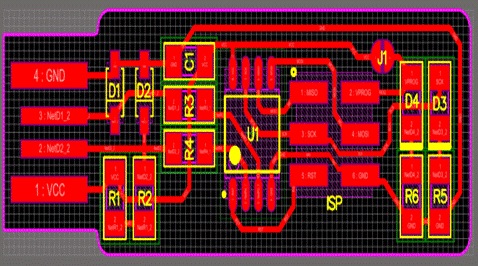

I am learning to do some basic electronics production, specifically

creation of a PCB by milling, then adding the components and finally

burning the code to it. I’ve made an in-circuit programmer

(FabISP) by milling the PCB. The FabISP is an in-system programmer for

AVR microcontrollers designed for production within a FabLab. It

allows us to program the microcontrollers on other boards which we

make during our upcoming assignments. Currently I’ve chosen the

FabTinyISP Minimal version - this uses ATtiny45.

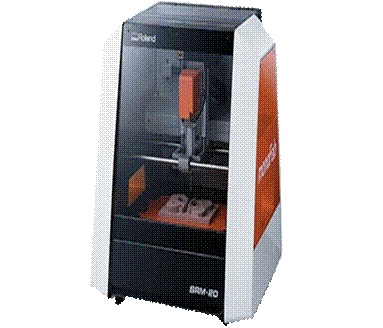

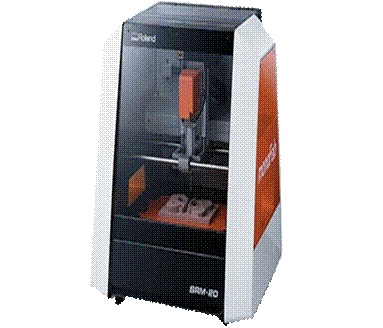

We have two PCB Milling Machines - Modella MDX-20 and Roland monoFab

SRM-20. I’ve used Roland monoFab SRM-20 for making my fabTinyisp

board. By observing on Roland site, I’ve understood that SRM-20 is

Roland's latest generation 3D desktop milling machine, incorporating

innovative subtractive rapid prototyping (SRP) features to deliver

accuracy, smooth finishes and efficiency in a compact format.

| Model |

SRM-20 |

| Cuttable Material |

Modeling Wax, Chemical Wood, Foam, Acrylic, Poly acetate,

ABS, PC board |

| X, Y, and Z Operation Strokes |

203.2 (X) x 152.4 (Y) x 60.5 (Z) mm |

| Work piece table size |

232.2 (X) x 156.6 (Y) mm |

| Distance From Colet Tip to Table |

Max, 130.75mm (5.15 in) |

| Loadable Work piece Weight |

2 kg (4.4 lb) |

| Control Command Sets |

RML-1, NC code |

| External Dimensions |

451.0 (W) x 426.6 (D) x 426.2 (H) mm |

| Weight |

19.6 kg (43.2 lb) |

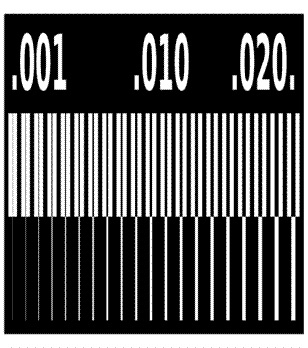

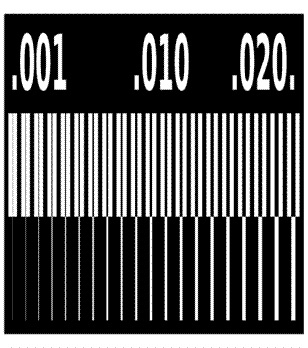

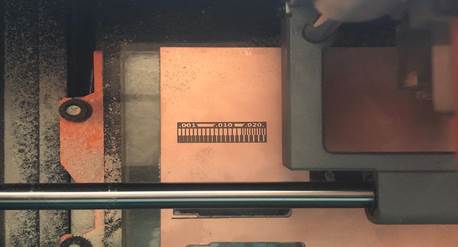

Group Assignment: We characterized

the design rules for our PCB production process. Line Test:

Manoj Sahukar and I teamed up for the assignment.

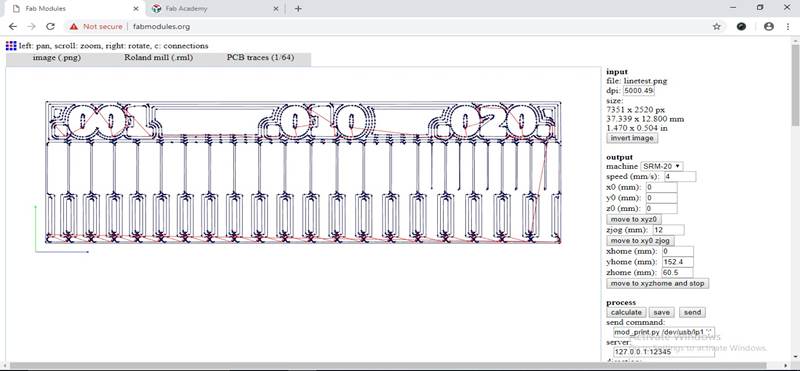

A. The line test images were taken from

Fab

Academy Electronics Syllabus.

B. We used

FabModules to generate

.rml files. Various other settings like process, speed, X, Y and Z

coordinates were entered.

C. There was 1 line of a Rectangle Red which showed the jog path. The

fab module did not create a close rectangle as can be seen form the

picture above.

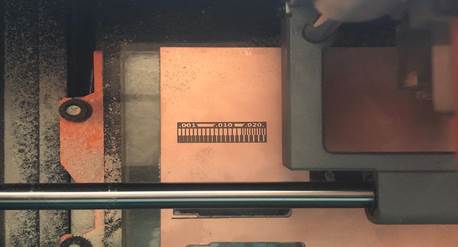

D. We cut the board on SRM 20 machine, gave 2 commands to trace the

lines of the various thicknesses and cut the outline.

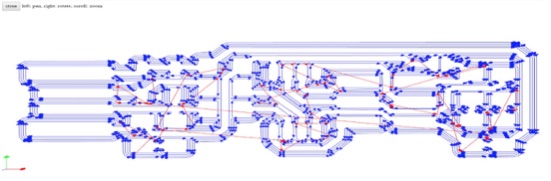

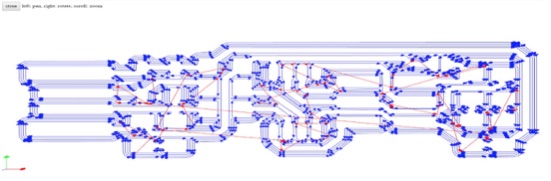

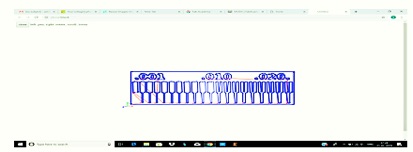

The line tool path looks as shown below.

The saved .rml image and after milling looks like this.

The board showed the smallest thickness line when it was cut properly,

thus giving the green signal for the tracing and outline ahead.

We cut the board with the grinding machine as it was not cut from one

side properly. Though this damaged the board, yet, the objective of

the assigment was achieved.

We cut the board with the grinding machine as it was not cut from one

side properly. Though this damaged the board, yet, the objective of

the assigment was achieved.

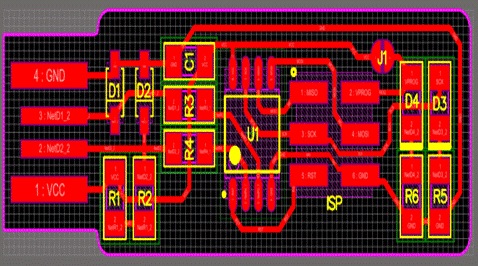

Individual Assignment – I made an in-circuit

programmer by milling the PCB, using SRM 20 and programmed it. Prof.

Neil introduced various ways to make our 'Fabisp'. Sean, Alex, Tomás,

Jonathan, Brian & Zaerc have worked using ATtiny45 and Ali,

Valentin, Bas, Andy & David used Attiny44. I choose the Brian's

Board to mill my PCB. So i downloaded the '.PNG' file of "Board

traces" and "Outline".

PCB Setup – The PCB Board of a suitable size should

be fixed on the sacrificial layer using the double sided tape. Care

should be taken to evenly place the board. Any variation may cause

breaking the tool. If the milling surface is not on level, then need

to apply pressure gently on the raised areas. In case it does not

work, redo the adhesive part.

Make sure that the level is distributed uniformly.

PCB Milling – I have used a Router for Milling the

PCB. The tools used are

SVP Laser

CNC Router

Single Sided Copper clad Circuit PCB Board

FR1 double sided Tape

Engraving Bits

Attaching the Milling Bit – The Milling Head has to

raise by using the “Tool Up” button on the Modella Control Panel.

Using the Allen Key, gently loosen the Hex Nut on the Rotating part on

the Milling Head. Then gently remove the existing Bit. Depending on

the type of cut, Select from the two available Bits – 1/64 for Traces

and 1/32 for Border Cuts.

While storing the bits, ensure that they should be placed in its

appropriate container cap on. It is also a good idea to place a sponge

or a soft cloth beneath the tool holder to ensure that the bit is not

damaged in case it falls while removing it from its container. In my

assignment, I have shifted the origin to 2.78 to mill on the space

available at the top left corner.

Then moved the Bit down by using the “Tool Down” button in the front

panel, till about 0.5 cms above the milling surface.

Finally used the Allen Key to loosen the Hex Nut holding the bit

firmly so that it drops on the milling surface perfectly and fastened

the Nut.

