Computer-Controlled Machining

Making something BIG and exciting!

The decision making process of what to make, specially when it's with a maching as utilizable and intimidating as a CNC machine can be sometimes more difficult than the design process itself!

I decided to create a piece of furniture, specifically one that I can use at home. I decided to create a laptop stand.

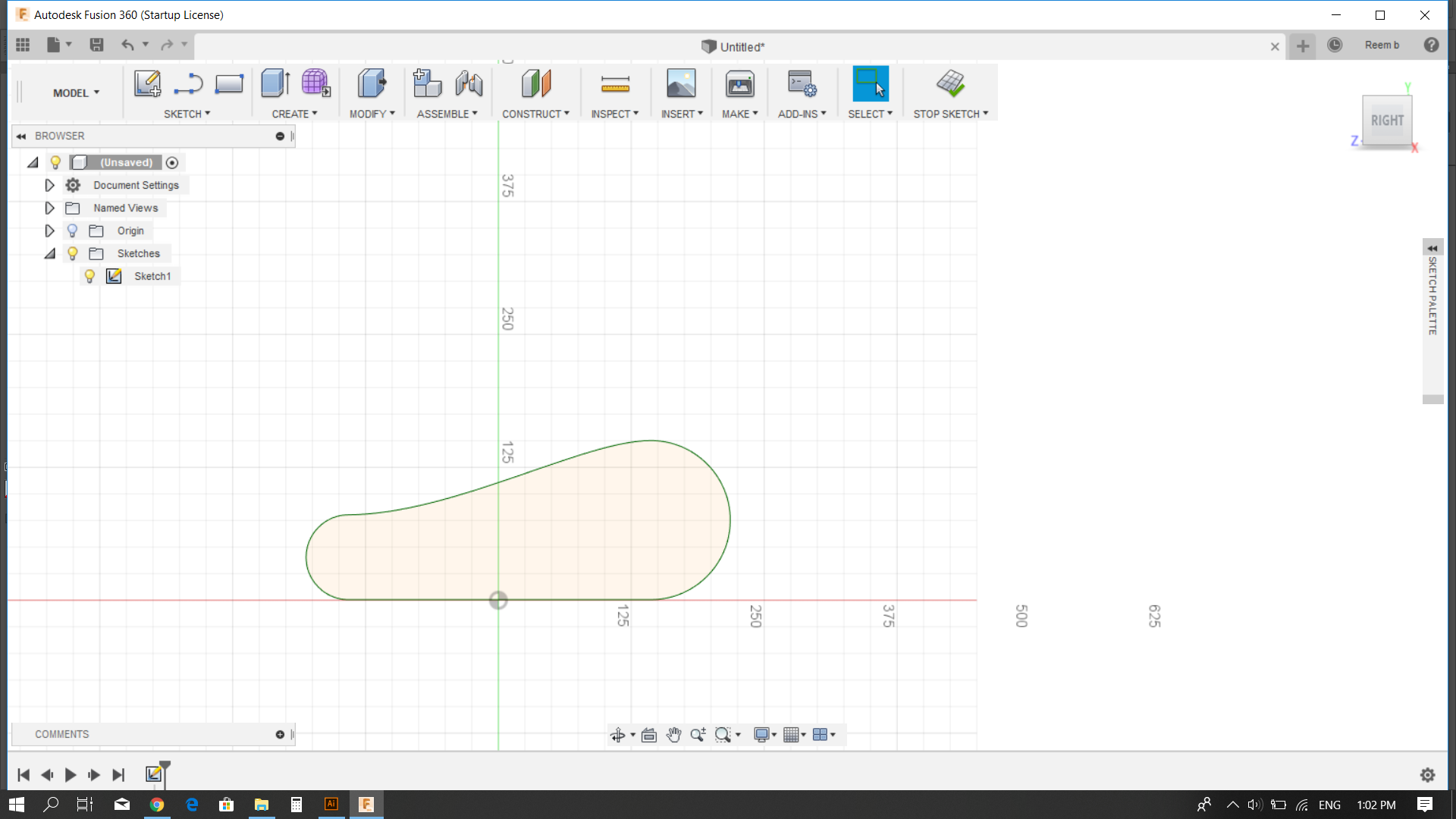

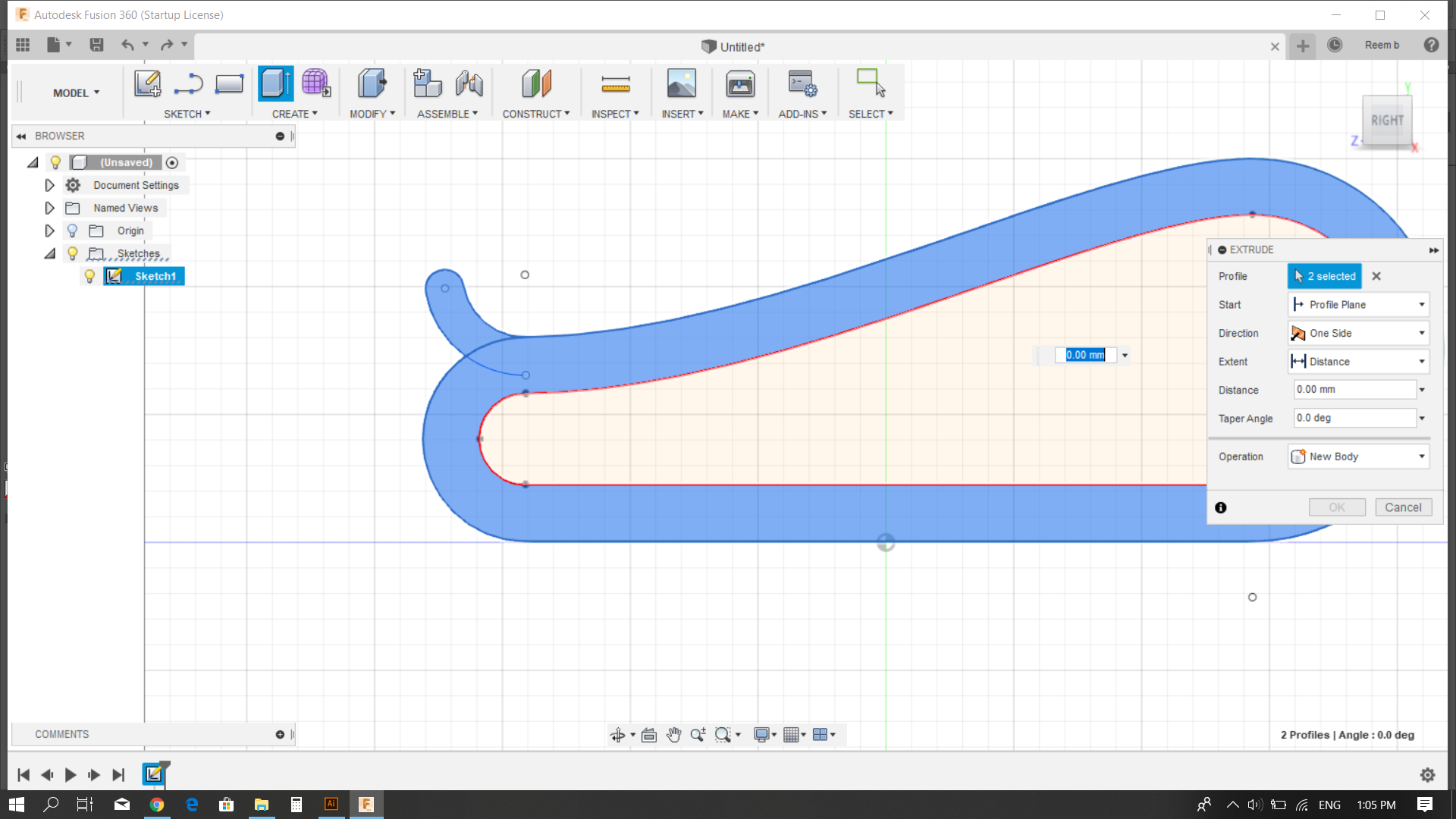

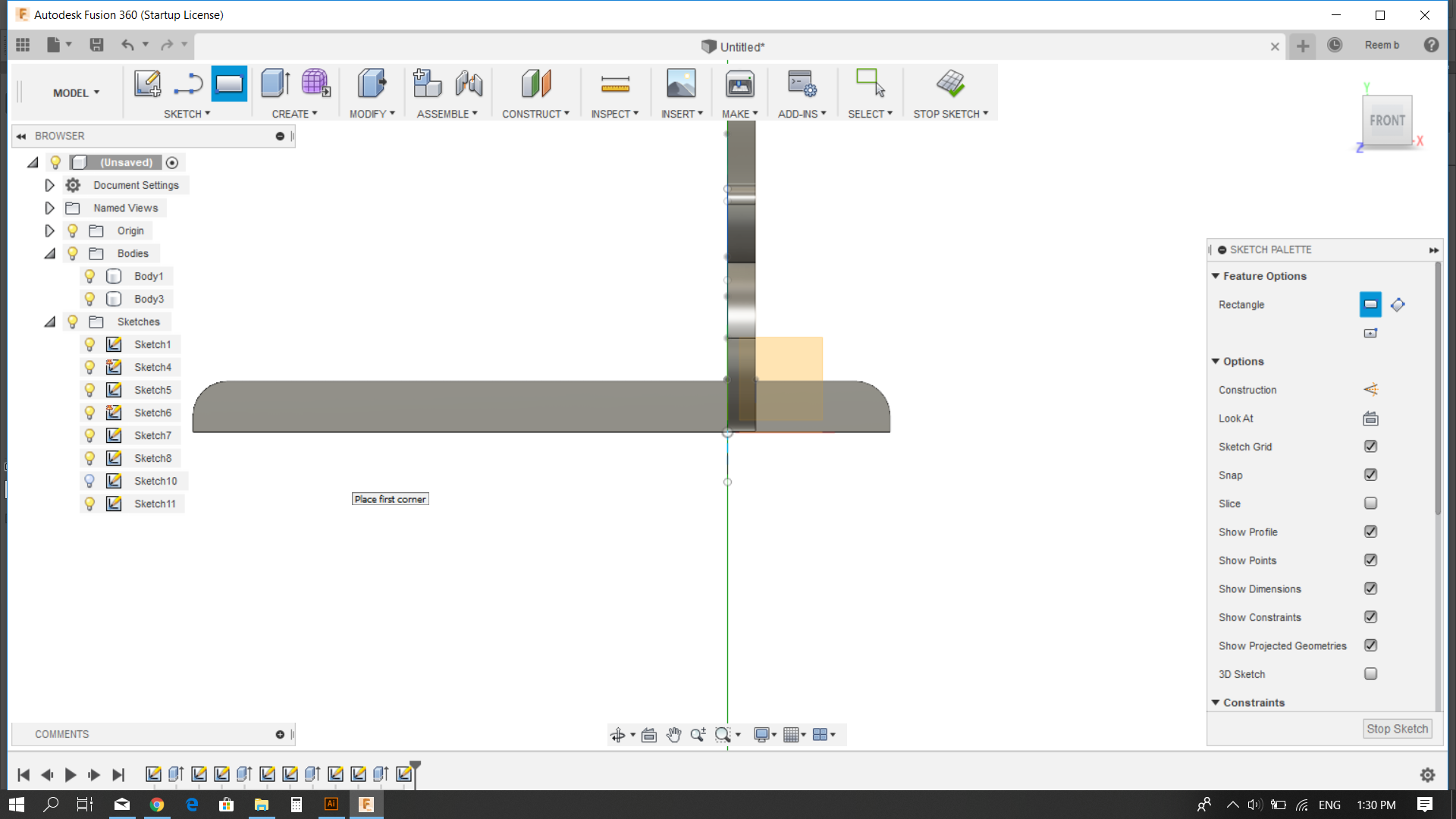

This was how it started:

I created the shape I wanted on Adobe Illustrator because I find it easier to control than Fusion 360, then imported it into Fusion.

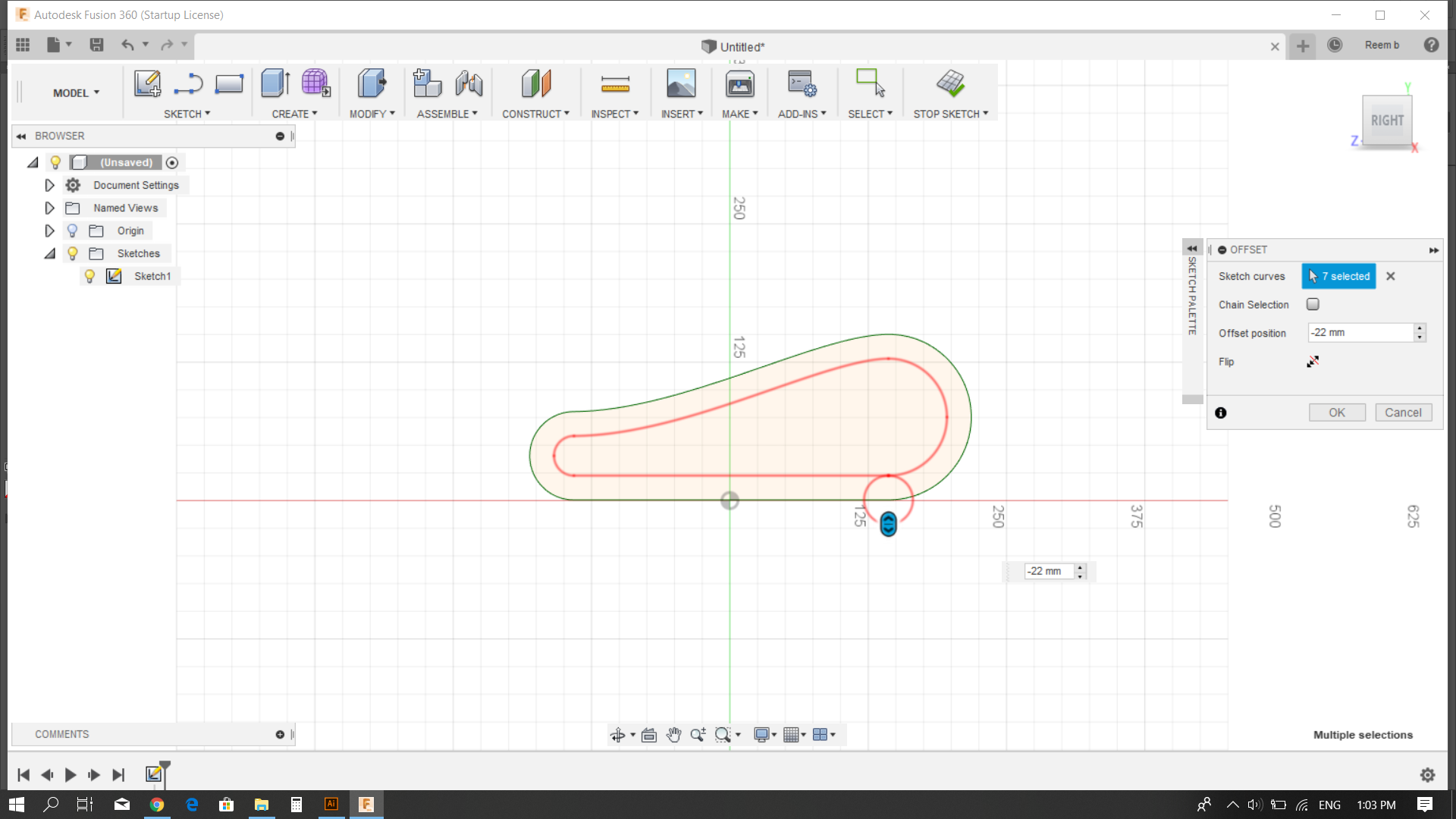

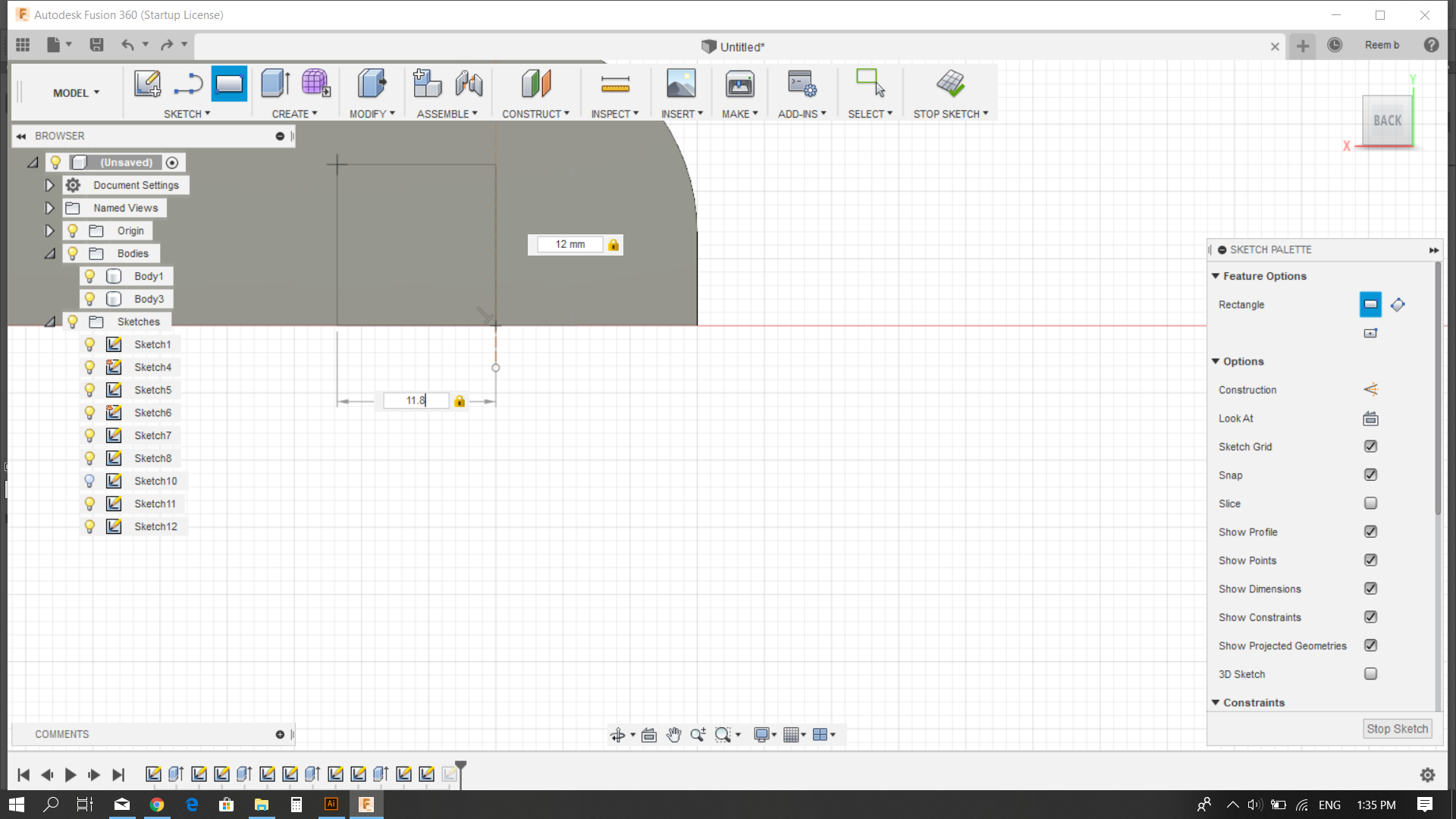

I created an offset:

