Computer Controlled Machining

For this week's assignment, It was required to

Make something Big!

So, What is a CNC?

The term “CNC” is a generic term which can be used to describe many types of device, this would include plotters, vinyl cutters, 3D printers, milling machines and others. CNC stands for Computer Numerically Controlled and basically means that the physical movements of the machine are controlled by instructions, such as co-ordinate positions that are generated using a computer.

The term “CNC Machine” is typically used to refer to a device which uses a rotating cutting tool which moves in 3 or more axes (X, Y and Z) to cut-out or carve parts in different types of materials. The information on these pages will focus on what are typically referred to as “CNC Routers” although it would be applicable to most CNC milling and engraving machines too.

Shopbot

A Shopbot is a computer-controlled cutting machine. A power tool router is affixed to the machine that directs its X and Y coordinates as it's cutting.

CNC routers can be used to cut wood, foam, and plastics, but most hobbyists use it for carving wood.

Available in traditional shop-size and larger, all full size gantry tools are available with 8” or 14” Z travel. In addition to our standard size tools – 96 x 48, 96 x 60, 120 x 60, 144 x 60 – we can build your tool to any dimension up to 10’ by 30’ and with plunge depths up to 24 inches. Other customizable components are available, including dual Z options with two Z axes on the main gantry.

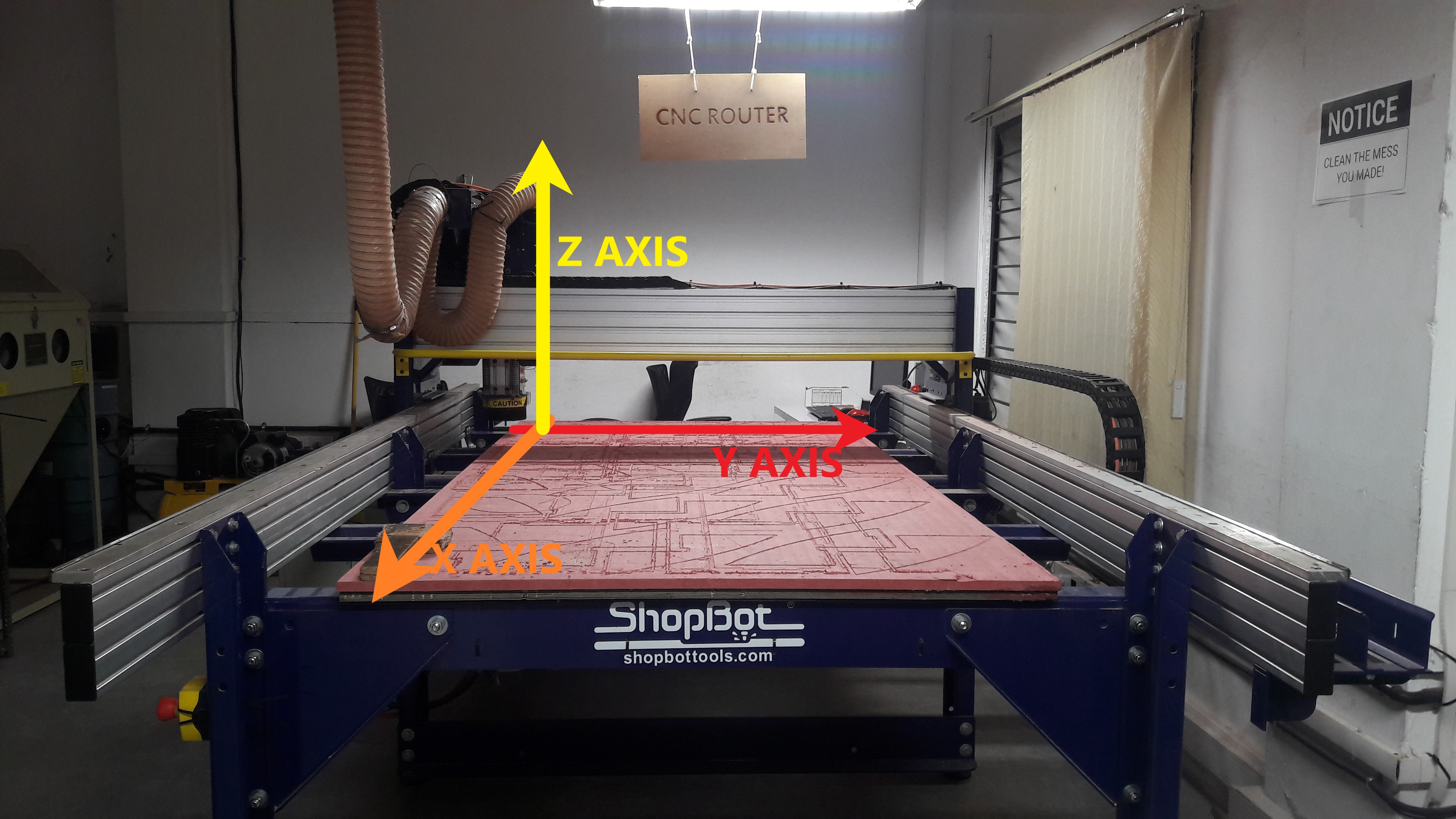

Shopbot consist of 3 Axis

X-Axis(Horizontal movement)

Y-Axis(Horizontal movement)

Z-Axis(Vertical movement)

