Algarve FabFarm

GROUP PROJECTS : MOULD AND CAST

MOULDING AND CASTING

WORKFLOW :

Divided works - Read the Medical Data Sheet - Design a basic mould - Mill negative - Silicone Rubber Process - Casting - Develope Group Page

TOOLS & MATERIALS USED

MOULDING AND CASTING

Introduction :

For this week group assignment we must to Rewiew the Medical Safety Datasheet about the materials used for mould and cast a test and learn tips and things about mill process which are important to consider before design a moul more complicated such as a mould in 2, 3 or 4 parts.

First we made was learn about the differents silicons founded at the market. The last year Pilu made this assignment buying the silicon present in CEU Fablab so this year was an opportunity for learn more about other kinds or brands.

Our remote instructor recommended to us buy at this website : Form.es because they deliver fast so there we was taking a look.

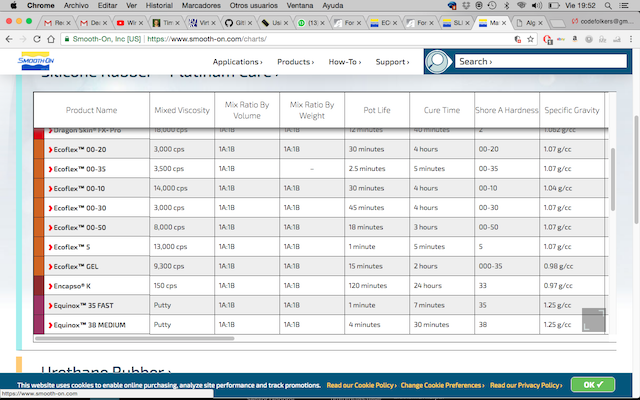

Finally, we decided to buy the Silicon Rubber Platinum Cure 3030 Slide from smooth-on brand so we went to their site for learn more about this product.There we founded the datasheet for dowload and read it before to start.

So here is the Technical Datasheet :

There we found usefull pages with technnical information about every materials they are developing :

1st EXERCISE

SUMARIZE THE TECHNICAL DATA SHEET FOR LEARN ABOUT THE MATERIALS :

About the cure process is important to notice that :

MEASURING & MIXING

POURING, CURING & MATERIAL PERFORMANCE

For best results, pour your mixture in a single spot at the lowest point of the mold. Let the rubber seek its level. A uniform flow will help minimize entrapped air.

2nd EXERCISE

READ THE MATERIAL SAFETY DATA SHEET FOR LEARN ABOUT THE MATERIALS :

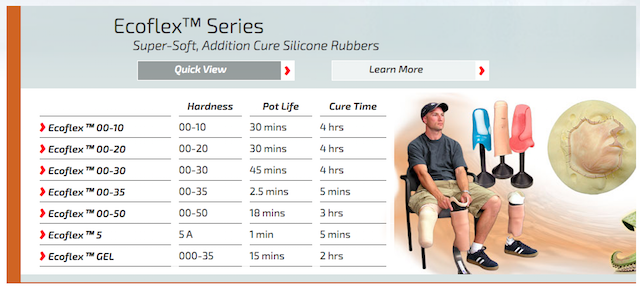

The Material Safety Data Sheet (MSDS) for this or any Smooth-On product should be read prior to use and is available upon request from SmoothOn so we was researching and finally we founded some. This one about ECOFLEX series :

And this one about differents kind of silicone between them the SLIDE 3030 :

We read both for review them.

3rd EXERCISE

REVIEW THE MATERIAL SAFETY DATA SHEET FOR LEARN ABOUT THE MATERIALS :

1. Classification of the substance or mixture : Not a hazardous substance or mixture according to United States Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (29 CFR 1910.1200), the Canadian Workplace Hazardous Materials Information System (WHMIS) and Regulation (EC) No 1272/2008 and subsequent amendments.

2. First Aid Measures :

3. Fire-Fighting Measures :

4.Personal precautions, protective equipment and emergency procedures: Only properly protected personnel should remain in the spill area; dike and contain spill.

5. Conditions for safe storage : Keep container(s) tightly closed and properly labeled. Store in cool, dry, well ventilated place away from heat, direct sunlight, strong oxidizers and any incompatibles.

Store in approved containers and protect against physical damage.

Containers that have been opened must be carefully resealed to prevent leakage.

Empty containers retain residue and may be dangerous.

Avoid water contamination.

6. Toxicological Information : In this section we didn´t find nothing about skin corrosion, reproductive toxicity, carcinogenicity or chronic exposure.

7. Ecological Information : No datas about toxicity, degradability, persistenceor mobility in soil.

8. Stability and Reactivity : We found important the thermal oxidative decomposition because can to produce carbon oxides, gasses or vapors.

9. Protection Equipment :

10. NEVER :

11. ALLERGEN : People who are allergic to durian, tree nuts and tree nut derivatives or musk thistle seed should avoid contact with this product.

4th EXERCISE

DESIGN A BASIC MOULD

5th EXERCISE

MILL THE MOULD

6th EXERCISE

MEASURES FOR MIX

7th EXERCISE

MAKING THE SILICONE MOULD

8th EXERCISE

CASTING

THE RESULTS & CONCLUSIONS