Welcome to Berytech Fab Lab

So the objective of the forth week is to learn how to produce a PCB (Printed Circuit Board) in the Fab Lab. There are many different ways that can be used to produce a PCB, such as CNC milling or using the Etching Method. However, the Etching method is not advised due to the toic chemicals used in the process. Thus we are going to discover and test the CNC milling method in this assignment.

Group Assinment

The group assginment was to characterize the specifications of our PCB production process.

PCB stands for "Printed Circuit Board." A PCB is a thin board made of fiberglass, composite epoxy, or other laminate material. Conductive pathways are etched or "printed" onto board, connecting different components on the PCB, such as transistors, resistors, and integrated circuits.

Machines Used

The main machine used in this week's assignment is the Desktop CNC Machine.

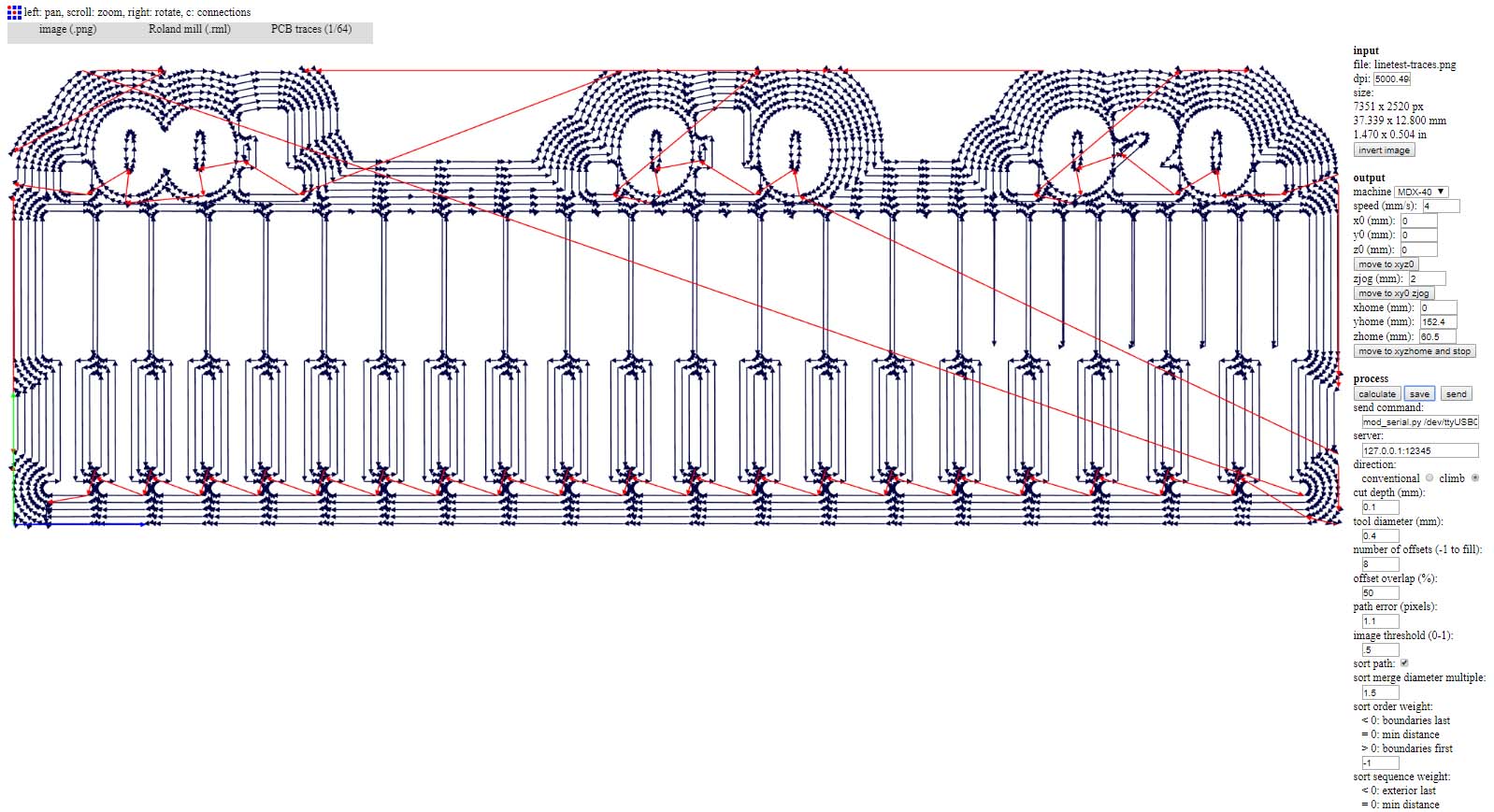

The idea is to understand the different settings of the CNC milling process that could affect the output products. There are many variables in the Milling process setting that could be changed and respectively affect the output of the machine. The settings are:

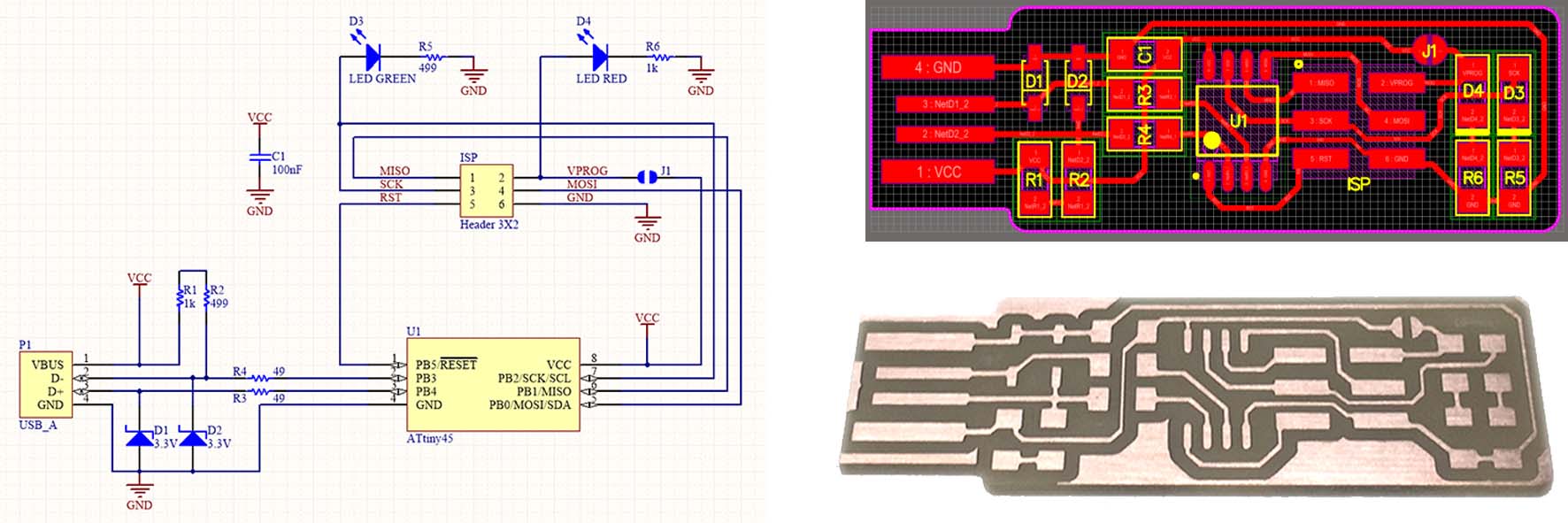

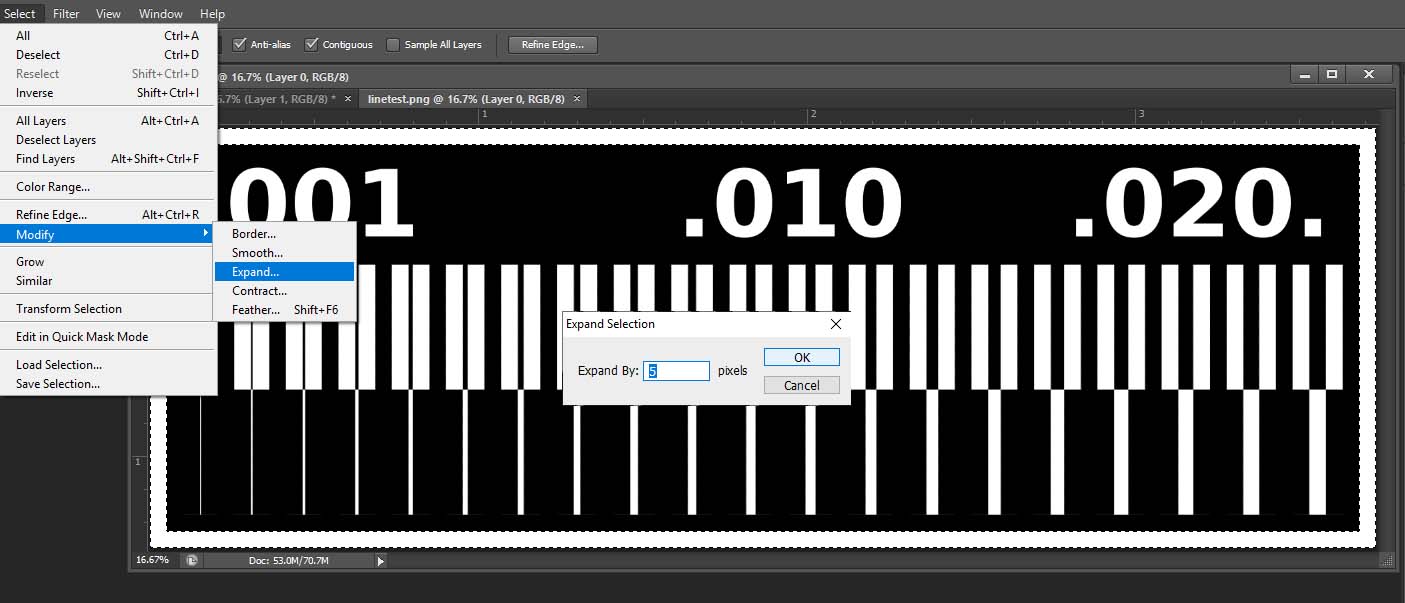

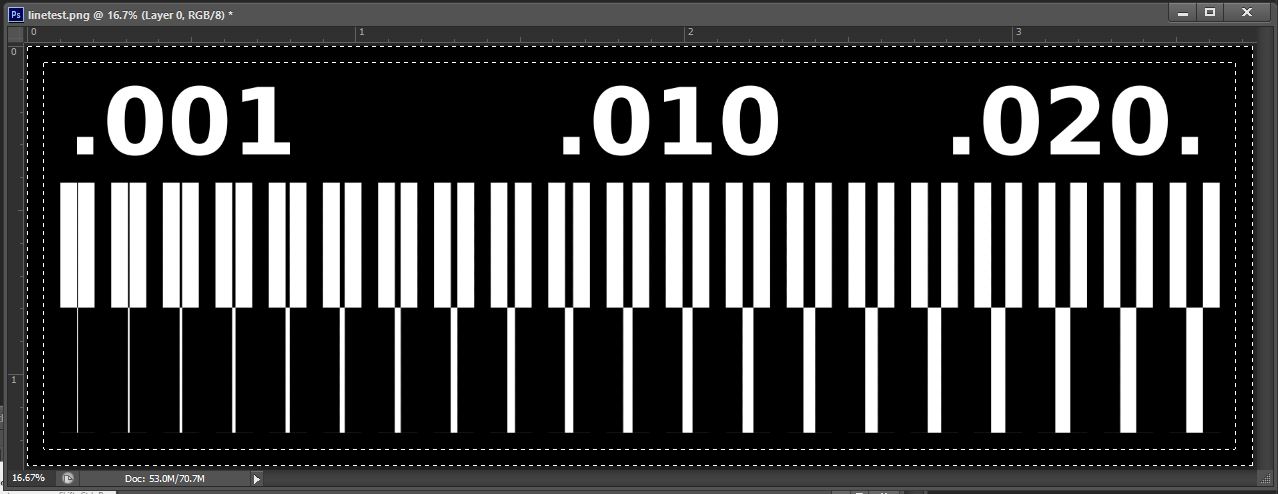

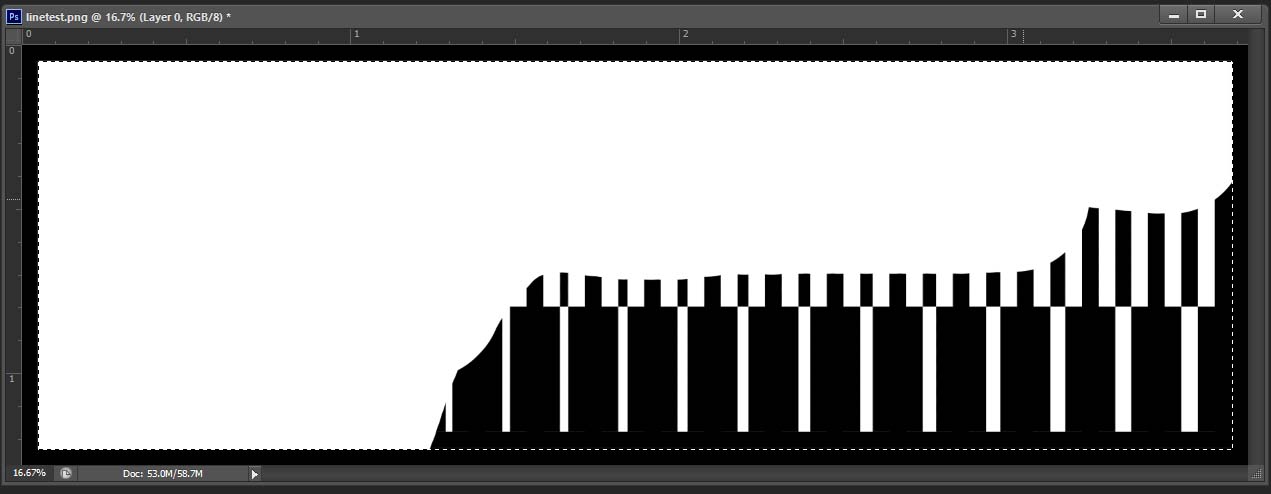

Before milling the test file we had to create 2 images, one for the internal traces and one for the outline cutout.For that we did the following:

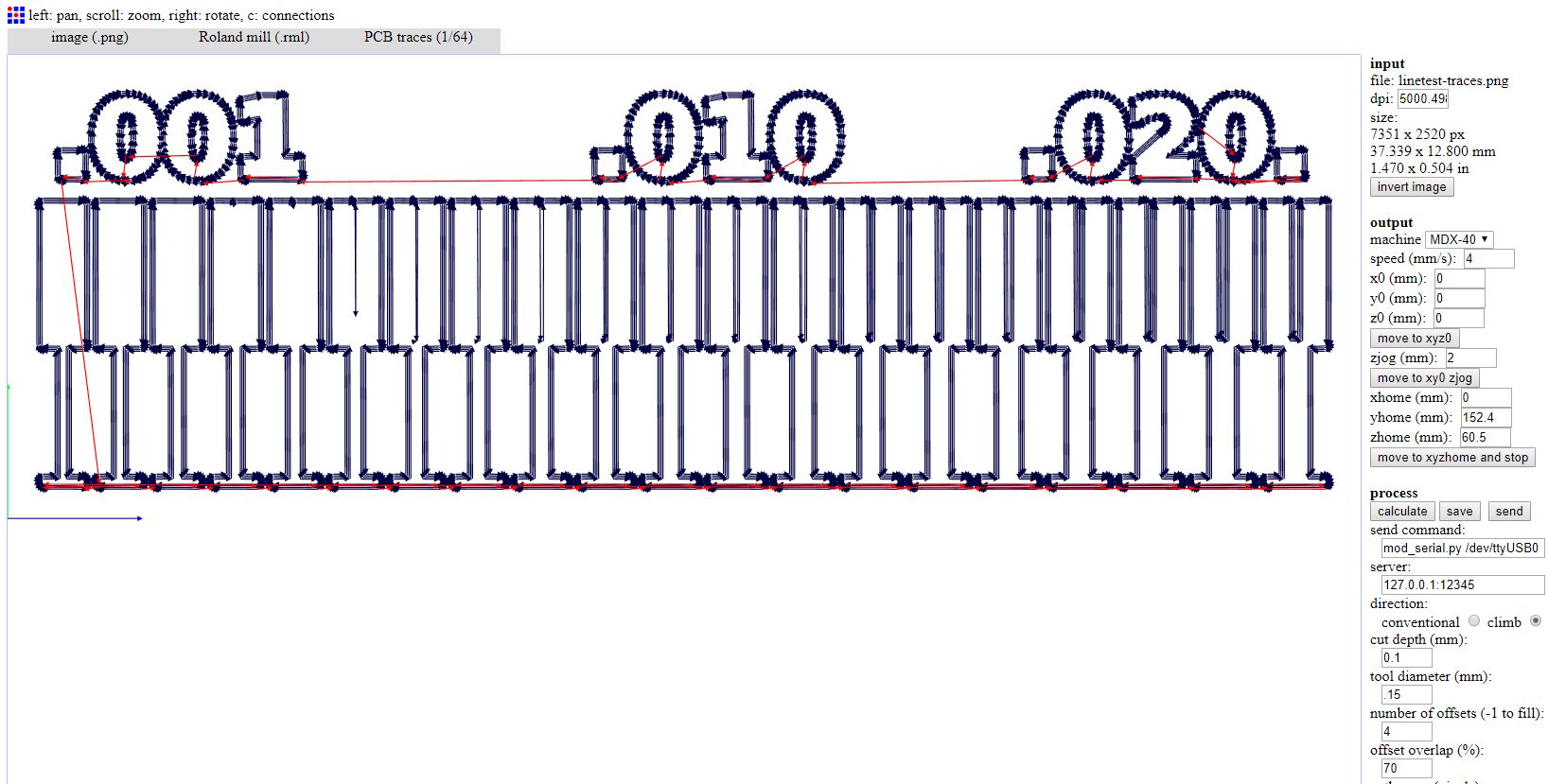

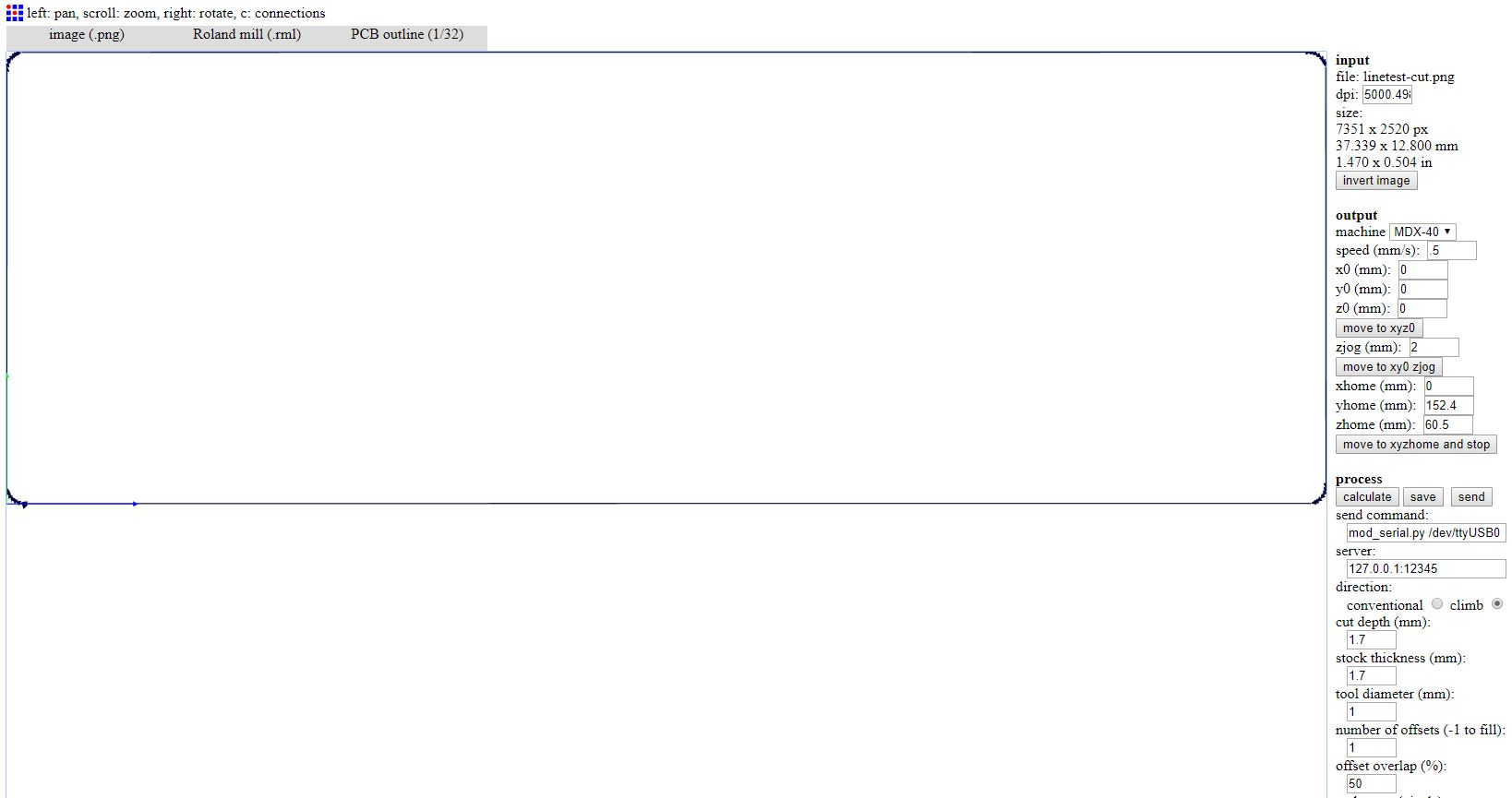

Now we will calculate the g-code for these images

You can download the g-code used for the test from the following links:

You can download the g-code used for the test from the following links:

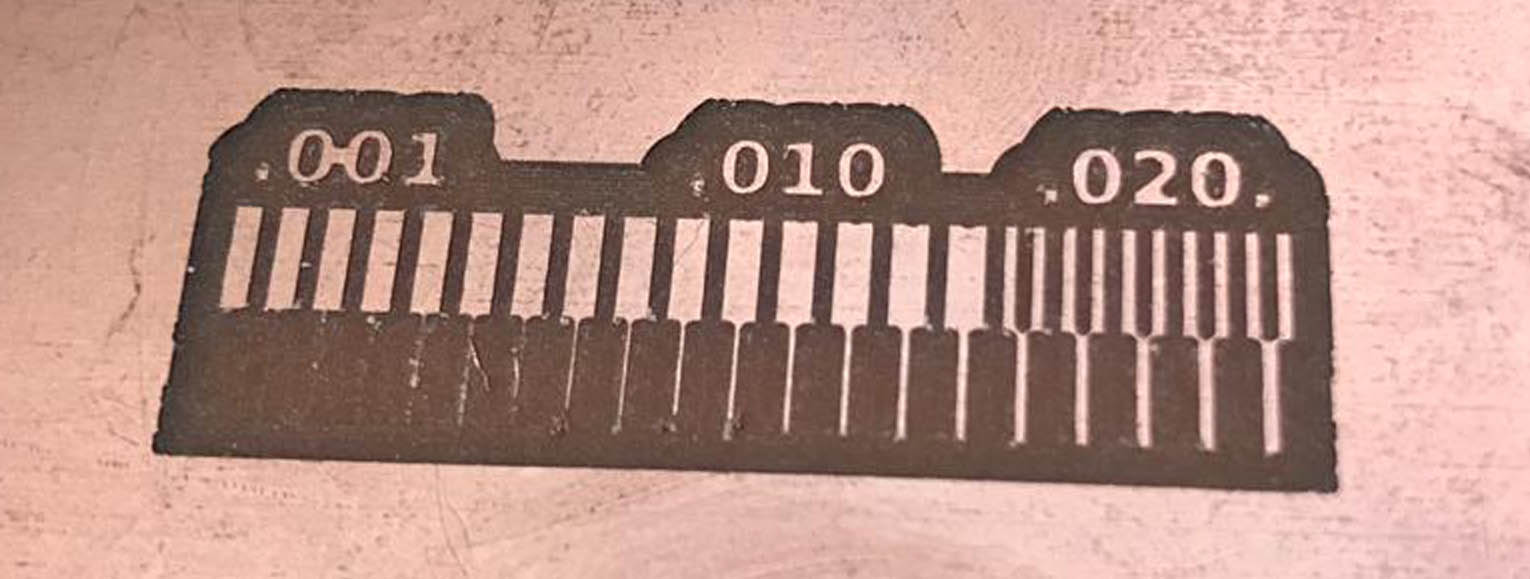

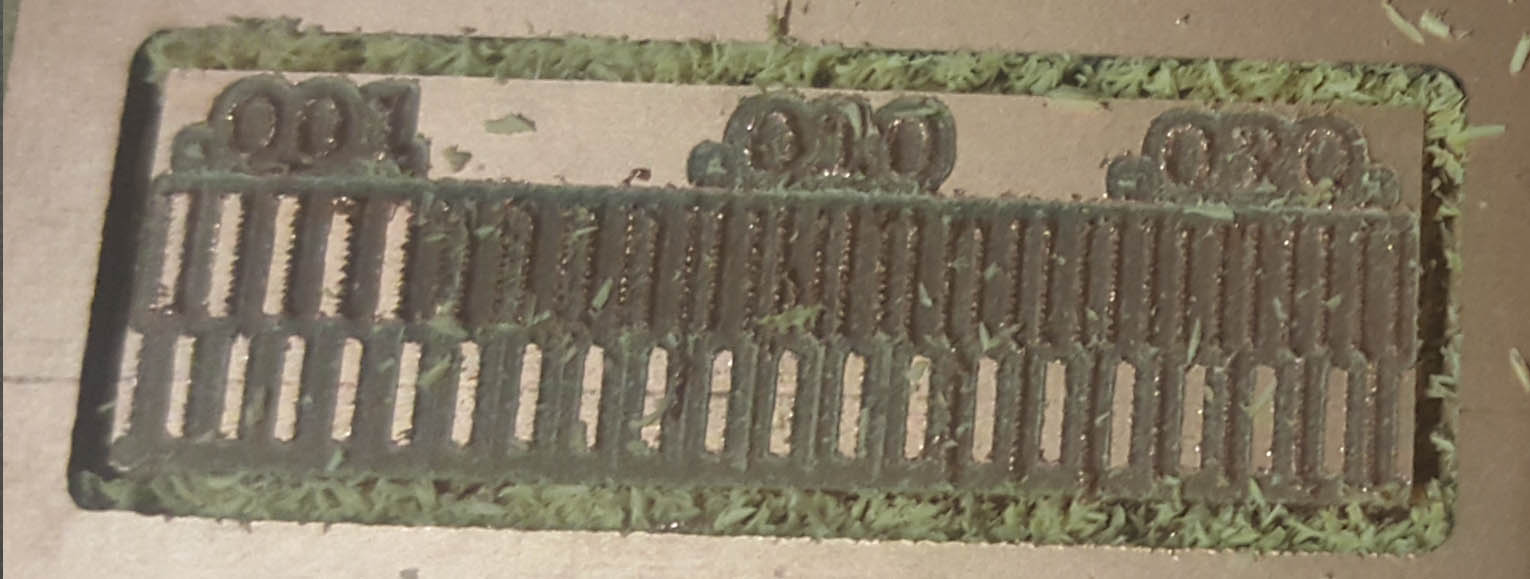

The results:

The result are not very satisfying, so we decided to do another test with another milling bit diameter 0.4mm instead of 0.15mm

The new g-code:

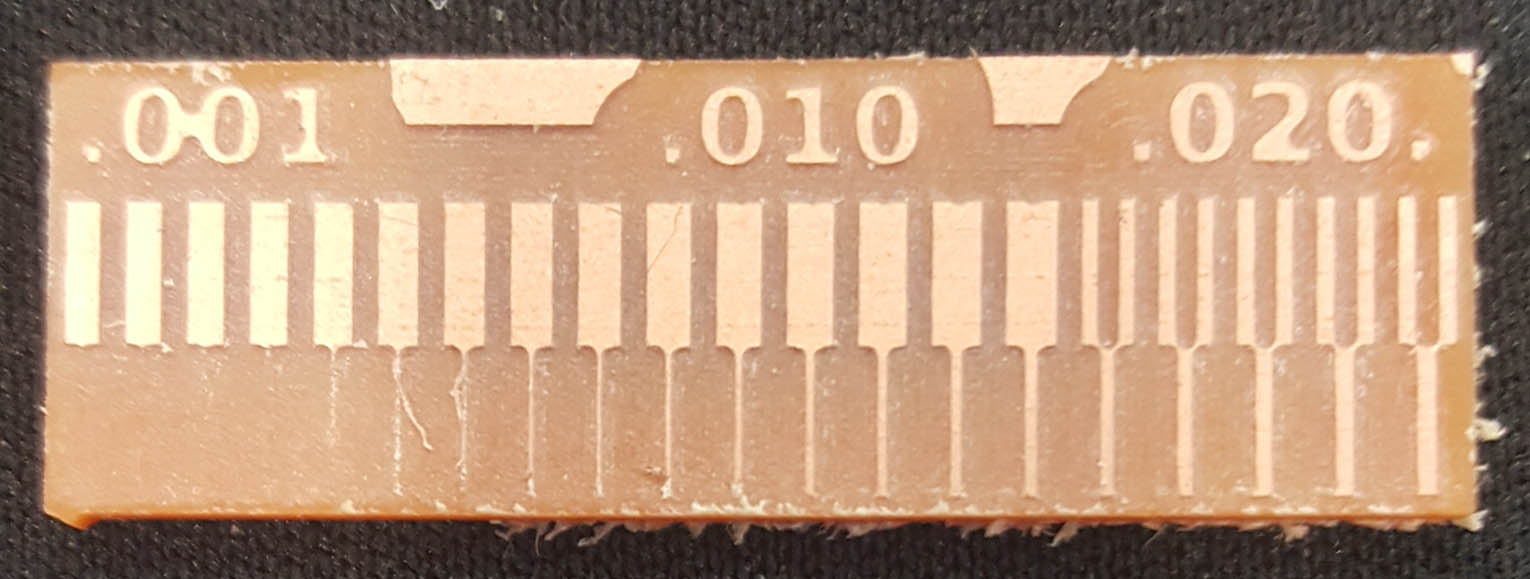

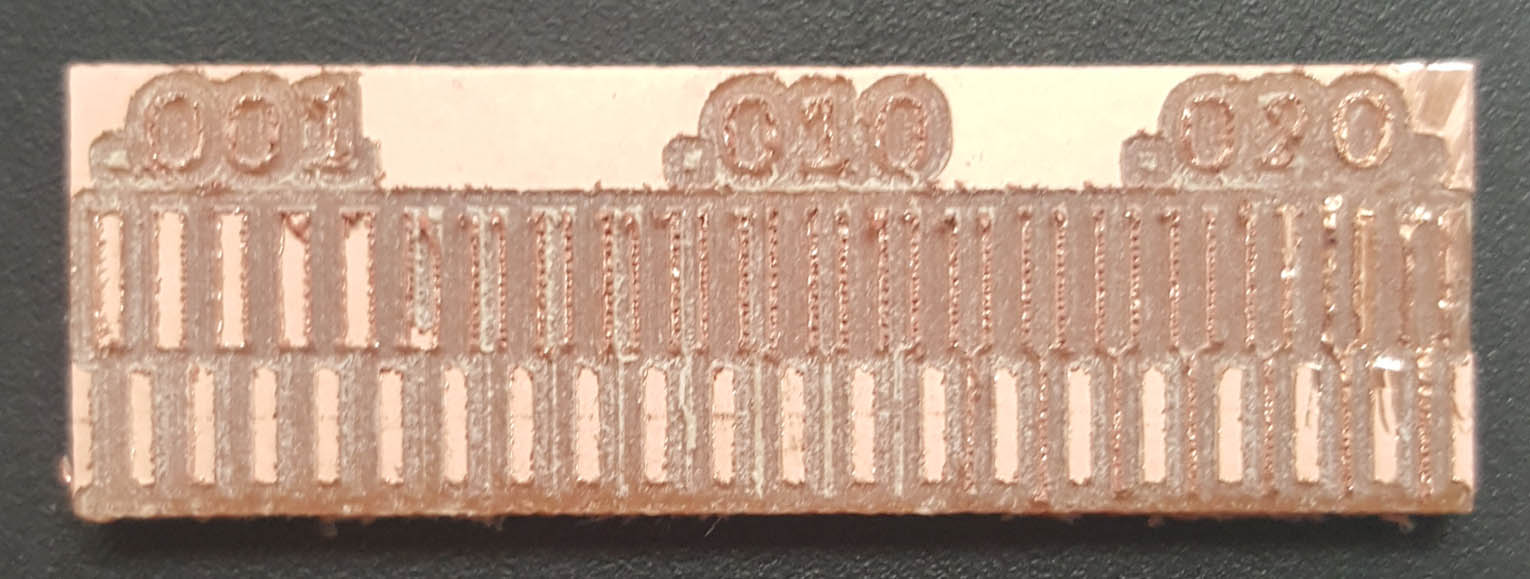

The new results: