-

Assignment

Computer-Controlled MachiningComputer-Controlled Machining

This week is defferent!! We are planning to make somthing big! using our amazing CNC Routre machine. During Nile's lecture I imagined that I'll make furniture parts and do somthing cool.

In our FABLAB, we have Shopbot The Full Size PRSalpha CNC (96 inchs x 48 inchs x 6 inchs) with their softwares (VCarve and shopbot)

VCarve is used to generate the suitable file for the CNC out of any design file (I used pdf and svg) and the output will be like Gcode. The shopbot software is used to run the machine and send the file that generated by VCarve. I did some tests to explain the speed and different jobs like (profile, pocket, and drilling)

There are two main prameters in CNC router machine, feed rate: the speed of the spindel movement in x and y. Plunge rate: the speed of the spindle movement in z. I can get the values from this Document

Then I moved forward to start designing the part that I thought about. It's creative table consists of 6 parts and you can arrange them in different ways to make the full shape and form. The following picture shows the designs and will be clear more in the next photos after setting it up and butting the parts togather

Then I saved the design file as pdf to import it using VCarve software. I opend VCarve software once again and clicked on file>>new then I changed the settings according to the machine dimension and my file (2400mm * 1200 mm). Also, I have to change the thickness, I'm using 18mm MDF sheet and finally the start point.

Dealing with such machines, you have to know more about the bits and cutting method because it's totally different from one way to another. I planned to make the cut using V-bit. So. I can get carved edges (cutting with slop)

I'v selected all the parts (6 parts) and clicked on porfile to make the cutting. As for the cut settings , first I determined the cut depth 18.7 mm to ensure the cut to be more than sheet thickness (18mm)

I set the number of passes as 3 so it will finish the cut by passing over the edges 3 times and the depth for each one will be 18.7/3 mm. I selected outside to cut the same outer dimensions

I set the number of passes as 3 so it will finish the cut by passing over the edges 3 times and the depth for each one will be 18.7/3 mm. I selected outside to cut the same outer dimensions

Then I moved to select the bit that I'm going to use (V-bit) 60 degree which was defined before as we defined all the bits that we have to use them directlly. As for the bit that I'm going to use, the spendle speed will be 12000 rpm, the feed rate 100 inch/min, the plunge rate 30 inch/min

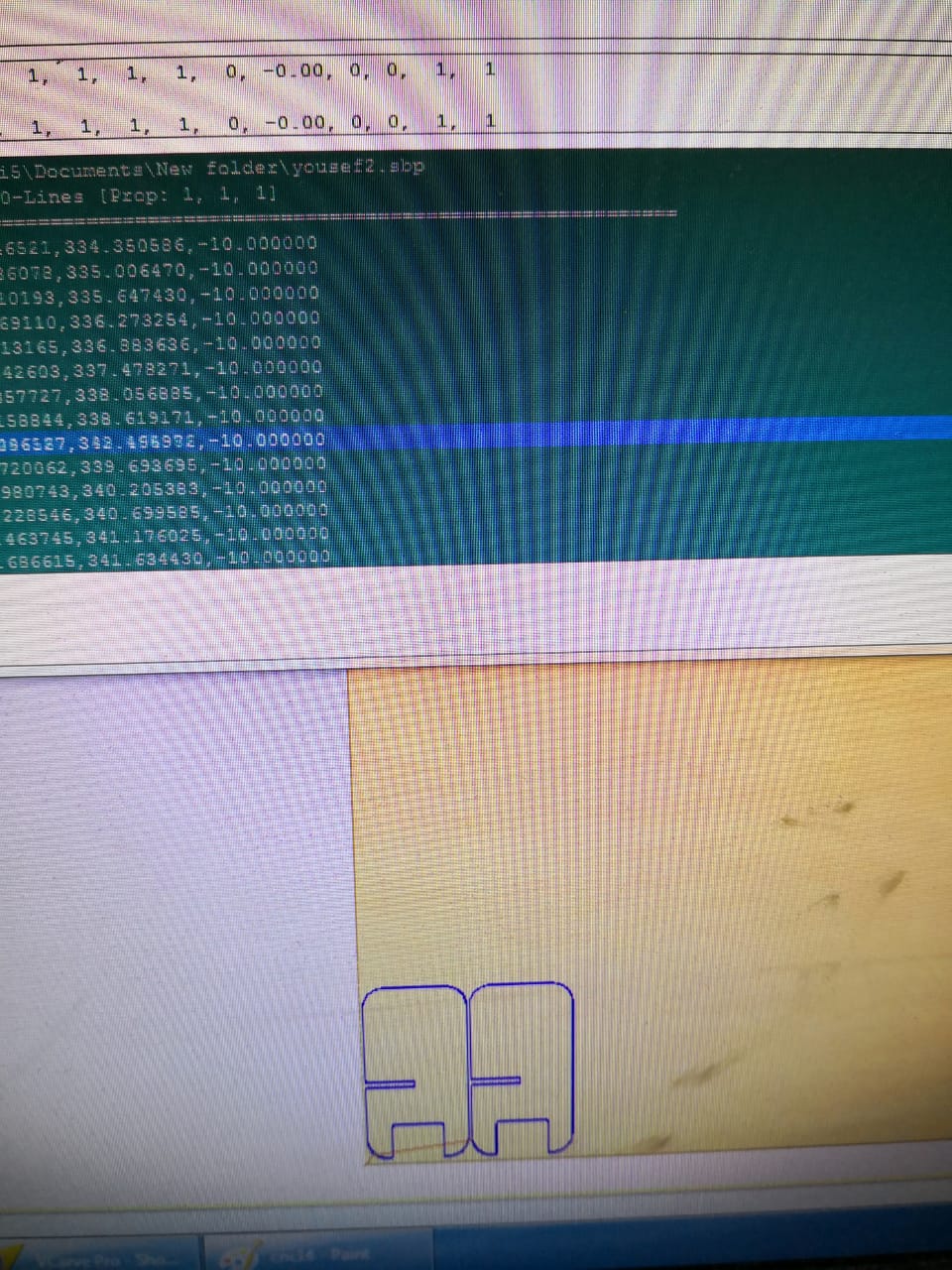

Finlly, I got the file ready to import in the Shopbot software. Befor saving the file, the program shows us the passes and router movement as shown below

I purchased table legs from IKEA Store in order to fix them to complete the project

Once I finished the cutting, I started the painting process. It was hard somehow because I need two different colors. The first one is yellow and the second one is white. The edges will be yellow and the top will be white

I used paper tape to cover the edges while painting the top. And the same thing (covering some top to paint the edge). So, I did it finally

