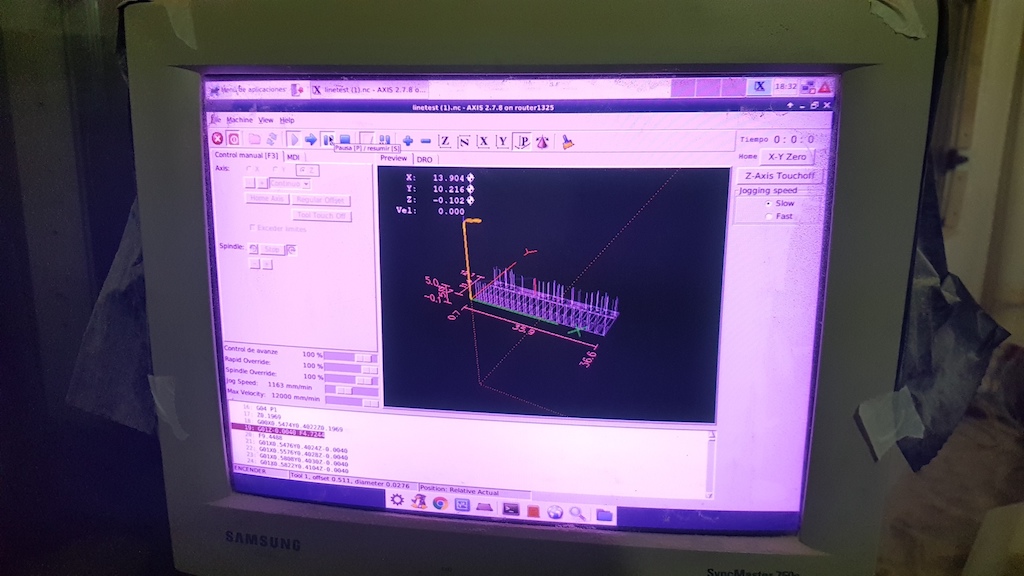

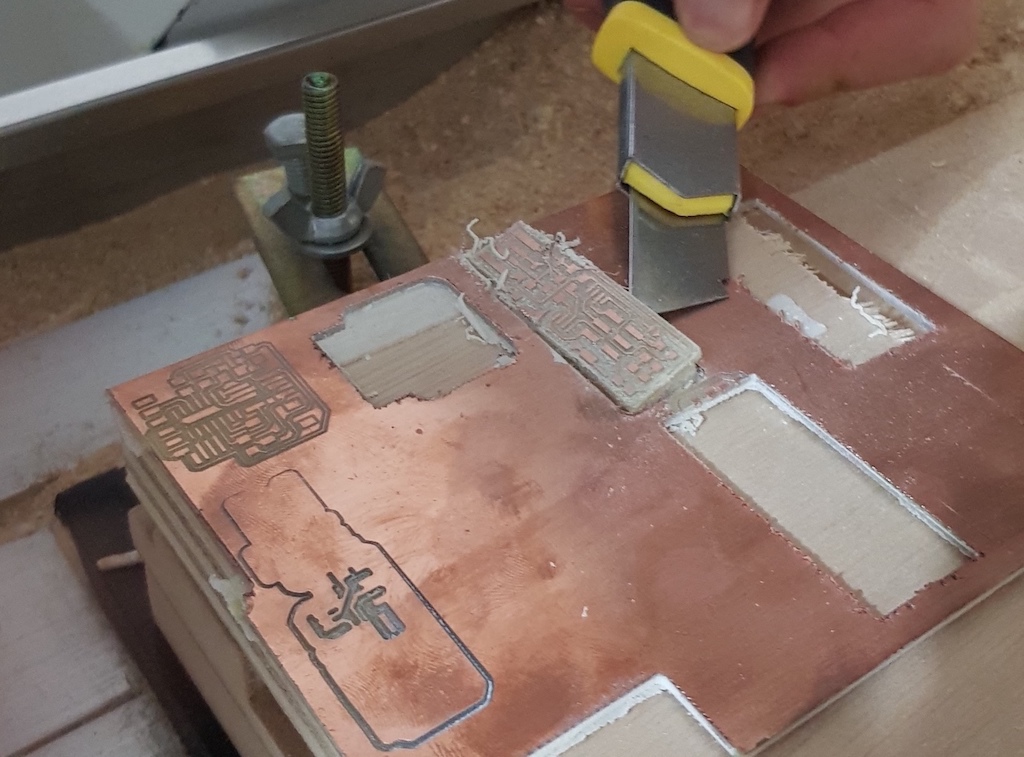

Our Fab Lab have the 1325 CNC router machine. It is a very precise machine, It is a very big machine, in spite of it the machine is very precise, we verified it in this assignment and works pretty goof for a PCB board.

