GROUU small nursery is a proof of concept for the modularity behind my project and firs proposal.

The first was aimed at developing a few modules to prove de system (see W12 - output devices, designed in 2017, a control board for a peristaltic pump module)

The intention now is to develop a tidal seedling tray.

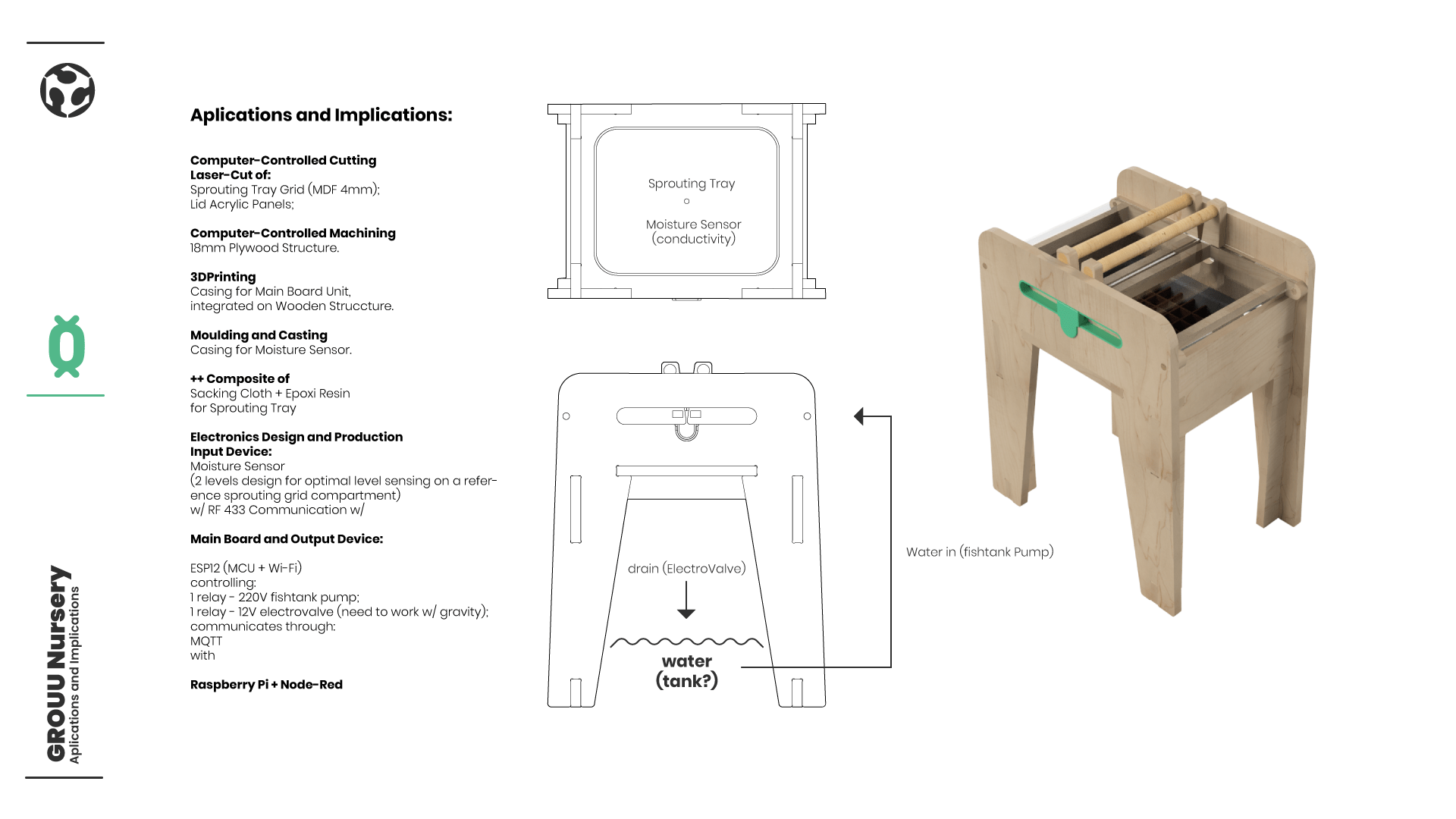

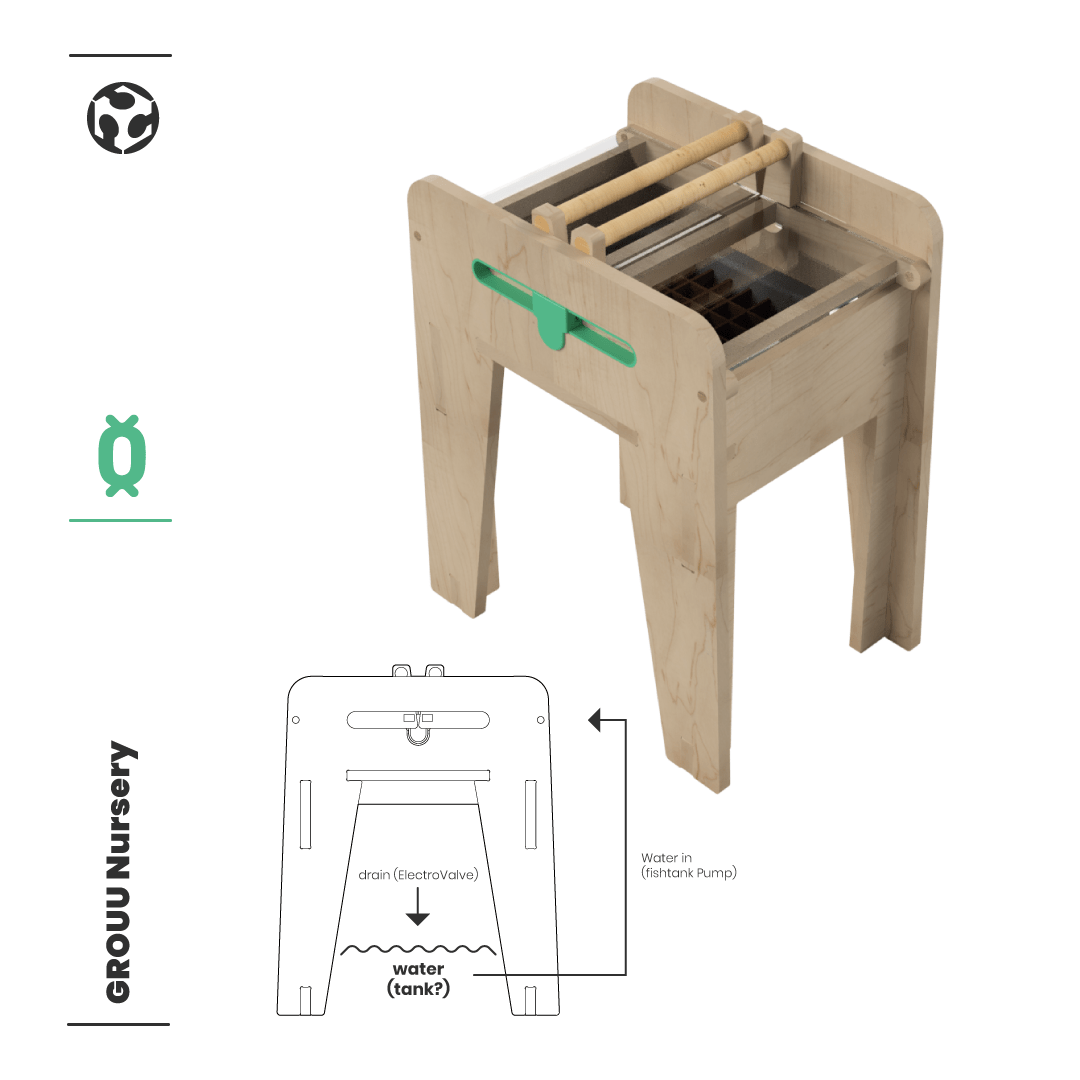

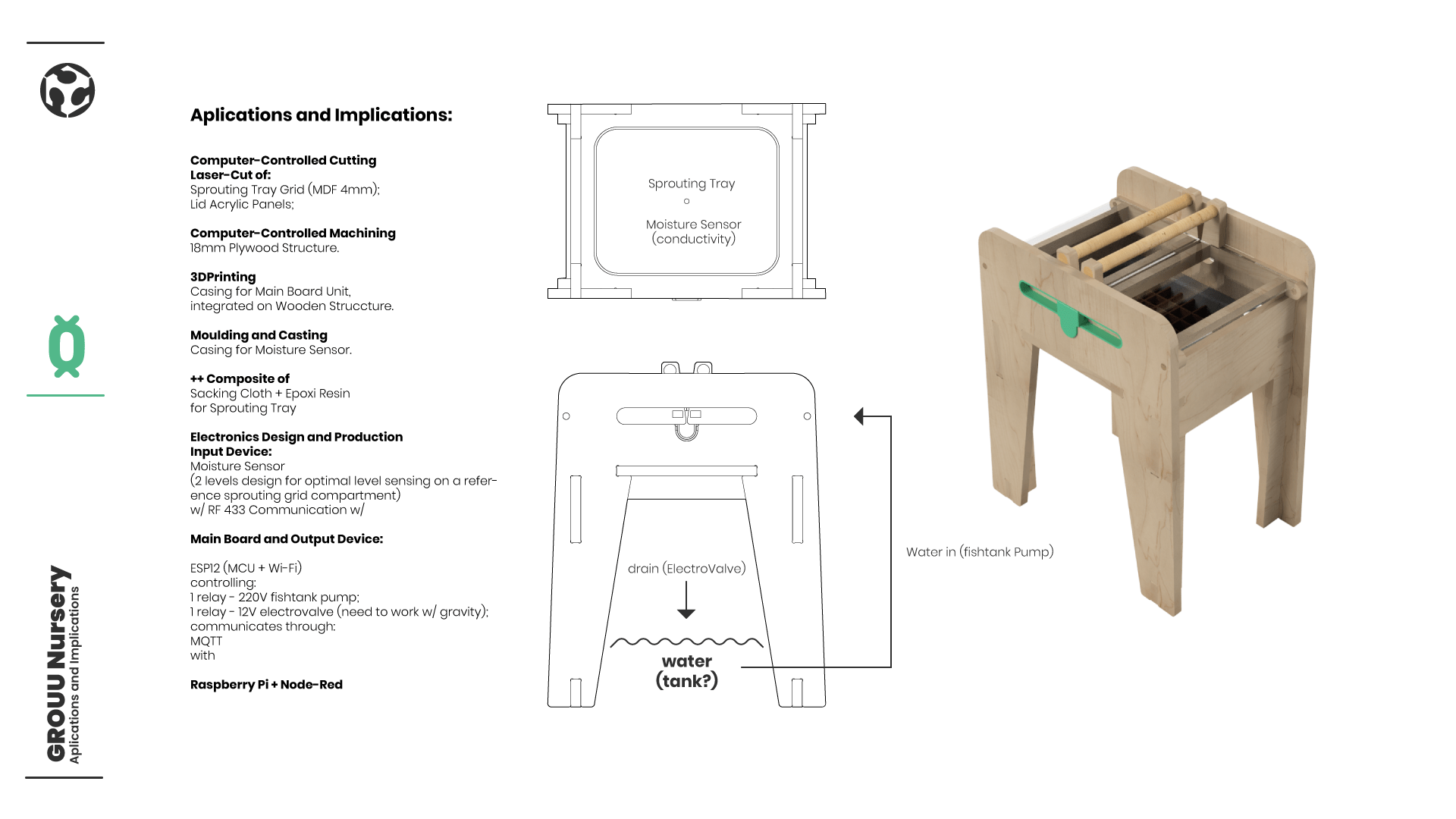

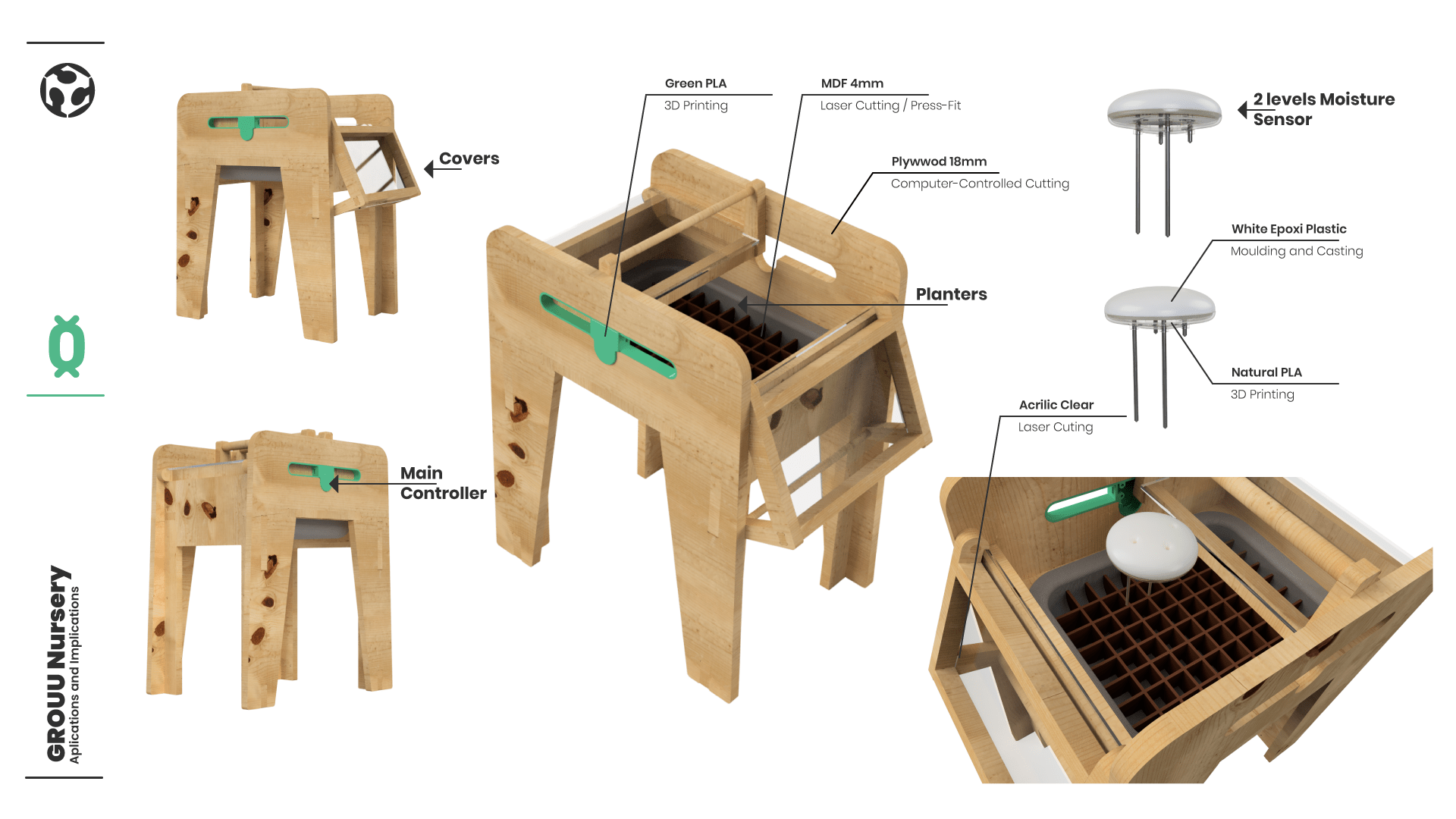

In this case, it combines a wireless moisture sensor board and an actuation module, which will trigger a small pump or an electric motor valve able to drain the remaining excess of water in the system.

The rest of the object allows me to practice different skills and techniques at the Fablab.

Parallelly, I left a larger copy of the system in Greece, where I will remotely orient further developments.

Arduino and all derivative projects have been looking quite interested in Automated Smart Precision practices in Agriculture and Farming. It is a vast IoT area, and a lot has been done already.

My personal interested as to do with:

I will design a small domestic furniture module / mini-greenhouse, and an automation module which will control the tides in a seedling tray inside. The automation will follow the measurements of a wireless moisture sensor, also placed inside the tray.

For this, I will need: