Electronics

Production (week 05)

†† Group assignment: characterize the design

rules for your PCB production process. For this section reader is referred to Bomi Doh section.

†† Individual

assignment: make an in-circuit programmer by milling the PCB (AVR ISP),

program it, then optionally try other PCB processes.

Several

things have to happen before this week assignment minimum requirements are to

be met. The first step is of course, designing the PCB circuit before soldering

components on it and then program the programmer so it will serve its purpose

in future electronic programming to come.

For this part we

will be using:

Eagle software to

design the PCB traces. (Eagle software)

FlatCam to generate the

G-Code needed on the CNC side. (FlatCam

software)

Soldering station

available in EchoFab

To program the

programmer itself, I opt for Arduino IDE software

BOM List:

|

Part†††† Value††††††††† Device††††††††††† Package†††† Library† Sheet |

|

|

|

C1†††††† 10pf†††††††††† CAP-US1206FAB†††† C1206FAB††† fab†††††

1 |

|

C2†††††† 10pf†††††††††† CAP-US1206FAB†††† C1206FAB††† fab†††††

1 |

|

C3†††††† 1uf††††††††††† CAP-US1206FAB†††† C1206FAB††† fab†††††

1 |

|

D1†††††† 3.3v†††††††††† ZENER_DIODESOD123 SOD123††††† fab†††††

1 |

|

D2†††††††††††† †††††††††ZENER_DIODESOD123 SOD123††††† fab†††††

1 |

|

IC1††††† ATTINY44-SSU†† ATTINY44-SSU††††† SOIC14††††† fab†††††

1 |

|

R1†††††† 1k†††††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R2†††††† 100††††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R3††† †††100††††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R4†††††† 499††††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R5†††††† 0ohm†††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R6†††††† 0ohm†††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

R7†††††† 10k††††††††††† RES-US1206FAB†††† R1206FAB††† fab†††††

1 |

|

U$1†††††

AVRISPSMD††††† AVRISPSMD††††††††

2X03SMD†††† fab††††† 1 |

|

U$2††††† CRYSTAL††††††† CRYSTAL†††††††††† 2-SMD-5X3MM fab††††† 1 |

|

U$3††††† USB_MINIB††††† USB_MINIB†††††††† USB_MINIB†† fab†††††

1 |

Designing PCB:

Normally one needs

to select all components needed, declare the links between them and then

generate the routes. This time, our facilitator, Francois Auclair

provided us with the full eagle project file and therefore we did not need to

attend this step.

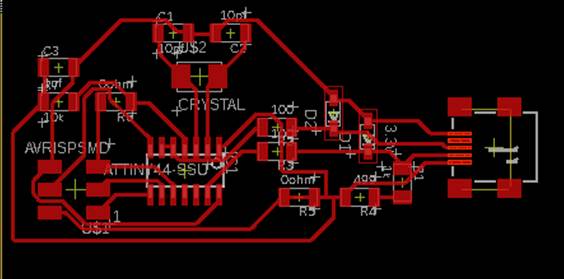

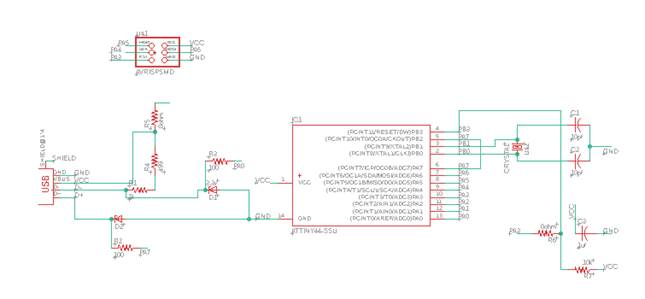

Find here views of

the schematic and board

From

this point forward, the necessary steps were done individually as follow (Onto FlatCam!!):

Into

Eagle project space a Gerber file was generated and fetch into FlatCam. This step needs to happen to translate, with

milling specification, the Gerber file into a (metric here) CNC G-Code file before

we can carve the PCB.

Specifically,

we used here the copper top Gerber

file into FlatCam software.

Here

in EchoFab, we retain by default the following

settings (preference) into FlatCam to mill our boards:

∑

Tool diameter: 0.1

∑

Pass number: 7

∑

Pass overlap: 15%

∑

Milling in climb mode

∑

Combine passes

Next step is to set geometry before we

can generate the G-code itself.

Critical for us are,

∑

Cut Z depth: 0.0508

∑

Travel Z: 10

∑

Feed rate rapids: 700

∑

Spindle speed: 24000

Next

step is to generate the CNC job object, transfer it to the CNC machine and cut

the board.

Note: In reality two files are

generated with more or less the same settings, one is the trace file (described

here before) and the second one is the profile (perimeter) of the PCB. This is

essentially done in the same manner with a bigger tool and single Z pass, only

deeper, to cut the piece out.

The

CNC machine we are using is made so that the X and Y axes homing is

mechanically assumed. On the other hand, Z homing position has to be done

manually.† Setting Z coordinates take

advantage of the conductivity of both the milling bite and the copper surface.

Essentially Zero position is done by using conductivity detection on a

multimeter. One probe in contact with the copper board, the second with the

bite waiting for the conductivity to show up on the multimeter while manually

the Z probe system is lowered. Upon contact we know, if steps are small, that

we are at the first limit of contact and Z relative positioning can be set.

Thereafter,

carving trace is only a matter of executing the G-code, supervising the process

in case of a fail and make a quick quality control assessment (visual

inspection) before we are to solder the components onto the board.

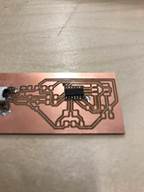

Miscellaneous

images of the milling process:

NB: Annie Ferlatte

and I have traced and cut-out our board in a single sheet, this was a first

attempt to be cutting two boards in a single run, saving raw material.

Essentially this implicates noting coordinate for the first board to be carved,

then carving the second before both are extrude of the surface while re-using

previously noted home position of the first one.

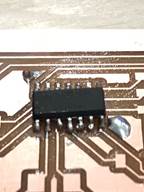

Satisfied

with the board cutting, itís now time to turn to the welding of the components

onto the copper traces.

Surface

mount soldering is a technic to acquire, but in my case the challenge was very

much it, a true challenge! I have lost my reading glasses and cannot properly

see were Iím to solder. I know how but I simply canít see well. So, after

several attempt with the aid of a USB microscope I had to come to turn with my

handicap. I managed to solder the parts on the paths, but results were far from

being satisfactory. Some welding Iíve done, aiming at the pad before being

blinded by the soldering rod, hoping, praying even that I would get it bull

eyeís, led some splattering all over the place. Eventually I opt for liquid

welding and got better results but not on this journey (see upcoming weeks).

Miscellaneous

images of the soldering process:

†

But

for now, the board is soldered and now we need to program it so it will become

an AVR ISP.

The

sequence of command is an easy one:

∑

Lorem ipsum dolor sit amet, consectetuer adipiscing elit.

Maecenas porttitor congue massa. Fusce posuere, magna sed pulvinar ultricies,

purus lectus malesuada libero, sit amet commodo magna eros quis urna.

∑

Nunc viverra imperdiet enim.

Fusce est. Vivamus a tellus.

∑

Pellentesque habitant morbi

tristique senectus et netus et malesuada fames ac turpis egestas. Proin

pharetra nonummy pede. Mauris et orci.

∑

Aenean nec lorem. In porttitor. Donec laoreet nonummy augue.

∑

Suspendisse dui purus, scelerisque at, vulputate vitae,

pretium mattis, nunc. Mauris eget neque at sem venenatis eleifend. Ut nonummy.

A

note: Here are presented the overall process we used answering this week

assignment. But in reality, for a fairly long time all team members here at EchoFab had a problem with the programmer we were trying to

make. Facilitator from our lab and others joined their neurons trying to

understand what was going on. After troubleshooting all possibilities, it was

realized that the Zinner diodes we were using were

rated to high for our needs. Replacing the faulty parts with the right ones,

solved the problem and we were able to move forward.†