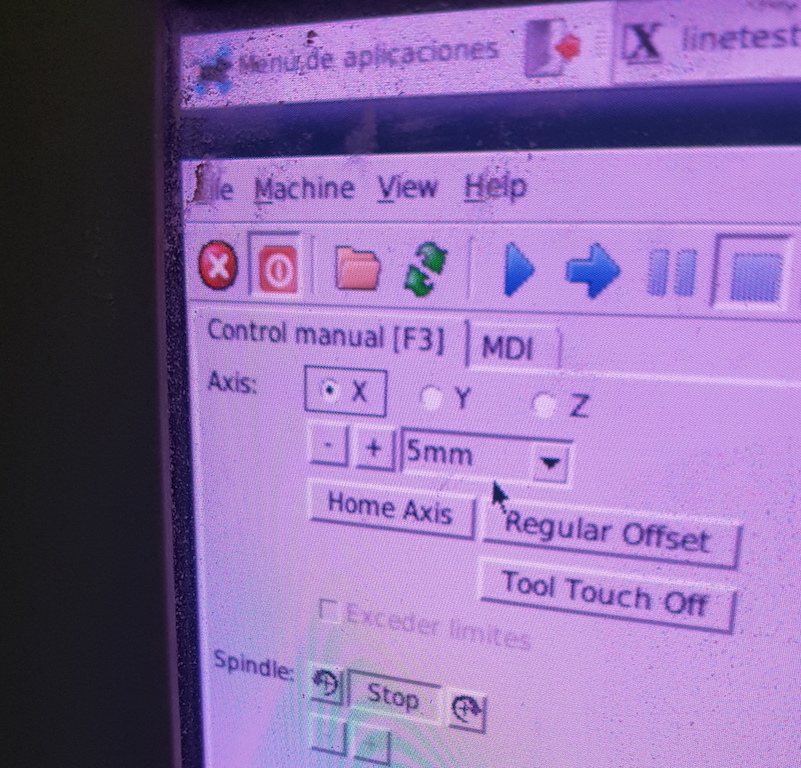

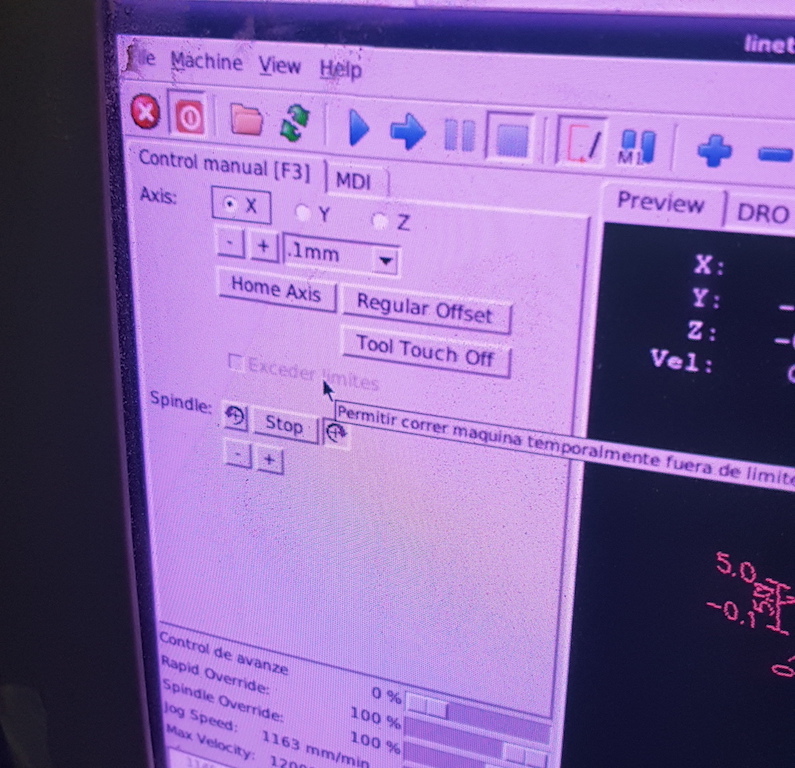

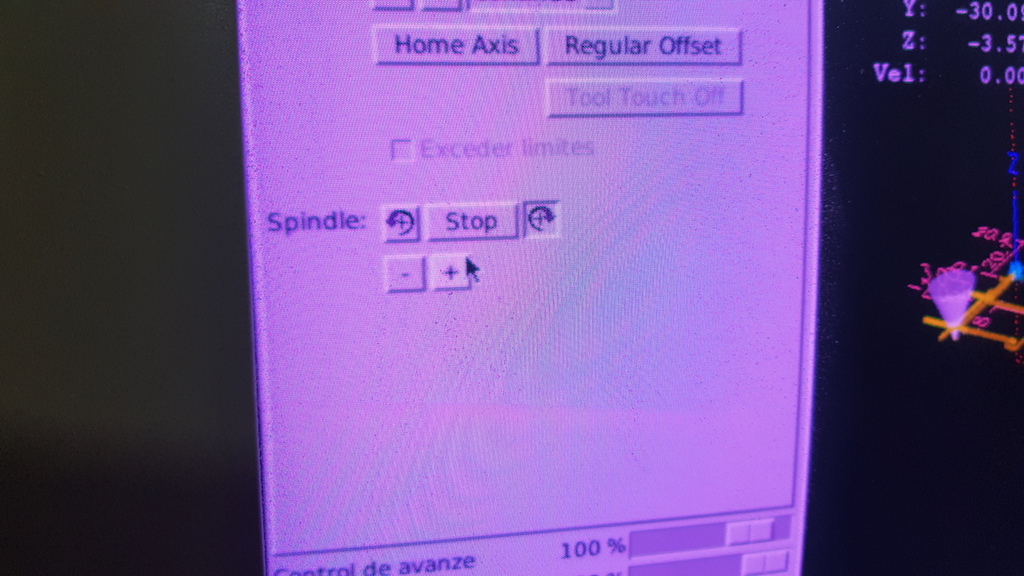

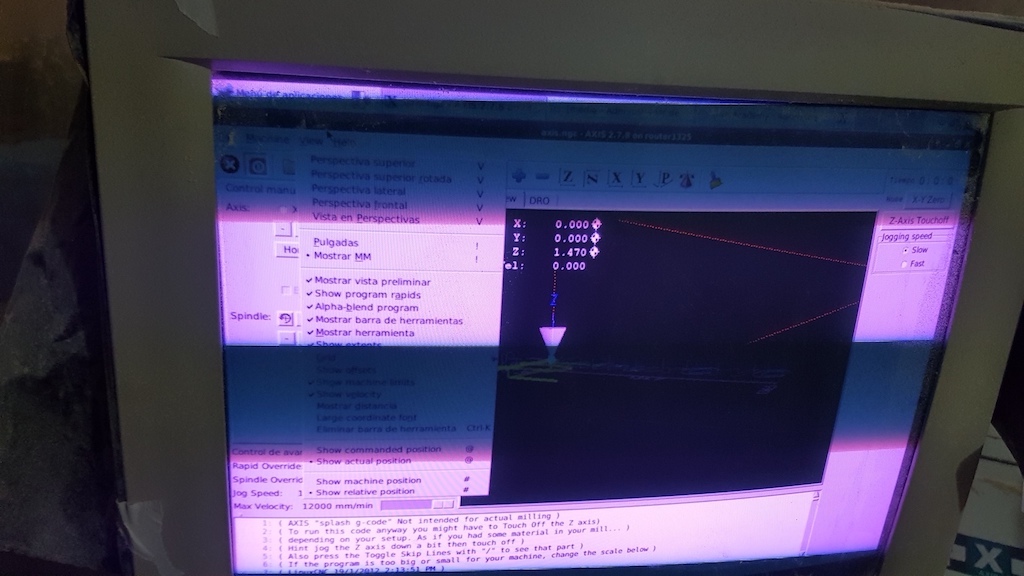

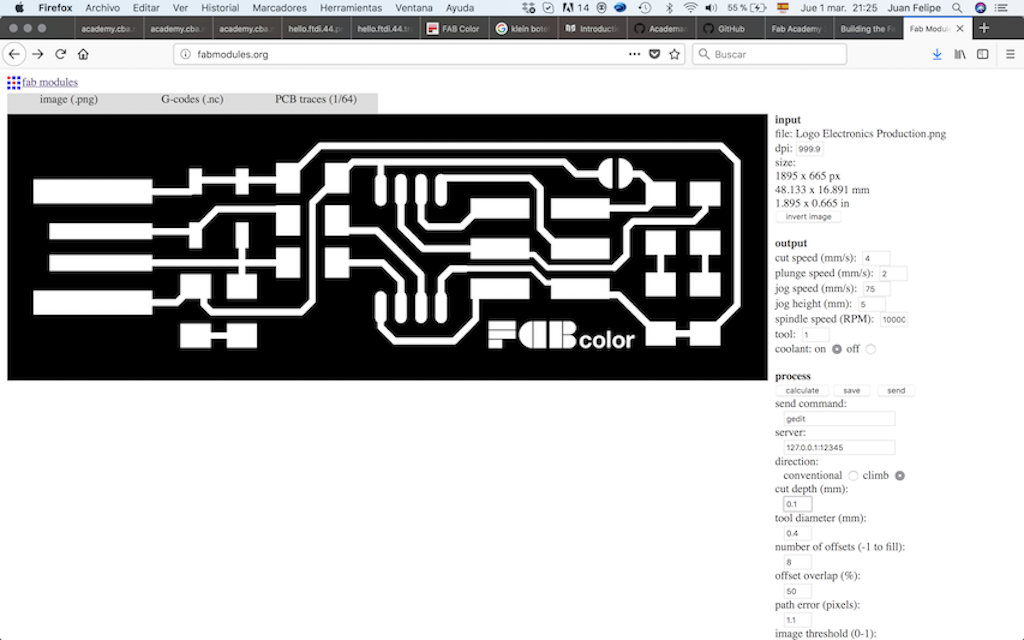

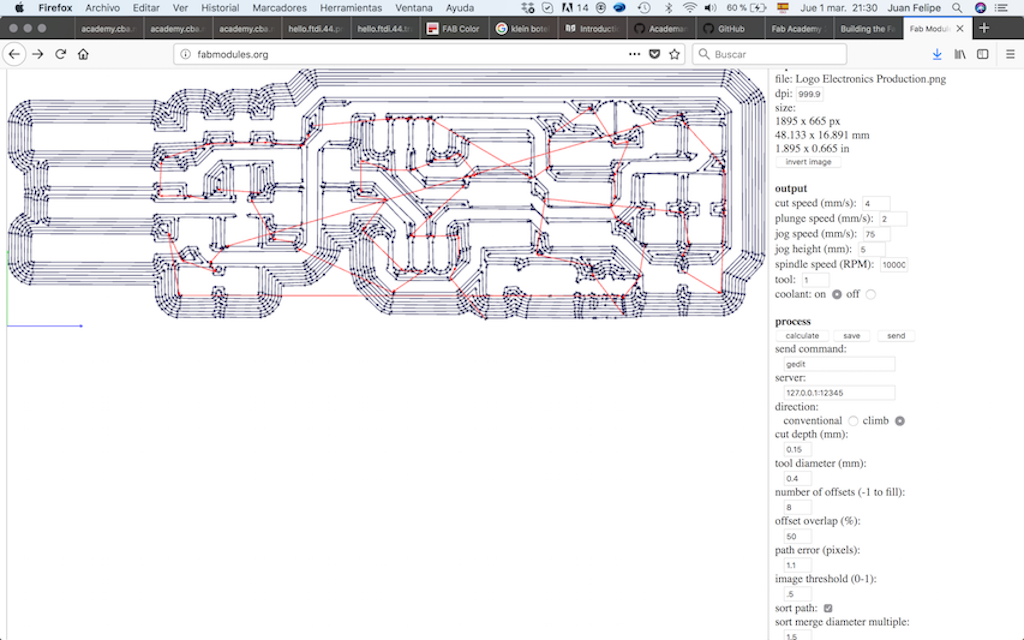

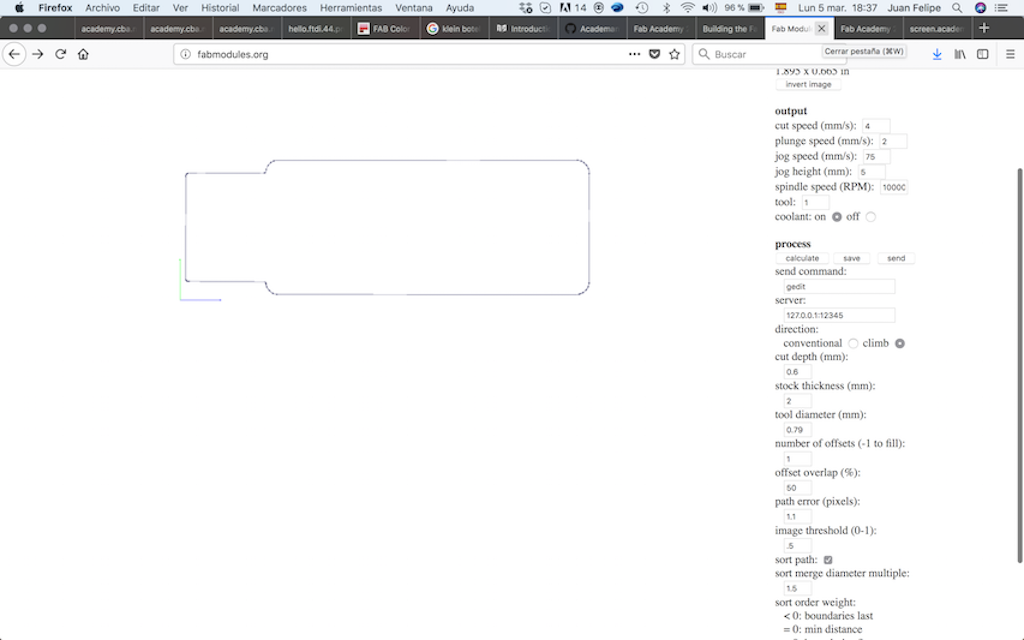

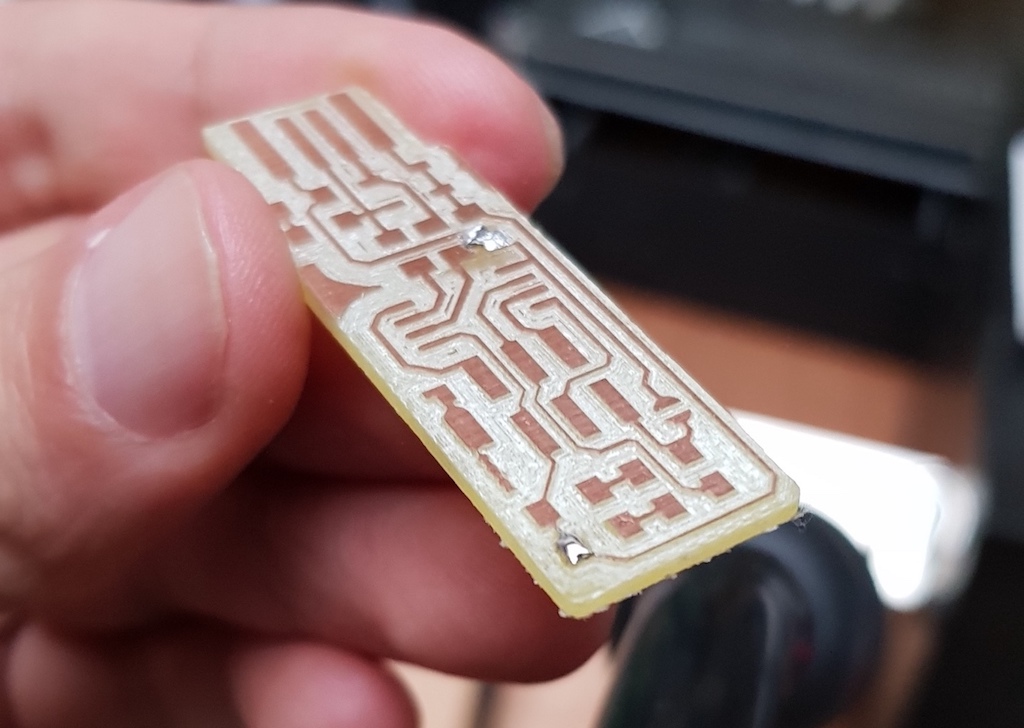

