This week, we have to think about a project idea. It can be a bit complicated because it has to fulfill all the requirements of the FabAcademy. Thank to my instructor Isaac, I am working on my final project since the first day of the FabAcademy, and believe me I am going to present it tomorrow, and I still find some things to make it better. For history purpose, it is important to know that this project is the prototype for a Startup project that I am developing with a friend of mine. You will see that I am not using cheap materials and basically it is because most the time, it is important to have a solid prototype because it is going to suffer with the testing process. The reason we decided to develop an Electric Longboard, is basically because we believe in electric vehicles, and if we develop the longboard well, we will have a solid base to make electric bicycles or any other small electric vehicle.

As you probably know, my project was a Longboard impulsed by two BLDCs motors and that could be controlled with some Force Sensitive resistors. However, it has been so complicated to make the "control" program of the FSR, so I am actually using my Phone with an App made with Blynk to control the Longboard. The cool part of it, is that they will be installed, and it is a question of programing, so in a second iteration, I will develop it well.

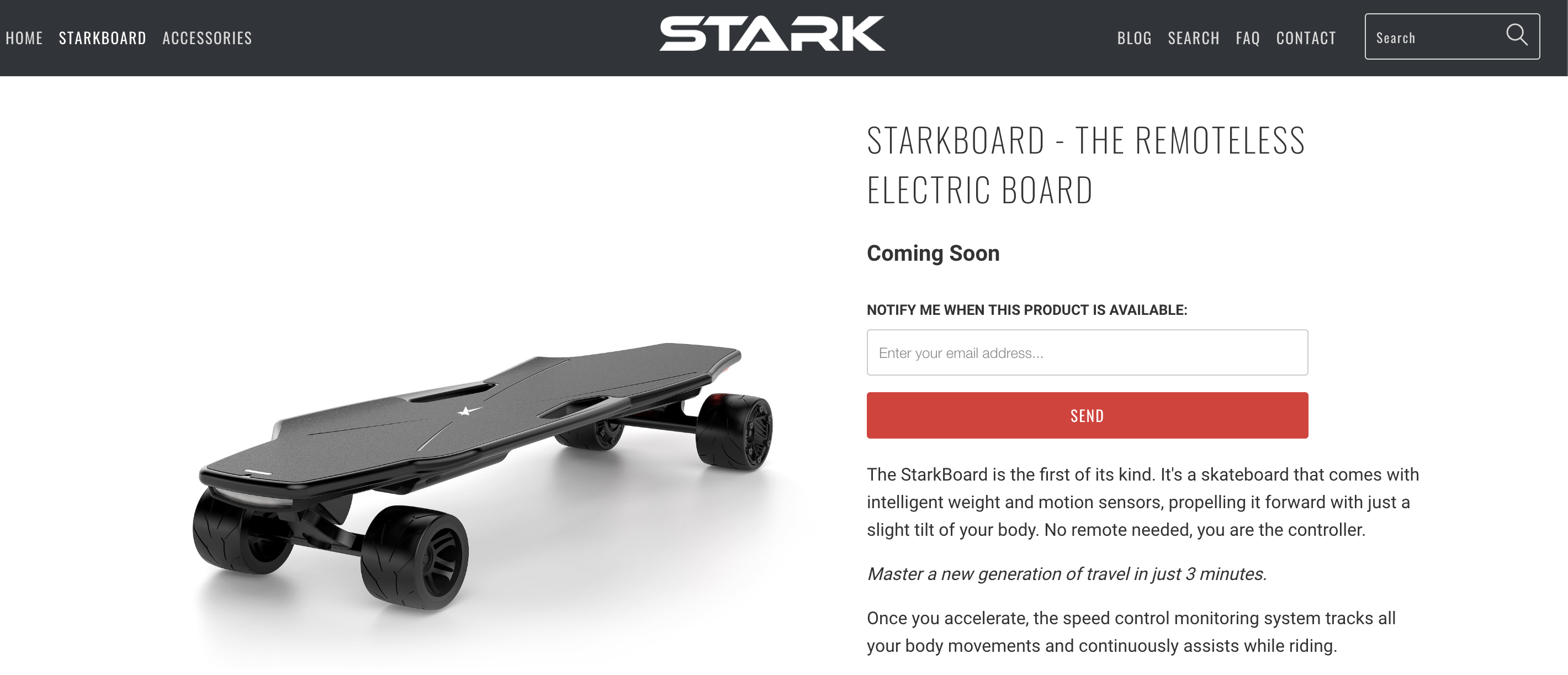

I am not sure if the product I have been inspired, has already been sell, but basically it is called StarkBoard. The reason I chose this kind of Longboard instead of the classic one that is controlled with a remote control, is because I think that there is a way to create well calibrated products that are controlled with Force Sensitive (sensor not only resistor). The best example is the classic Segway.

For this project, I had the idea to design everything, I only wanted to buy the motors. However with the time and after talking with Neil, I also bought the ESCs because nowadays they are very commercial and very complicated to make. But I will very soon post is this webpage, a tutorial to build 80Amps - 25V ESC. I have design all the mechanical parts, the motor support (divided in two), the pulley for the motor and for the wheel. The case for the electronics, the Longboard by itself, the Board, the App, the laser cut Grip, the Vinyl Sticker and the Battery.

Here you have the table with the materials I am using, their cost in dollars and the quantity of each one. If you click on the image, you will be redirect to a page with more detailed information as total costs, investments and machining costs.

Basically, I have bought the BLDCs and the ESCs, from HobbyKing based on the info posted of the Fabacademy Website. The rare small things as the nickel strips, connectors, brackets for battery, battery level tester, has been bought on amazon. The SMDs Mosfets, A4965 driver (when trying to build the ESC), have been bought on arrow, which is the best webpage for electronics in my opinion because it is cheaper than DigiKey, the products are excellent and the shipping is free to Peru. Finally, the 18650 batteries and the BMS have been bought locally because in the case of the battery, you need special permission to import them, and in the case of the BMS, we first bought the BMS, and Later, bought the ESCs which were compatible with a max 6S battery and our BMS was for 10S, so we bought a new one locally. The spot welder has been bought on aliexpress, but really even if it looks cheaper, it is better to buy it on amazon because aliexpress doesn't gives you a real door to door service (at least with my provider). The FabLab also, gave me a lot of materials and electronics components.

>Electronics (PCB)

>Battery

>Composite Longboard

>ABS 3D printed Parts

>PLA Case

>Laser Cut Grip

>Vinyl Sticker

>Milled Mold

>2D and 3D Design Using Fusion360

>Composite Materials for the Longboard

>3D Milling for the Longboard Mold

>Precision Machining for the Electronics

>Hand Soldering

>Laser Cut

>Vinyl Cut

>ABS and PLA 3D Printing

Because I had already make the electronics and programing part of the microcontroller and the Blynk, now I had to have lot of care with the mechanical part because I am not very good at it. I have to buy the belts for the traction, calculate the diameter of it and finally design the pulley for the motor. This will obviously came with some changes that I will have to make to the 3D Design of the motor support. Finally, I have to check if both motors will fit at the back, or if I will have to put one in the back and the other in the front and make the cable management in the case.

My presentation date is the 19th of june, so basically I have to finish everything as soon as possible. I give me 1 week to finish all the mechanical parts, clean the longboard and make the cable management.

>Will my two BLDCs motors fit at the back of my Longboard?

>How to Design the pulley for the motor?

>Will the motors have enough power to move a person?

>Is the Longboard strong enough to do not flex too much the case?

I think that my project would be a success if the longboard can move, change the color of the LEDs, everything controlled with the App made with Blynk. As well as being able to see the speed on the app, and the Battery Level. As an extra, it would be awesome to make the FSR works, but I think this will be made later in a second iteration.

Please Contact Me For Any Collaborative Project