Project Development

Project Plan

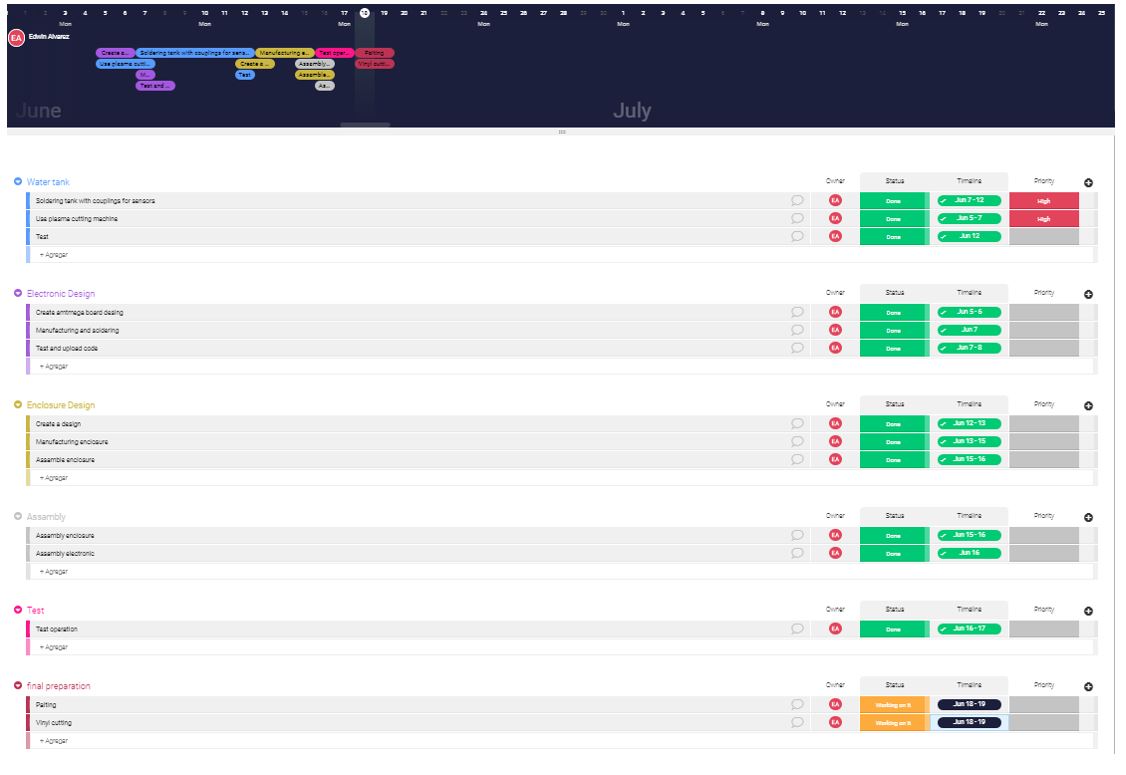

Using the web Monday.com, a free website to create a work cornogram, as shown in the picture.

Here is the detail of the project.

Here is the detail of the project.

With this plan we can work comfortably and reach the correct deadlines.

In each stage, the purchase of sensors or materials that we do not have in the lab is contemplated, in addition to purchases at the time of assembly.

With this plan we can work comfortably and reach the correct deadlines.

In each stage, the purchase of sensors or materials that we do not have in the lab is contemplated, in addition to purchases at the time of assembly.

It is very important to comply with the deadlines and require help from laboratory technicians to avoid possible bottlenecks.

The main bottleneck is the manufacture of the tank, because without the tank I will not be able to finish the project.

what tasks have been completed, and what tasks remain?

In my case I have already made the design of the enclosure and electronics. Tests of each sensor were performed to verify its correct functioning.

Then all the electronics in the atmega designed specifically for the final project were implemented, giving good results.

What remains to be done is the implementation of the sensors with the tank and perform the final tests, once the tank covers are welded, the final tests will be started.

what has worked? what hasn't?

Of all the sensors used work perfectly in the basic tests. It began to implement some sensors in the tank and one does not work well.

The sensor to measure the water level using the continuity of the water stopped working.

The problem was when adjusting the cables inside the tank, when the covers were soldered it is impossible to remove the cables.

There is continuity between the cable and the tank, the reason I am thinking is that, at the time of welding, the cable cover was melted and makes direct contact with the tank.

We must be careful when including water and avoid damaging the sensors

what questions need to be resolved?

A basic question that I must answer is whether there will be water or steam leaks in the connectors or welds.

To avoid these problems would be to use special clamps to properly adjust the separation between the cables and the hose.

what will happen when?

If there were small leaks, the enclosure of the design will begin to deteriorate to be water and steam. A security measure that I am implementing is the use of a fan that will be activated immediately when the resistance is activated, this way heat will be extracted unwanted inside when you start generating steam.

what have you learned?

The fabacademy taught me to implement digital design to projects of any kind, especially in design.

It improved my electronic skills by allowing me to create my own electronic boards, in addition to learning how to use machines and tools for manufacturing. I never thought I would make molds or I would use carbon fiber to create a product (wildcard week).

With this acquired knowledge, it only limits our imagination, since I can make it possible using different tools.