Principles and Practices.

What is that?

This machine is used by clothes designers and manufacturing, it is a steam iron more powerful than a conventional iron. By having more steam, ironing is more efficient and is done in less time.Why this project?

That machine is a basic machine, because you don’t have any control of the steam, temperature and level. Some clothe’s designers need this machine and, some of them, are very basic or very expensive.I want want to develop this machine because i want to control some variables, make it open source and low-cost machine.

What already exist?

For the project, I will use a commercial machine as a base, taking advantage of the fact that I was able to obtain an already used one to take advantage of the components.

How it works?

This machine has a very simple operation. It has two buttons, one for start the iron and another for the steam generator. When the button on the iron is activated, electrical current passes through the plate's resistance and heats it, just as a conventional iron works. If the steam generator is activated, electrical current passes through a resistance inside a water tank to heat it and produce steam, a process very similar to a conventional water heater. Both systems are independent, but when the steam is activated it is recommended to activate the iron, in order to perform a faster and better-quality work.How much it cost?

The cost of this machine in Peru it is about 250$ a used machine or 500$ a new machine. It is very expensive machine. I want to made this machine for less than 100$.What is lacking and problems?

The problems of this machine are mainly two: the lack control over the steam and the level of the internal deposit. The heating of the water does not have any type of control and for some studs it is harmful to apply steam in excess or at a high temperature. Regarding the level, many do not indicate it or the way to indicate the level of water that remains is very simple or nothing is visible.What could be improve?

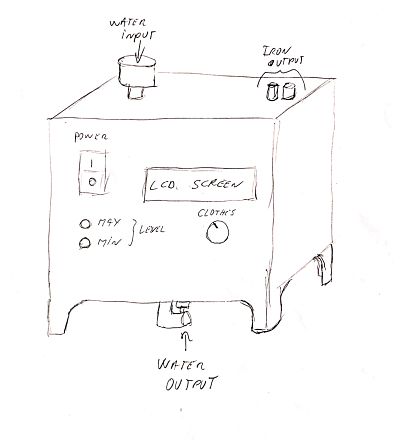

An advanced control for water heating will be added, sounding only an ON / OFF, for this purpose they will be used some inputs like a level and temperature sensors to control all the variables of the machine. Also, the machine will have an LCD screen where show some variables like temperature and level.What will I do?

Improvements

As an improvement to the machine, a better control of the variables of temperature and steam will be incorporated, and it will not have to present any type of control of the manipulated variables, besides lacking a correct level control of the internal tankIntegration

It will use a controller that has the necessary firmware to have control of the temperature and level, as well as an LCD screen where we can visualize the variables and a buzzer that will give a small acoustic signal to know if the machine needs attention or is ready.What will I do?

I will use wood to create a case in which all the electronics part and the internal container will be incorporated. The internal water container will be made of stainless steel and the case will be of medium density fiberboard or similar and glass fiber will be used to isolate the container.The next picture is the first sketch of my final project.