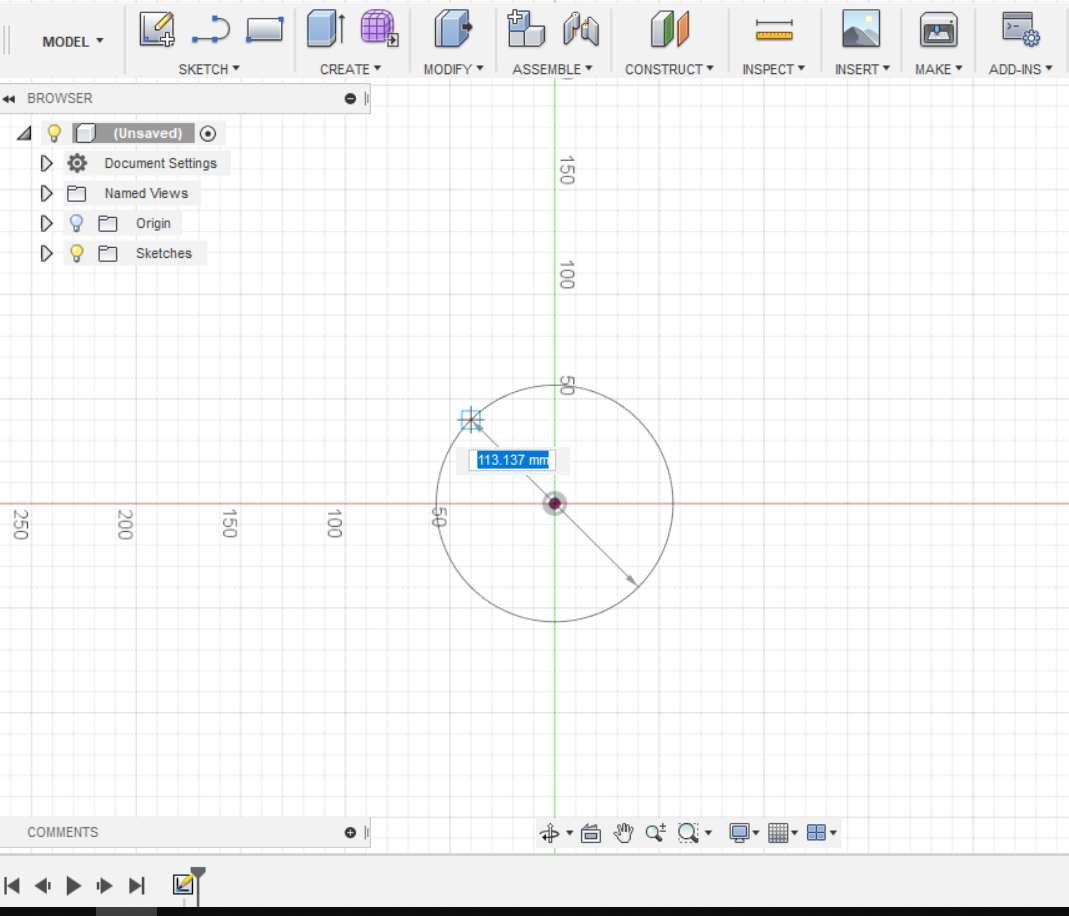

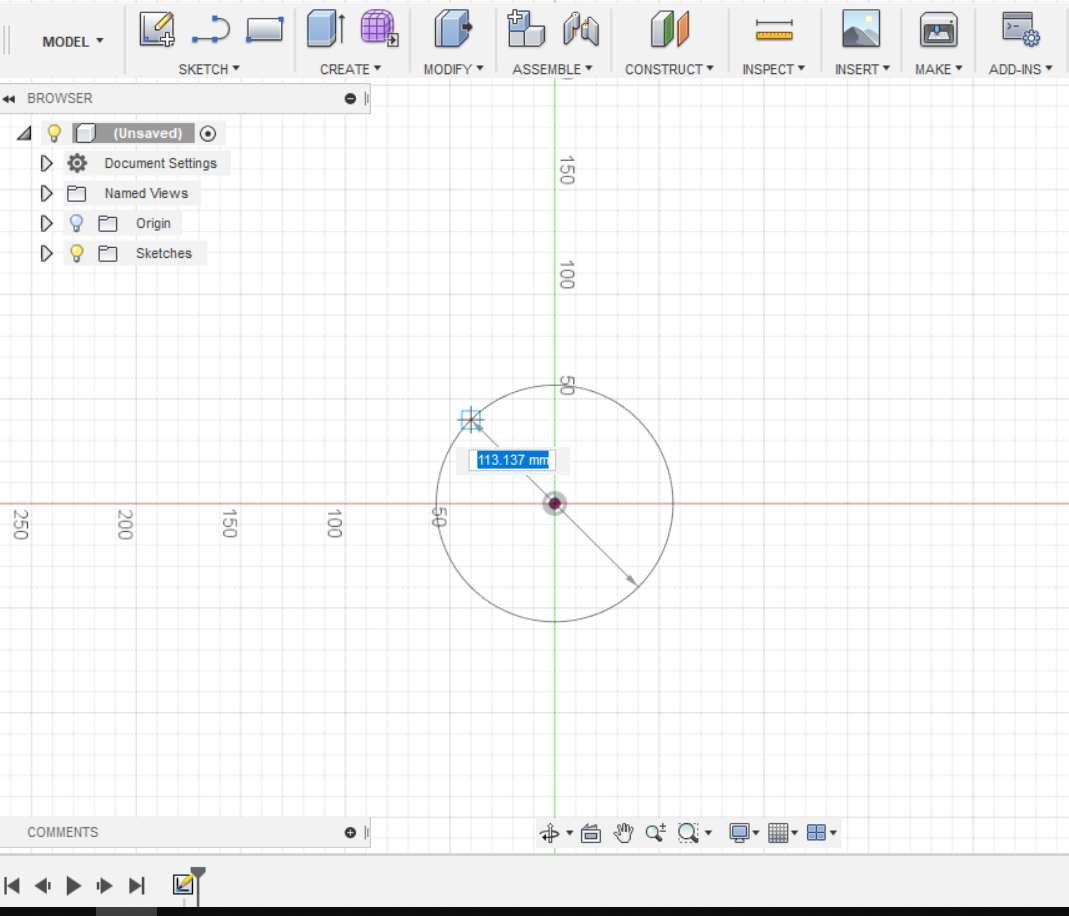

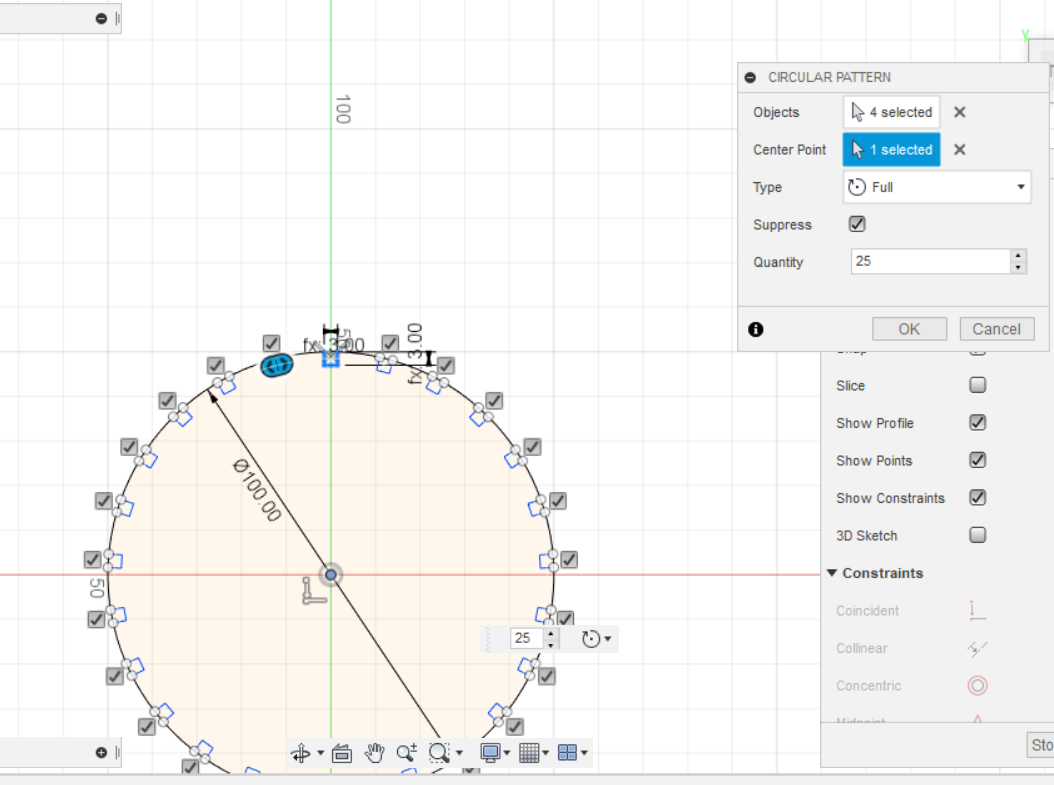

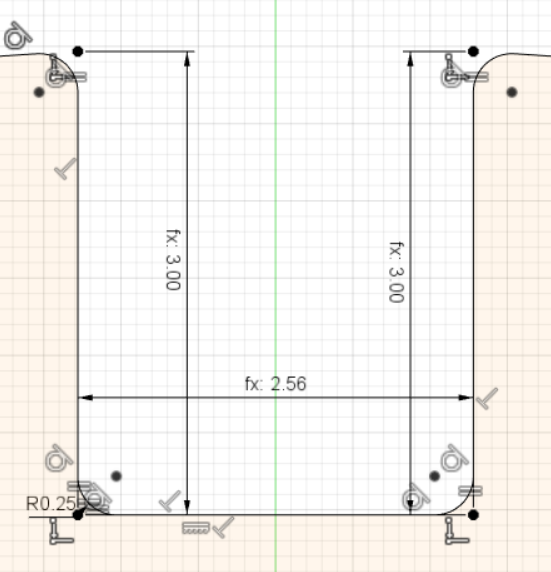

as we know we need a design to operate the machine , I was thinking to make a simple design that will help to understand the machine more , so I started to draw using Fusion 360 , my idea is to draw a circle with 20 slots that I will put the same parameters for each slot .

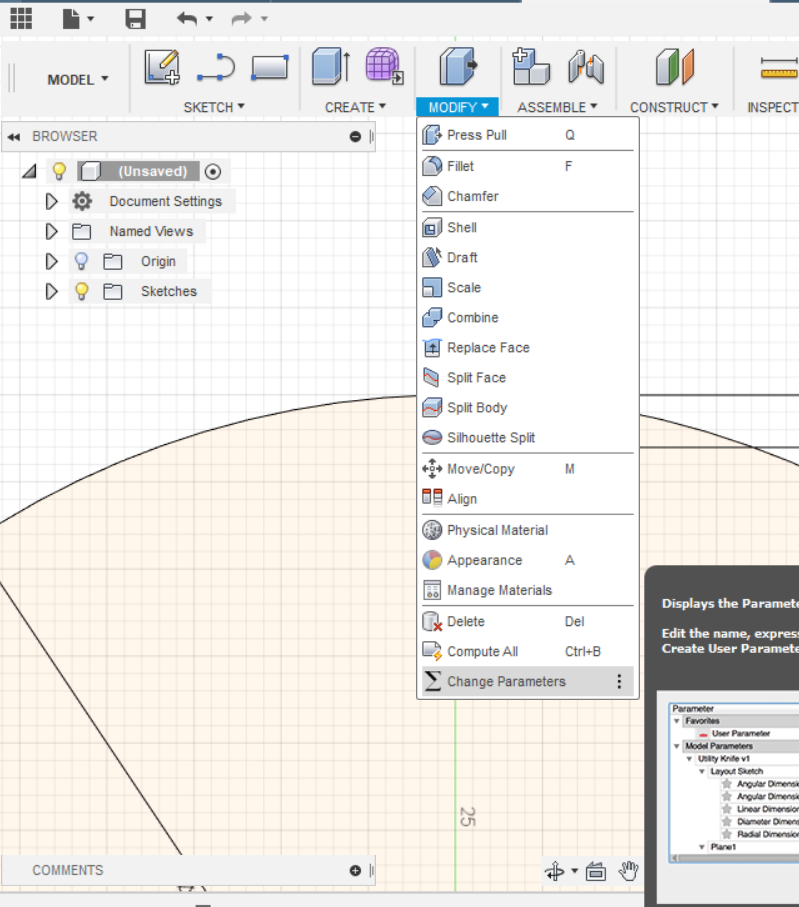

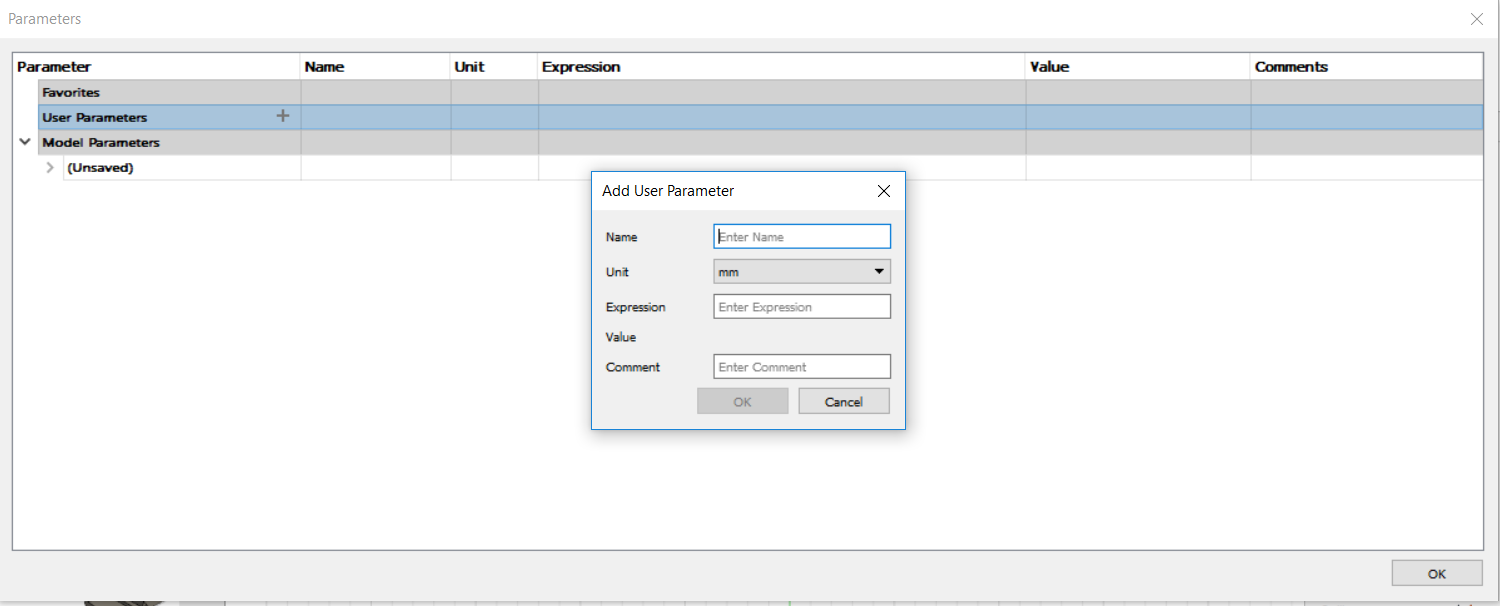

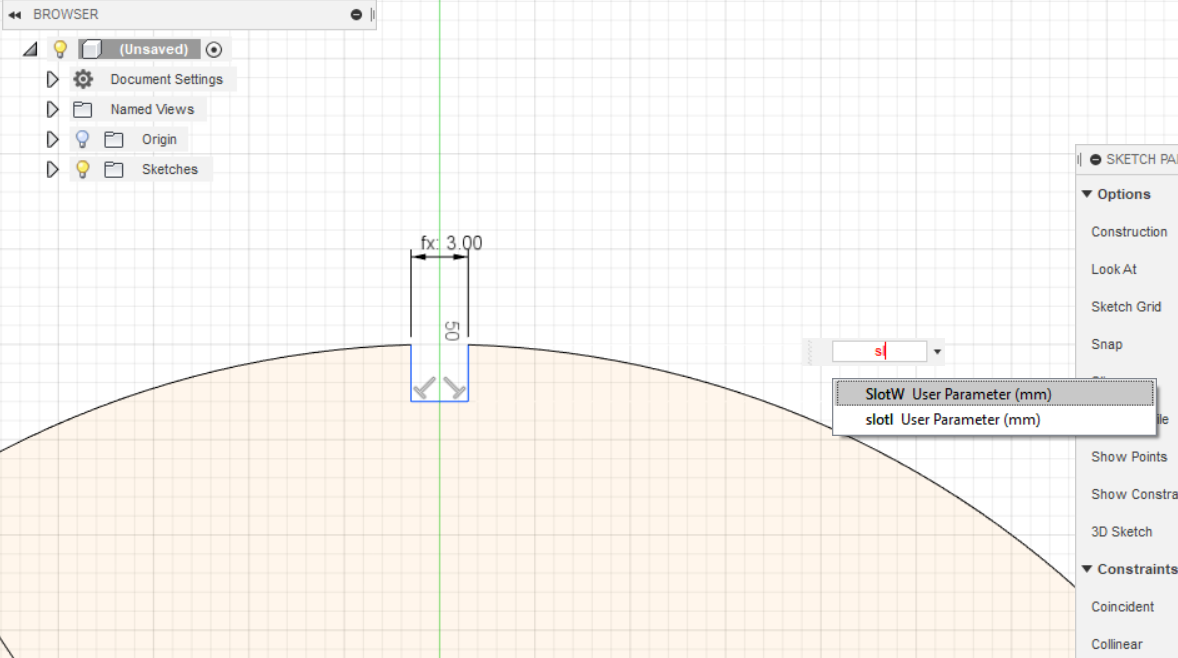

So I choose change parameters option and modify my parameters that I need for this design .

