3D Scanning and Printing

Assignment:

Group project: test the design rules for your printer(s) - design and 3D print an object (small, few cm) that could not be made subtractively - 3D scan an object (and optionally print it) (extra credit: make your own scanner)

Work:

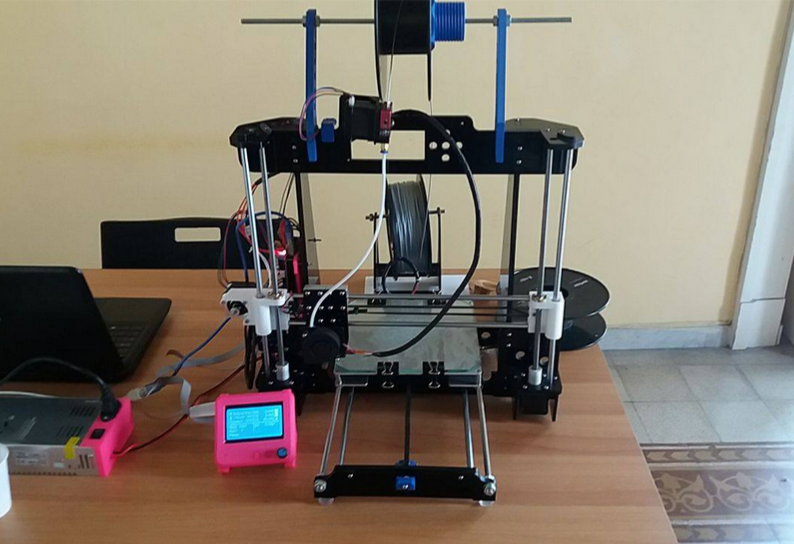

Group Assigment: For the group assignment I test the design rules of the Zortrax M200; This is one of the 3D printers that the Fablab Napoli have; and I also have at KromLabòro FabLab. I print this test for measure the thikness and the tolerance of one or multiple 3D printed joint. You can found this test on thingiverse, at this Link

In the First print, the piece have 0 tollerance, and the piece don't fit.

After do this, I create other female joints progressively larger with Rhinoceros:

and I print It. I do this until i found the good joint. The tolerance for the Z-ABS is 0.25mm. It mean that F.E. If the male of the joint is 7mm, the female must be of 7.25mm for fit. After this test I design a small cube of 20mm x 20mm and I print it with the Prusa i3 I have to the KromLabòro FabLab.

I assemby it from a Kit; and I change some important piece like bearings, the display, the noozle, and belt; and I set it as bowden extruder for lighten the zeta axis.

All the parameters are ok! There is only a problem: For this cube i use an ABS filament, and it need to be in a hot box, because the thermal shock can crack or raise from the plane the piece.

Design and 3D print an object (small, few cm) that could not be made subtractively:

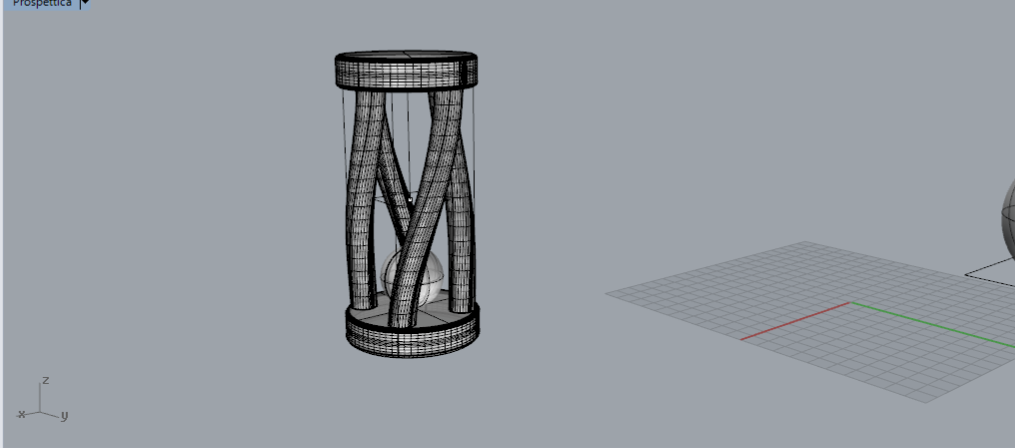

For this assignment I choose to design a rolling ball into four closed helical rail. I use Rhinoceros for this design:

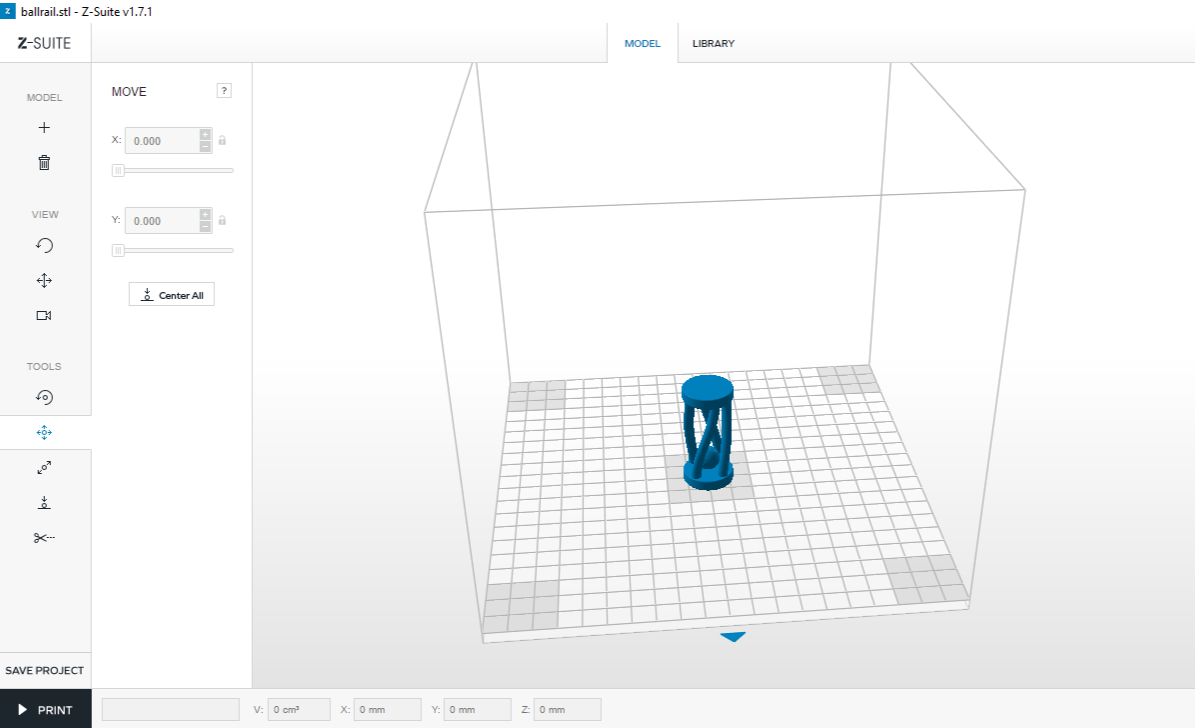

It's a very simple design but with it we can know that this kind of piece can't be made with subtractive technologies. For print this piece I use the Zortrax M200, with Z-ABS. I open the Z-suite and import the file i need.