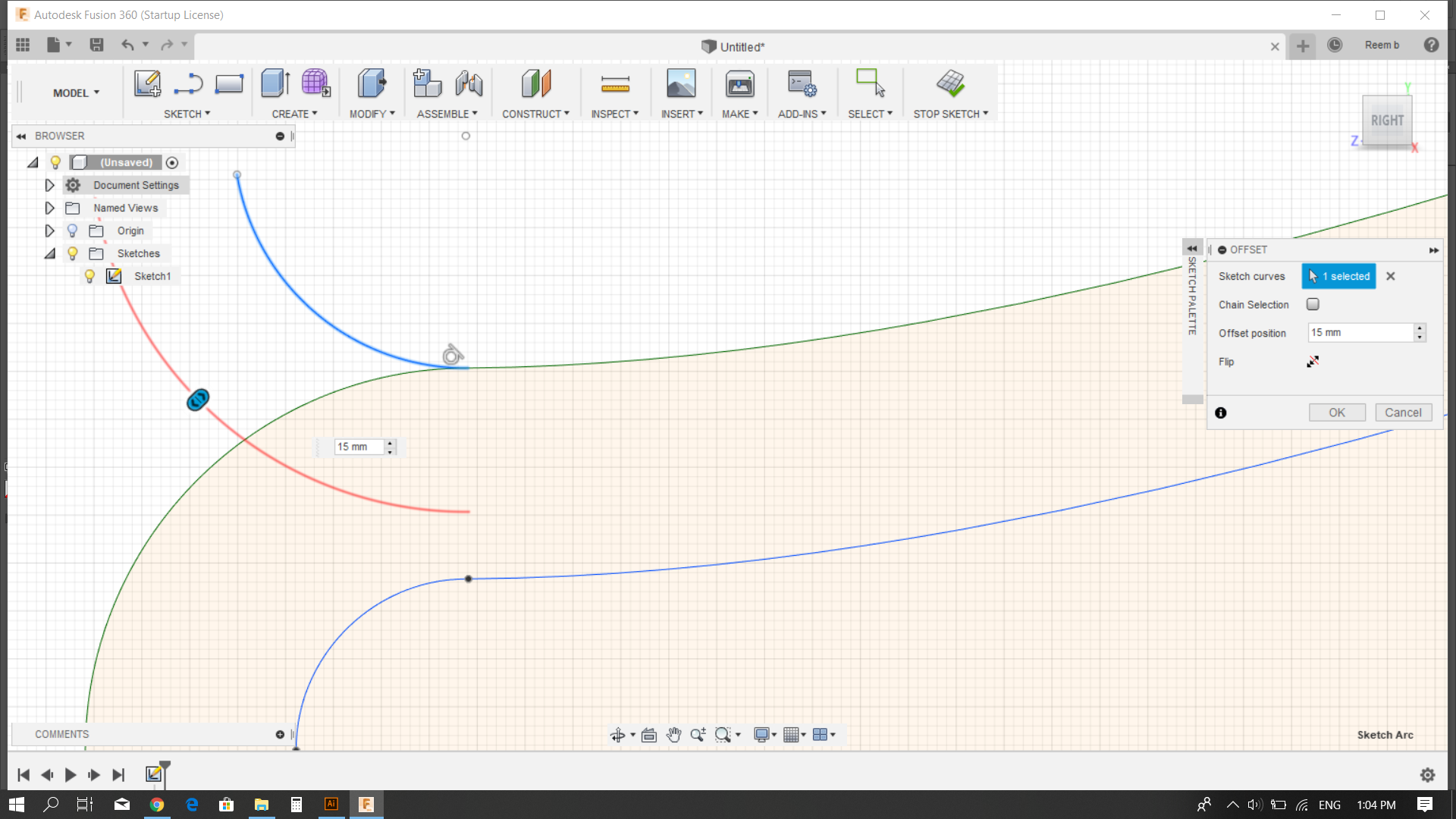

Extended the outer shape, and created an offset of it:

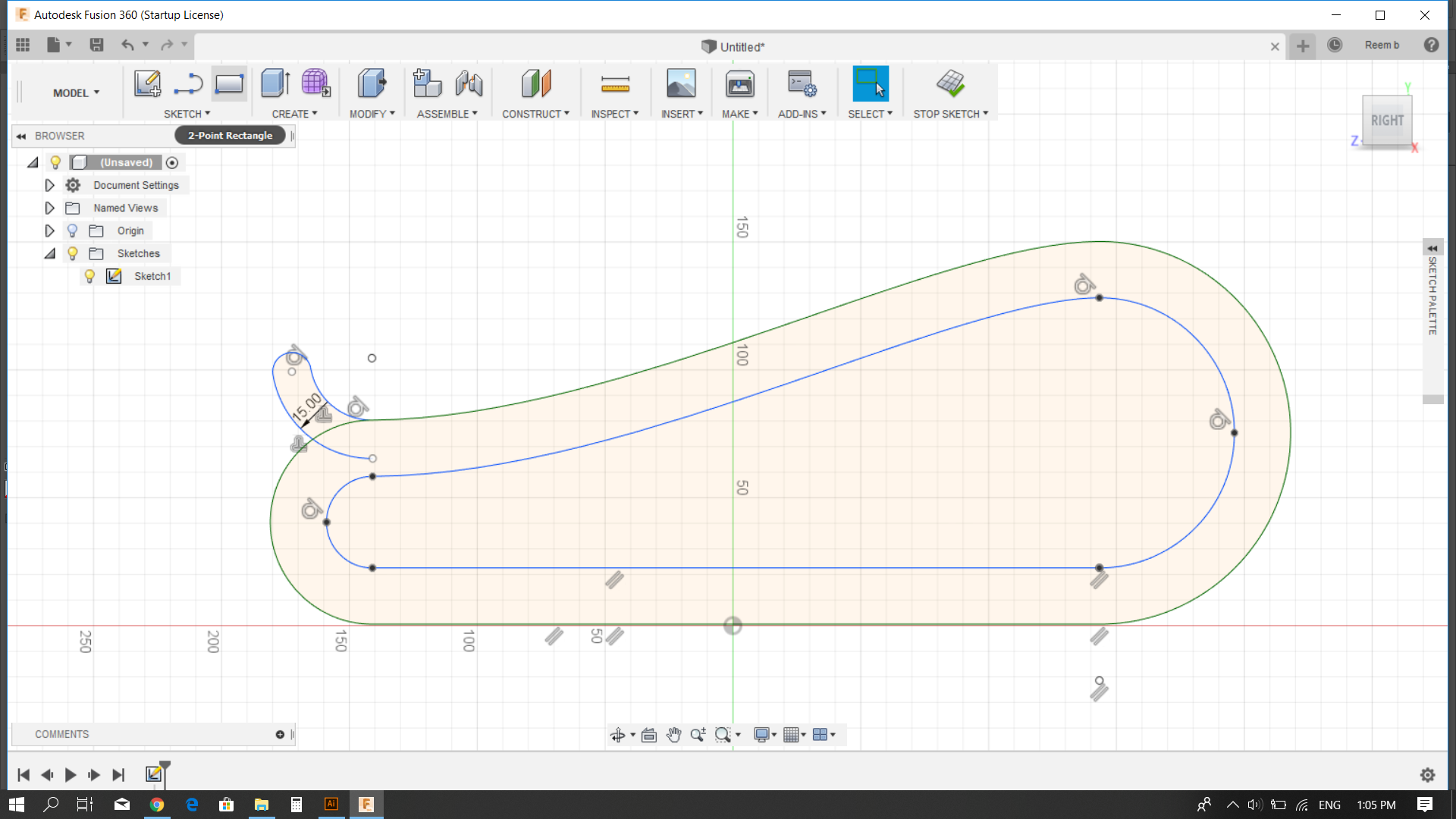

Then connected the two curved together

- creating the full shape I'm looking for my units.

