Back to Mónica Pedro ←main page ←Assigments

individual assignment:

design a mold around the stock and tooling that you'll be using,

mill it (rough cut + (at least) three-axis finish cut),

and use it to cast parts

group assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

Started to print the model I thought on using as a Necklace for my niece

To undestand and analyse the aesthetics of the idea, Then went to Milling workflow...

since I'd made the print from a fusion360 design, id exported it to DXF

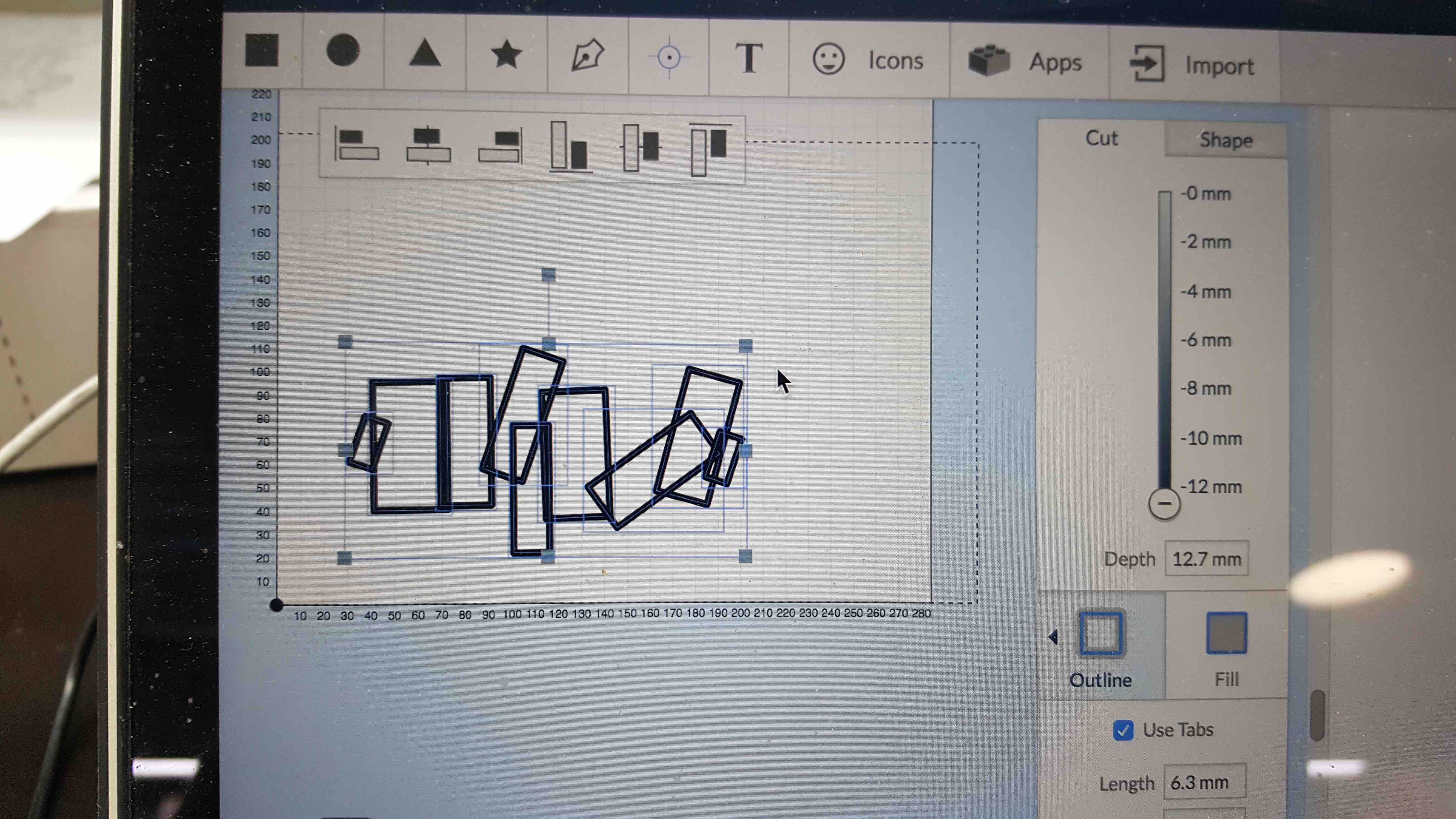

open the DXF in EASEL, and got this Bad result

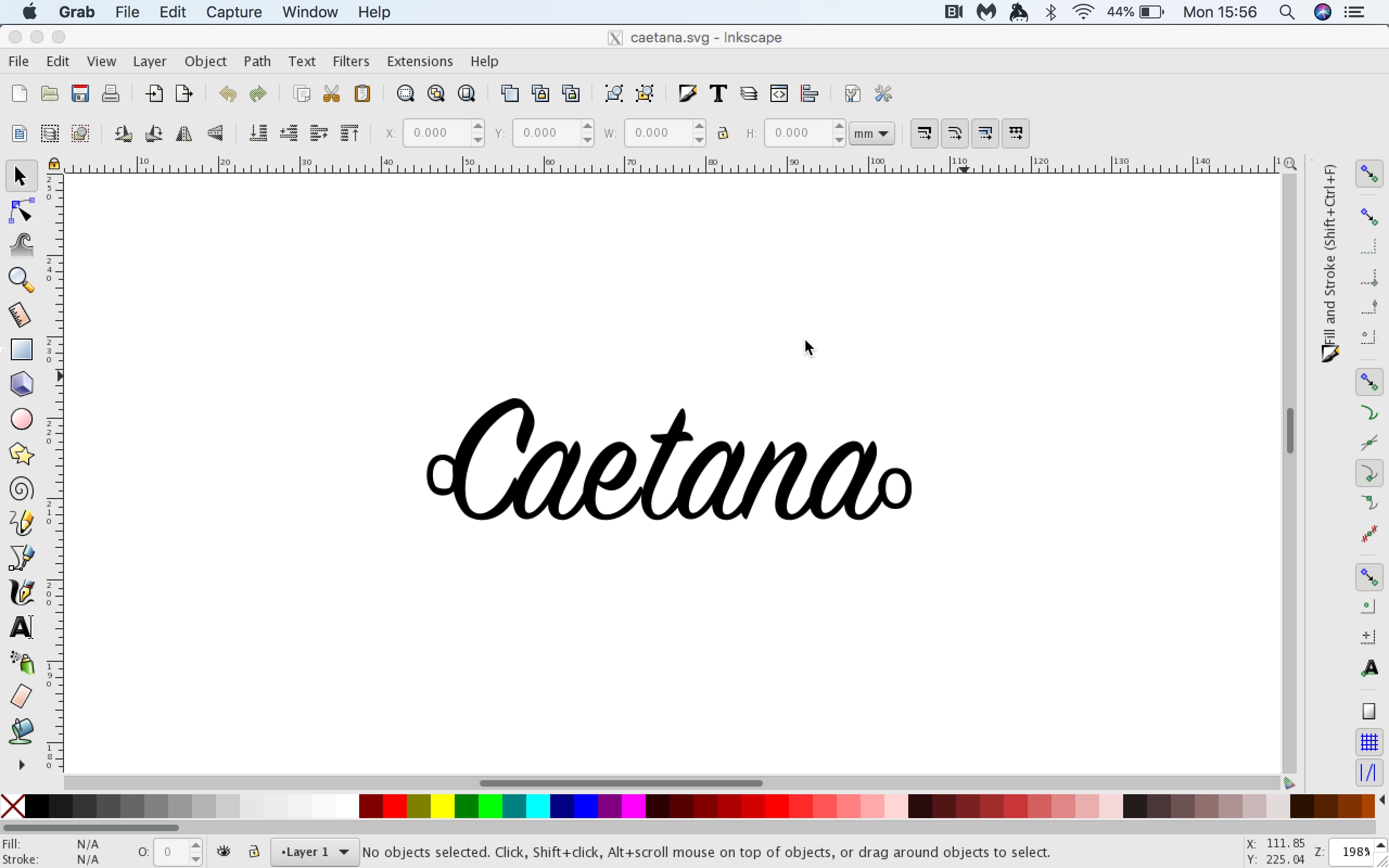

So I decided to went to Inskape to make a new design...