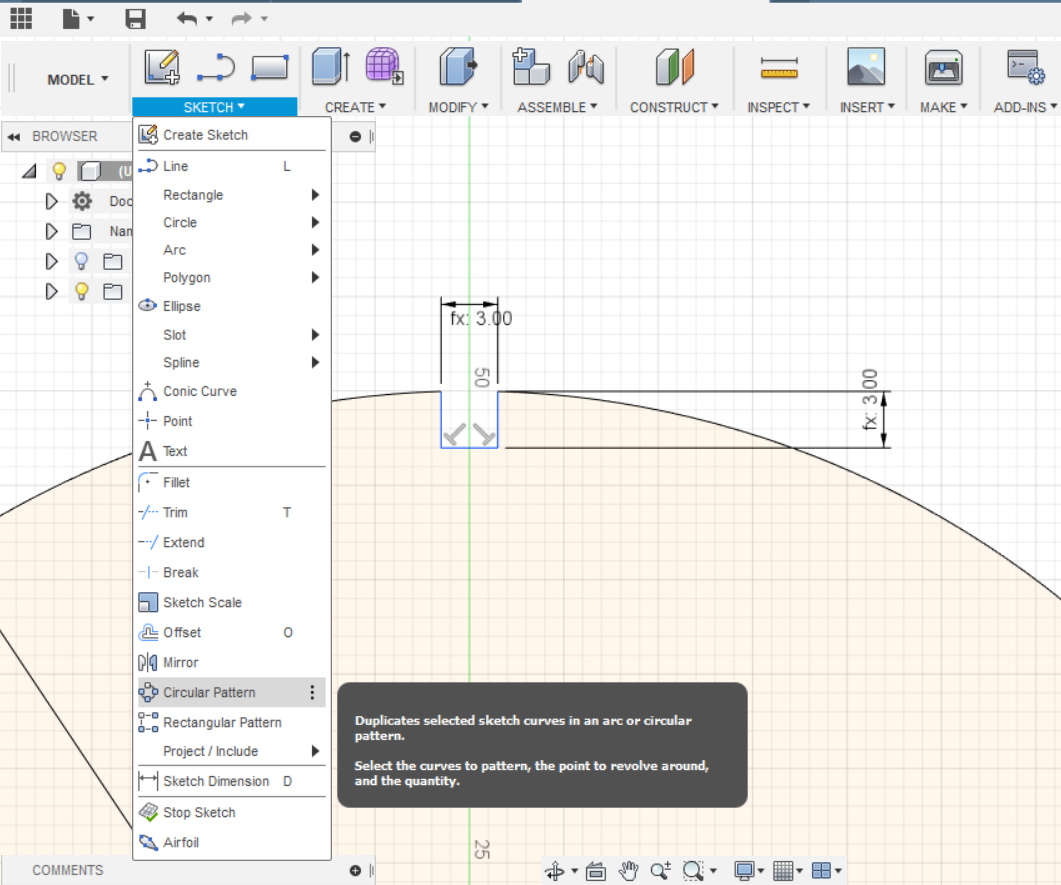

however after I modify my parameters that will help to adjust my dimensions easily with only one click , I drew the one slot then I used the circular pattern to do the others .

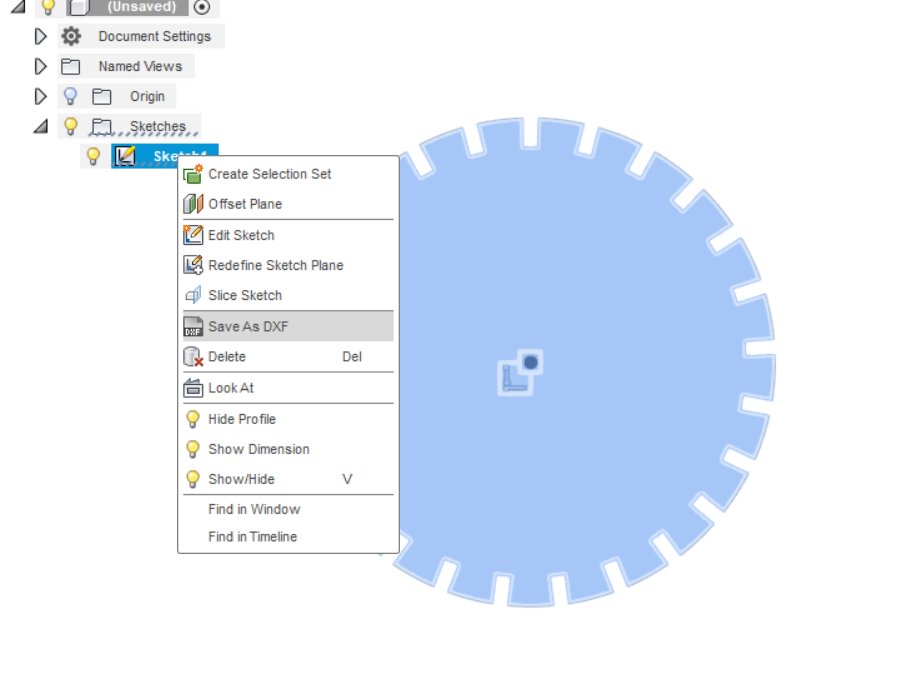

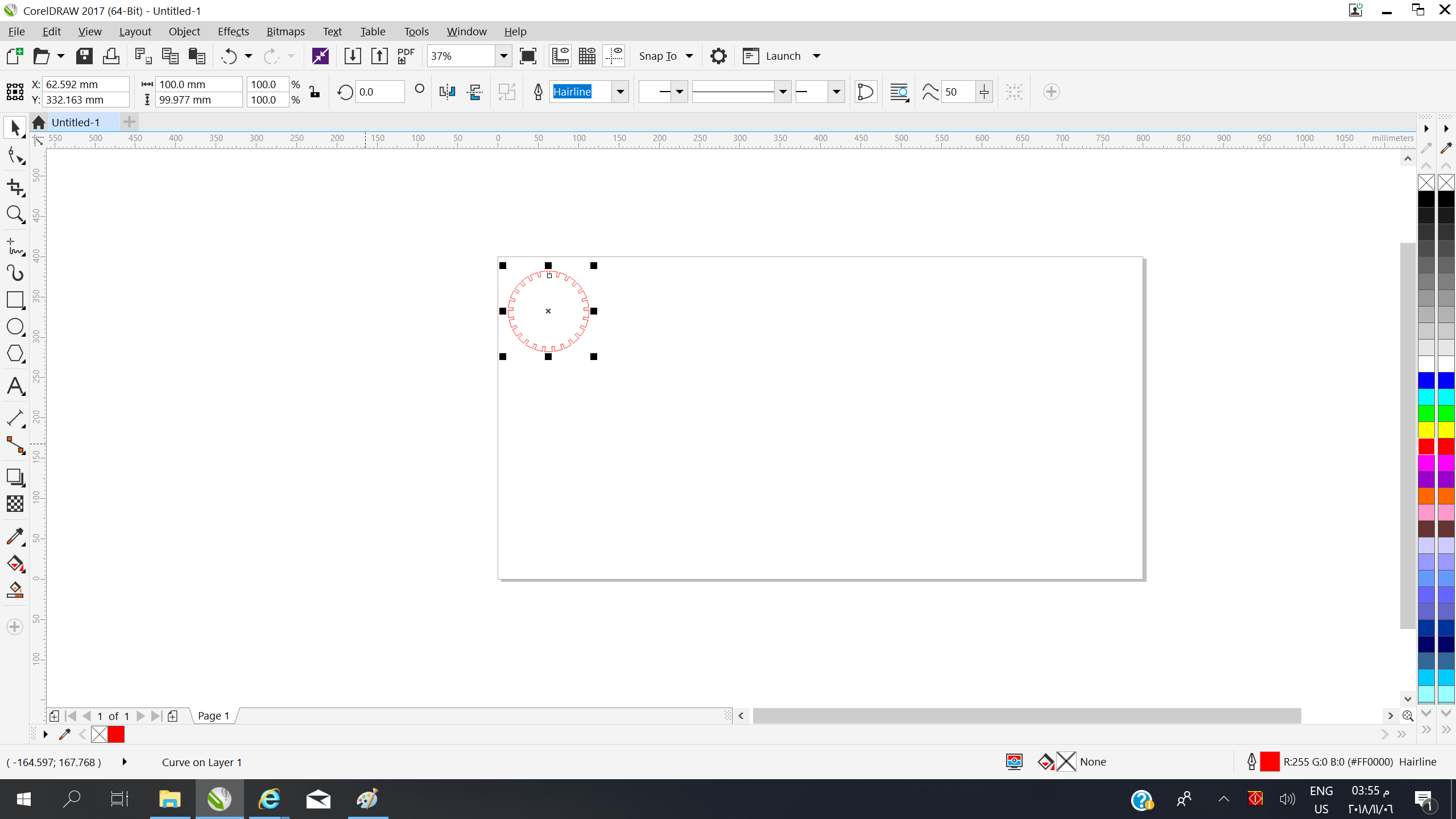

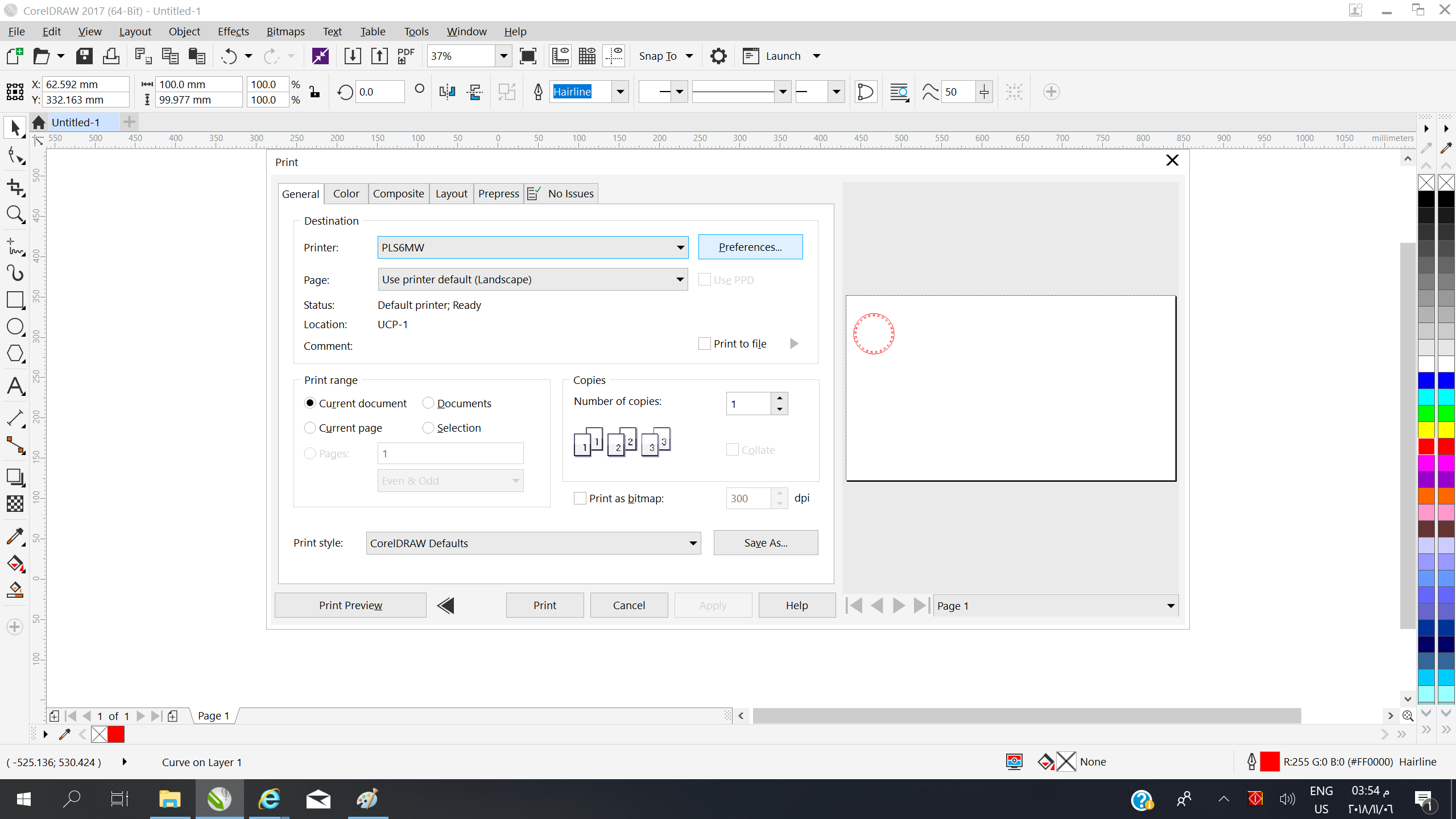

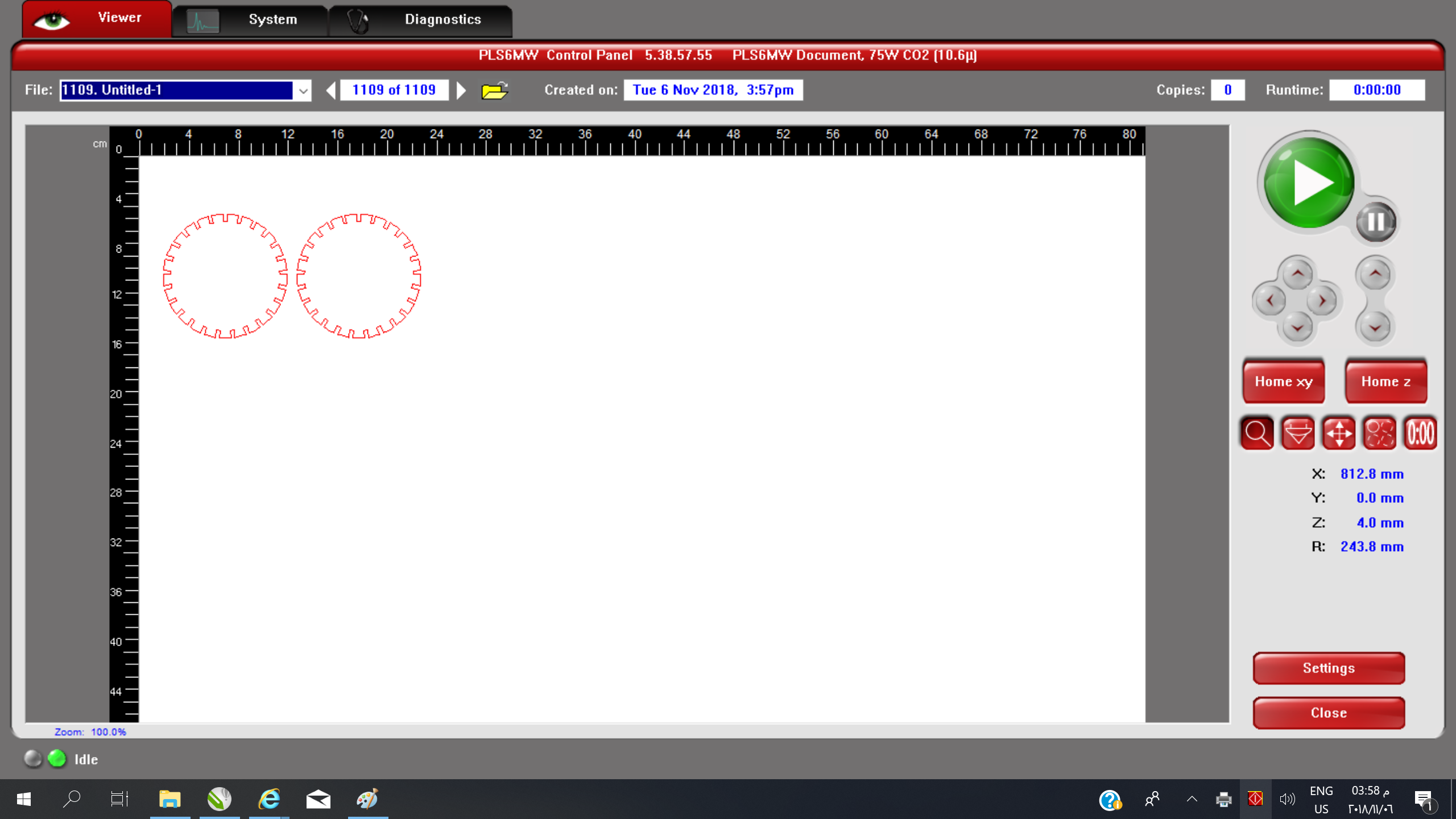

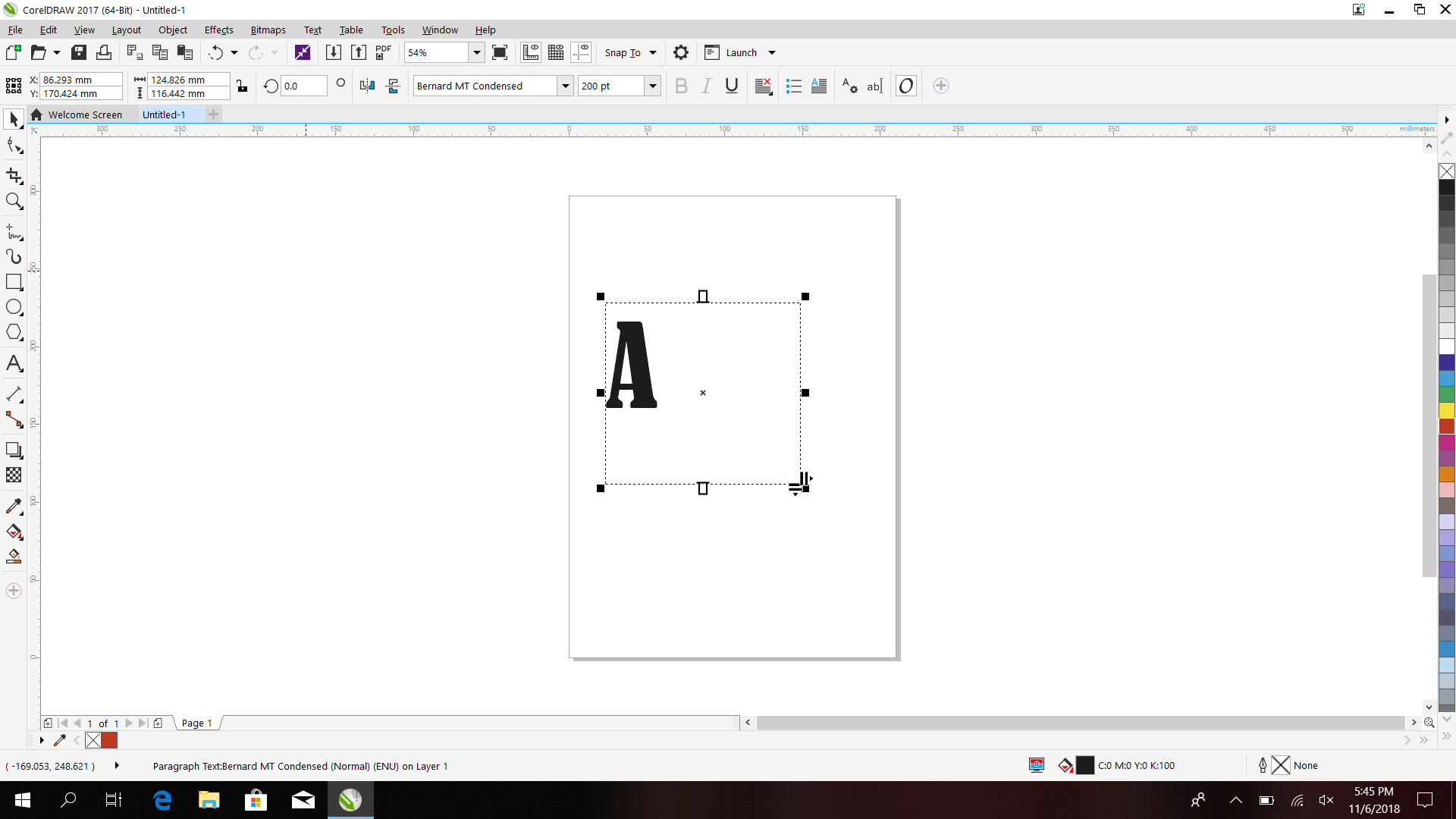

After finishing my design i save it as DXF , and open on coral draw to set it up for the laser cut ,