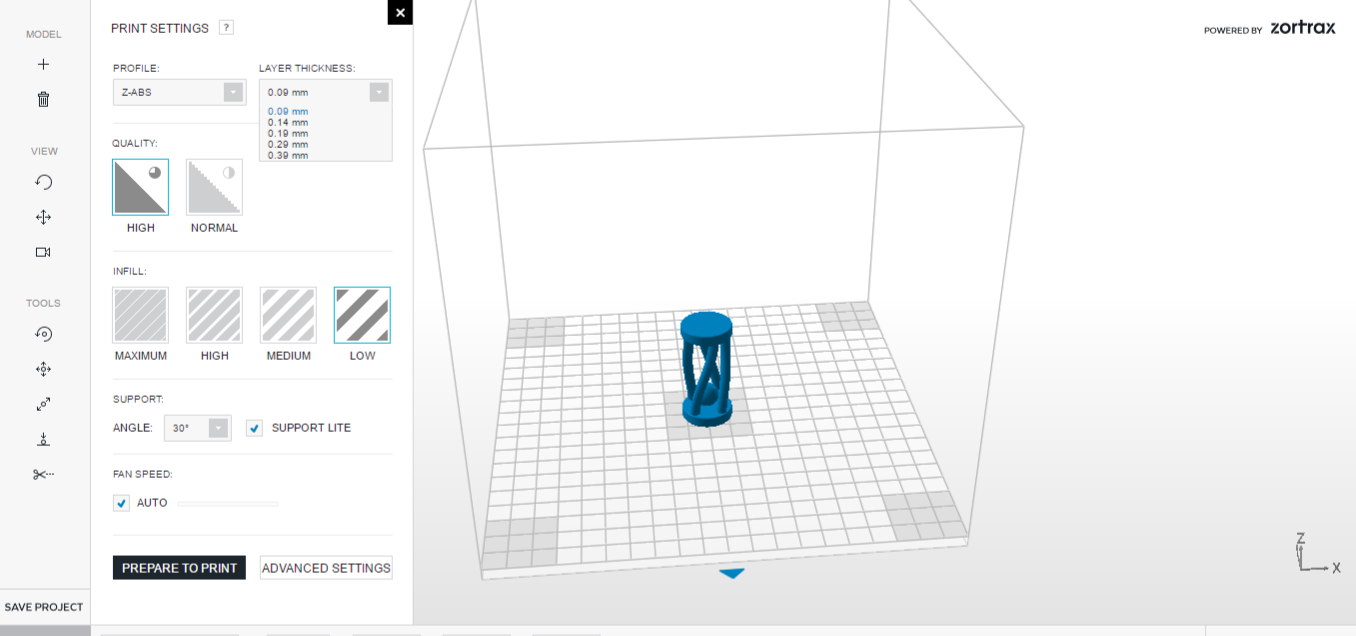

This Object can't be print without support because the top of the piece can't be made with smart bridge(the bridge between two distant edge), so I insert in the Zsuite that i want a support lite (co I can remove it easily) I set the infill to Min. because thin setting on the Zortrax can obtain an excellent piece. The Layer I choose is 0.09 for the ABS i want to use; and I choose the quality of the object to the Max, and the fan speed to auto as default.

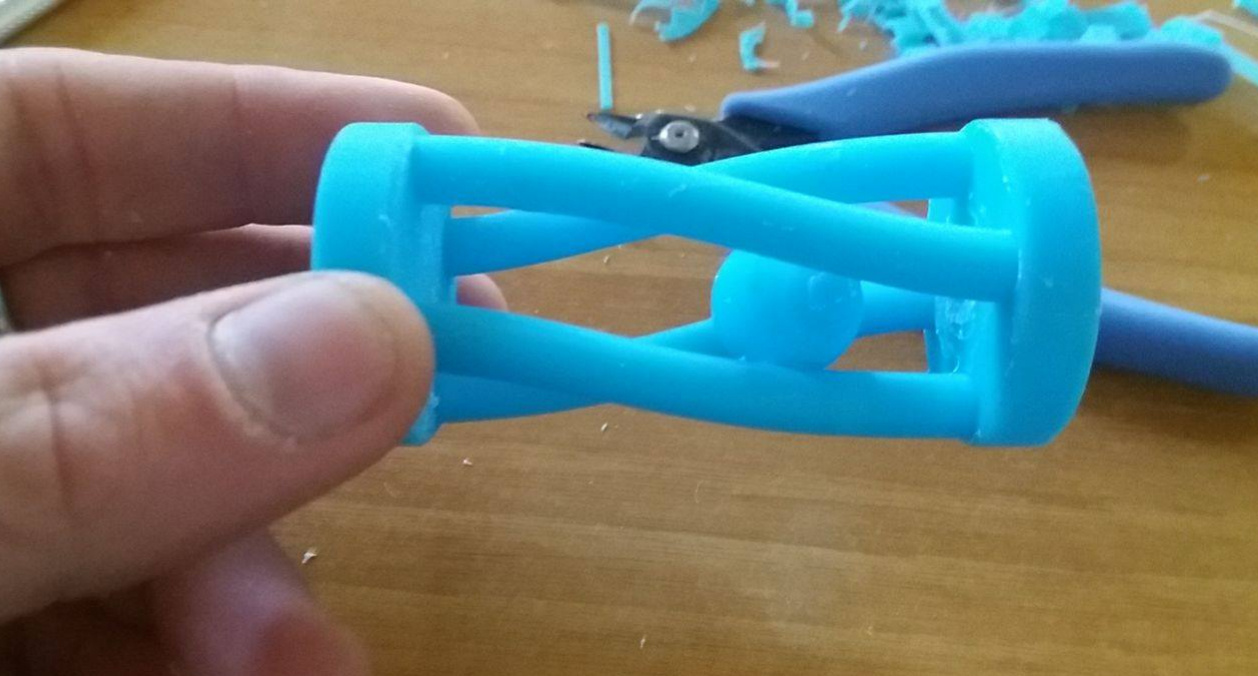

In the next image you can see all the support that I must remove, and it seems a very difficult work, but when I did it was easy.

Here some image when I print the piece:

Here the file of my object:

Download

Extra Design

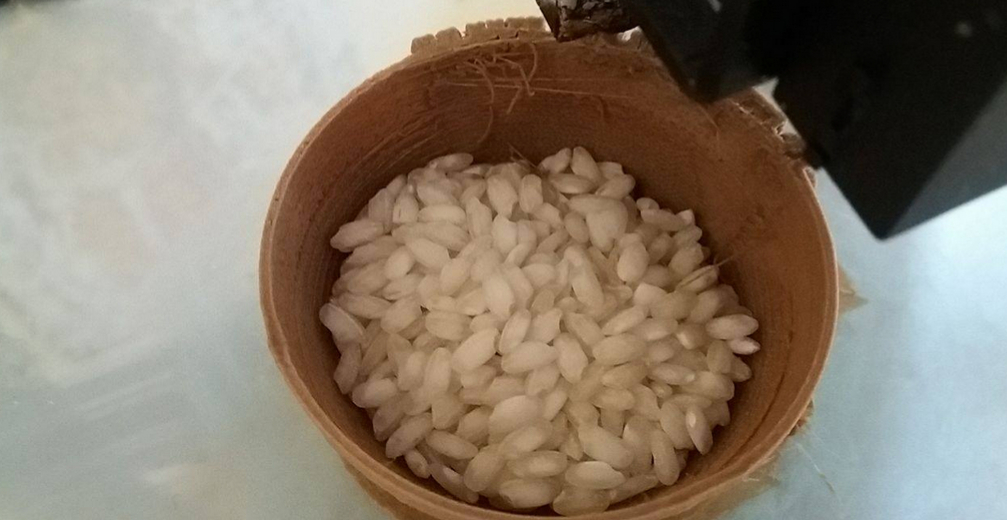

I design also this maracas, and I print it with a hemp filament and also in ABS, for see the difference between the two materials. I made it with a handful of rice inside. First I design it with Rinoceros, here the file on sketchfab: After Design, I print it with the Zortrax and the Prusa i3. When i print it with Zortrax I insert a pause on Zsuite at 80%, in this way i can insert the rise inside the piece after this the 3D printig process close the piece forever and the rice remains inside the piece.