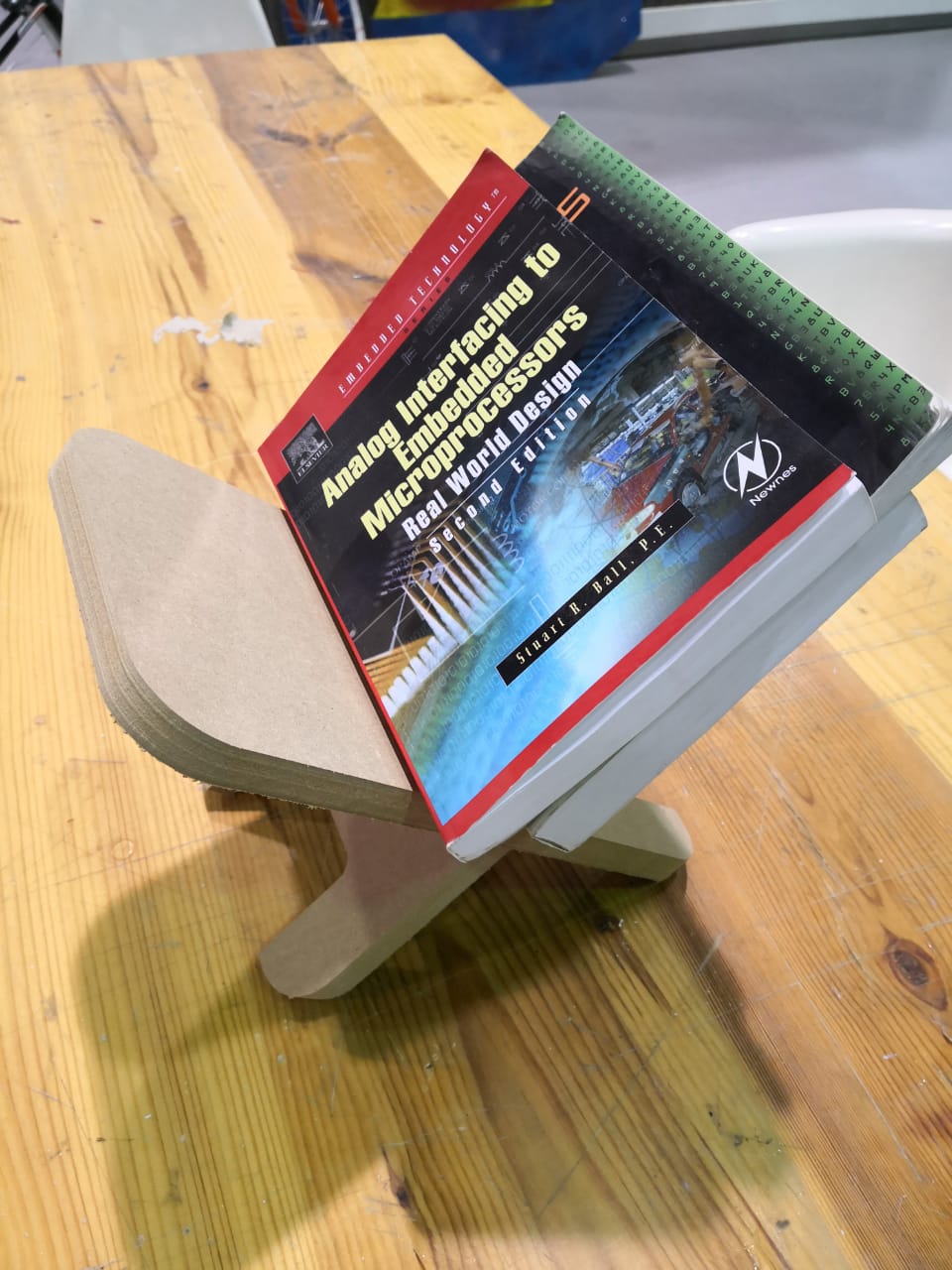

Now, start thinking to do something with joints with no screws. I want to design a book/s holder. Designing a project with joints need to know the material and material thickness I'm going to use

I created new document using Onshape, I started sketching by simple rectangular, then I curved the edges, after that I did a joint and it should be the same as the material thickness, So it's better to use the variable once you edit the material thikness the joint will be suitable accordingly

I copied the shape and extrude it by 18mm, the joint should be the same as the two parts should be fixed together

I clicked on the assembly tap and used the fastening tool to fix them together

Starting the job with 1/4" upcut bit. As for the bit that I was going to use, the spindle speed 12000 rpm, the feed rate 210 inch/min and plunge rate 90 inch/min

Taking the parts from the main sheet after complete the cut

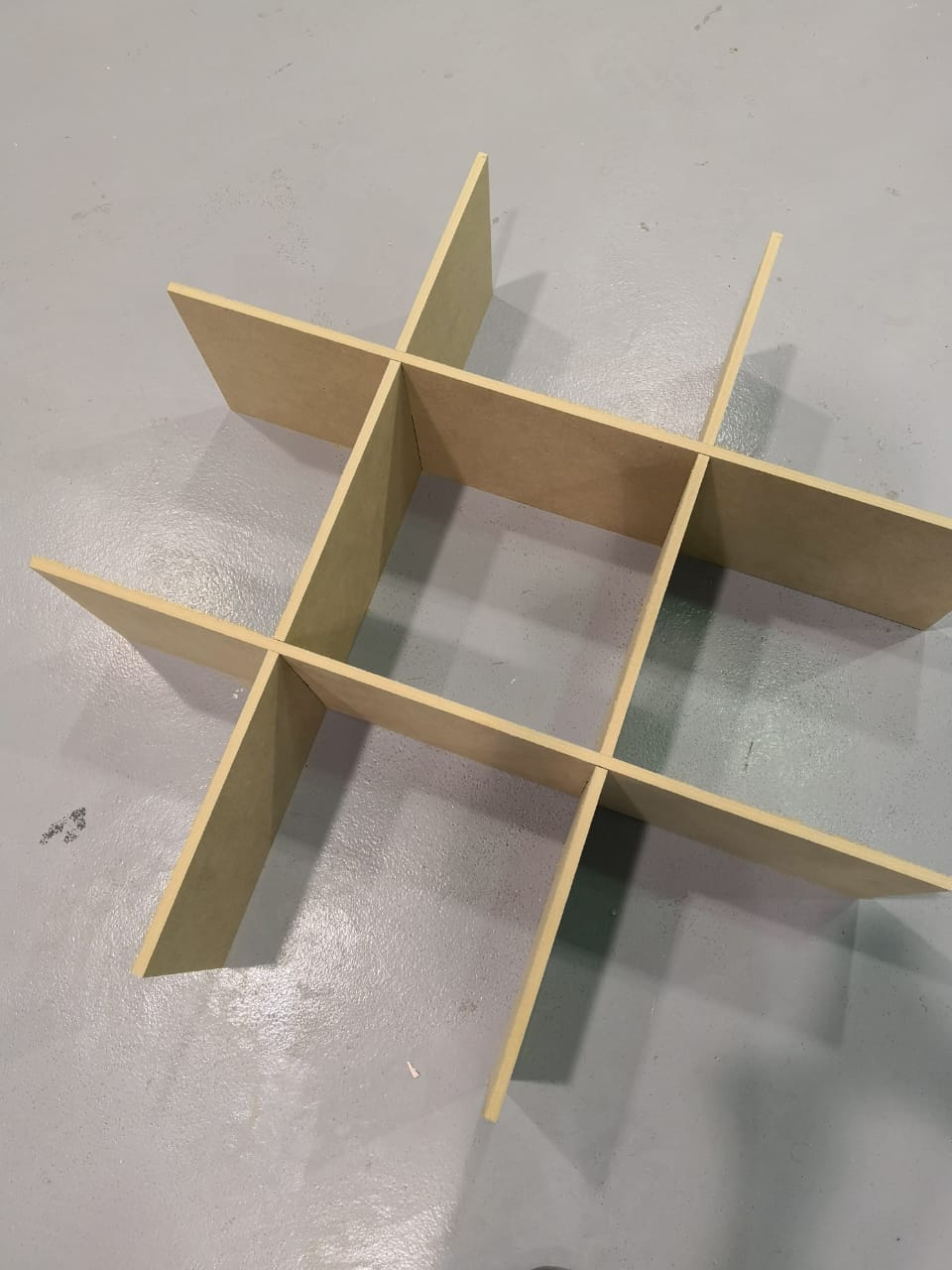

Combining the parts with each other without screws, just fixing the joints. They are tight and good to hold the box

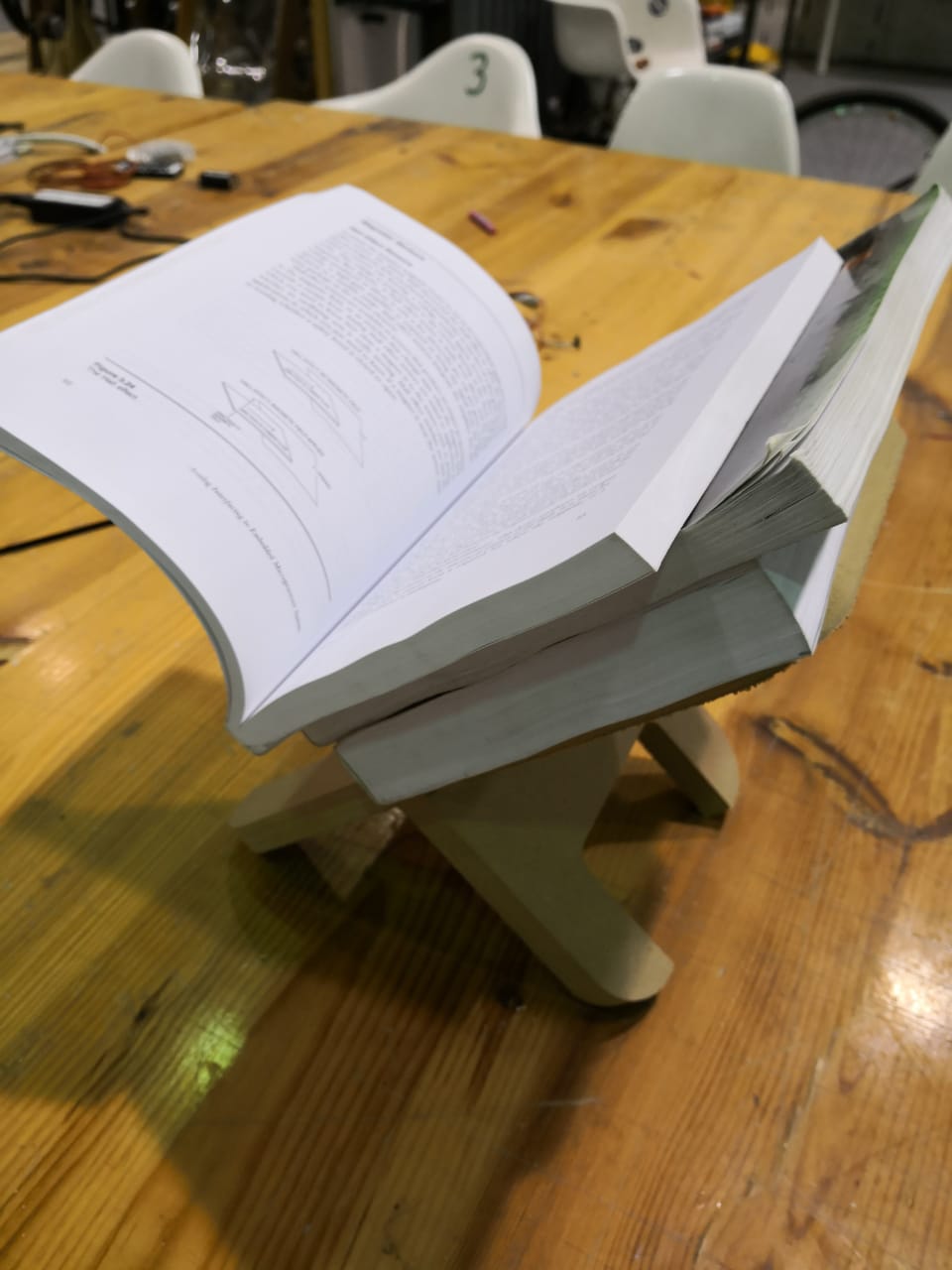

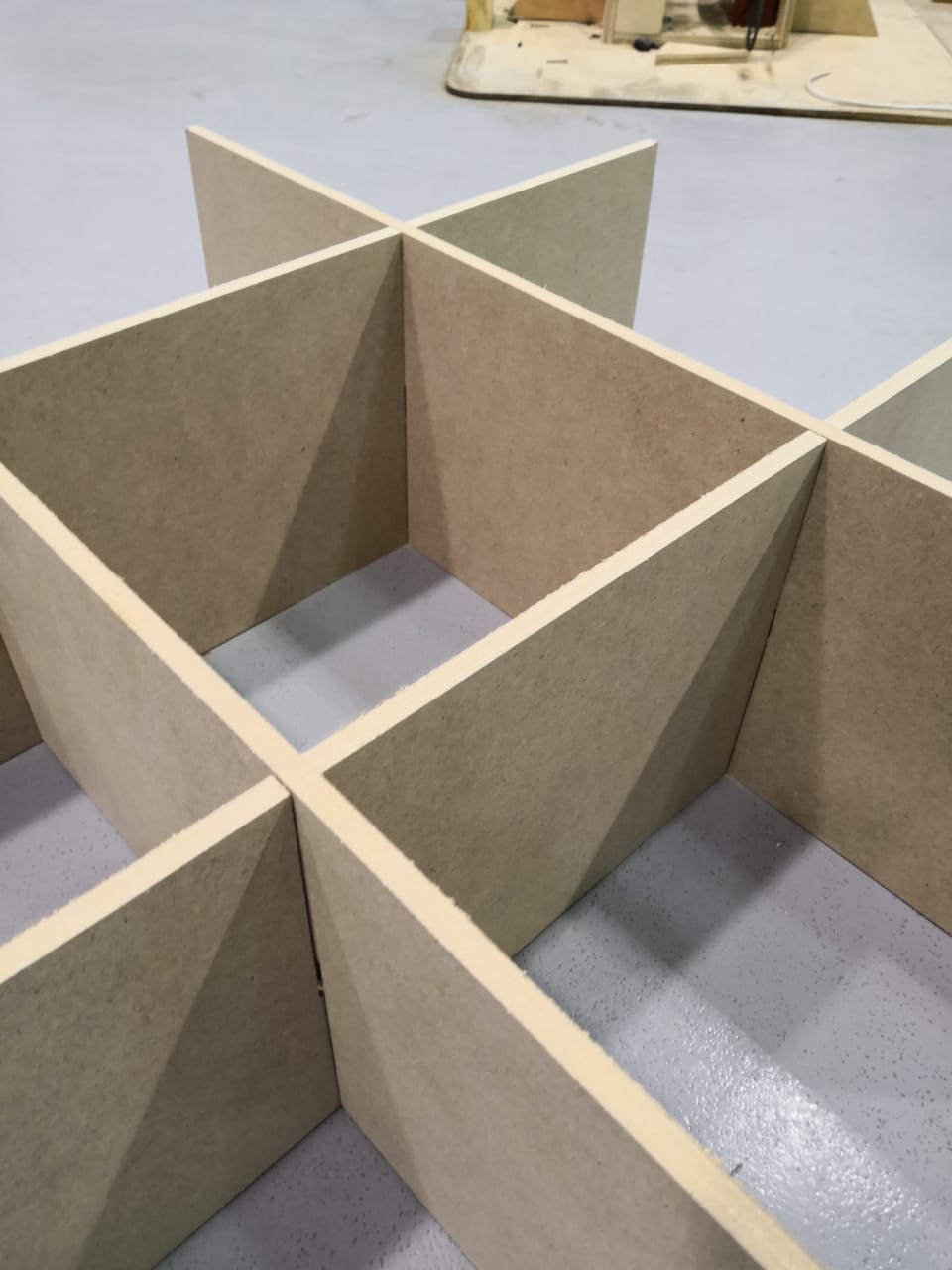

What I have just done, inspired me to make something bigger. So I can organize all the books that I have in home library

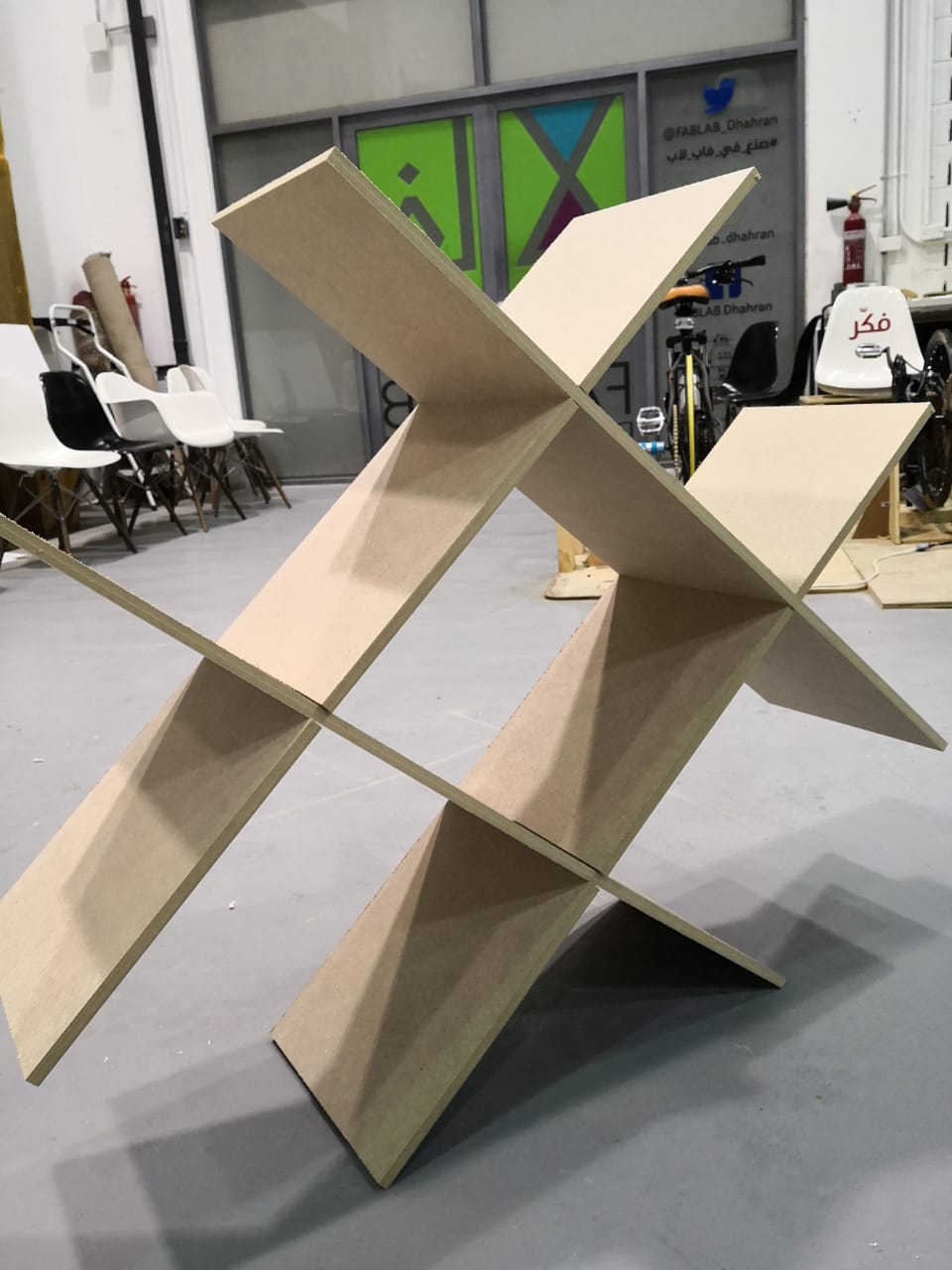

Using the same idea but long parts with two joints in each one as the following

I extrude them with spcific depth

I used fastening tool to make sure the design is complete befor moving to cut it

Preparing the design to cut using VCarve. I selected two parts to cut at first to make sure everything is okay before cut the complete parts. I fixed 12mm MDF sheet instead of 18mm in the previous project

I saved the cut file keeping in mind that the cut will go 14mm to make full cut

Opening Shopbot prgram and run the machine to cut the saved file

start cutting the parts

the first two parts were good in terms of joints and shap. So, I cut the rest two parts to make the full project

I start assembling process just after collecting the parts. The project looks awsome and it's really useful. I will take it home to use it

So, basically, I have done multiple interesting projects starting with the tables and ending with projects have many joints to be fixed and shaped as a 3D big model

Download Files' Links: