WILDCARD WEEK

The objective of this week is to design a digital form, which is not included in another assignment.

1. Individual Assignment

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles, biotechnology, robotics, folding, and cooking.

1.1 CHOICE OF DESIGN

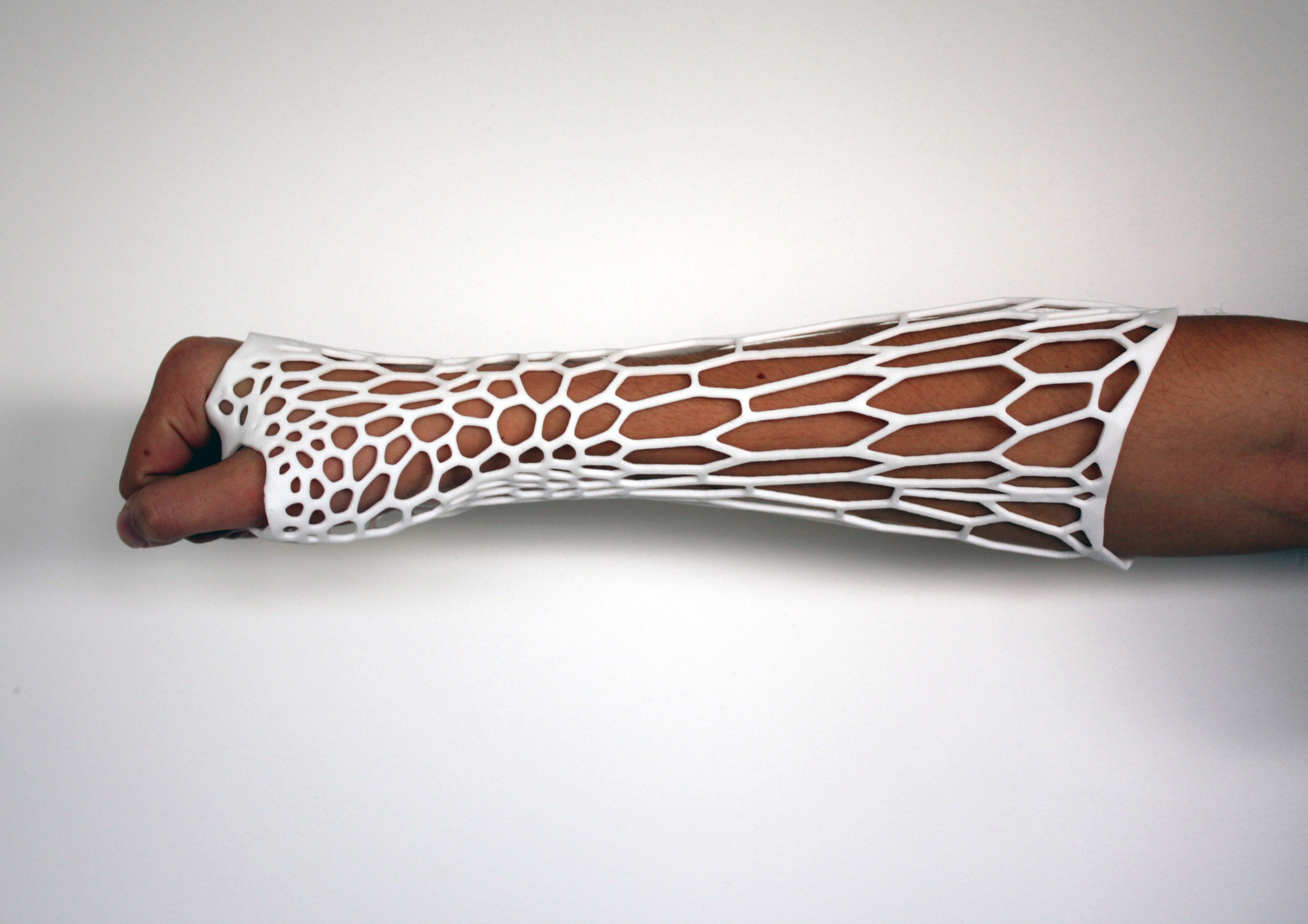

I work in an emergency service; In the area of traumatology. And it is very common to see lesions in different parts of the extremities. Most of these injuries require the affected part to be immobilized for several days. In this case we use the splints. These splints can be made by different materials. But the most frequent thing is to use plaster and cotton. This is uncomfortable for the patient; and they remove it themselves. Causing many types of injuries.:

