Machine Design

Part 2 of our group project

The task this week was the second of two parts for the group assignment. As a group, we made the decision to create a 2D plotter using a whiteboard marker. A future opportunity is to make this plotter more flexible by being able to attach different tools in place of the marker.

Planning and Execution:

The tasks were divided on the team members in order to get things done on time. The first part was planning and CAD. Of course, nothing was specific because it depended on the electronics and available resources at the lab. Therefore, the electronics team members were working in parallel so CAD can be perfected. Along with Ahmed Alhaj, my task was to work on the digital fabrication. He took care of the 3D printing, while I worked on the computer controlled cutting using the Shopbot.

First I had to prepare the files on VCarve Pro, where I added all the presets and exported for use at the ShopBot Easy Panel - the dashboard of the Shopbot.

I added the file on ShopBot Easy and screwed the wooden piece into the machine. I had then to sit the x,y and z origins:

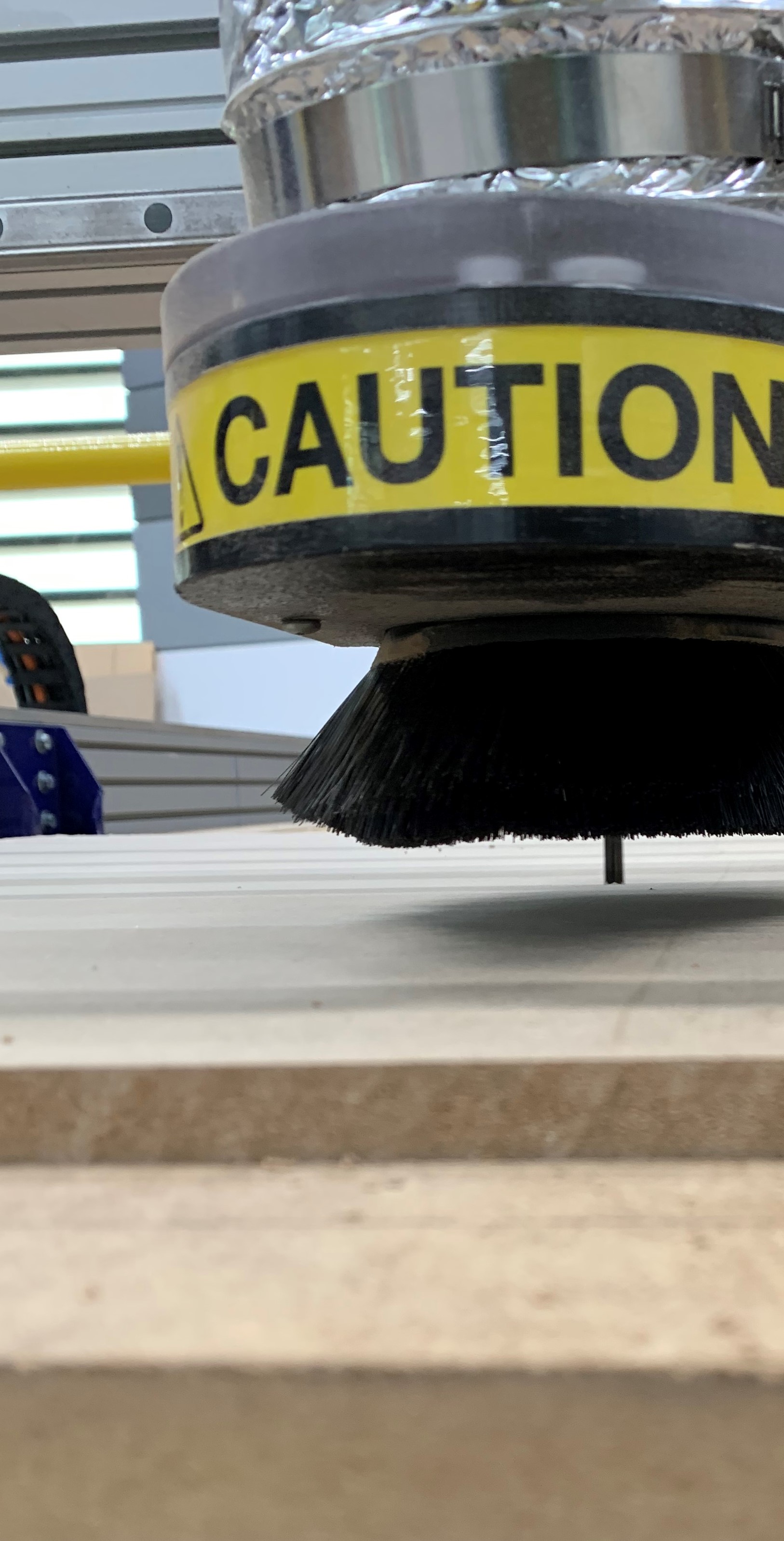

The machine then did the cutting:

Problems:

The main problems we were faced with were:

- As a team, each of us had a full-time job as well as other personal commitments. It took a lot of effort to put us all in the lab together. What we did to overcome this is to just meet once a week briefly, and communicating mostly online. We grouped ourselves not only based on expertise and interest but also availability. Those who has similar time preferences worked together.

- Time was an issue - that's why we limited our choices to 2D only.

- On a personal level, working with the Shopbot had a lot of complications. The machine, although works usually well, had an issue in the settings that delayed the work for a few days. This issue was handled by the staff of the Fab Lab.

To view more about the project, please see QBIC Fablab's page.

Future Development:

As a first step, we really hoped we had time to expand the project on 2 dimensions: 1. Having a third access, turning it to a 3D plotter - and 2. Program it to be flexible with different tools, not just whiteboard markers.

Files:

Base Frame.dxfMain Motor Holder.dxf

Side Walls - Left.dxf

Side Walls - Right.dxf