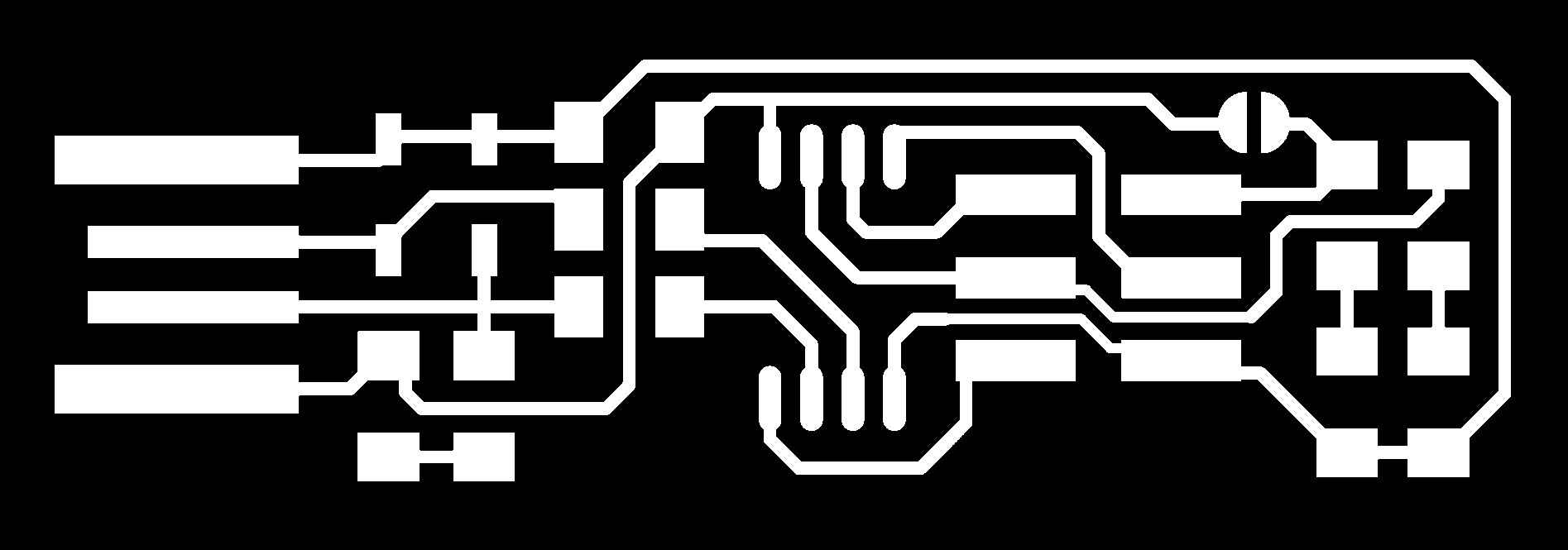

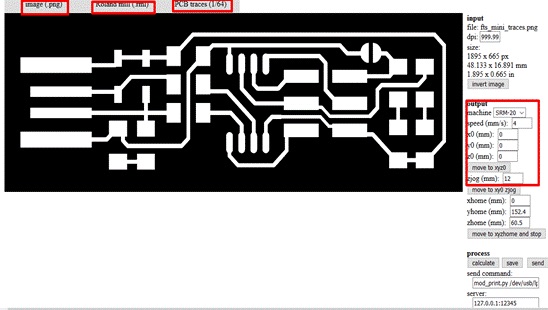

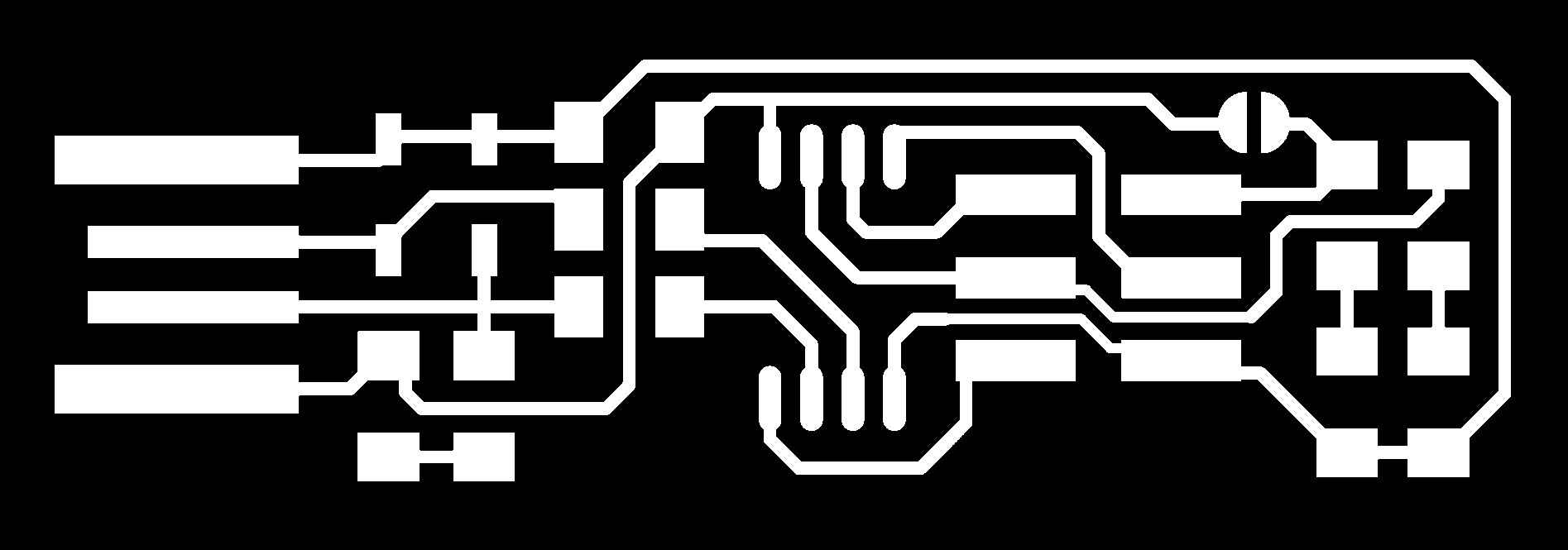

The board layout needs to be available as an image .png file in black

and white colour.

The black portion is removed by the miller and the white portion

remains as the circuit trace as shown below.

I have used Brain example as reference follwed as under –

http://fab.cba.mit.edu/classes/863.16/doc/projects/ftsmin/index.html

Files from Brian: “Ttaces and “Outline Cut” files in

PNG format of 1000 dpi were downloaded from Brian.