I extruded the externl shape, getting rid of the internal space.

I then created the holes that would connect to the other two units that hold the product together.

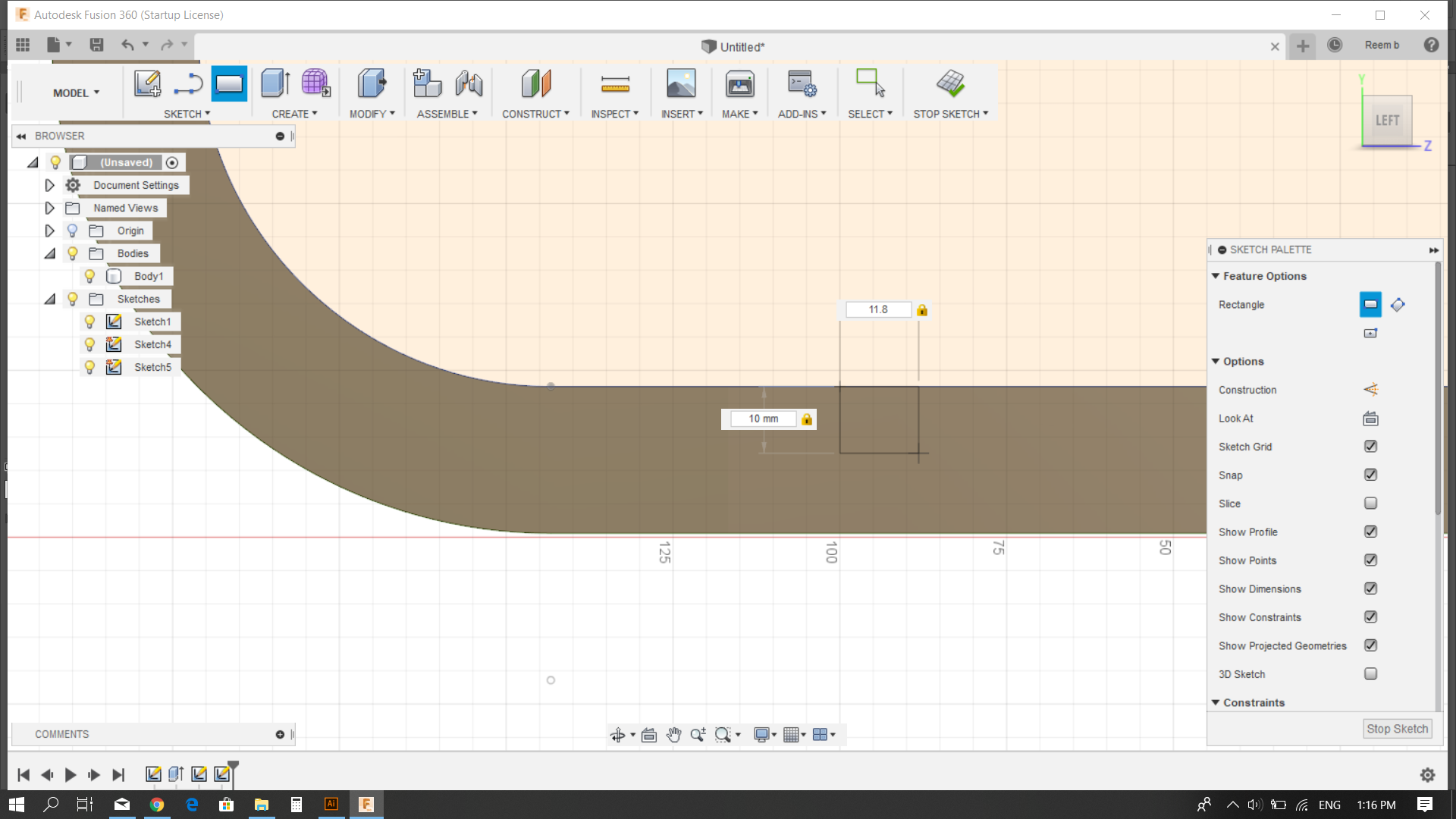

I then started creating the other unit, of which I'm going to have two copies.

I extruded it.

