Week 7 assignments:

Computer-Controlled Machining:

From Fab Academy 2018 assignments

1. Make something big (on a CNC machine)..

Have:

Explained how you made your files for machining (2D or 3D)

Shown how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)

Described problems and how you fixed them

Included your design files and ‘hero shot’ photos of final object

Test CNC Machine (GROUP PROJECT)

What's CNC?

The numerical control by computer, or better known as CNC, is a system that allows to control at all times the position of a physical element, usually a tool that is mounted on a machine. This means that by means of a software and a set of orders, we will control the position coordinates of a point (the tool) with respect to an origin (0,0,0 of machine).

The CNC controls all the movements of the tool when we are manufacturing and not only the coordinates, but also the way to move between them its speed and some more parameters.

How does the routing work?

Routing is a roughing process.To this end, a cutter with cutting edges is used, which cuts the material by means of chip cutting when turning.

The CNC Router works with the two axes, X and Y, this allows the cutting tool to move and rough out in both dimensions.

The Fablab Yachay has a CNC SHOPBOT Alpha milling machine of dimensions 2440 x 1220 mm. To test the CNC machine, in group work, we manufacture a device that allows to validate the pressure adjustment.

Before starting the practice of the week some important elements of the CNC machine are recognized.

ShopBot Alpha milling machine

Before of manipulate the CNC machine is very important following safety tips:

Manufacturing test device (Group Project)

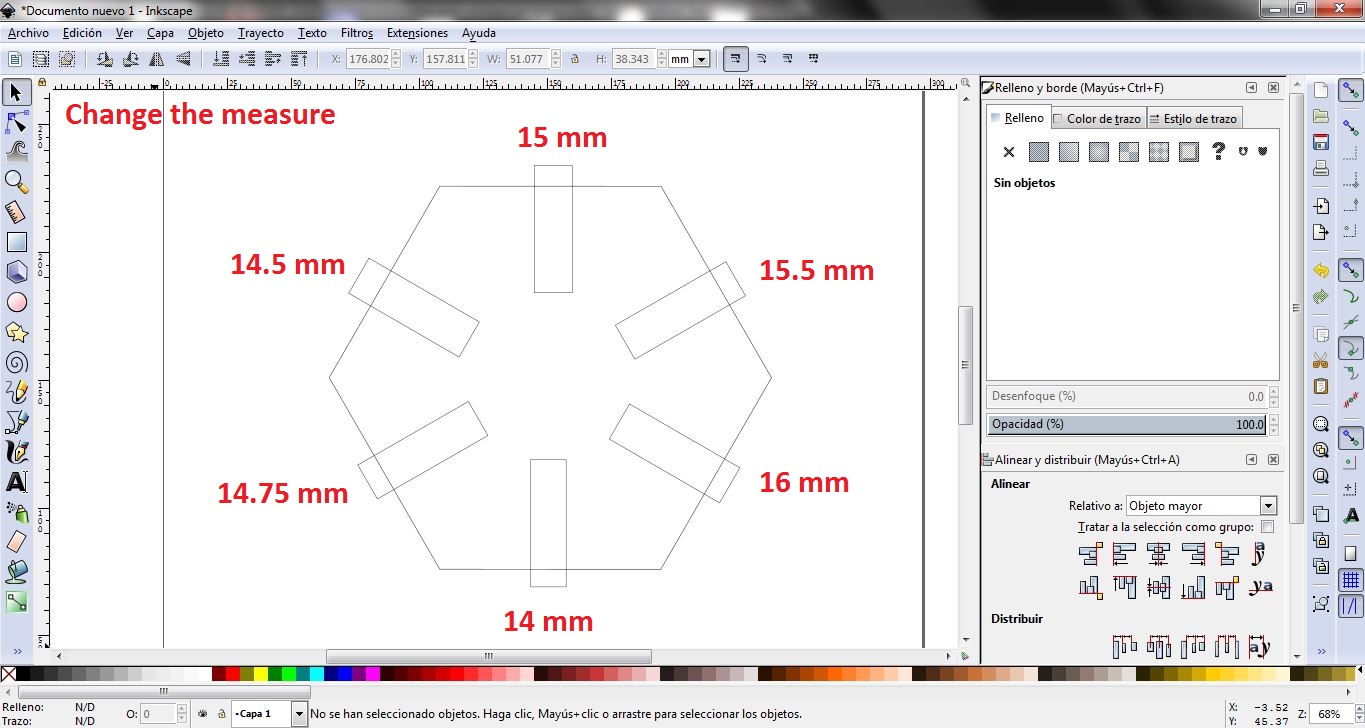

For instruction in computer-controlled machining in group assignment we have designed a device that allows us to validate the press fit, this device allowed us to find the ideal measure to subsequently apply the parameters and exact measurements in the final design of the assignment this week.

