COMPUTER - CONTROLLES MACHINING

The present assignment represents a challenge, since I have always manufactured small pieces in millimeters, and this time I have to make something of very large dimensions.

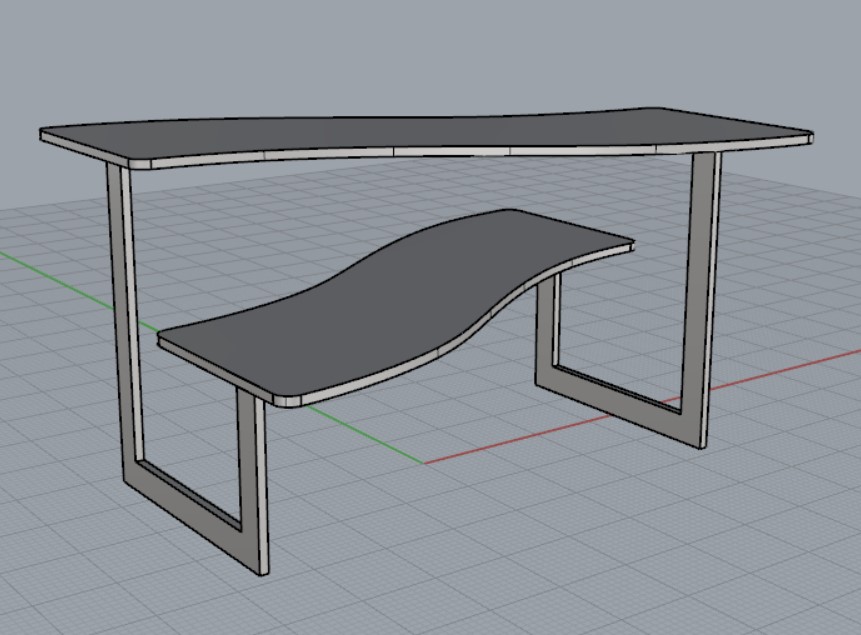

In the development of this work, I first made the design in Rhinoceros to obtain the parts of the model to work, which will be a coffee table. Then I will pass the design file to lines, in this way to be able to use the CNC machine with which we have in our FabLAb.

STEPS TO TAKE

2D and 3D design

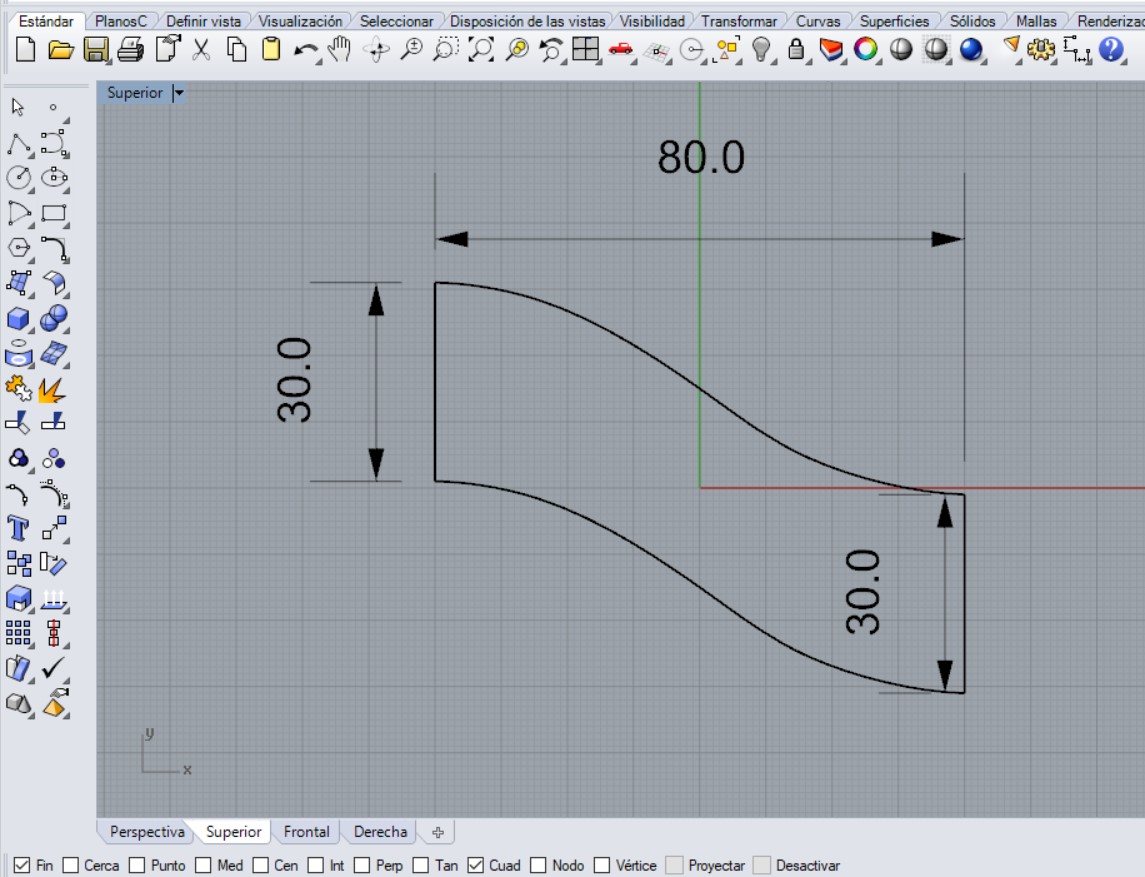

After thinking about the design of the coffee table, I start drawing the lines in Rhinoceros.

The following image shows the design of the lid in centimeters.

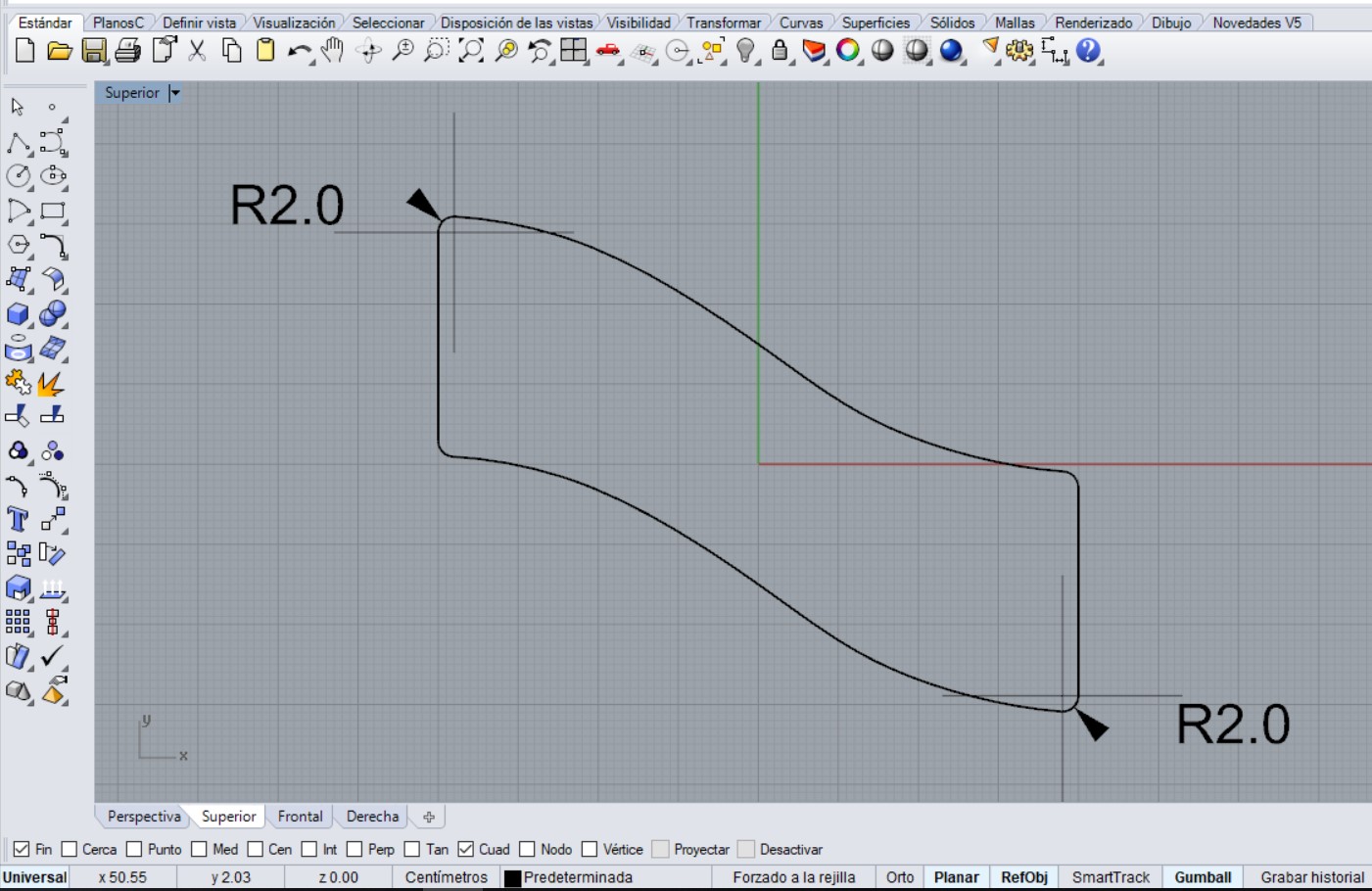

Before continuing with the design, I will round the corners to avoid users getting hurt with the table.

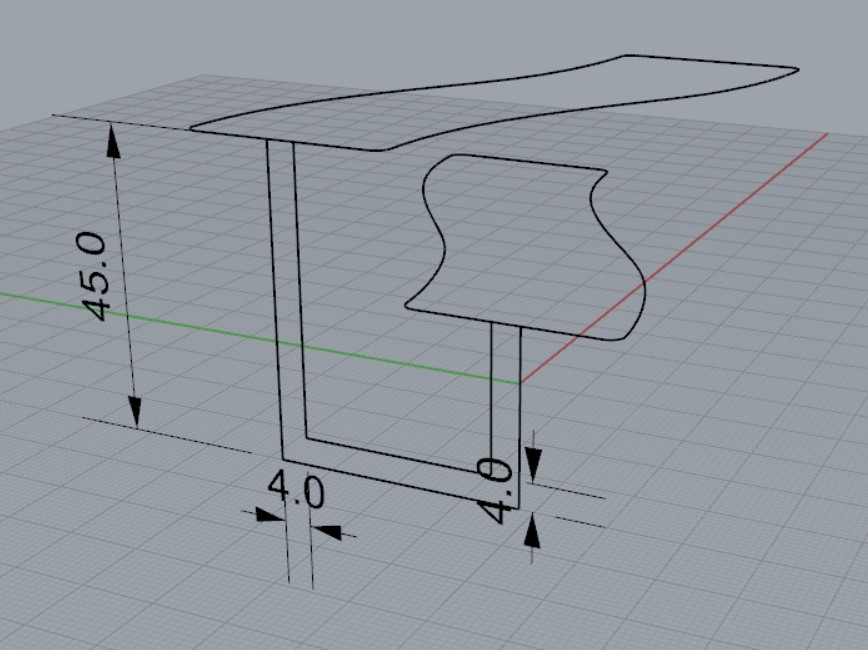

With the information I got from the internet, I saw that the suggested measure for the height of the table is between 40 cm and 45 cm, with this data I draw the lateral part (Supports for the covers).

Now with the complete line drawing, I proceed to represent in virtual form the thicknesses of the material, for this case I will use material with a thickness of 12 millimeters.

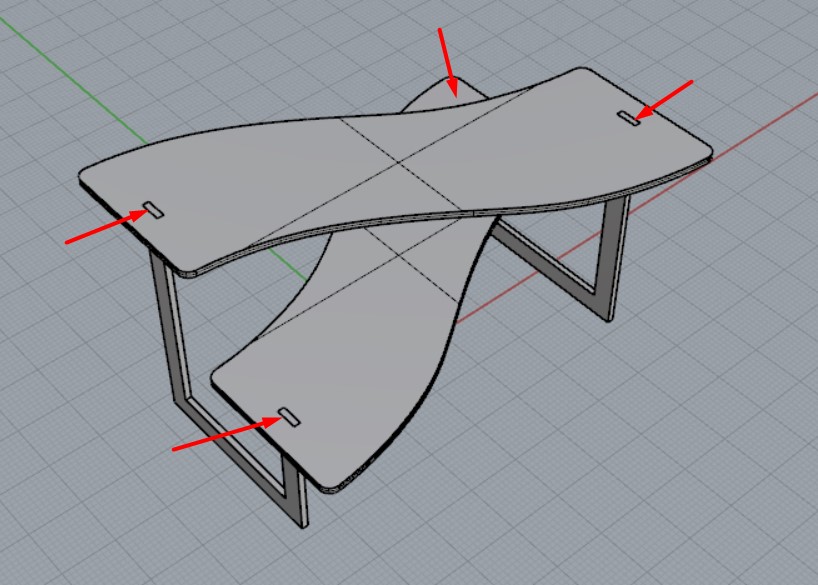

It is now necessary to generate the holes to be able to have the couplings between tables and supports.

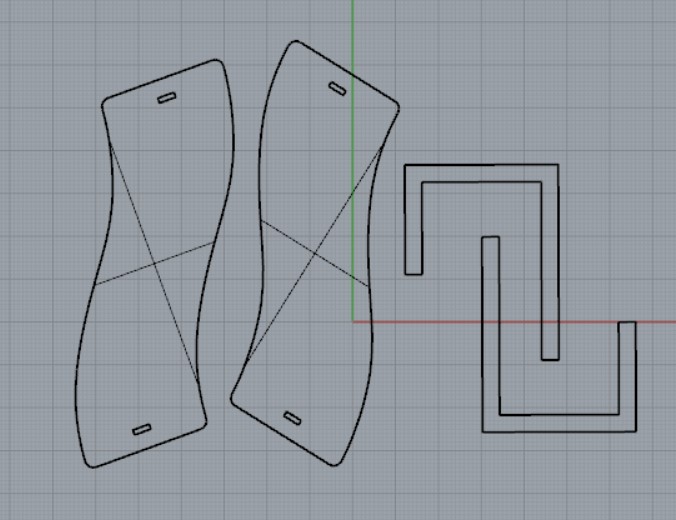

Ready, now to distribute the pieces for the respective cut in CNC.