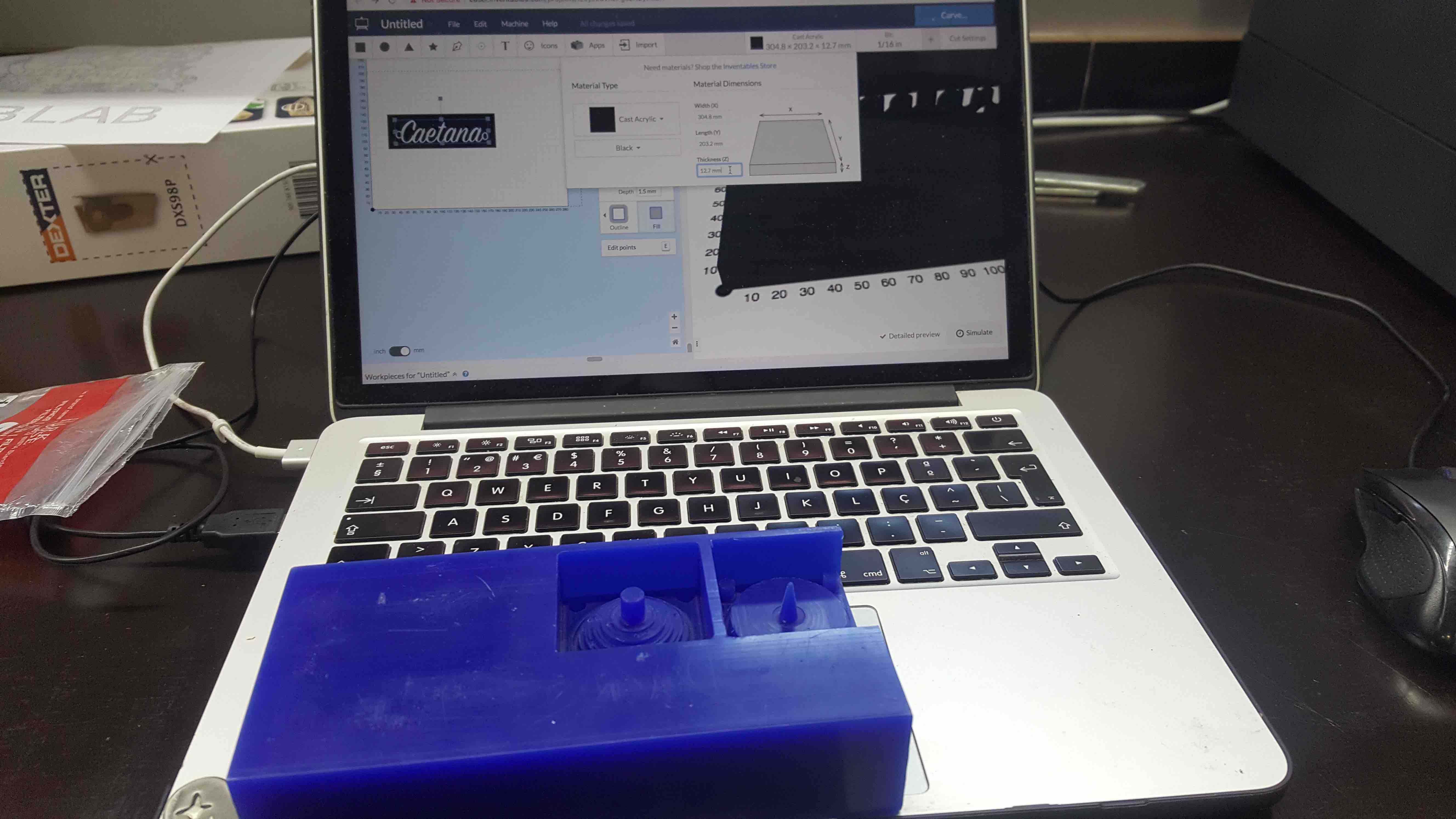

This was ok for Easel...

But CarveY does not have the Z-axis enought to cut the Resin of 34 mm thickness, so we decided to use MDF as material for the molding...

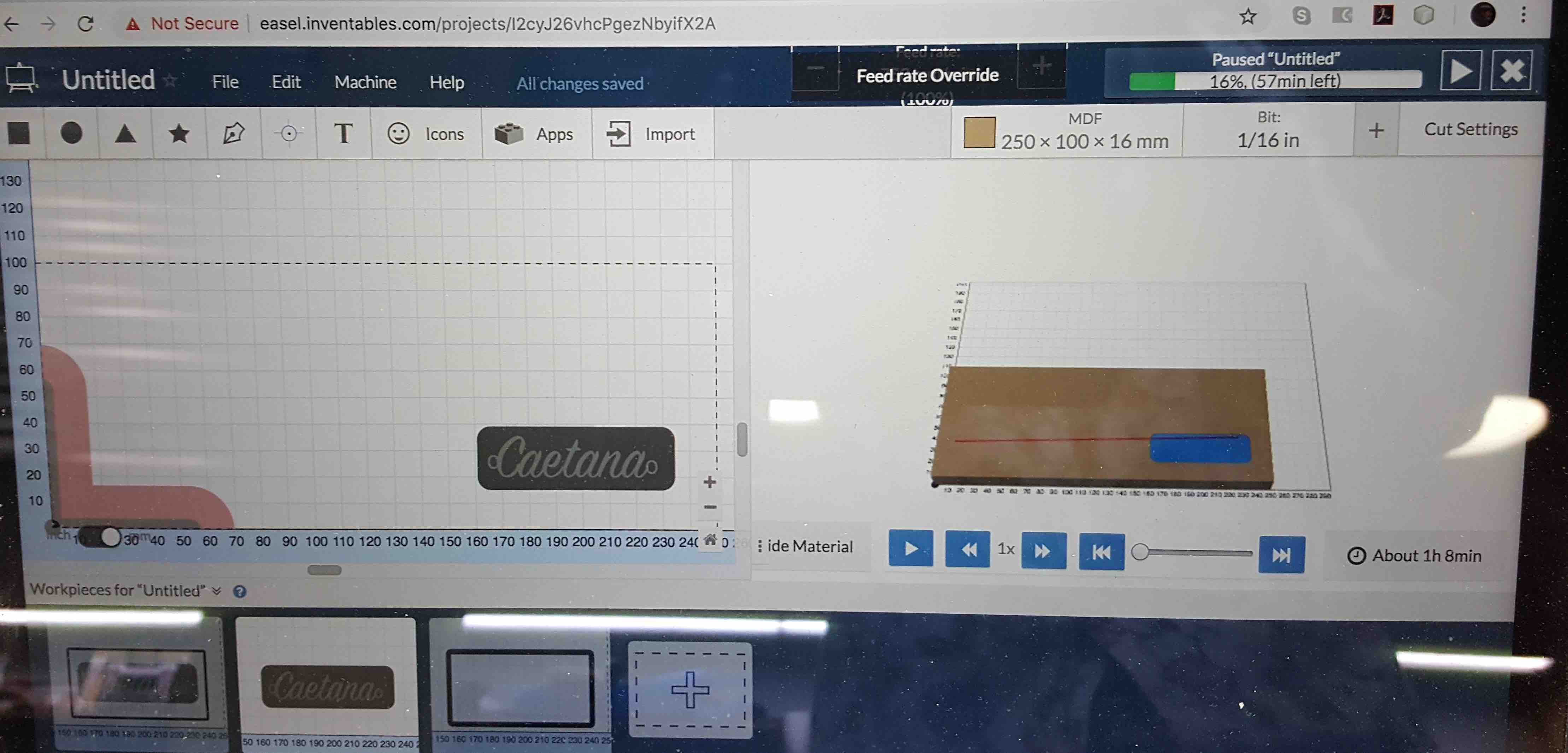

Opened the file in online program EASEL

with the following settings:

