Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually.

For the group activity, Yachay team have divided to fabricate the groupal project in this way:

It should be noted that this is the first time that I will design a structure for an electronic plate engraving machine, for which I am very happy in the development of this activity.

We have planned among all the team members to develop a machining milling machine of similar operation and structure that our Roland MX-40 CNC milling machine, the advantage of the machine is that it will have the detachable headstock system so that it can be linked with drills that vary their diameter.

As a starting point it is important to use design criteria in the selection of the type of recorder to be made.

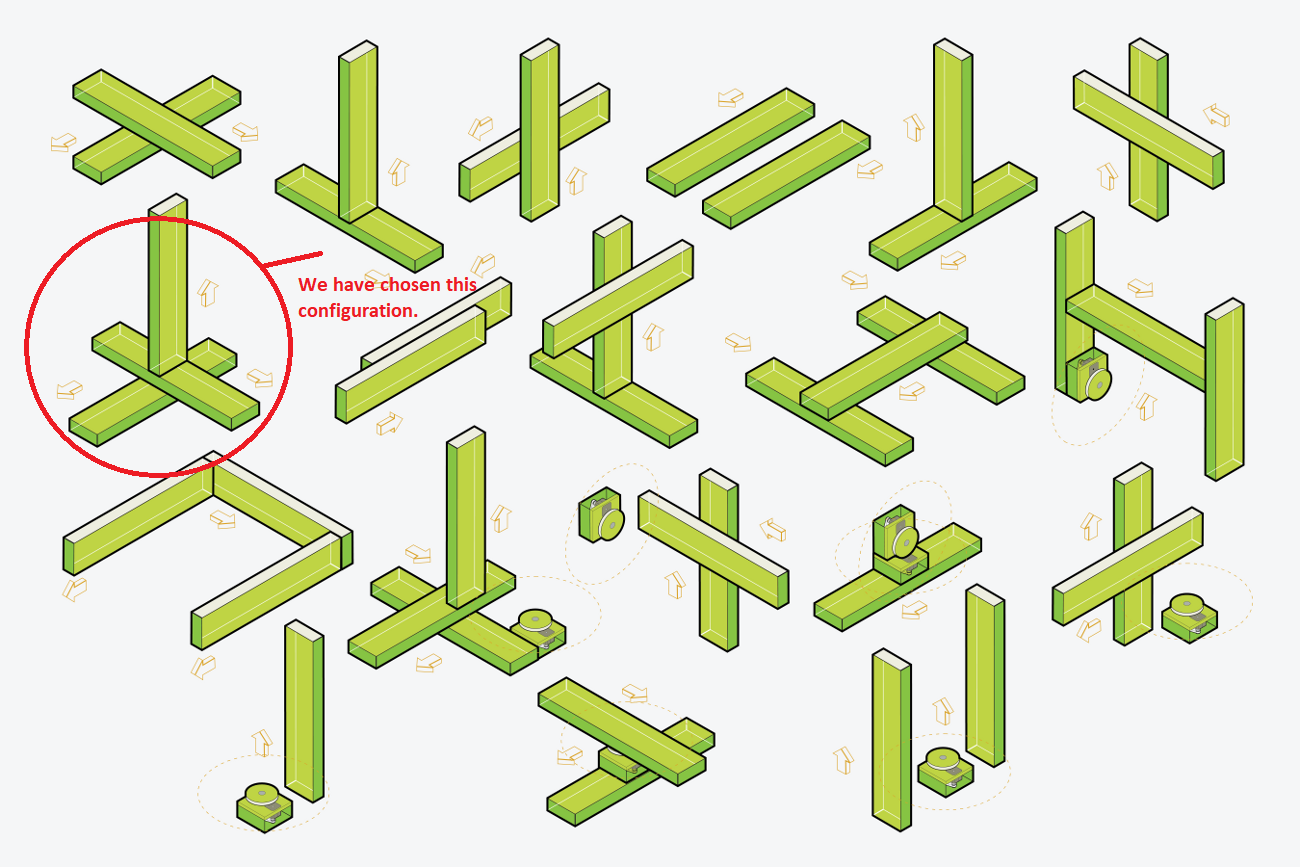

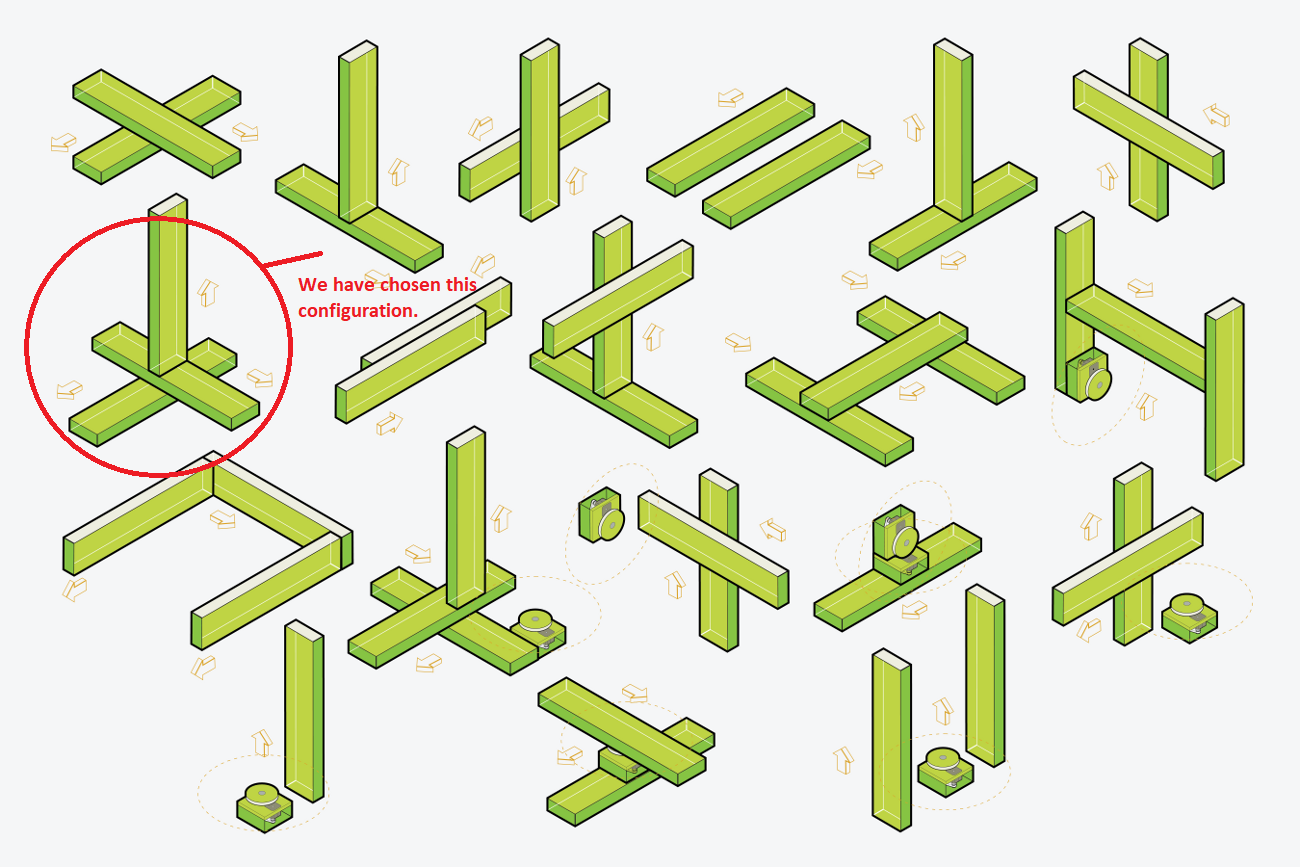

If we go deeper into the subject we will find that there are a number of configurations of the displacement axes

Firstly, it is important to identify the most suitable system to build according to the activity that our machine will perform, in this case the engraving of electronic boards. CNC machines have many configurations of their step motors, their positions vary, the following graphic best illustrates some of the possible configurations.

Once the system to be made is chosen, the design of the structure must be planned in CAD software, the collection of materials to be used, the cutting of parts and assembly of the electronic boards, as well as the testing of the stepper motors, the development of the electronic system and the compatibility with the software of engraving or printing.

For this activity it is important to have all the necessary materials for the development of this activity, according to an analysis made with the work team, we have come to identify that for this activity the following elements are required:

MDF Material.- EDIMCA is a ecuadorian company who has given us some MDF tables to fabricate prototypes, so we have not bought this material

Once identified the materials, it is important to get them, but to know their location it is important that we design them in CAD design software, in this case the software that will be used for this activity is SolidWorks for its efficiency at the time of design.