Applications and Implications

Assignment

Propose a final project masterpiece that integrates the range of units covered

FabTrolley

The FabTrolley is a suitcase addressed to a regular traveler, lover of nature and outdoor travel. It is also suitable for the professional who travels frequently, and who does not want to give up a soft bed to rest a few hours at the airport, waiting for the next flight.

My final project proposal is called FabTrolley. I will try to answer the following questions to explain the functionality of my project, the technologies used, the costs and the time to complete it

Answering the questions:

What will it do?

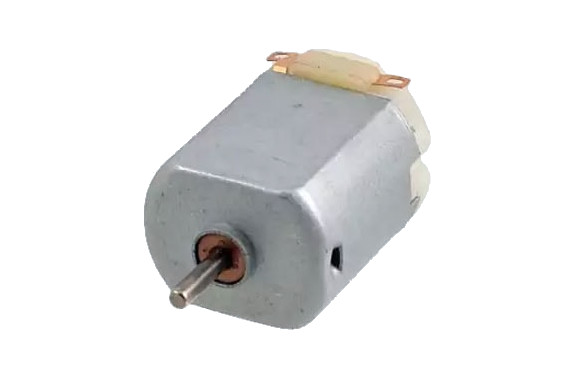

My suitcase has the characteristic of containing an air bed inside it, which can be inflated using special air pumps installed inside it, and connected with the trolley handle mechanism.

What will you design?

I will go to design the mechanism for opening the air bed. My main need will be to occupy as little space as possible once the air bed is deflated; and at the same time have an optimal capacity for trolley. I will therefore design the frame and the parts that allow the movement of the trolley. Another challenge will be to design the mechanism that will connect the air pumps to the trolley handle mechanism. Finally I will design, with the help of model paper and modeling software, the pieces of fabric which will then constitute the fabric part of the trolley itself (hinges, stitching etc.)

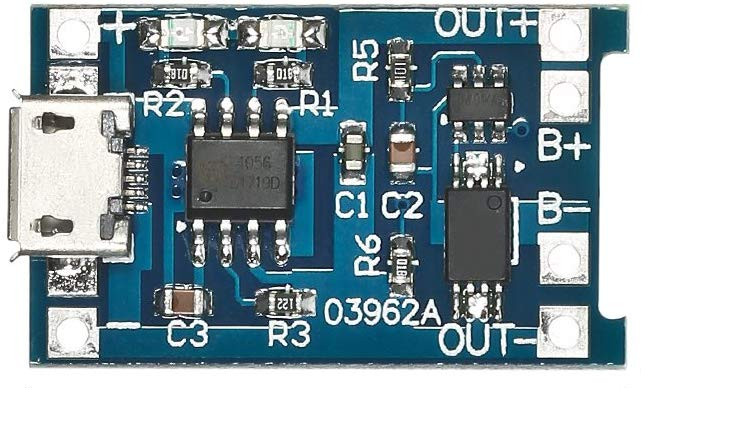

What materials and components will be used? - Where will come from? - How much will they cost?

Who's done what beforehand?

During these years I never found anything that came close to my idea of FabTrolley, and it is really hard for me to try to make comparisons. I am more than certain that mine is a valid idea, and that it can bring benefits in the field of tourism and travel However, I found some very interesting projects, which surely inspired me, but which unfortunately does not reflect my idea of a trolley.

Alternatives I've discarded: Electric pump for inflating the air bed.

I would like to create a suitcase for a traveler / pilgrim who does not have to worry about finding points where to charge the batteries for the electric pump.

The first really interesting project I found is this: produced by TravelmateRobotics

The second project, very interesting but still very similar to the first, is this: produced by NUA robotics

The most interesting project, because it applies the concept I want, is the following: The project is called THE Trip, and was produced by a Dutch company; at the moment it is not yet possible to order this product, but I believe it is feeling a lot of interest.

What parts and systems will be made?

First of all I will build the trolley frame, the wheels (3D printed with PLApro) and the system that allows it to be transported. The frame will be purely plywood with pla joints. I will build the connection system between the air pumps and the handle opening / closing mechanism; and between the air pumps and the air bed. I will go to create the air bed and all the valves that will allow the air pump to inflate. The trolley handle will also be printed in 3D; this time using the Entwined hemp filament. Finally I will go to create the fabric part, assembling all the cut parts, by stitching and gluing

What processes will be used?

I am planning to use the following techniques:

- 2D and 3D design

- Laser cutting

- 3D printing

- Textile (Extra Cost and Time)

- Electronic Design & Production

- Embedded programming

What questions need to be answered?

Will our hero "Michele Turco" be able to complete the FabAcademy this year ?? Stay tuned to find out and you can say: I was there too!!!

How will it be evaluated?

- Mechanical resistance of the structure and the frame

- Correct operation of the inflation system

- Correct functioning of the air bed closing, after deflation

- Proper opening / closing of the trolley handle

- Comfort of the air bed

- Inflation times

- Total weight of the suitcase