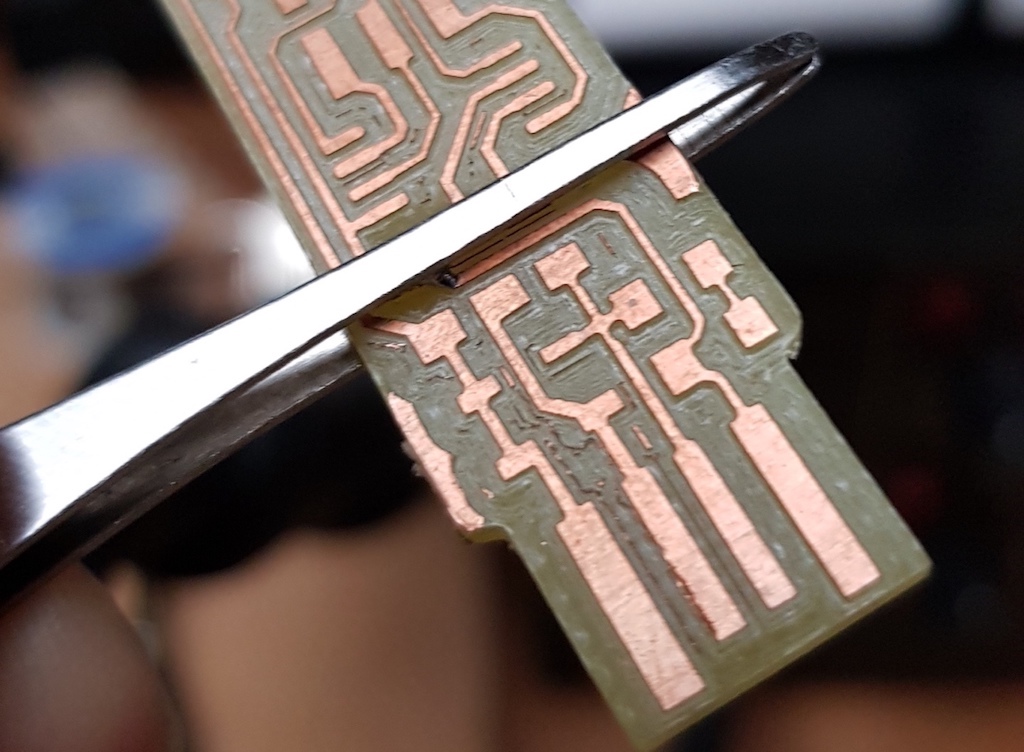

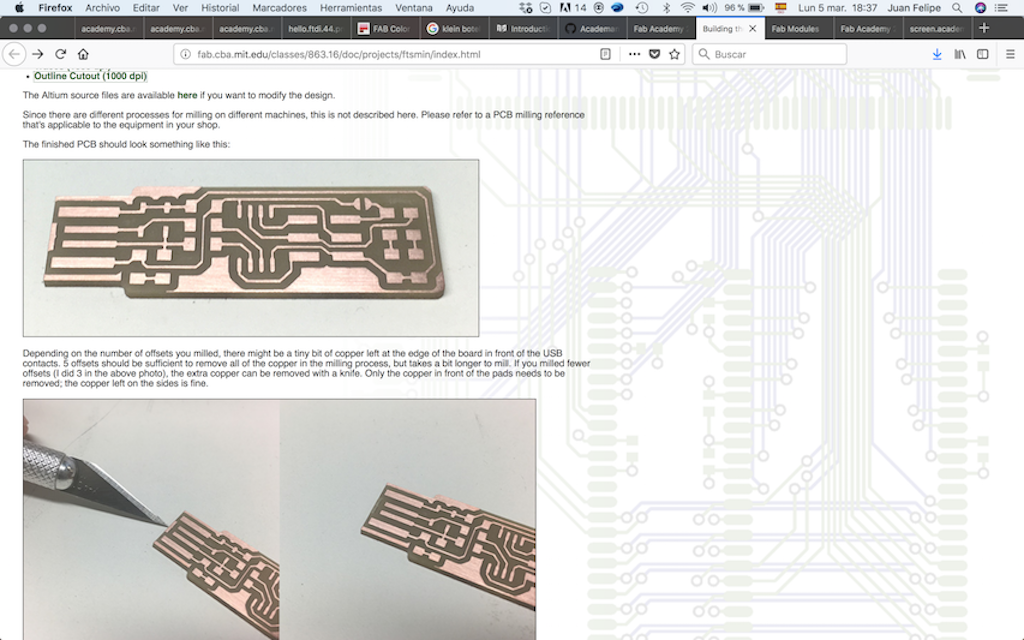

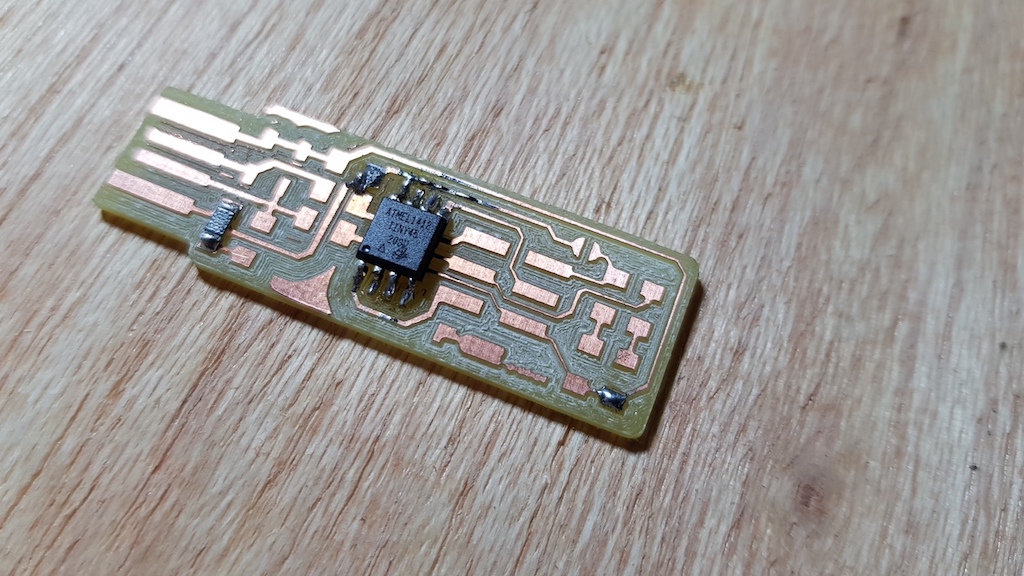

With the tutotial I download the files, configure the offsets and depth of the cut and launch to cut the files.

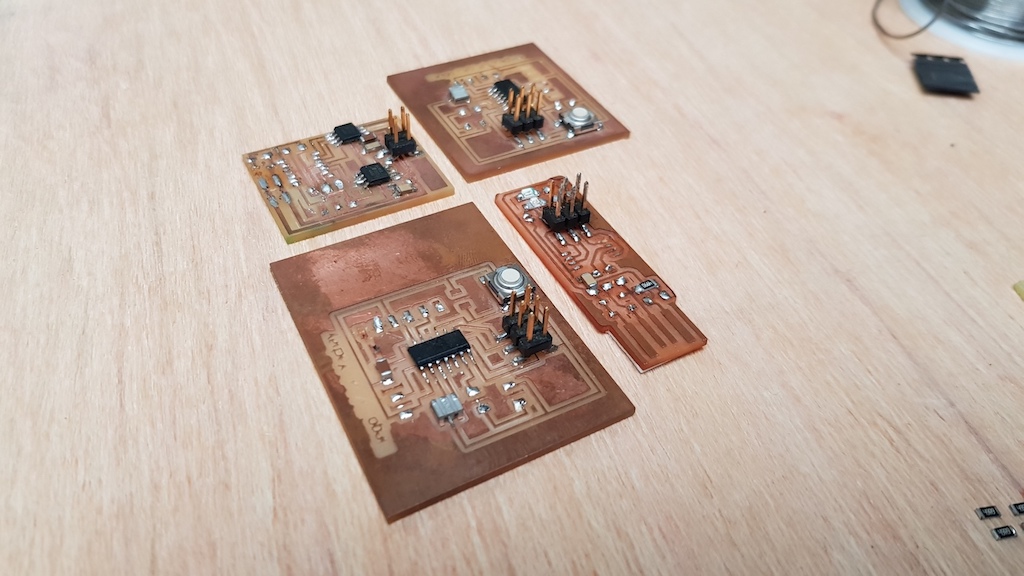

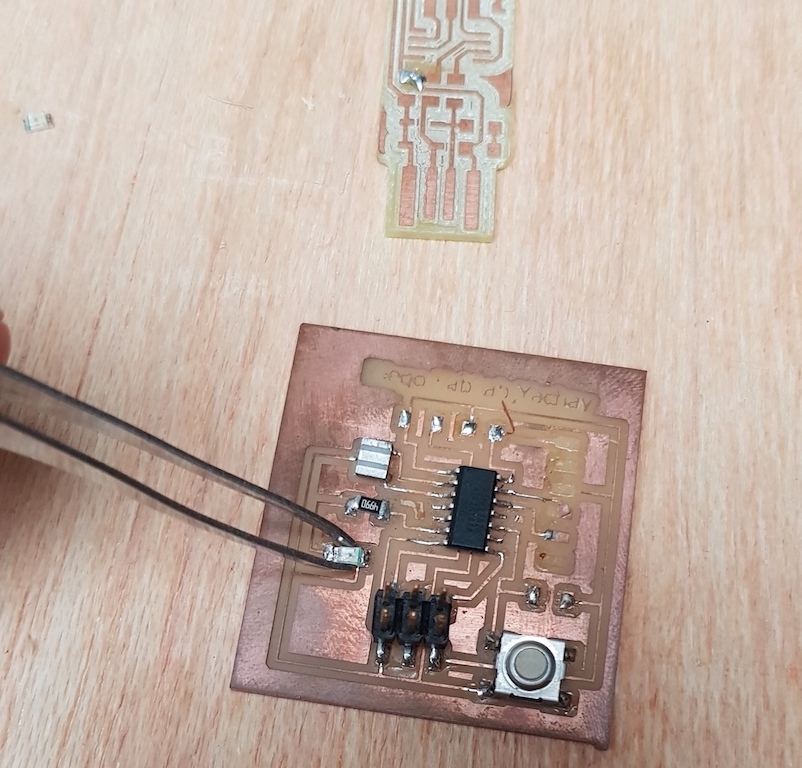

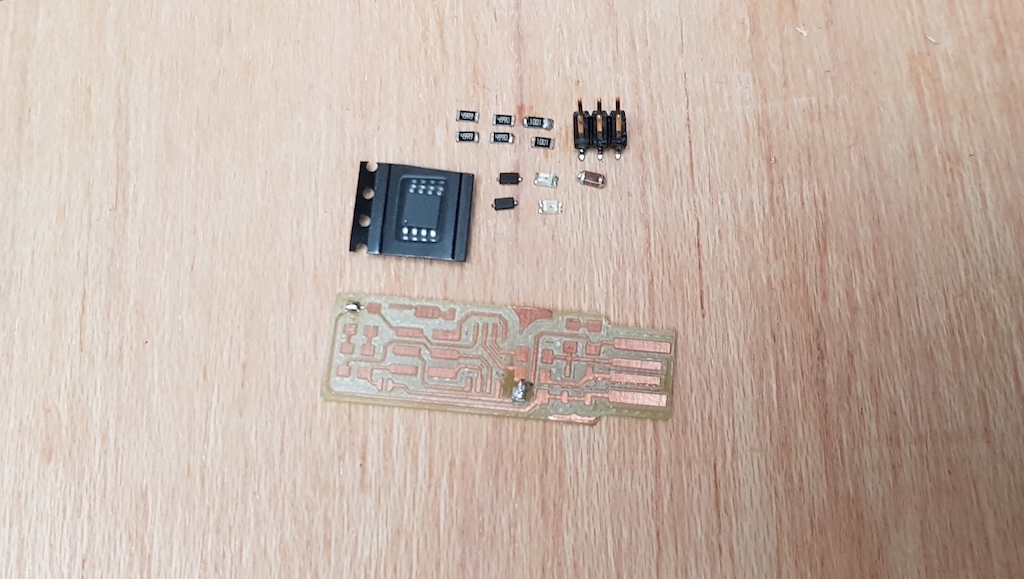

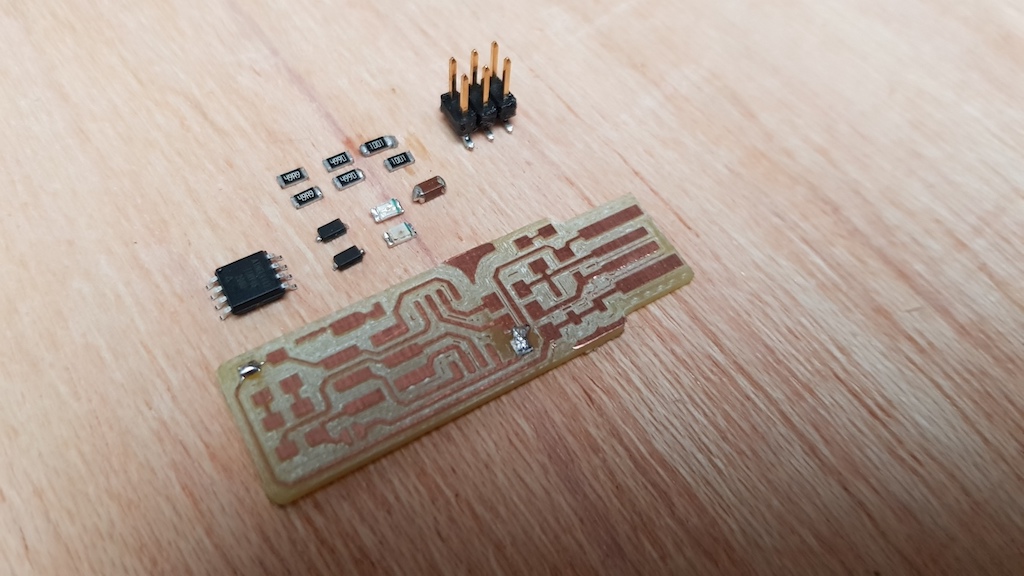

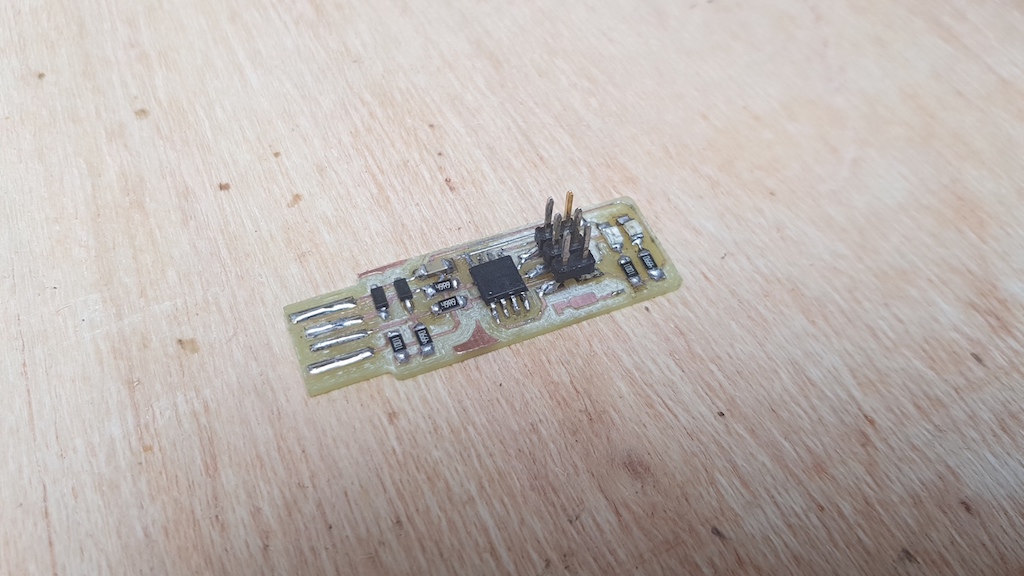

Finally following the tutorial, I prepared the components to weld the plate. He started the exercise by desoldering components from previous plates to re-whip them with the new one. This exercise allowed me to exercise the pulse and the power of the weld. Once all the components were ready, I