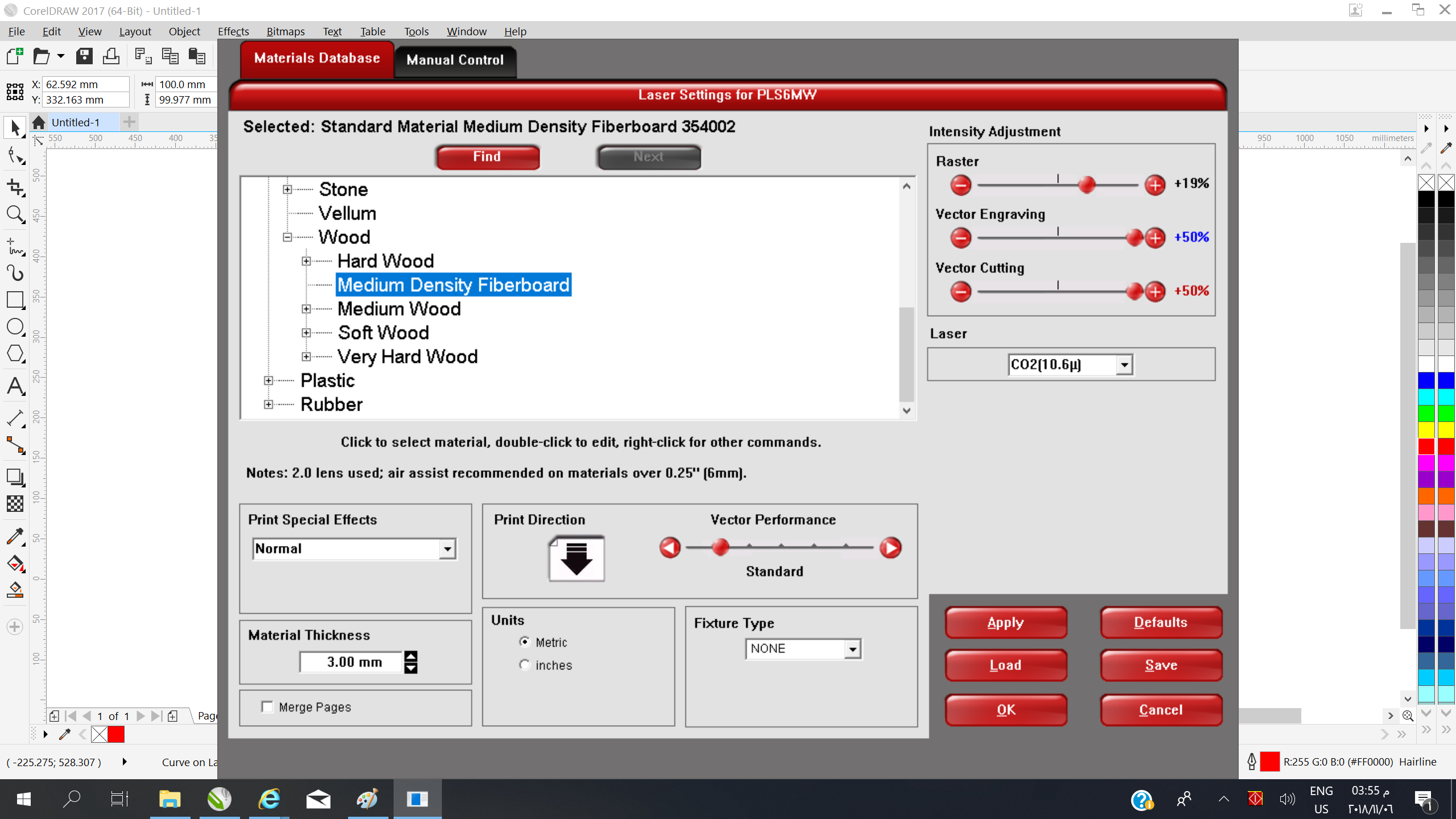

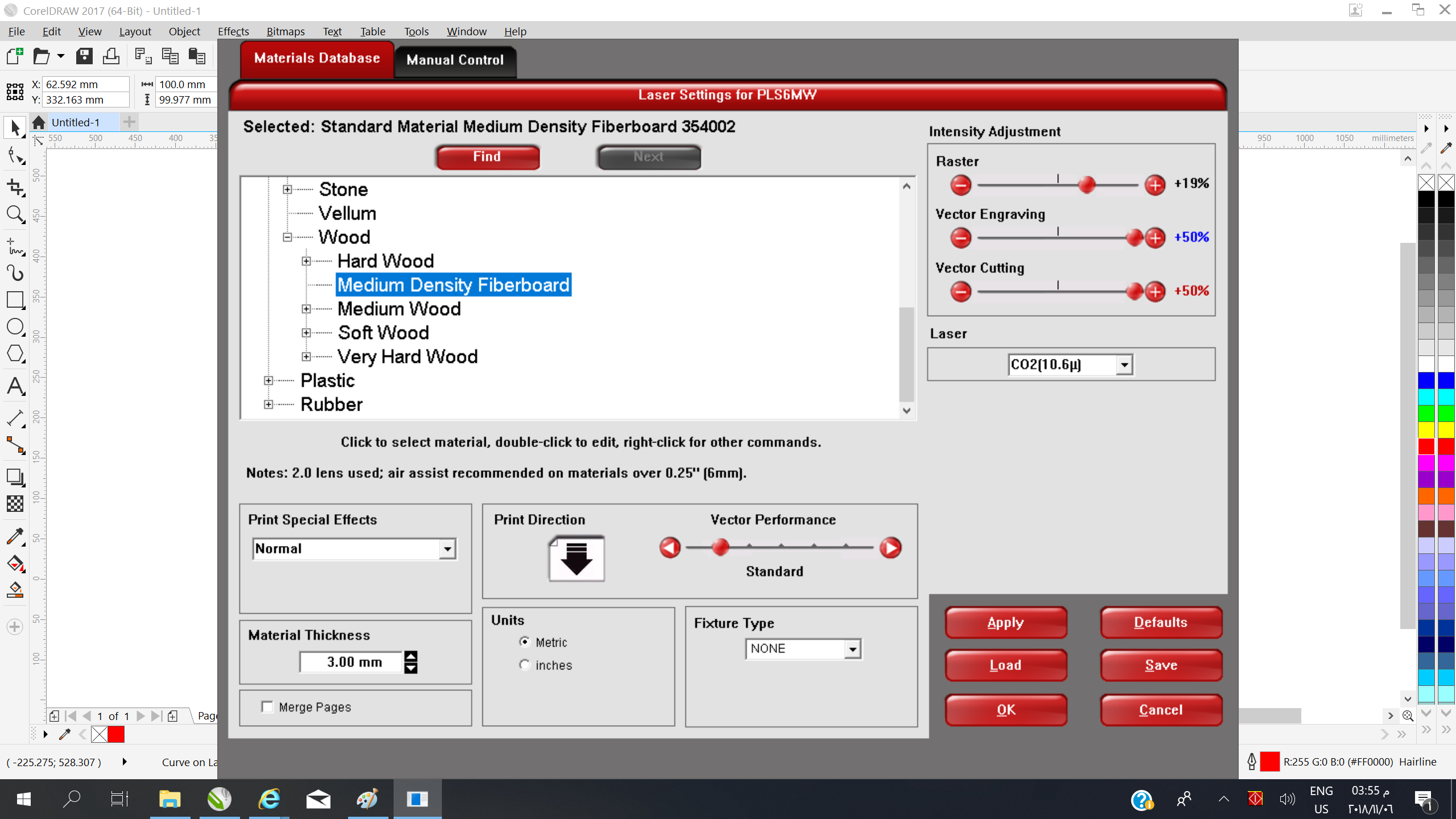

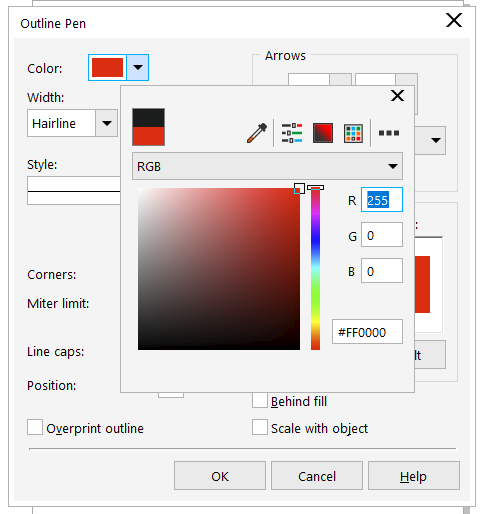

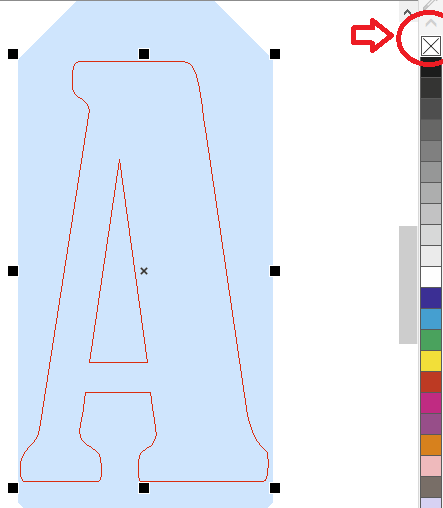

I learnt the set up and the parametric modifying when we work on the group assignment , so the main thing that the lines color should be red , for the machine to understand that I want to cut , however after changing the color to red and making the lines width as hairline . I went to set up the machine .

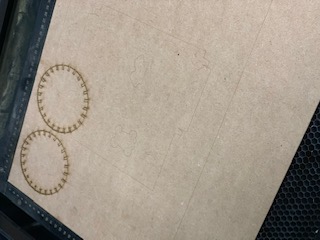

but unfortunately , it did not fit properly , so I changed my parameters, and edit my sketch by doing a fillet so it can fit easily and I decreases the diameter as well, to meet the desired Kerf which it was 0.44 mm .

I have to admit it without the group assignment , it will be difficult for me to do it.

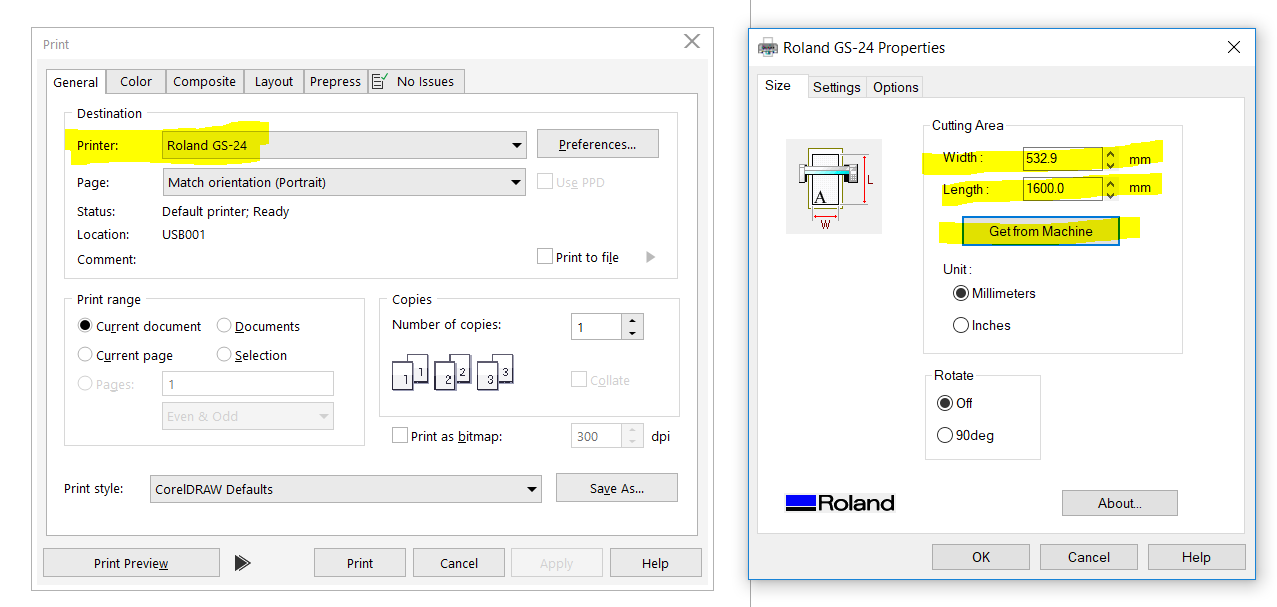

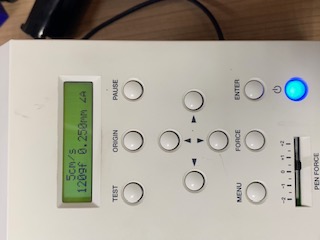

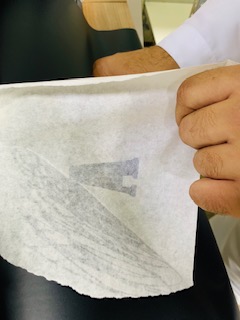

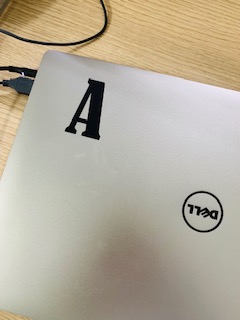

after that I chose the machine that I want to use and determine the width and the lenght of the sticker that the machine will determine automatically , and I will choose the force that I will use .

These two machines are amazing I am sure that I will use them on my final project , You will find all my working files on this Zip Folder.