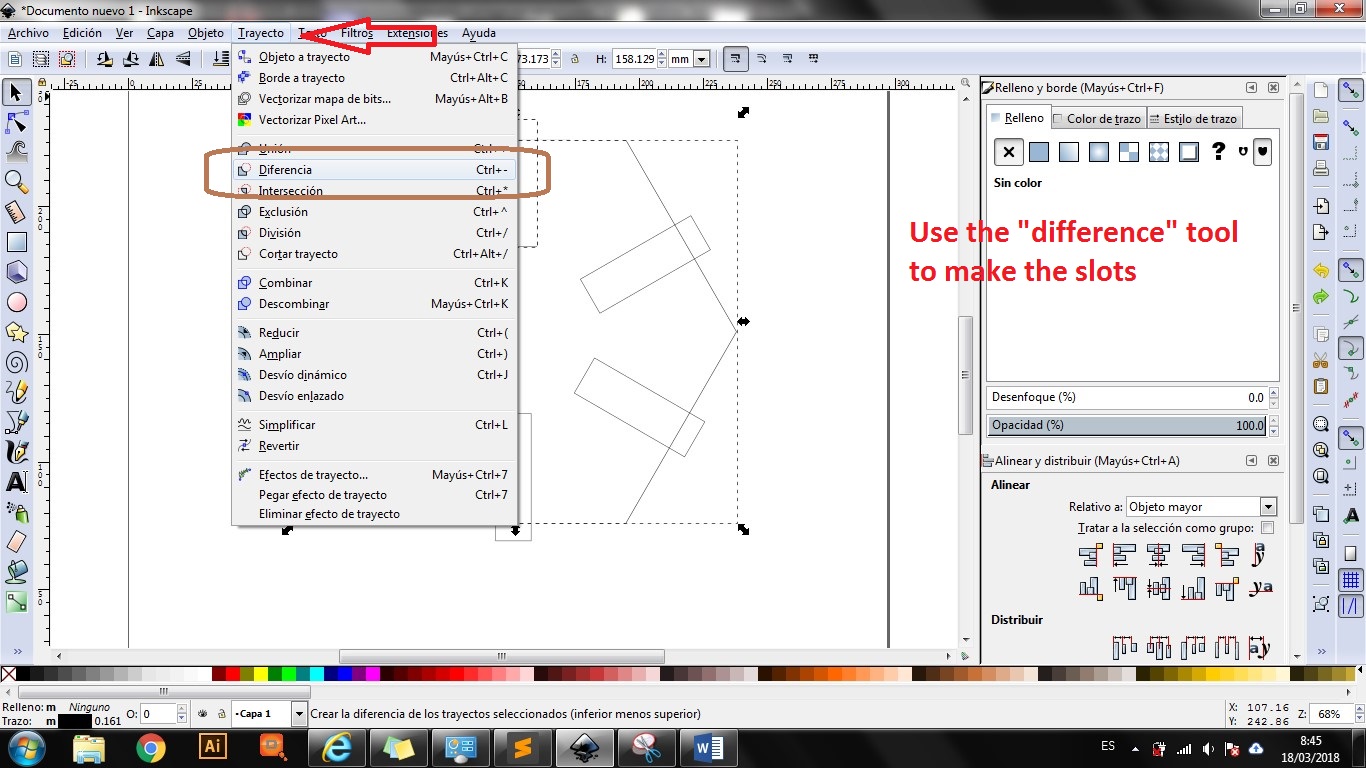

Design in Inkscape software

The main consideration when cutting on a CNC router is the shape of your cutting tool. It is not possible to make square inside corners using a round end mill. You can approximate squareness by decreasing the tool diameter, but there will always be a little extra material in the corners obstructing material passing through.

The easiest way to circumvent this limitation is to remove extra material from inside corners. These extra cuts are commonly called "dog bones" due to the shape of the resulting hole or notch

Import design to V-Carve Software

VCarve Pro provides a powerful solution for cutting parts on a ShopBot CNC Router. There are tools for 2D design and calculation of 2D and 2.5D toolpaths and along with the ability to import and toolpath a single 3D model (STL, OBJ etc.). There is also support to import multiple Vectric Clip Art 3D models (V3M) to create 3D assemblies.

Setting parameters in the machine

Start cut

Make something big (on a CNC machine)

For this assignment I made a piece of furniture for the desktop in the solidworks software, then the steps of design and fabrication by CNC cutting are indicated

Base design

Support design

V CARVE SOFTWARE

Manufacturing

Applications

CONCLUTIONS

- For the design and manufacture of the furniture used solidworks itself that allowed me to validate the design receiving its feedback on the characteristics and dimensions.

- The material used was chipboard of 1 inch thick same that gave great stability and resistance to the furniture.

- The purpose of the furniture is to raise the monitor in such a way as to allow the operator of the machine to improve its position and avoid health problems

DOWNLOADS

- File 1: Furniture Design

- File 2: TEST