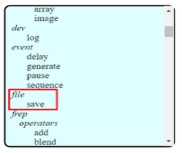

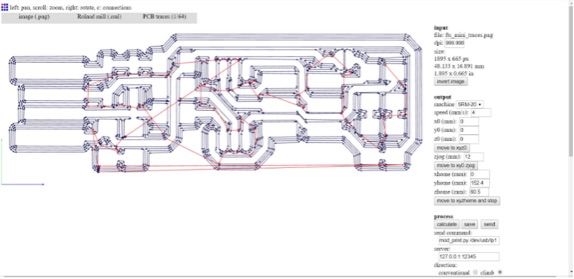

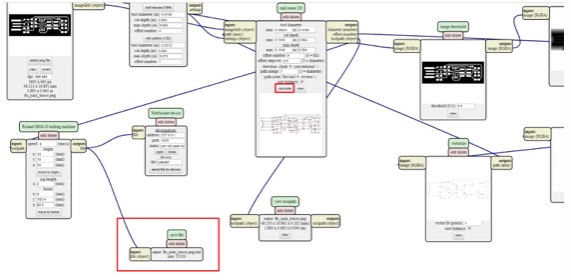

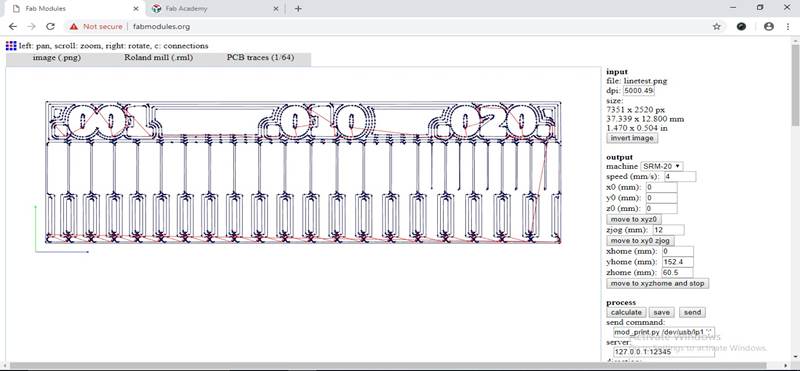

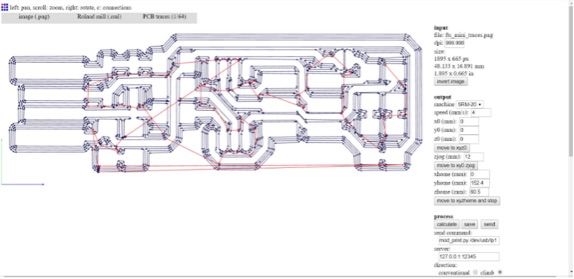

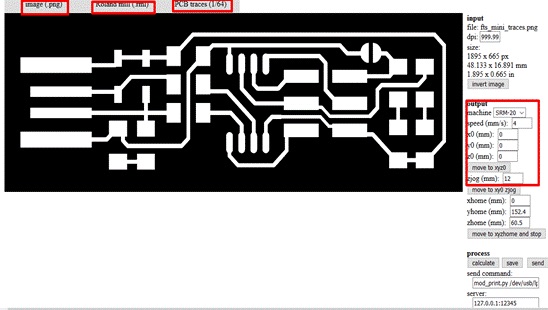

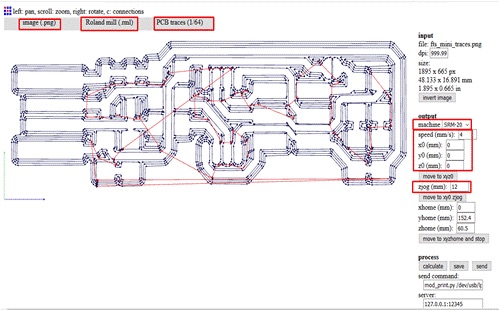

Fab Modules : I have used the Gab Modules to change

the settings and format the png.file as under –

The process to convert images using FAB module -

1.Go to the online fab module.

2.Import image, set SRM-20 machine.

3. Make X,Y,Z to zero and Zjog-12.

4.Then calculate; then png image will be converted into .rml and we

can see it’s traces.

5.Download the .rml image and share to the Vpanel.

Procedure I have followed -

Input File – selected the image .png format as the

file is in this format.

Output File – Roland Mill .rml is the desired format

of the output file as it is supported by SRM-20.

Process – For engraving and traces, I have selected

PCB traces 1/64. For cutting PCB Outline 1/32.

Machine – I have used the SRM-20 milling machine for

Milling.

X,Y,Z axis – all the 3 values were adjusted to 0mm.

Fan Speed – 4mm/s for both the processes – Traces and

Outline.

Zjog- 12mm is the safe distance when the end mill

moves to mill from one part of the design to the other.

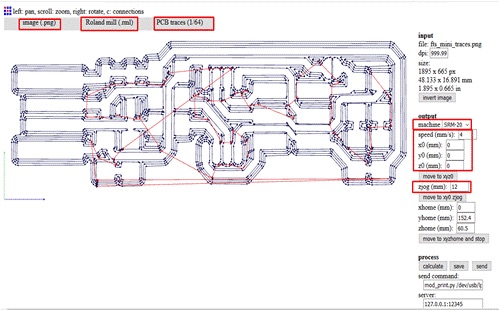

The rml trace is shown below -

Calculate –

Calculate – Shows the path of the end mill in red

lines on the file design.

Save –

Save – I have saved the file in .rml format and it

is now ready for milling.

Setting the Origin – The origin has to be set to

enable the machine start the operation, which is vital in order to

select the desired area on the copper board on which I have to mill

the pcb.

First, select the “move to xmin, ymin” option. This would move the

milling head to 0 (20, 20) by default. Then I have changed the values

to locate the desired area.

Calculate – Shows the path of the end mill in red lines on the file

design as seen here under.

Save – I have saved the file in .rml format and it is now ready for

milling.

Setting the Origin – The origin has to be set to enable the machine

start the operation, which is vital in order to select the desired

area on the copper board on which I have to mill the pcb. First,

select the “move to xmin, ymin” option. This would move the milling

head to 0 (20, 20) by default. Then I have changed the values to

locate the desired area.

This is the rml file trace - A5 Electronics

Production_files\fts_mini_traces

(2).rml

This is rml file cut - A5 Electronics

Production_files\fts_mini_cut

(2).rml

Milling the Board – I selected the PCB Traces option

under the Process Drop Down Menu. Then adjusted the cut depth to

0.1mm, which mills the copper.Selected the Calculate Option to

generate the tool path for the device. Went to the Tool Path and saw

if all the traces were available. It was interesting to note that if

we give 1 as the offset value, then all the copper, except the traces

will be removed. Lastly, clicked the Send Button to send the tool path

to the device to start cutting. A status window is displayed showing

the elapsed time and remaining time. Mine too about 10 minitues to ill

the traces.

Sacrificial Layer – As the name suggests, it

sacrifices itself for saving the base plate from any damage, just in

case something goes wrong and the milling bit goes further than

expected, it might end up in damaging the base plate. The procedure is

to apply the dual sided tape onto the copper clad board which is about

the same or of a greater size to that of the plate which is going to

be milled. For cleaning and placing the sacrificial layer, I have used

Acetone to clean the surface. The width of the acrylic sacrificial

layer in our lab is a smooth and uniform surface, which vitally

decreases the chances of the bit getting damaged.

Sticking the FR1 board to the sacrificail layer – I stuck the double

sided tape on the bottom of the FR1 board and stickerd it on the

sacrificial layer.

V Panel Software and Machining –

V Panel Software and Machining –This software gives

the access to set the origin and adjust the axis and give the command

to the machine.

Setting the X&Y axis – Under the User Coordinate

system and looking at the space on the FR1 board, the origin was set

up.

Adjusting the End Mill in the Collate – The End Mill

is inserted in the Collate and Moved to set the X, Y origin. I have

set collate loose and allowed the End Mill to touch the board.

Setting the Z axis –

Setting the Z axis – After tightening collate, this

fixed position was marked as the origin for Z axis.

Set up and Tracing – Under the Set up Command, the

file was sent to the machine and it started tracing.

Operation – The end mill moved and traced the board.

The speed and spindle value was visible on the software.

Changing the End Mill –

Changing the End Mill – The End Mill was changed from

1/64 to 1/32 for cutting the outline. I have followed the same

commands keeping the X, Y origin positions constant. The Z origin was

marked again because the position may slightly while changing the end

mill.

Operation –

Operation – This time to cut the board, the end mill

went deeper showing the value in the display. The machine stopped on

completing the instruction and then I removed the PCB from the sheet.

In case the task is not completed satisfactorily, then redo the traces

with a little more depth as I did.

Once the traces are ready, then replace the bit with the 1/32 bit and

repeat the same process with the border for cutting out. Be sure to

“cut out board” option in the process dropdown menu.

I have the .png file that looks like the one below for border cutting.

When the process is completed, then I have removed the cut board from

the mill.