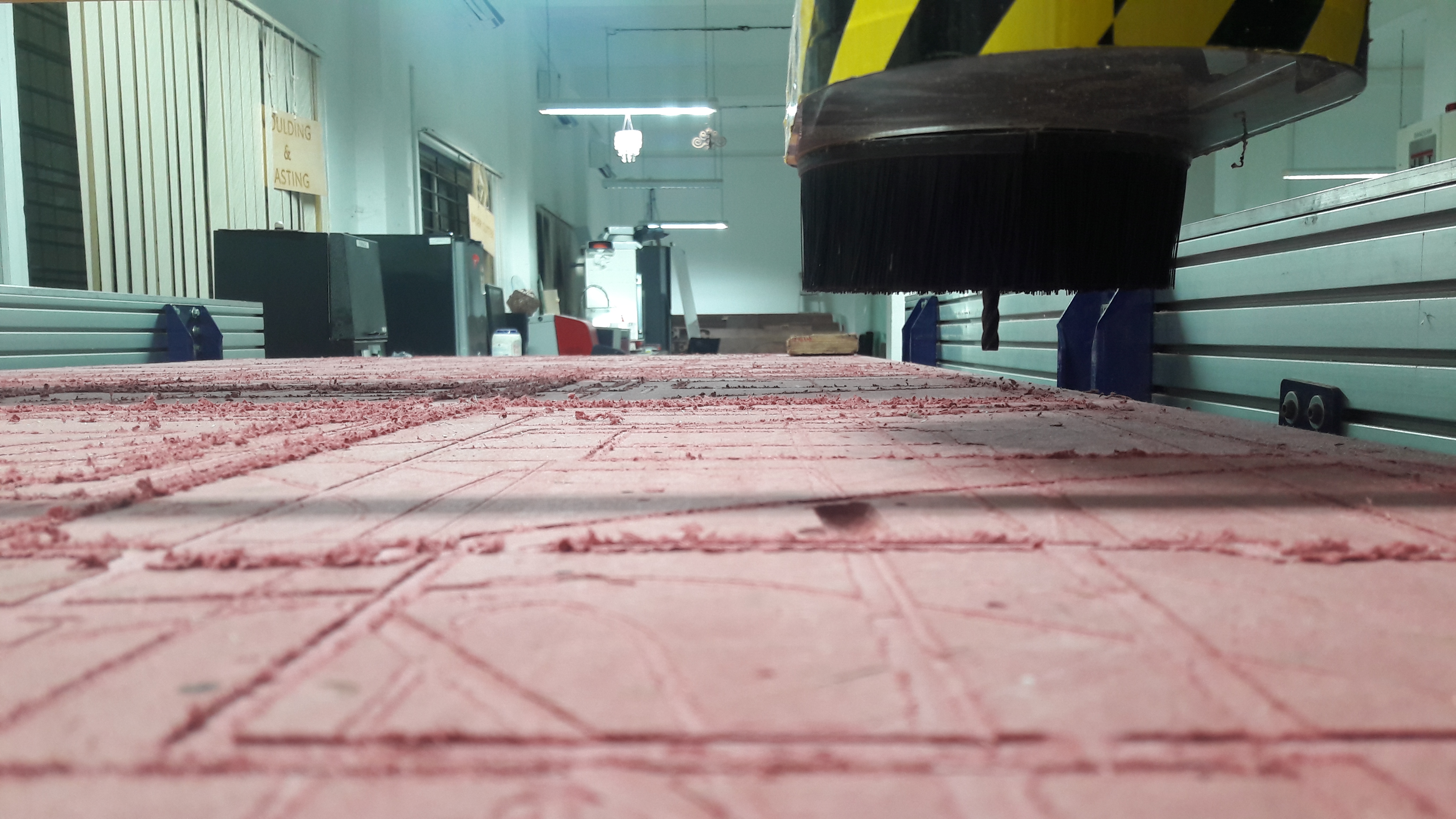

The X and Y axis are for Horizontalmovements. The vertical movement is covered by the Z-Axis. The Z-Axis contains "Spindle" and "Vaccum". Spindle contains the drill bit. Vaccum helps to clean the bed.

The end of the Vaccum is connected to a suction vaccum cleaner.

Control Box

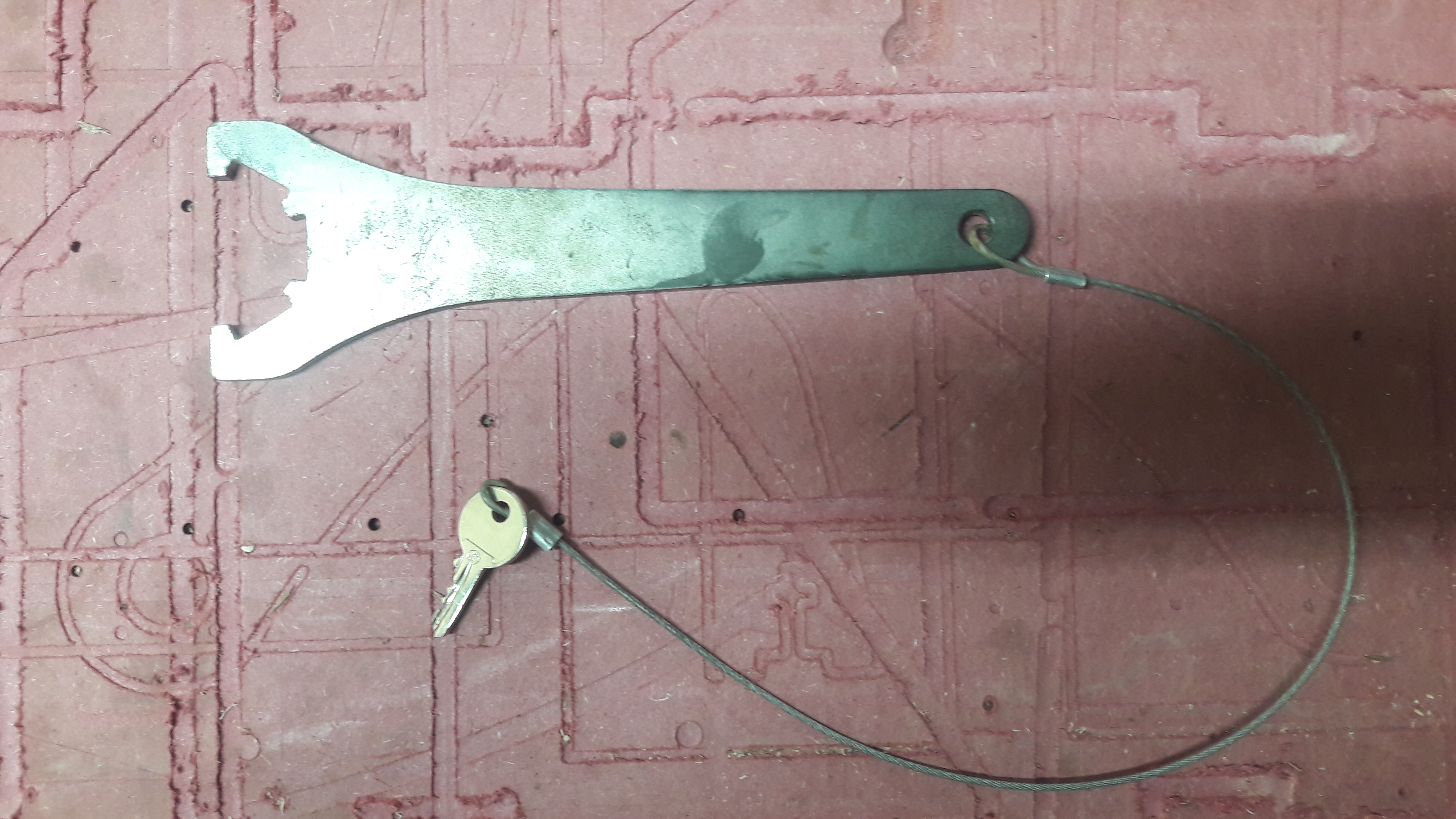

Spindle Key and Spanner

We need the Spindle Key to Start the Spindle without the key spindle will not rotate.

Vacuum Systems

ShopBoat have a Powerfull Vacuum system.This is every helpful during the cutting process.

Bits Specifications

Bit material:Router bits used in Shopbot are made from a variety of materials such as solid carbide, carbide-tipped steel, and high-speed steel.

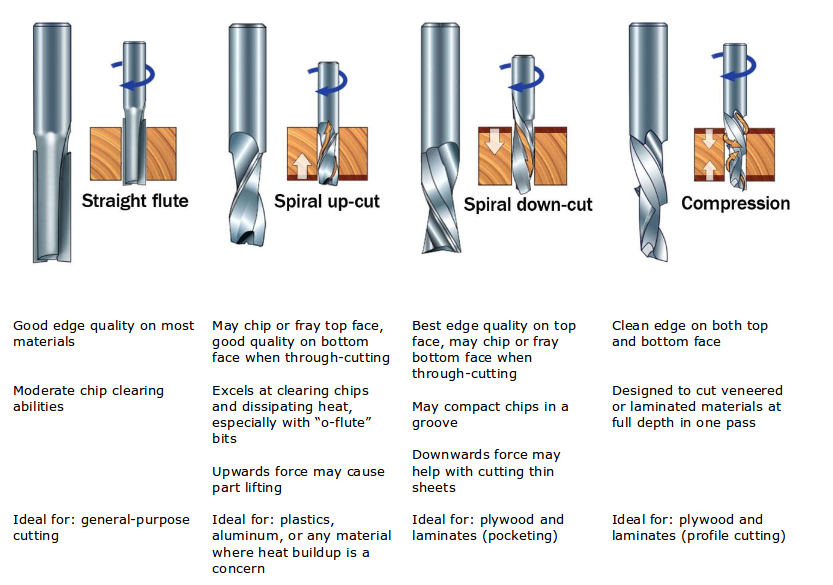

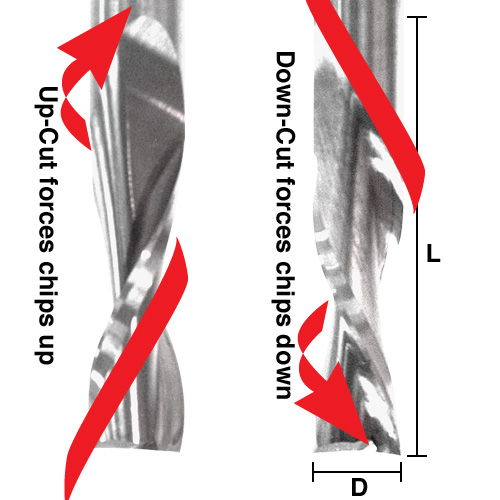

Flute type : There are four basic flute types: Straight, spiral up-cut, spiral down-cut, and compression

Drill bit Vs End mills :A drill bit need to cut straight into the material hence will have teeth at tip. But an End mill needs to cut from the sides also, that means it needs to have a cutting edge spiraling all the way up to the flute.

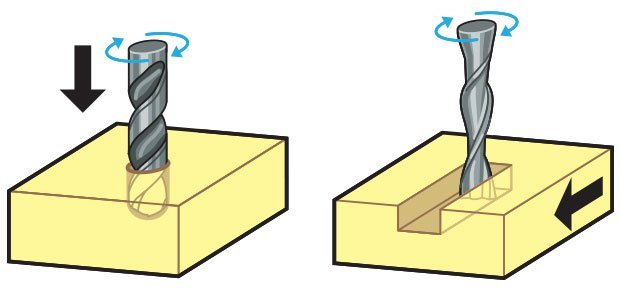

Upcut & Downcut

In an Upcut type end mill the teeth on the flute will point upwards. This means that the end mill is cutting and drawing out the wood through the flute. This is good for cutting deep into the stock. But this leaves a bad surface finish on the top of the surface. A downcut type end mill has teeths that point downward on the flute. This means that the end mill will cut and try to push the material into the stock. This will give good surface finish on the top, but it is not very efficient at removing material.

Flat/ball end

Flat end leaves flat surface profile on the stock and are good for removing large volume of material, but steps are formed when used for making curved surfaces. Ball end leaves curved surfaces and forms smooth curved finish while cutting cavities. They are used for finishing cuts.

Collet and Covernut

A collet is a subtype of chuck that forms a collar around an object to be held and exerts a strong clamping force on the object when it is tightened. It may be used to hold a workpiece or a tool. We are using ER25 collets, ER collets are slotted (alternately) from both ends and therefore compress onto the cutter along the whole length of the collet when tightened. This not only provides a better grip on the cutter shank but also allows some variation (typically 1mm) in shank sizes that may be used in a single collet. The smaller size collets are best used to hold cutters no more than 0.5mm below the nominal size. Collets are inserted into the covernut.

ESTOP Switch

ESTOP switch is Emergency STOP switches are used for stopping the work during emergencies there are two emergency stop switches will be there, One is ESTOP box which contains two additional switches one for Starting the spindle and the other for Reset. Ensure these ESTOP switches are in the OFF position position by rotating the RED STOP button on the DONGLE COUNTER CLOCKWISE

Safety First

Safety is very important while working with the big machines like Shopbot CNC.

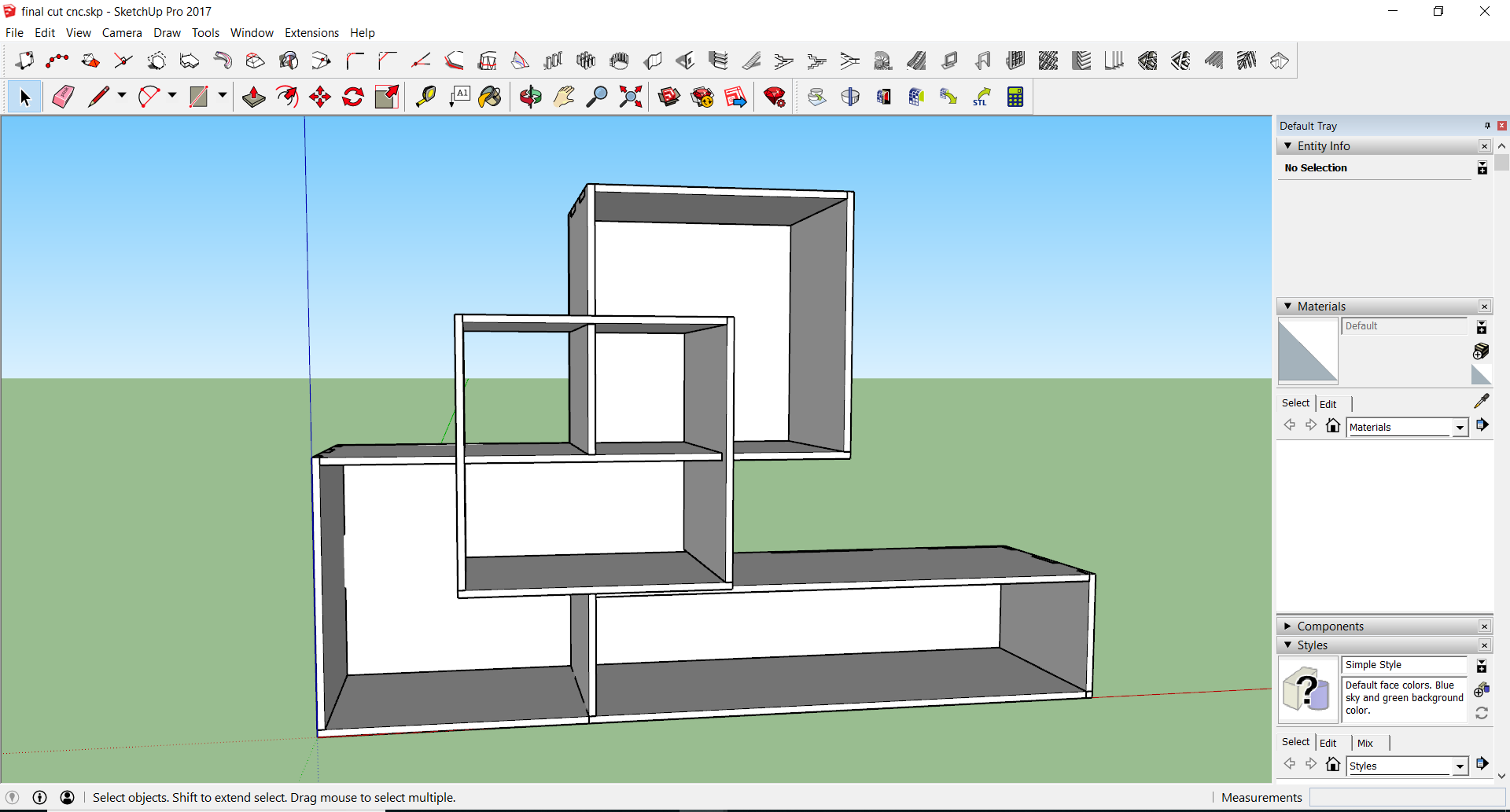

DESIGN

You can download the render lumion file from here.