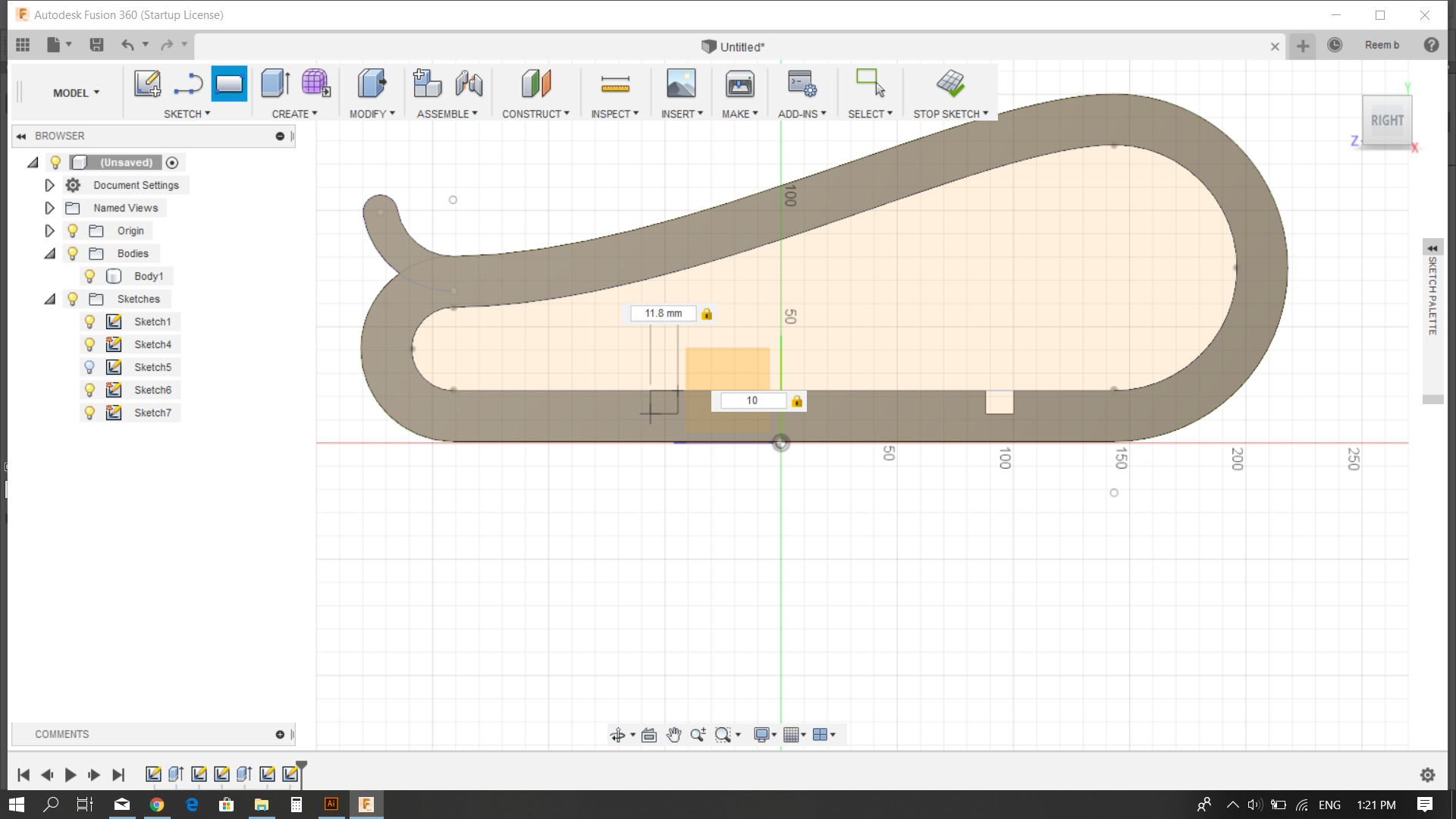

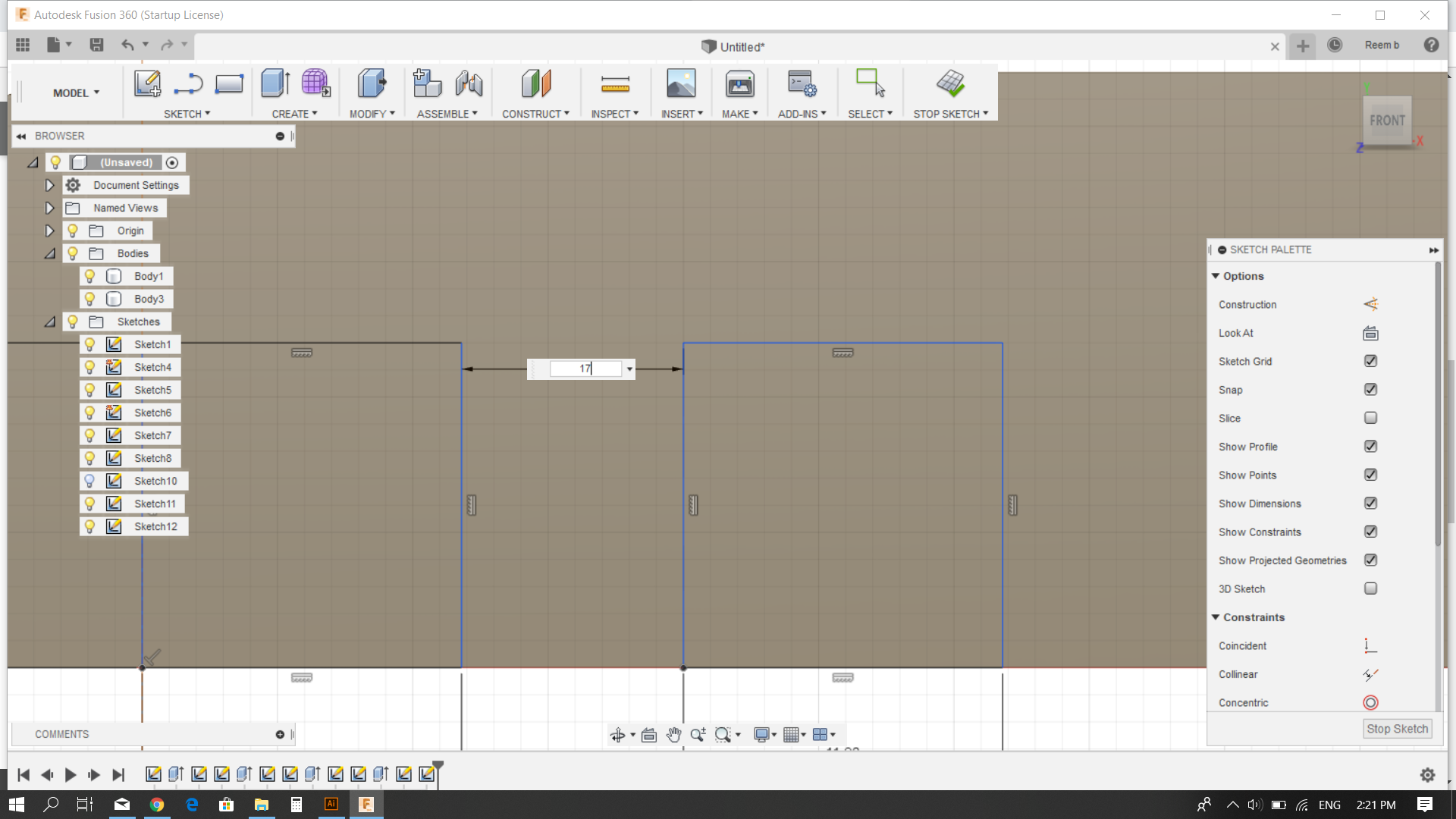

Started to create the openings where the other unit would fit.

Made sure the spacings between them are equal:

and extruded them out:

Note that I added t-bone structures to all 90 degrees, diameter of each drill is 6.4 mm as the radius of the tool is 3.2 mm.

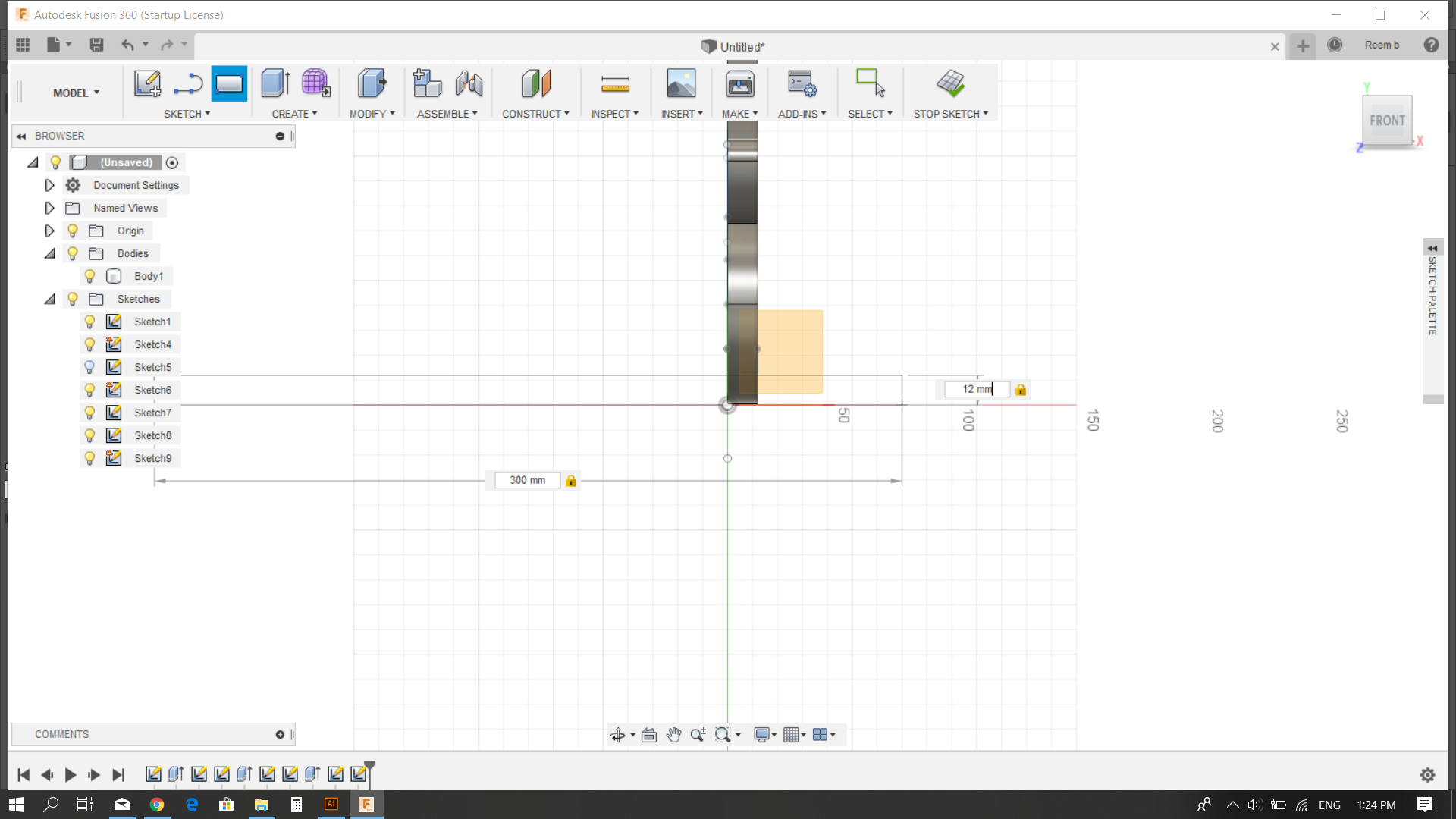

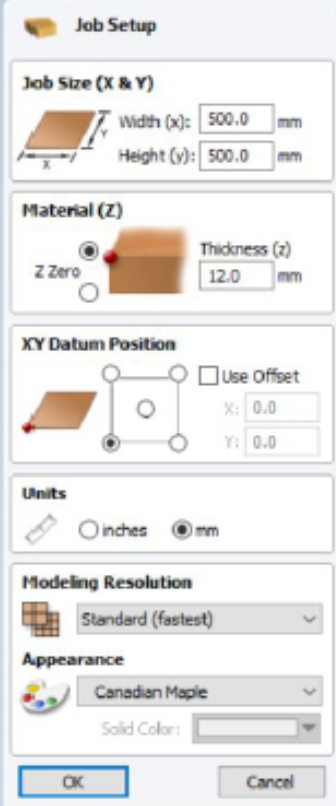

After saving the files as DXF, it was time for the cutting. We didn't have 12 mm wood in the lab at the time so I used an external Shopbot. To prepare the files, I used V-Carve Pro to prepare the files for cutting. I sat the parameters of my material - 12 mm MDF wood.

Added the information again in the material setup tab:

In the cutting panel, I set the cutting depth to 12 mm - the thickness of the wood.I cut on the vectors and edited the passes to 4.

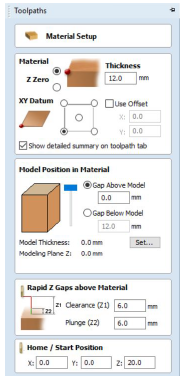

I then used ShopbotEasy to set the origin and submit the cutting command:

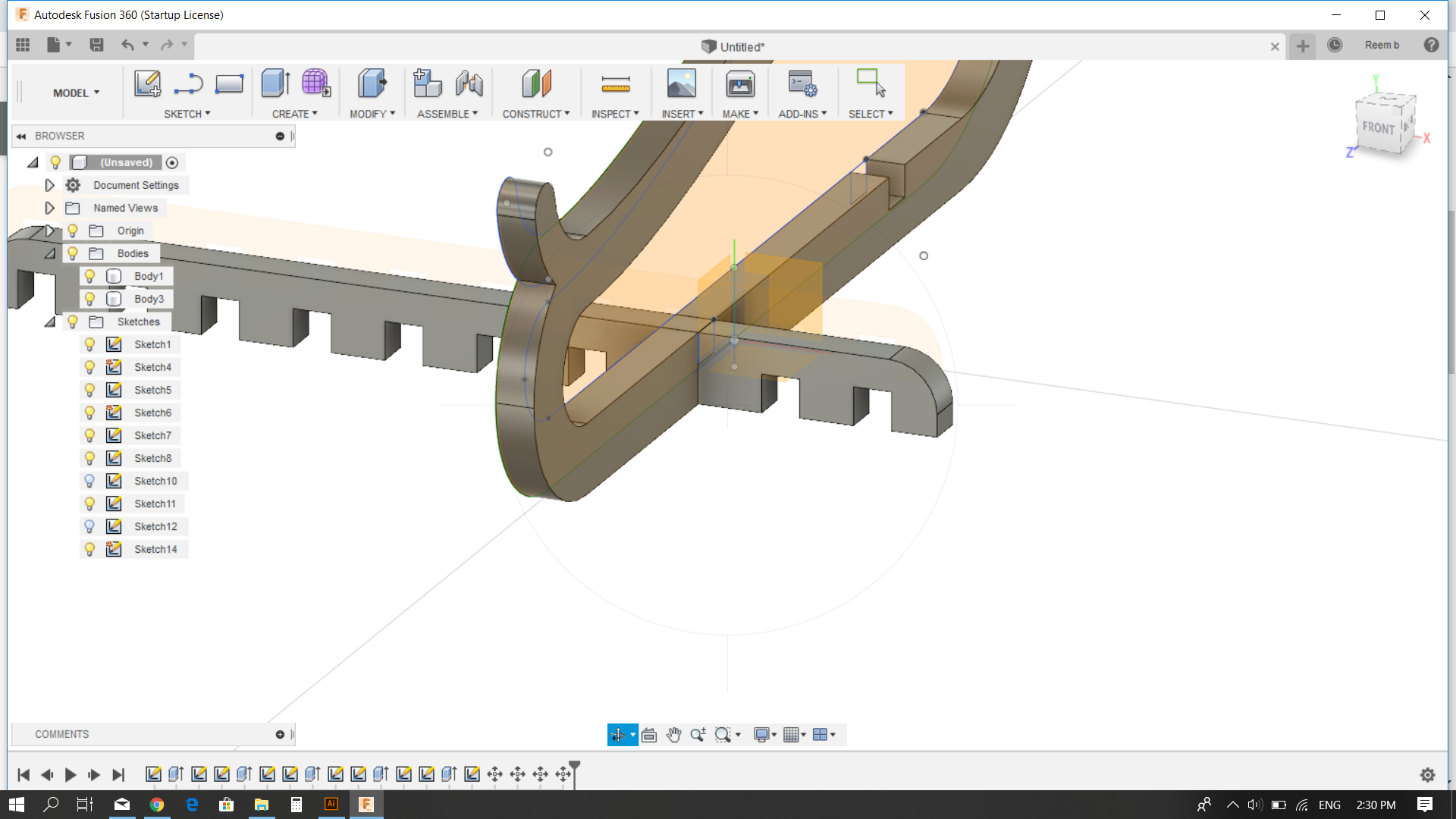

2 of this:

and 10 of this:

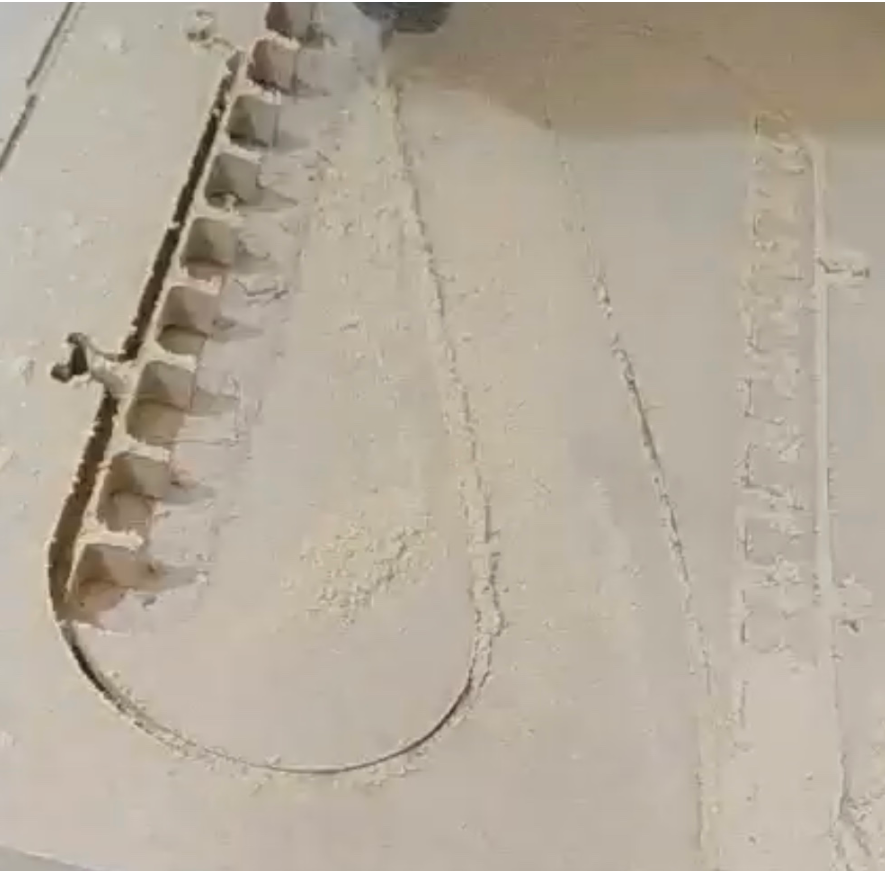

Then I started the assembly.

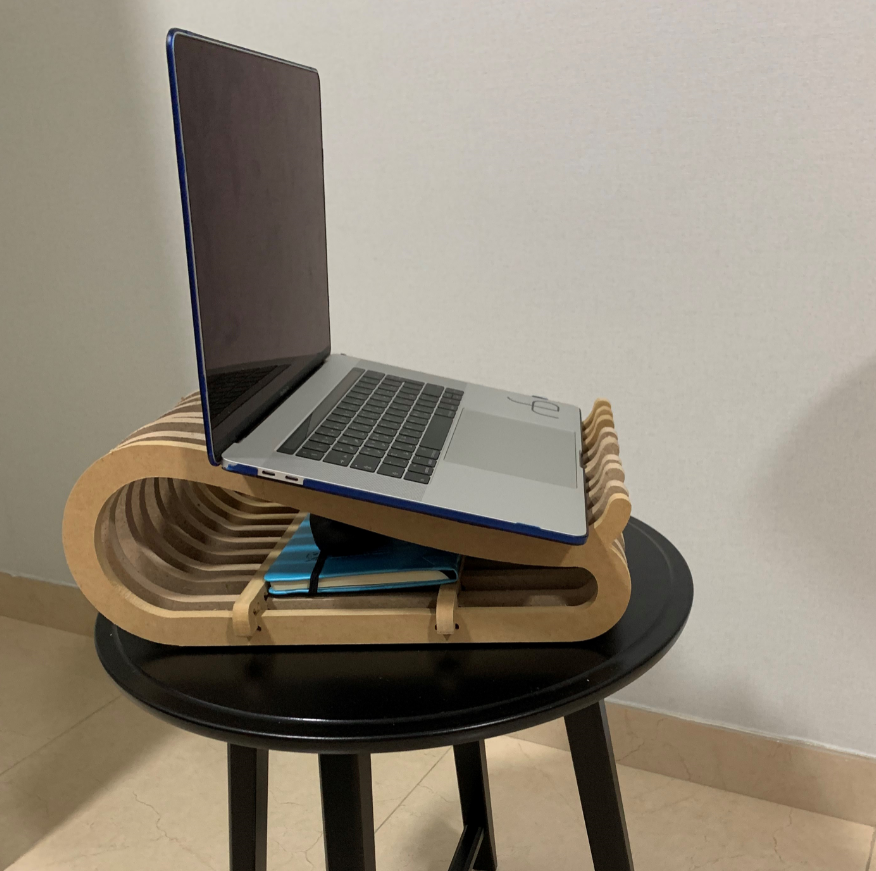

Turning into the final product!

I'm satisfied with the final product, the units fit perfectly in each other, making it stable with no need for nailing or screwing. However, the two units holding it all in the middle were weak, next time I'd make them thicker. Also, it's worth mentioning that this is not a portable stand. It can be used on desks or domestically only as it's not practical to be moved around with.

Files:

File1*10.dxfFile2*2.dxf