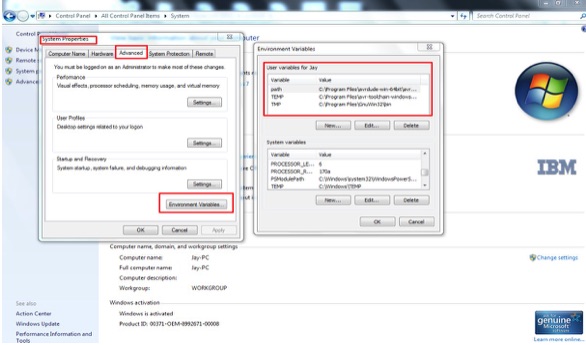

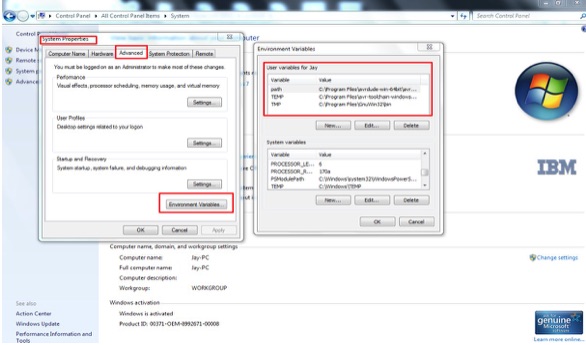

Under User variables, select "Path" and click the Edit button.

If you don't already have a variable called "Path", click the new

button to create it, enter "Path" without the name, and fill out the

value as described below.

C:\Program Files\avr8-gnu-toolchain\bin

C:\Program Files (x86)\GnuWin32\bin

C:\Program Files\avrdude

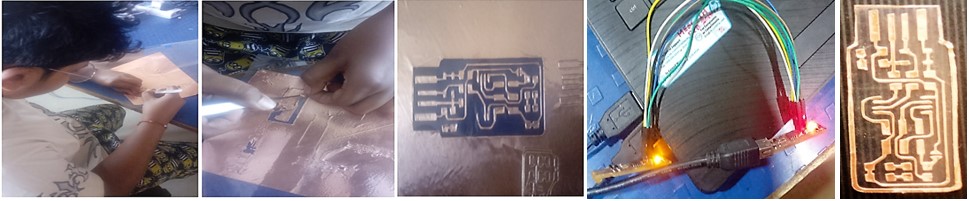

Stuffing -Once the board is milled the next task is

solder the board with the components. Stuffing means assembling the

parts on the board. First, the components are selected and marked on a

paper for clarity. Stuffing can be done by manual soldering using the

electronics workbench or by a more automated process using

pick-and-place and reflow oven.

It is important to identify and note the orientation of the parts,

which go into the Board. It is suggested to palace them in a mark able

tray/sheet to solder them onto the board. The zener diodes are marked

both in and on the drawing and on the packages, with a little line on

the cathode side.

The LED cathodes on the PCB drawing are marked with dots and thicker

lines. The one in our lab has a green line visible on the cathode side

of the epoxy lens.

Soldering - Soldering is a process in which two or

more items are joined together by melting and putting a filler metal

into the joint, the filler metal having a lower melting point than the

adjoining metal. Unlike welding, soldering does not involve melting

the work pieces.

Material Used for Soldering-

Material Used for Soldering-

- Sand Paper – I scrubbed the PCB board with the sand paper. This

made the surface rough and easy for the filler to stay on the

board.

- Components of the Circuit – I have used the Fab Tiny ISP parts

as follows for my Brain Board.

1x ATTiny 45 / ATTiny 85

2x 1k / 2x 499 Resistors / 2x 49 Resistors

2x 3.3 v zener diodes

1x Red LED / 1x Green LED

1x 100nF Capacitor

1x 2*3 pin head

Equipment Used for Soldering –

Filler – Wired melted in contact with the soldering

iron and dried immediately the moment it is place on the PCB board

which fixes the board and components.

Flux – This chemical facilitated my soldering

process. I tried both liquid and solid. But I enjoy with the liquid

flux.

Soldering Iron Rod – I have used the soldering rod

@333C to melt the filler and place it between the components and the

board. Then placed back the iron rod in the stand.

Hot Air Gun - The hot air at a very temperature

melted the filler instantaneously. This tool was very handy during the

DE soldering.

Exhaust Fan – This exhaust fan pulls off the gases

released during melting the filler.

DE Solder Pump – The pump sucked the filler and

helped removing the components from the board. The Mr. Cleaner.

Tweezers – The tweezers were very helpful to pick

and place the components onto the board.

Magnifying Glass – The components are marked and the

words written on it are tiny. This tool helped me a lot in seeing the

board clearly.

Night Lamp – The light was useful in identifying the

small components of the circuit and find the gaps to solder.

Fixing and Handling –

Fixing and Handling – By looking at the diagram fro

Brain, I have placecd the above components using the equipment

soldered my PCB.

I faced an epic failure as it got damaged; but moved ahead to build

four more PCBs.

Then I have built another one and more. But the final built was a good

one, which works after it bork using for electronics design.

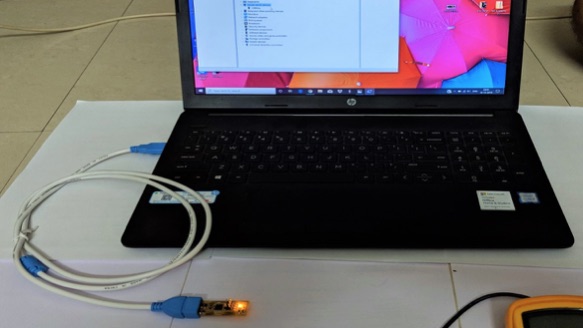

Testing – I have tested the soldered PCB’s using a

Digital Multimeter. The PCB test of a board will use capacitance and

resistance. The Capacitance test will test for opens and shorts by

sending a charge on the trace and then probe each net to measure the

induced capacity. The Resistance test measures resistance as the

current flows through a conductor/trace, in ohms. I have also checked

for the continuity between the soldered components and the traces by

using the continuity mode on multimeter and the LED is blinking wbhen

connected to the laptop as shown below.