Machine Setup

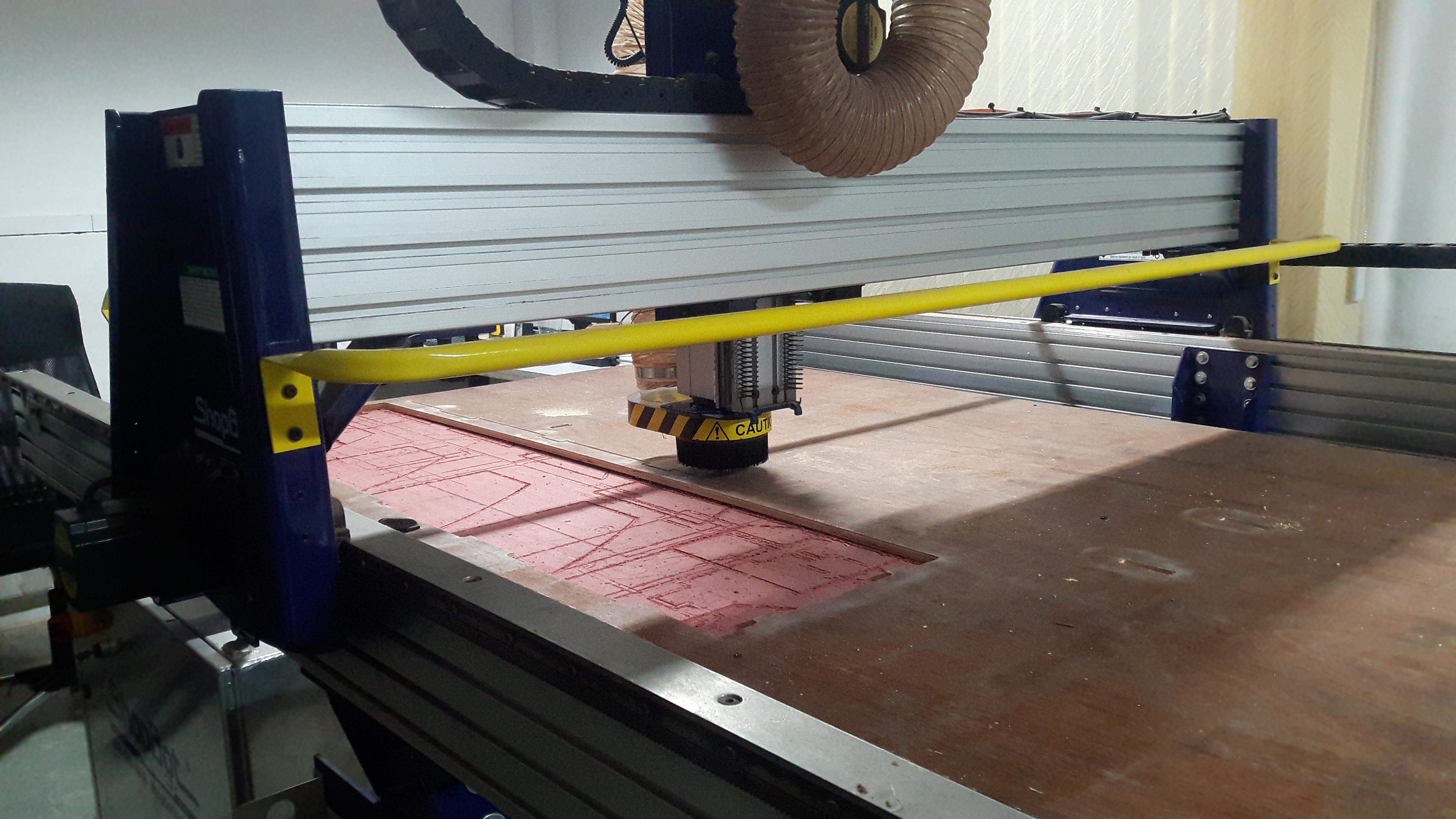

We need to setup the machine before Cuting, so first clean the sacrificial layer and load a new Plywood.

I used 12 mm plywood

So we have prepared the work piece. Now we need to cut it.