Locally we'd just this two bits:

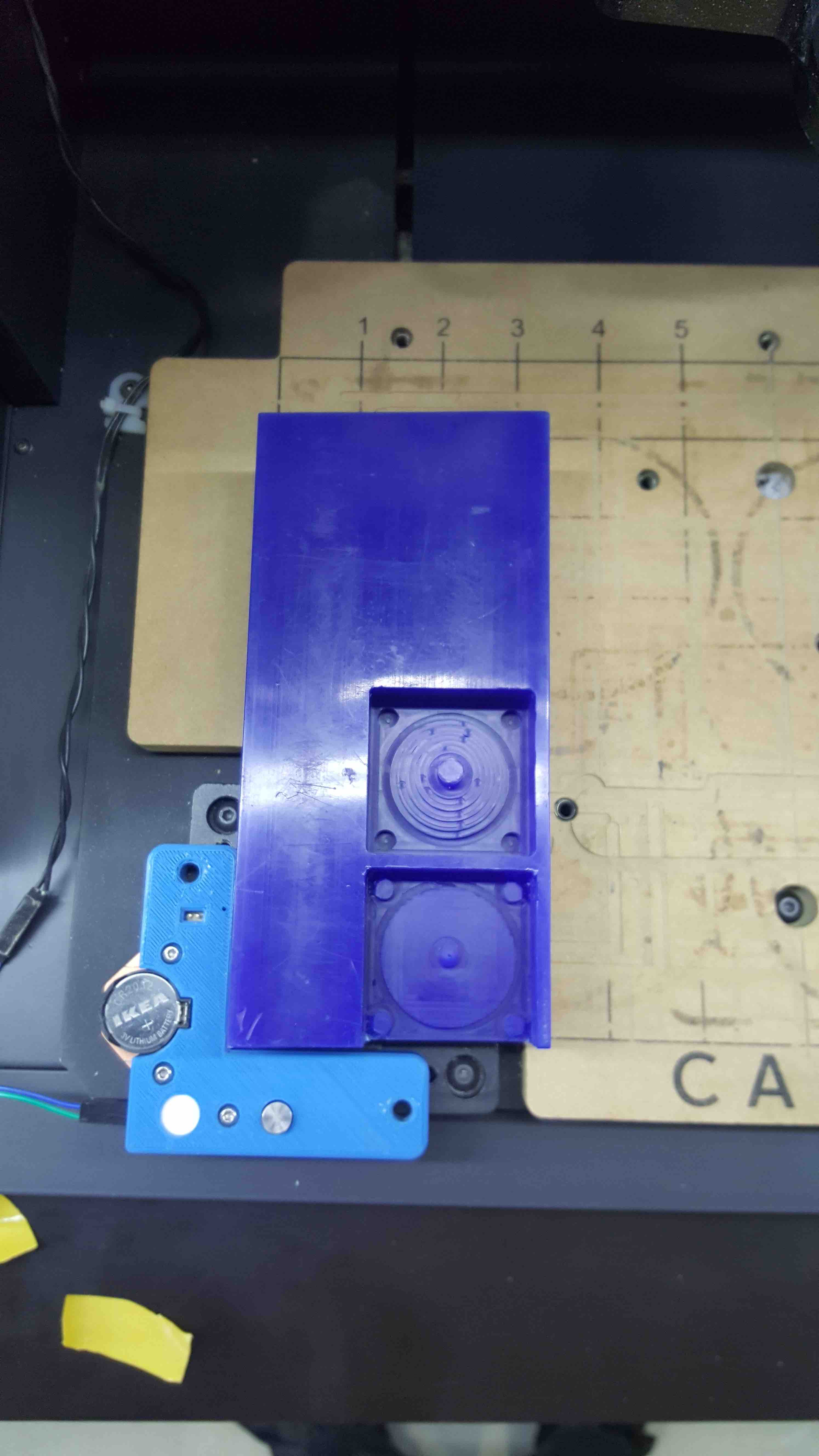

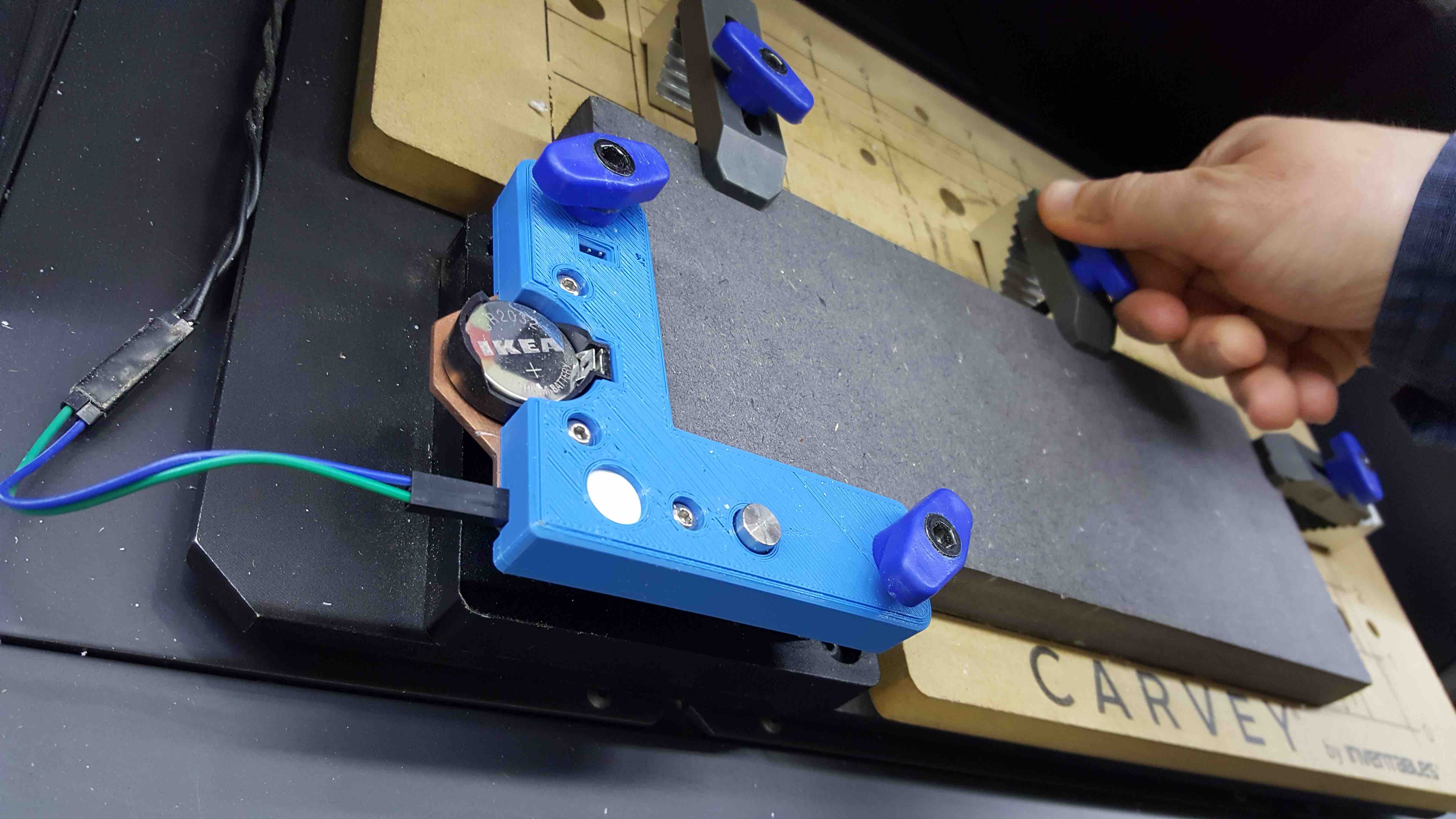

It is important to well secure the MDF to cutting bed....

after milling, due to the absorption of MDF, I'd used Verniz to prepare the Molding