started welding. First I had problems with the power, it was very high and I managed to burn the plastic of the components so it went from 4 to 2 and from that the solder points went very well.

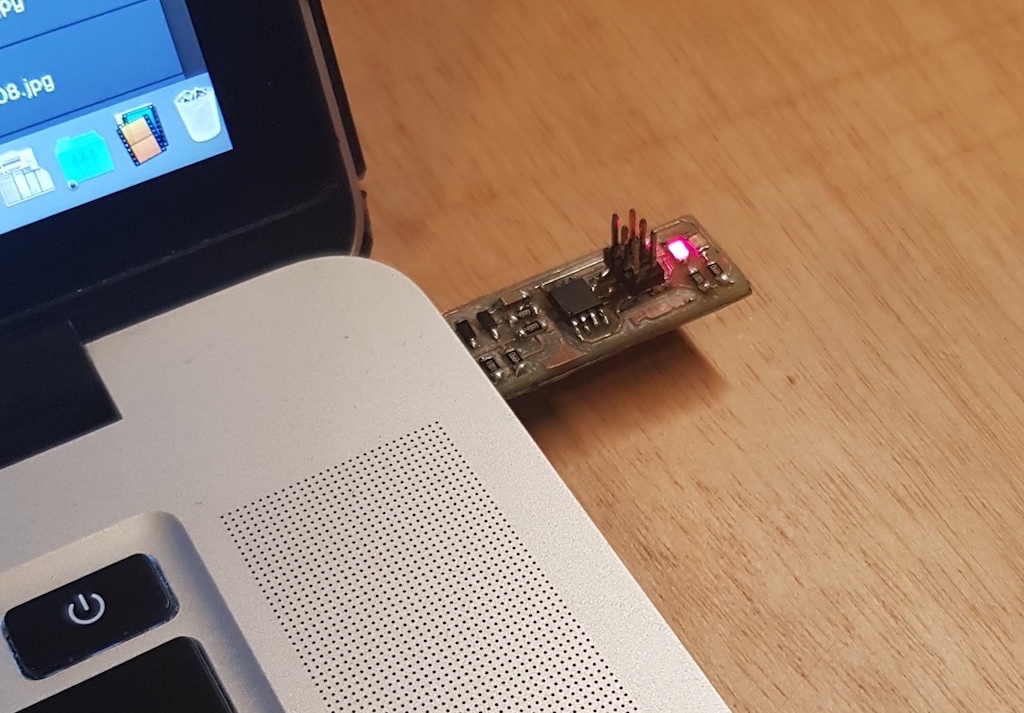

To finish the PSB, at the end of the weld I checked that all the circuits were working, I improved a solder that was not connected. We paste in the bottom of the PSB a mica to give it more body and voila! It turned on the bulb when entering it in the computer.