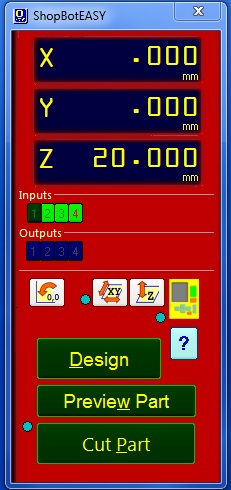

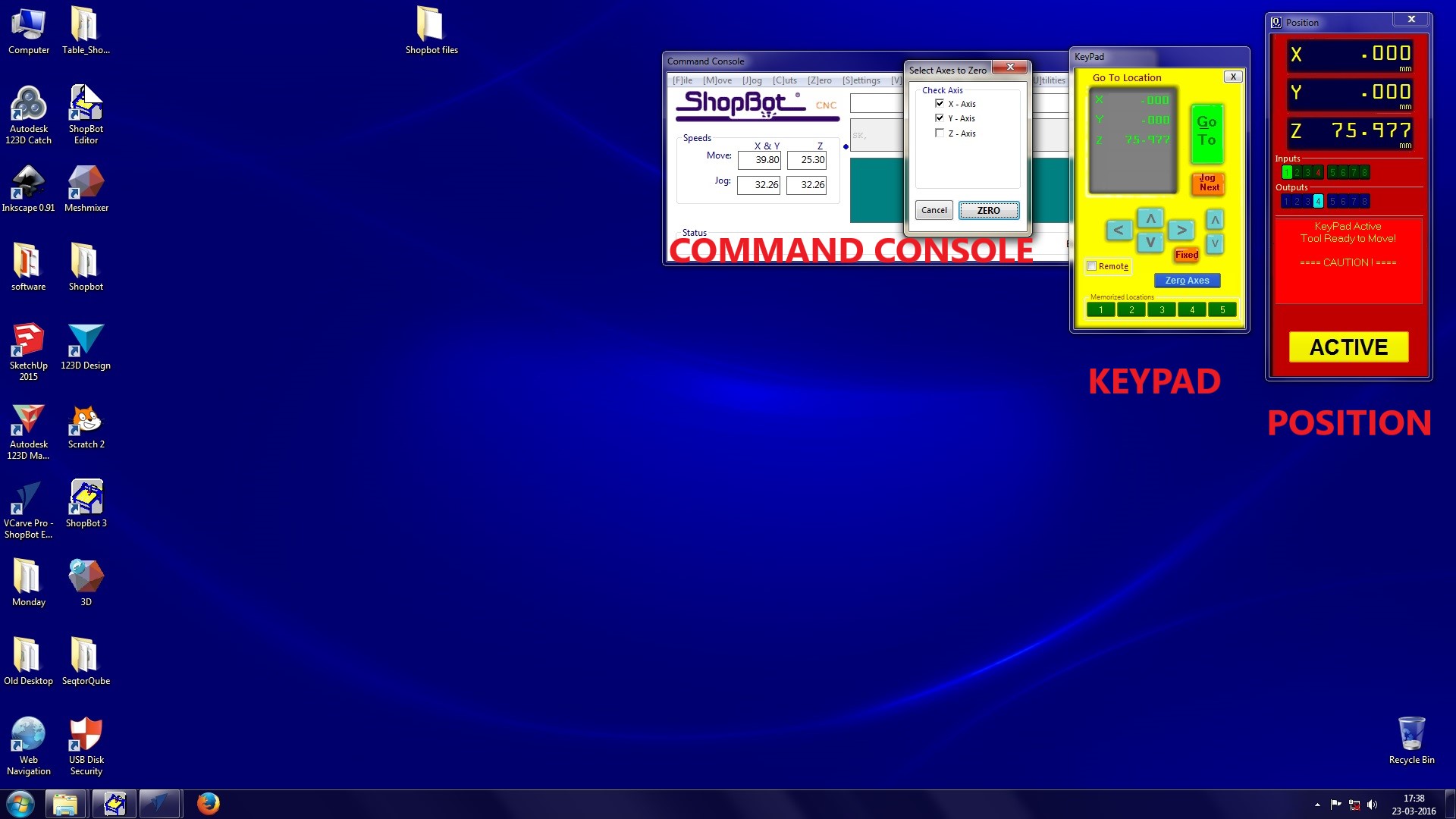

For that open CNC controller.

Now we need to reset the axes from the previous work. For that twist the controller in the control box and push Reset button.

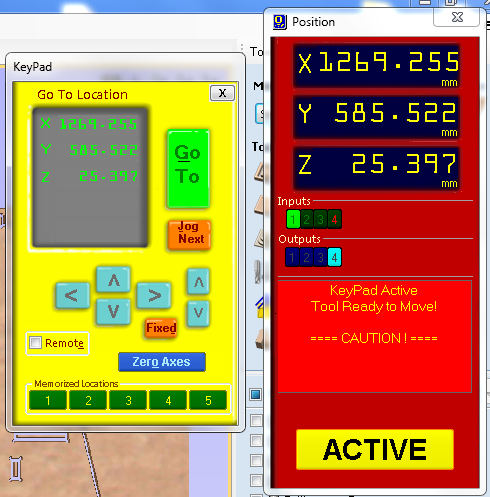

Now position the control box and set X,Y and Z axes.

then Click on zero axis and Tick all the boxes.

We can adjust the X and Y axis by usig the Arrows in the software, after that we need to set the Z axis.For setting the Z-axis we have a plate which is electrically connected to the machine.Place the plate on the surface and the machined is moved on z axis to touch the plate.This completes the circuit and z axis is marked.

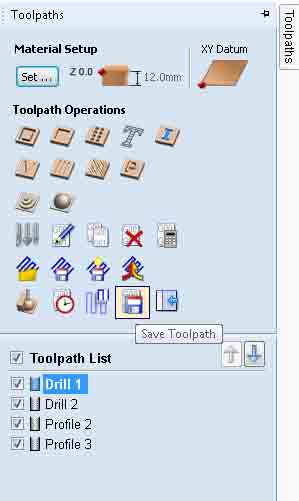

Next we need to Generate the .sbp file from our design file, we are using V-carv Pro Shopbot Edition software.

Next i added Dogbone for fitting the Pressfit and also added the Tab to fix the cut part so it will stay with the balance part.

I used Draw Circle tool to Draw the Dogbone.

Click the button "Save Toolpath to File" and save it.

Next we have to open the file in the shopbot application.

The software has a simulated DRO(Digital read out) and it has 3 main parts

A position fedback main window .It shows the status of all the functional parats of the machine.

A simulated keypad for manual jogging and setting origins

An Integrated command console.

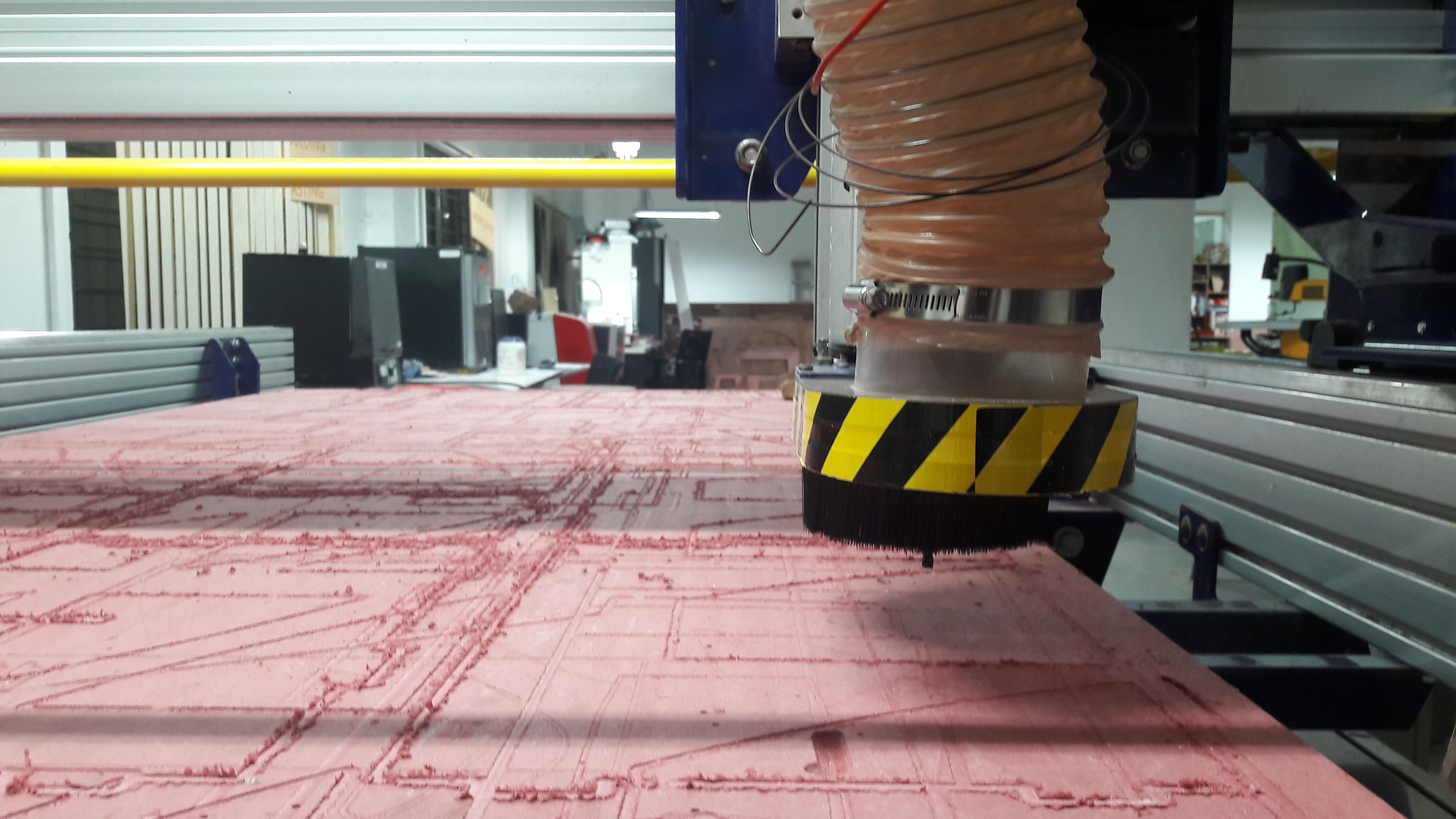

Cutting

Now we need to add the design file needed to be cut. For that click on "Cut Part". Open the first file and follow these steps.

Click start

Click "start" button to start the spindle.(Make sure to turn the key on.)

Click "ok" on the screen

The process will start immediatly.

I added the drill holes first to fix the work piece to the bed.

After fixing them to the bed, I started milling the rest of the pieces.

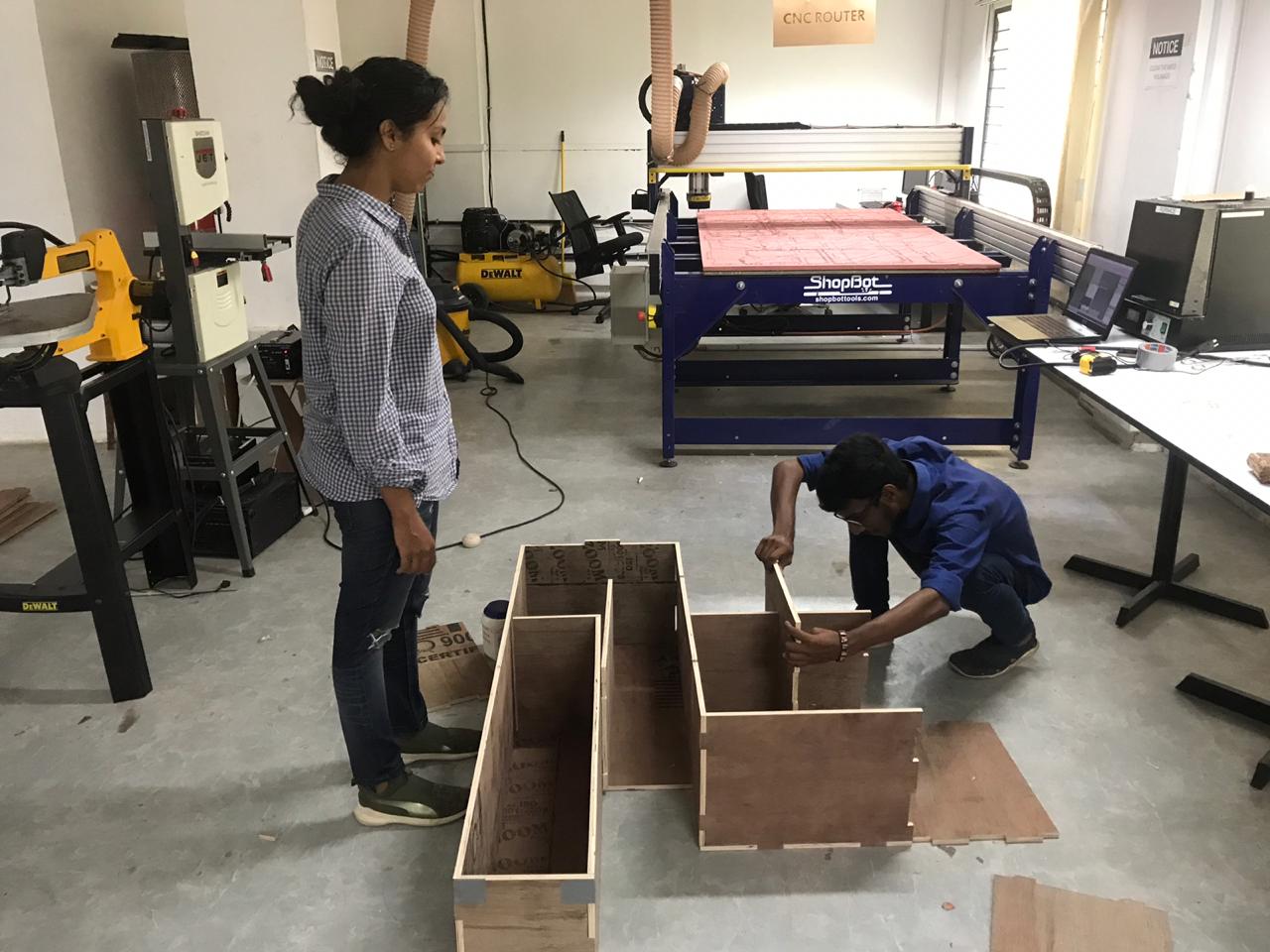

After milling all the pieces i started assemblying the parts.due to minute errors some portions was not properly pressfit.I used screw to correct the error and make it firm.

You can download the whole project from here.

HERO SHOT

Group Assignment

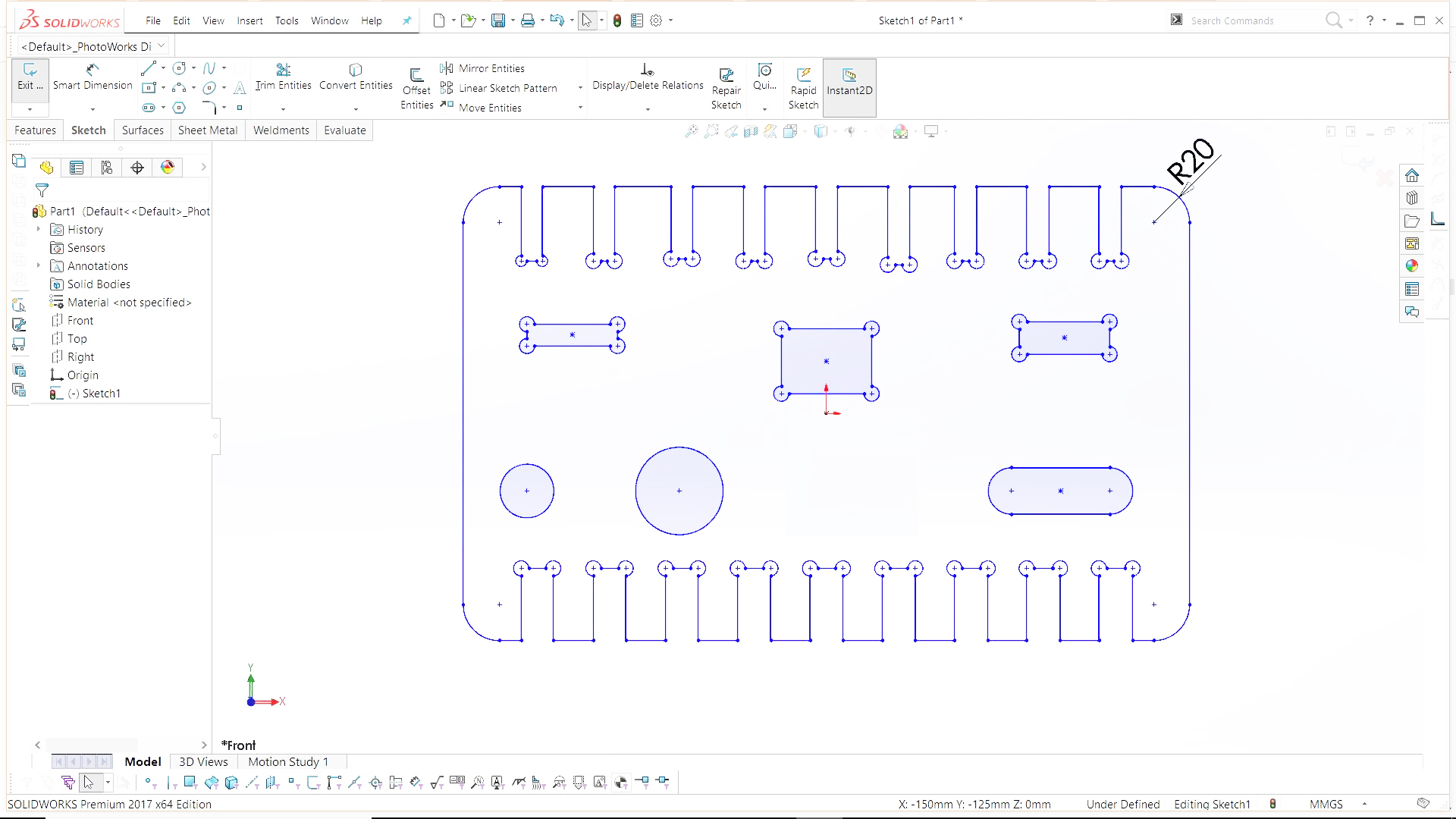

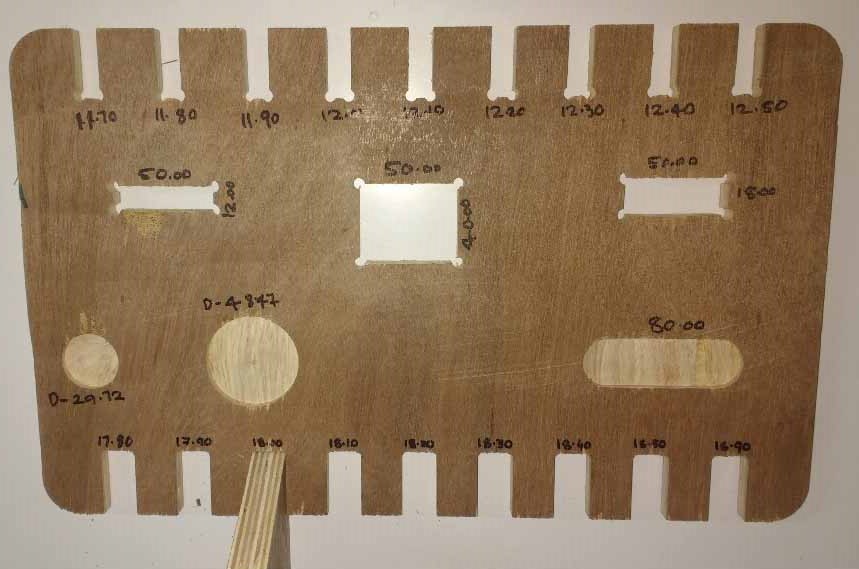

Test runout, alignment, speeds, feeds, and toolpaths So for testing some parameters in shopbot, we have designed a structure in Solidworks.

This was our group assignment to find the press fit dimension for the 12mm and 18 mm plywood .So we cut slots from 18.90 to 17.80 in steps of 0.1mm and for 12mm from 11.70 to 12.50 in steeps of 0.1 mm. We found out that the right fits comes somewhere near 18 mm and 11.7 mm.