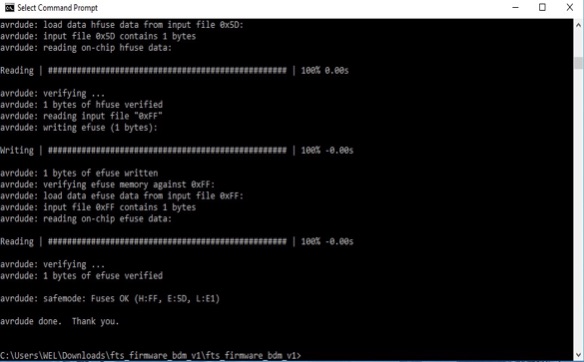

Programming –

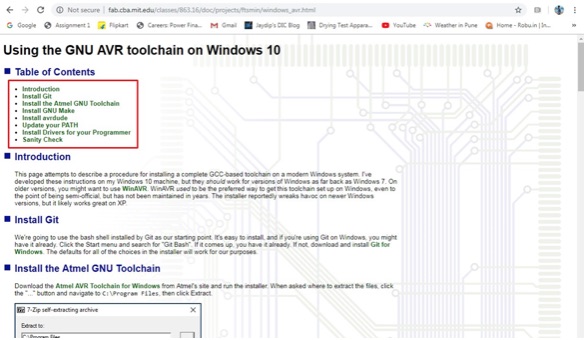

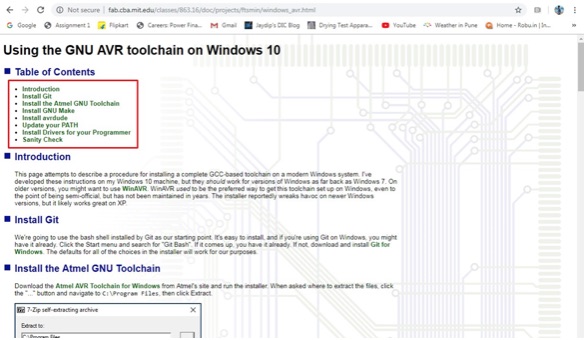

Programming – It is the process of taking an algorithm and encoding it into a notation, a programming language, so that it can be executed by a computer. Although many programming languages and many different types of computers exist, the important first step is the need to have the solution. I have followed this process

http://fab.cba.mit.edu/classes/863.16/doc/projects/ftsmin/windows_avr.html

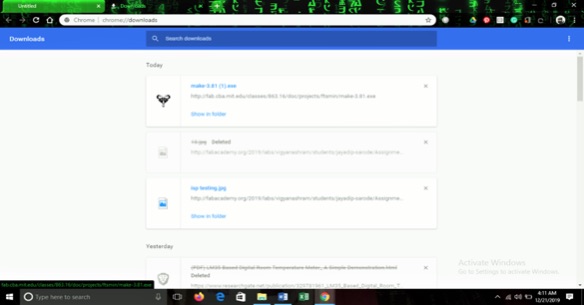

Later installed the Atmel GNU Toolchain from

https://www.microchip.com/mplab/avr-support/avr-and-arm-toolchains-c-compilers and ran the installer. When asked where to extract the files, click the "..." button and navigate to C:\Program Files, then click Extract. I Download Gnu Make and launch the installer. Accept the default location for the installation.

I downloaded

Avrdude and extracted the zip file. Then extracted the file copy and pasted in 'C:\Program Files' and completed the Installation.

Later installed the Atmel GNU Toolchain from

https://www.microchip.com/mplab/avr-support/avr-and-arm-toolchains-c-compilers and ran the installer. When asked where to extract the files, click the "..." button and navigate to C:\Program Files, then click Extract. I Download Gnu Make and launch the installer. Accept the default location for the installation.

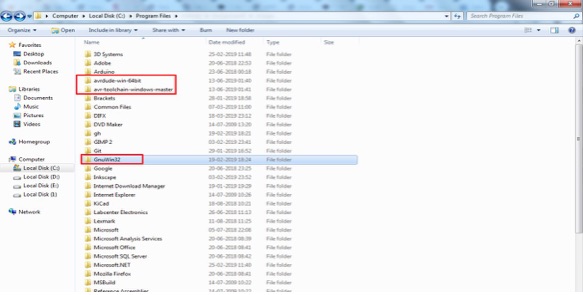

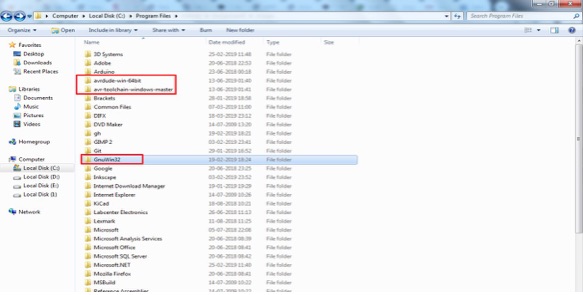

For updating the path I opened the Control Panel, then go to System, choose "Advanced System Settings". Under the Advanced tab, click the "Environment Variables" button. As I din't have a variable "Path", I clicked the New button to create it by entering the "Path" without the name. These three values were added as follows:

C:\Program Files\avr8-gnu-toolchain\bin

C:\Program Files (x86)\GnuWin32\bin

C:\Program Files\avrdude

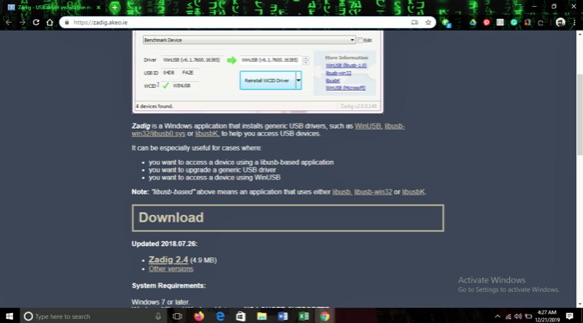

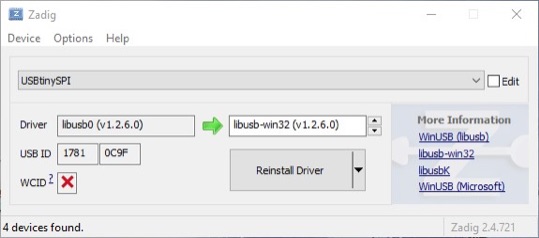

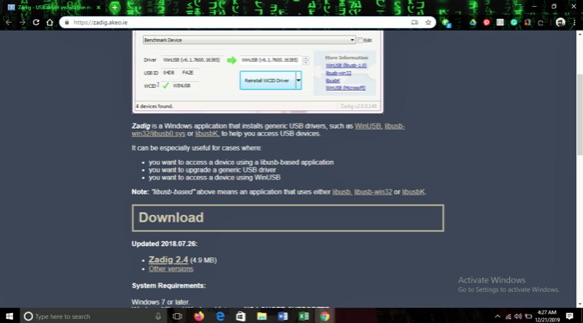

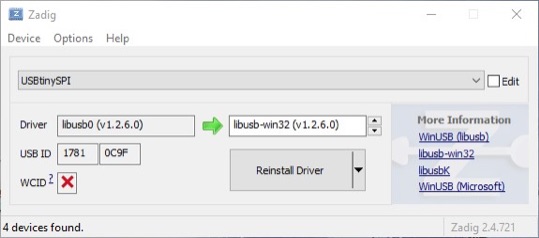

As per the assignment requirement, I programmed my FabISP board with Jaydip’s 'FabISP Programmer' using 'Zadig' software. Zadig is a Windows application that installs generic USB drivers. Then I downloaded Zadig and selected the "USBtinySPI" device from the list.

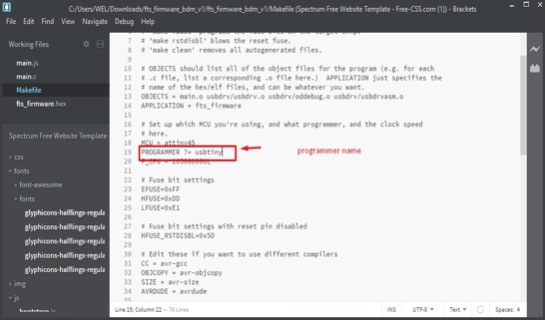

And selected

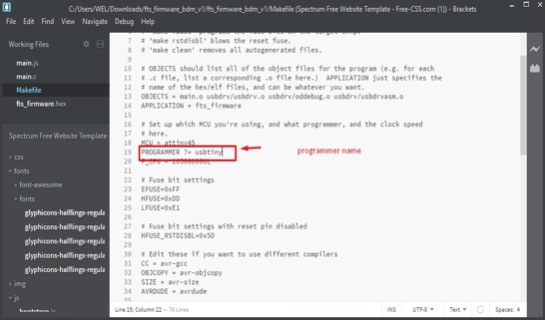

Before the Programming we need to edit "Makefile". But we need to set the programmer name like usbtiny and edited the Makefile.

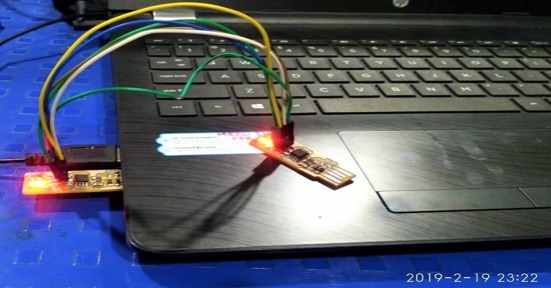

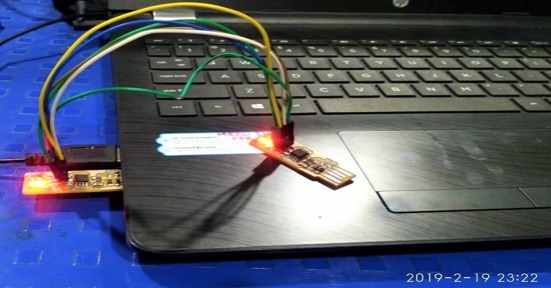

Then I connected them with jumper wires and started programming on my laptop.

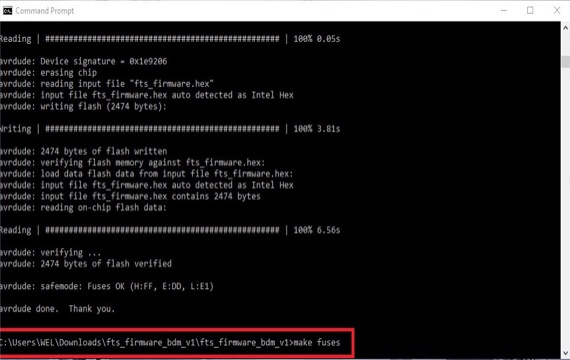

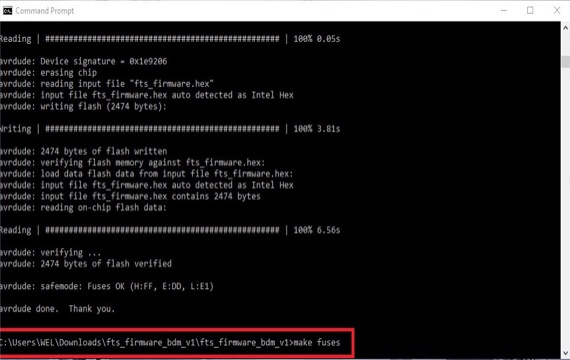

I ran the following commands.

make flash

Using this command I burned the program in my board using another FabISP.

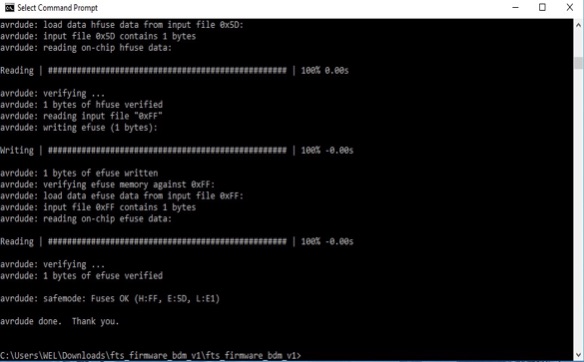

make fuses

Fuse memory is a separate chunk of flash that is not written when you update the firmware.

make rstd

Using this command I made my board as a Fab ISP Programmer.

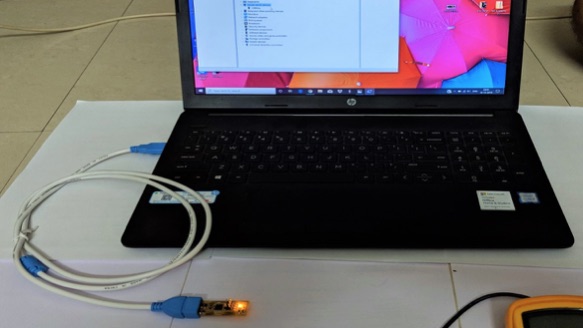

Testing the Fab ISP Programmer – After completing the burning process, I checked my Fab ISP Programmer by connecting my Laptop using the Male-Female USB cable. Then I checked in Computer management>Device manager>libusb-win32 devices as shown below.

My USBtiny device is now showing in the 'Computer management>Device manager'.

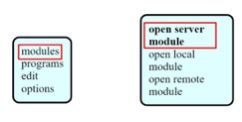

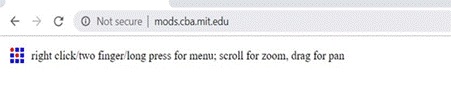

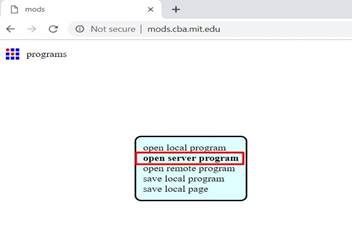

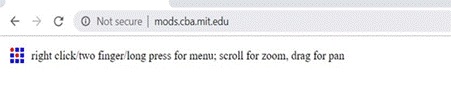

Exploring Mods in browser recommended by firefox/chrome.

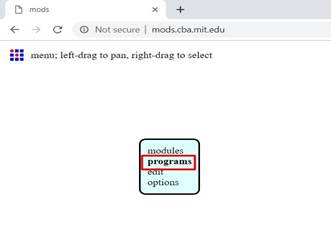

Exploring Mods in browser recommended by firefox/chrome.

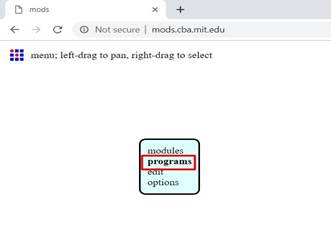

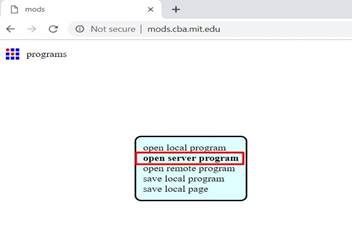

Then Right click anywhere and select PROGRAMS -- select OPEN SERVER

PROGRAM

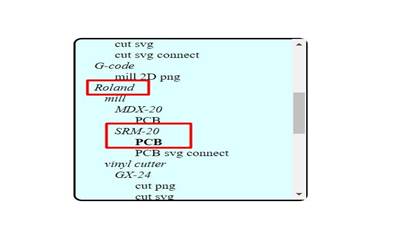

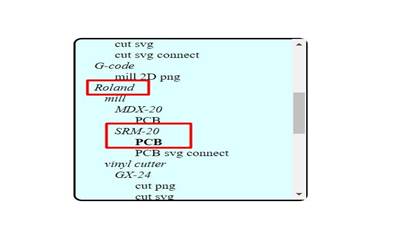

Select ROLAND > MILL > SMR20 (choose the machine you will

use)

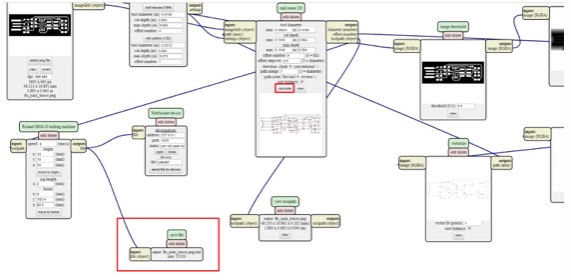

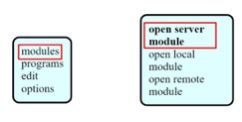

I added another module to save the file automatically. So looked for the program/component that outputs the file. Then, I Right clicked anywhere in the white space and selected MODULE > OPEN SERVER MODULE > SAVE FILE. Then connected the elements by clicking on OUTPUT of RolandSrm-20milling machine and clicking again in INPUT of save file module to make the connection/ wiring between them.

Opened my traces of the image file - Go to READ PNG MODULE SELECT- PNG FILE - selected traces image.

SET PCB Default module and click in MILL TRACES.

<

<

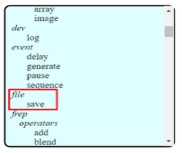

For saving file. Right click-->Modules-->open server module.

file-->save

Then I joined the Input file to Output file.

Mill Raster 2D Module click in calculate. When done, the file was

saved automatically in my download folder. I have also made a flexible

PCB.

Flexible Fab ISP - I have also made a flexible PCB on the Vinyl Cutter.

Procedure followed -

I’ve downloaded the .png file from Brian and opened it in the terminal.

Commands used -

Sudo Fab

Enter password

From input format select (image).png

Selected Roland Vinylcutter (.camm)

make_png_camm

Then I loaded .png file and sent it to the Vinyl Cutter.

I’ve cut the print on Vinyl Sheet and removed all the unwanted parts by using the X-Acto knife. As seen below, it’s ready and working.

This is the png file trace - A5 Electronics

Production_files\fts_mini_traces.png

This is png file cut - A5 Electronics

Production_files\fts_mini_cut.png

Research, Trail & Error I have tried out my pcb

design on this laser metal engraving machine from a commercial vendor

Fine Mark Laser Engravers in Hyderabad after going through the

following link as shown below.

http://fabacademy.org/archives/2015/doc/fiber-laser-cutting-pcb.html

This is the first trial – Power 95, Frequency 10,000 and Speed 300 on

10 watts on 5 passes.

The second trial – PCB was burnt after 3 passes.

The third trail – On another machine with Power 80, Frequency 75,000,

Speed 600 on 50 watts on 12 passes.

You can view the videos from this link below –

https://photos.app.goo.gl/1mcs6J8xZUdErJMQ8

Design file –

A5 Electronics

Production_files\new

uno.brd

Learning Outcome – I have got an idea about PCB

milling and programming by doing a lot of learning and relearning,

while unlearning. Must admit that my soldering skills have improved

now. The fab modules on browser using MODS to ease the process was

exciting. Now I glad that I have made PCBs, make a Programmer and

Program it on my own.

Reference –

http://fab.cba.mit.edu/classes/863.16/doc/projects/ftsmin/index.html

http://fabacademy.org/2019/docs/FabAcademy-Tutorials/week04_electronic_production/srm20_windows.html

http://fab.cba.mit.edu/classes/863.16/doc/projects/ftsmin/windows_avr.html

https://www.microchip.com/mplab/avr-support/avr-and-arm-toolchains-c-compilers

http://fabmodules.org/mods.html

http://fabmodules.org/mods.html

<

<