That is why I decided to make a wrist splint that you have certain properties that help the patient to better carry his injury. My ferula has to be rigid (I decided to make a 3D impression with PLA), besides my ferula has to be flexible (I decided to fill the ferula with silicone).

1.2 DESIGNING 3D MODE

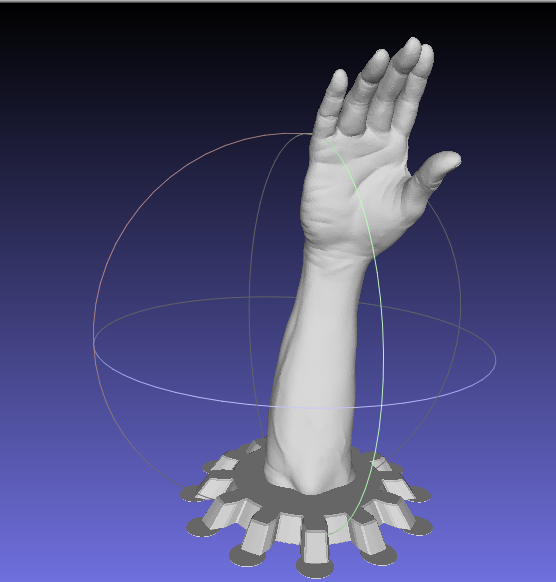

I searched the web and found a design that served as a template to design the splint (

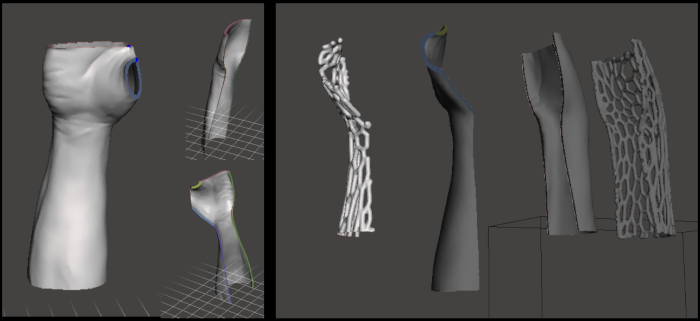

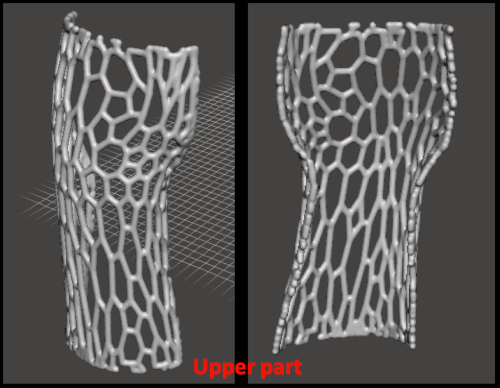

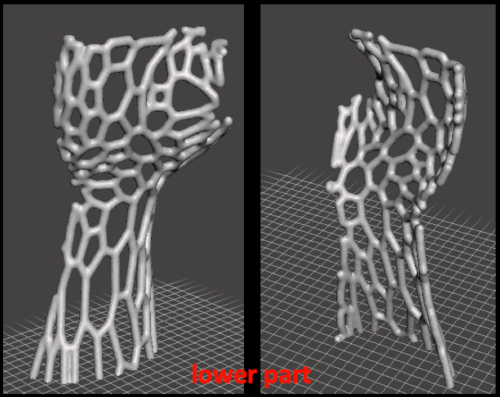

To carry out the design I used Meshmixer. This software allowed me to make the cuts of the model. And make the template for the template.(

At the end we have two mesh type splint. The first is to protect the back of the wrist and the second to protect the anterior part of the wrist.

