Week 10: Molding and Casting

Group Assignment

This week's group assignment consists of looking for the safety data sheets of the materials that we use to make the molds and also with those that we carry out the casting.

Moulding

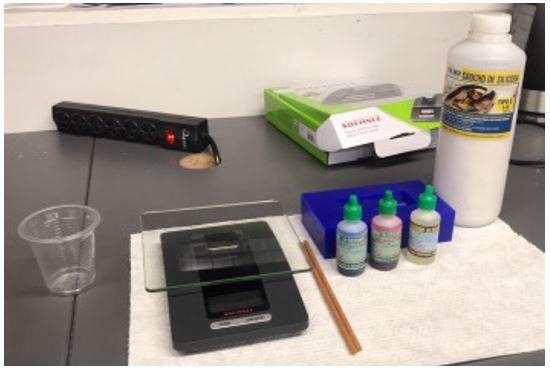

Material 1: RTV Silicon

To manufacture the molds we use 3 different materials, the first was RTV silicone rubber, which requires a catalyst in proportion of 20 drops per 100 grams of silicone.

Safety data sheet here

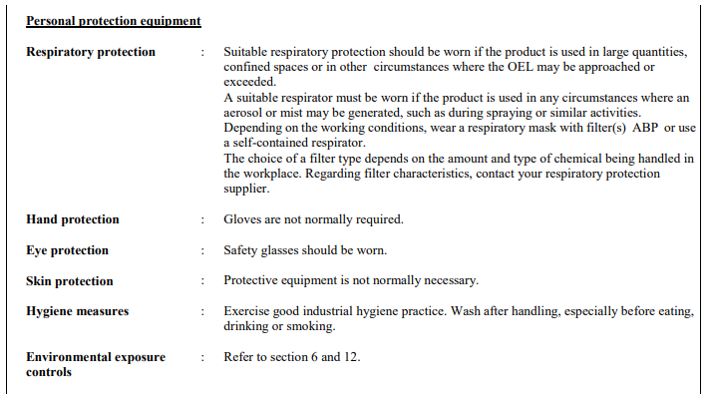

According to the information gathered, these are the personal protective equipment that should be used for the manufacture of molds of this material.

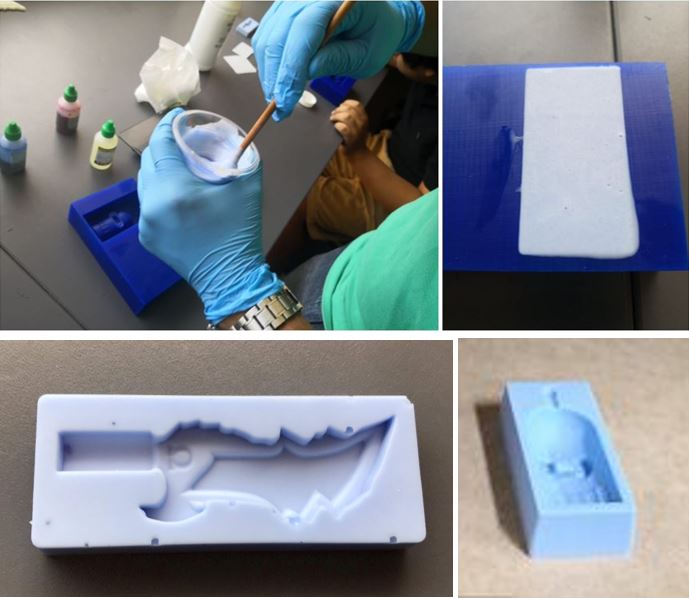

The manufacturing processes are found in the personal repositories of each member of the team. Below are some results

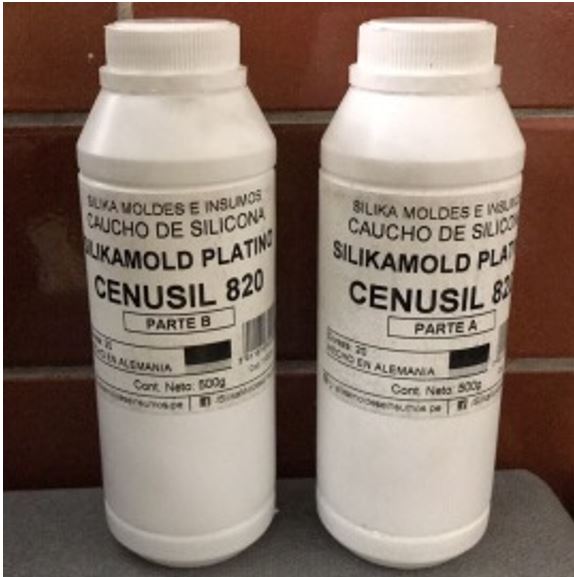

Material 2: CENUSIL 820 platinum silicone rubber

The second material we used was CENUSIL 820 platinum silicone rubber, of German origin. For the manufacture of molds it is necessary to mix part A and part B in proportion 1-1.

Safety data sheet here

According to the information obtained, it is recommended to wear gloves and protective glasses.

Here are some results

Material 3: Platinum rtv silicone rubber

The third material that we used for the manufacture of molds was platinum rtv silicone rubber. For the mixture must have part A and part B in equal proportions.

Safety data sheet here

From the information collected, the following recommendations are obtained when manufacturing the mold.

Below are some results

Casting

For the casting, we chose 2 materials.

Material 1: Polyester Resin

The polyester resin requires a catalyst to perform the curing process.

Safety data sheet here

As you can see in the data sheet, this material requires a respirator, due to the odors that are released.

Below are some results

Material 2: Epoxy glass resin

Epoxy glass resin, to carry out the curing process, combine part A and part B in a ratio of 1 to 2 and stir the mixture for 3 to 4 minutes.

Safety data sheet here

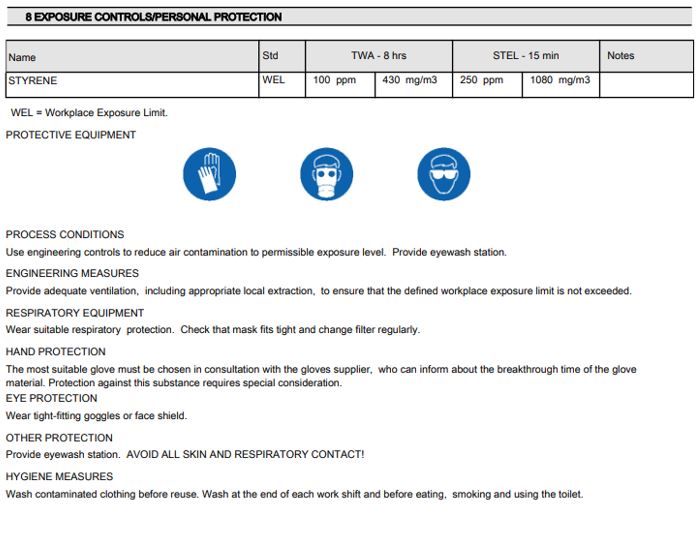

According to the information obtained by reviewing the product file, the following recommendations were obtained.

As you can see, respiratory protection is essential due to the gases that emanate.Below are some tests.

Each member of the group performed tests combining the different casting materials. The results will be presented. For more details, they can review each member's personal repository.

Each member of the group performed tests combining the different casting materials. The results will be presented. For more details, they can review each member's personal repository.