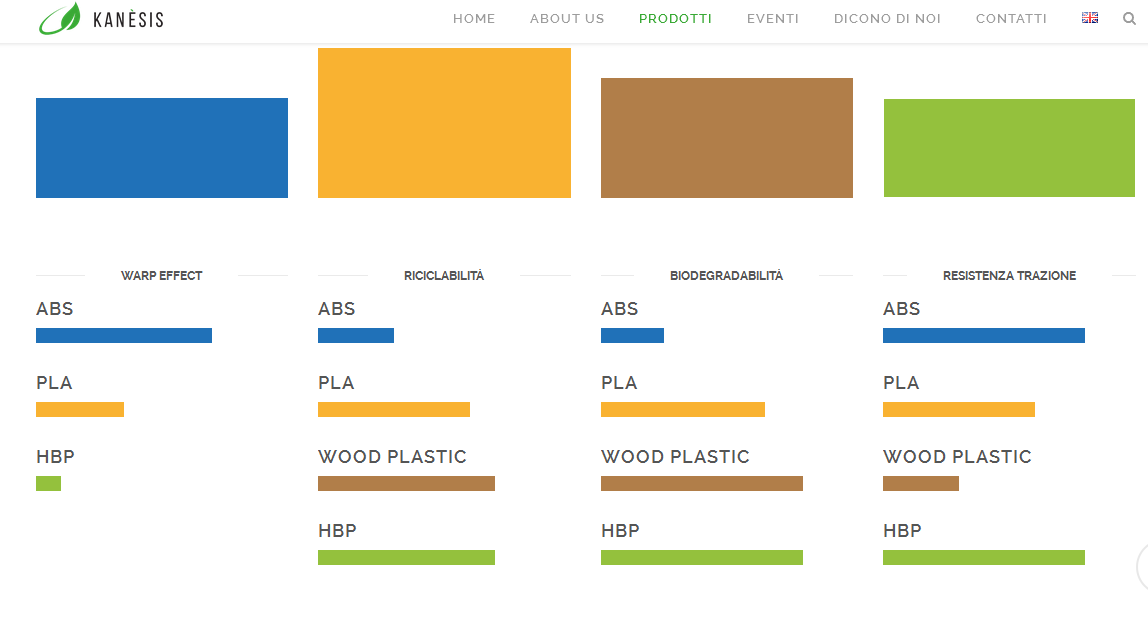

After I print the same object with hemp filament. I have the fortune of test this special filament; it's produced by Kanesis, an Italian Company that produce some different kind bioplastics using the wastes of different types of industrial productions like food production waste, etc. More information about Kanesis Here:

. The Filament can be used at different temperature, i try different test, and i know that the good temperature for use is 175°

For print with hempbioplastic I use this settings:

1) Temperature Extruder : 175°

2) Bed Temperature : 70°

3) Print Speed : 70 mm/s

4) Fan 20%

5) Noozle Diameter 0.4 mm

6) Support (Line)

7) Layer 0.2

8) Retraction 0.5 mm

It's a very beautiful material, because it need of few finishing touches, need of low temperature and give excellent result. The same piece printed with this filament, is more elastic and more resistant. I print this object with prusa i3, and I use Repetier Host, this have a good control of the 3D Print, and can give too much control of the machine. In my case i use inside the repetier the slicer I need, for this print i choose Cura Settings. You can find Repetier host Here:

Here some features and difference between other filament:(Info on www.kanesis.eu)

3D scan an object (and optionally print it)

For this Assignment we use the Sense 3D Scanner produced by 3D System:

In this assignment we decide to work in group and to scan one with other for print a Minime. This Scanner have an own software for scan, and you can choose if you want to scan an object or a person, in my case I choose person. Enrico ask me if I can scan him full body, but when we scan somethinng it is very important the lightning in the room, the distance from the object or a person and in my case It is very difficult to scan Enrico's legs. After this scan i ask to a FabLAb Napoli associate If i can scan him. This is the image of him:

After do this I ask to Enrico if he can scan me,because I want to print myself.

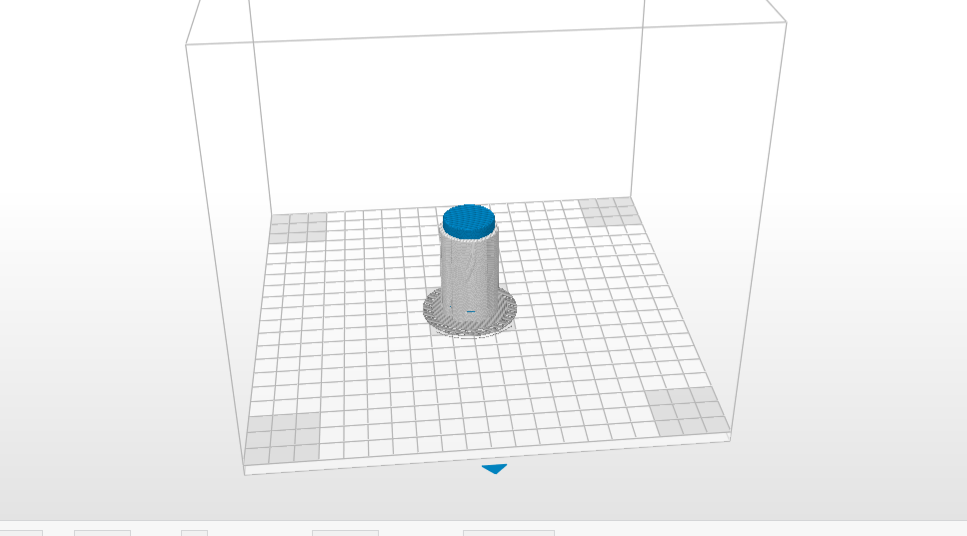

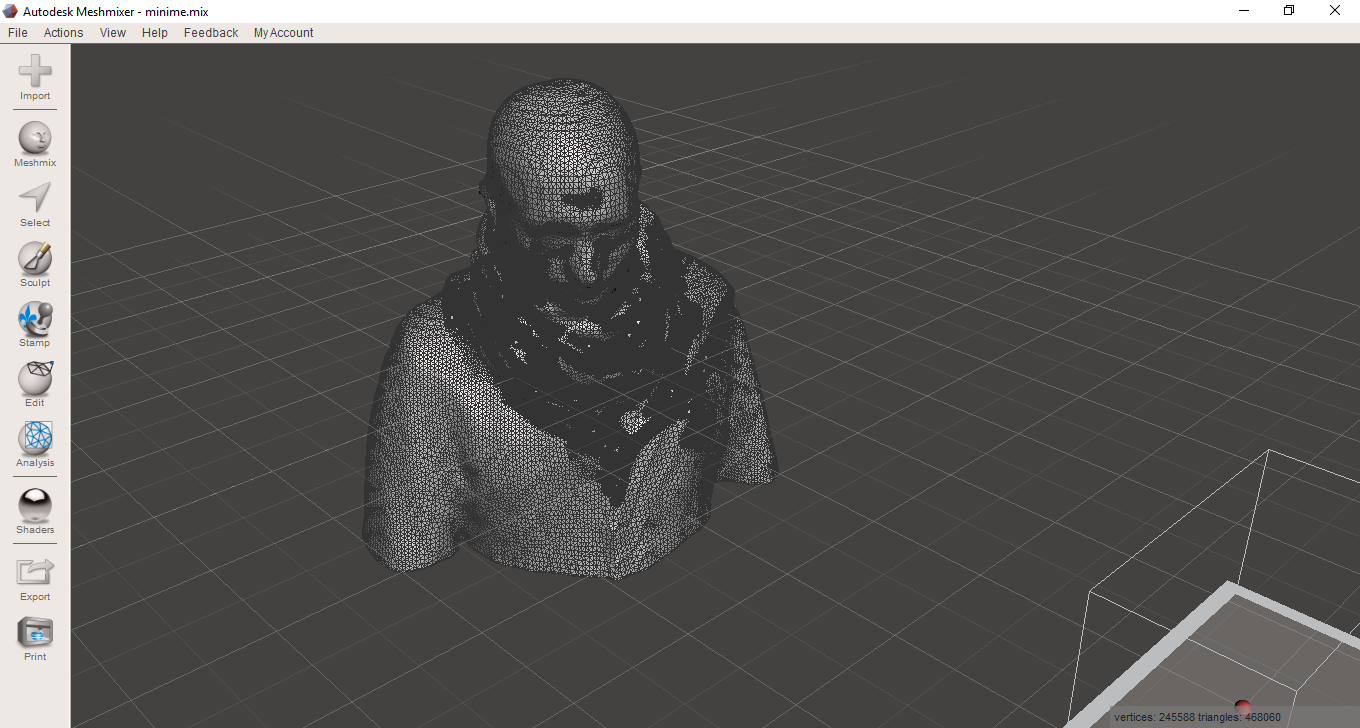

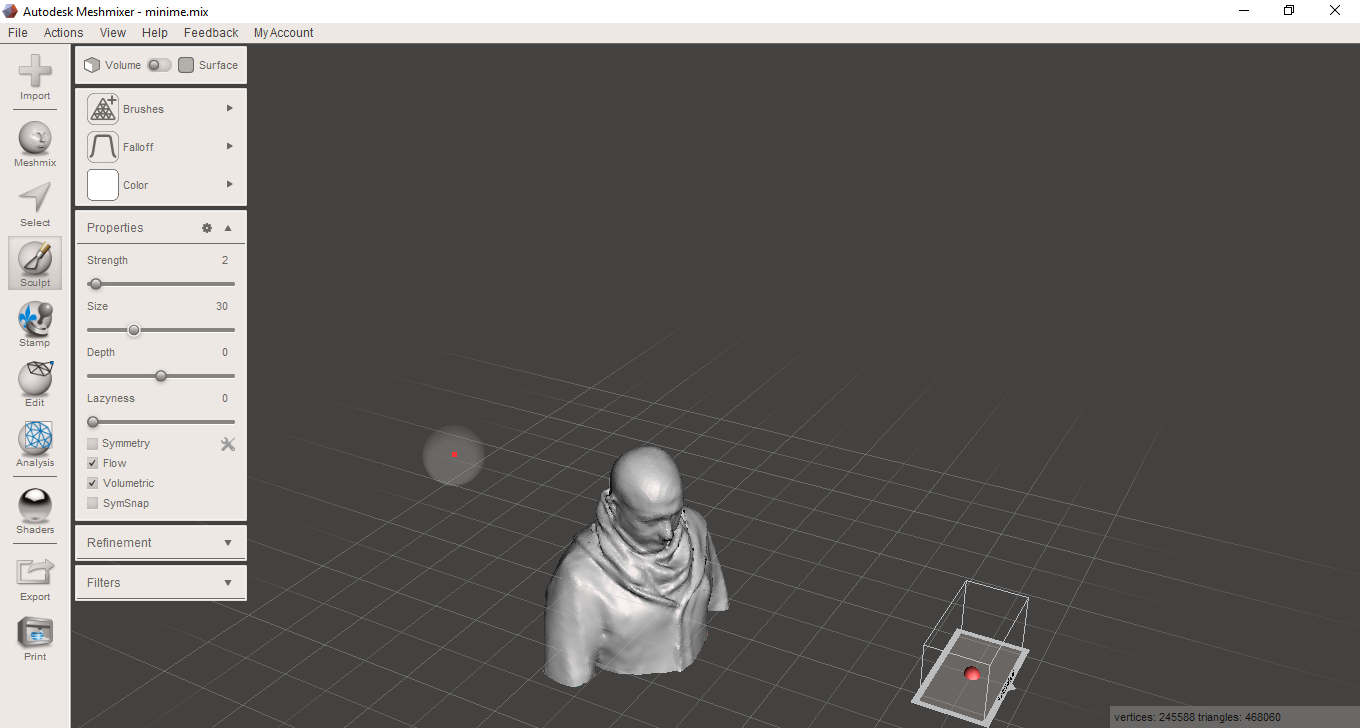

When Enrico scan me, the file generated by the Sense softare in .wrl and I import It in Meshmixer for repair it from hall spikes other mesh forms and imperfections.

In the previous image you can see a minime printed with the Zortrax M200; after I print the same model resized with Prusa i3. You can see in this picture that with this Prusa i3 there's the problem with the cooling of the piece, because the ABS need of a very hot plate and enclosure system.

For repair this piece, I did some post production operations:

- Glue the cracks

- Smooth with sandpaper

- Filler

- Primer

- Paint

Download ZONE

- Back To: Home

- Date: Febrary

- Topic: 3D Scanning and Printing