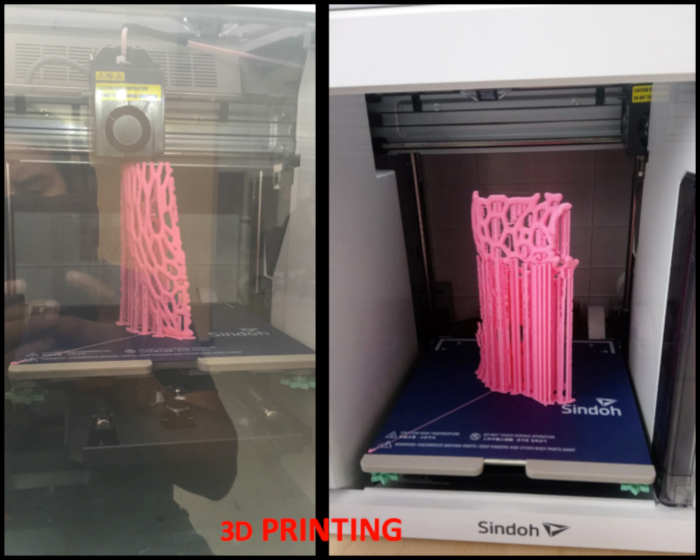

1.3 3D Print

The material that I used for the pre-cast was "Paraffin 74". I made paraffin blocks from recycled material (previous projects). I placed the paraffin in a container under the direct heat of an electric stove. I waited for the heat to melt the paraffin to later place the wooden boxes. The volume of paraffin block 40mmx80mmx100mm.:

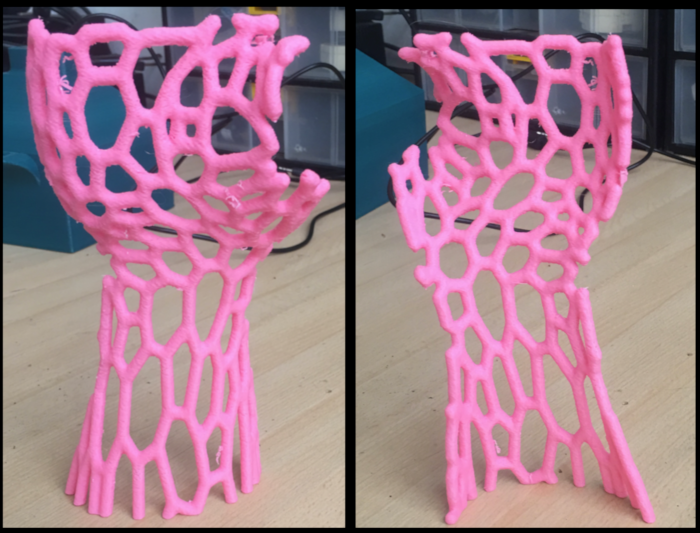

In the end a mold is achieved that is rigid, but does not tolerate bending. The advantage of this design is light.

1.4 MOLDING

To give the property to the splint, I used the silicone. First I put an external liner to contain the silicone in the splint.

After placing the silicone in the splint, this is expected to dry. This takes around 30 minutes. Once the splint is dry, the coating is removed carefully and the mold is finished.

1.5 RESULTS

The result obtained is a splint with characteristics of rigidity and flexibility. By using it, it feels comfortable. This conforms to the hand.

After placing the silicone in the splint, this is expected to dry. This takes around 30 minutes. Once the splint is dry, the coating is removed carefully and the mold is finished.

SELF EVALUATION

ADVANTAGE:

- Comfort

- Light

- Aesthetically pleasing, especially for children.

DISADVANTAGES:

- The 3D printing time of the splint, around 6 hours per piece.

Contact Me

Feel free to contact me via email or phone.

FabAcademy 2019

FabAcademy 2019