The Face Vace

I've been building a vase. It's an

heirarchical world of regular objectification and oppression but when confronted with furniture, a non-living thing, it seems to bring out a lot of the emotion the everyday oppression doesn't. Getting a chance to build one of these pieces made me quite excited.

heirarchical world of regular objectification and oppression but when confronted with furniture, a non-living thing, it seems to bring out a lot of the emotion the everyday oppression doesn't. Getting a chance to build one of these pieces made me quite excited.

Shaping the vace from a face

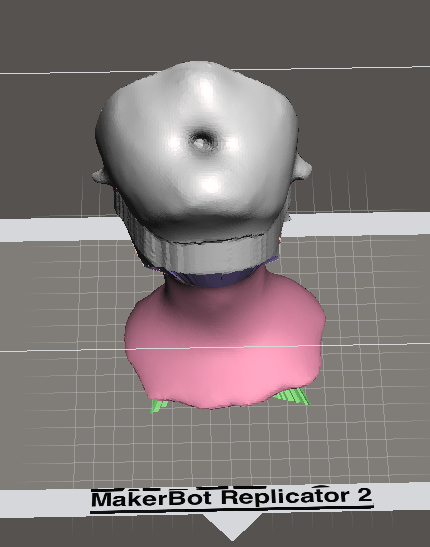

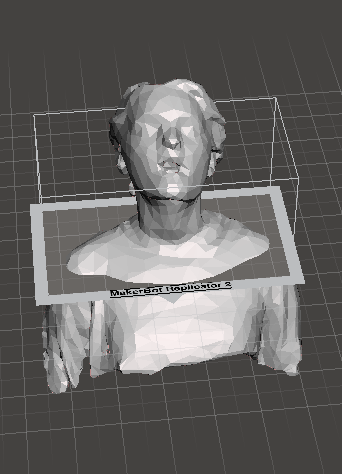

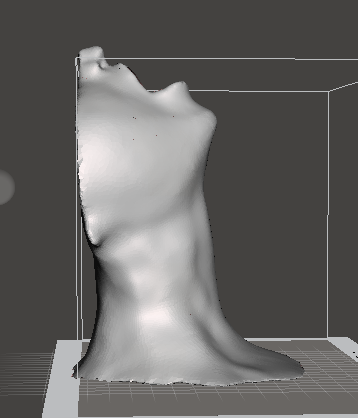

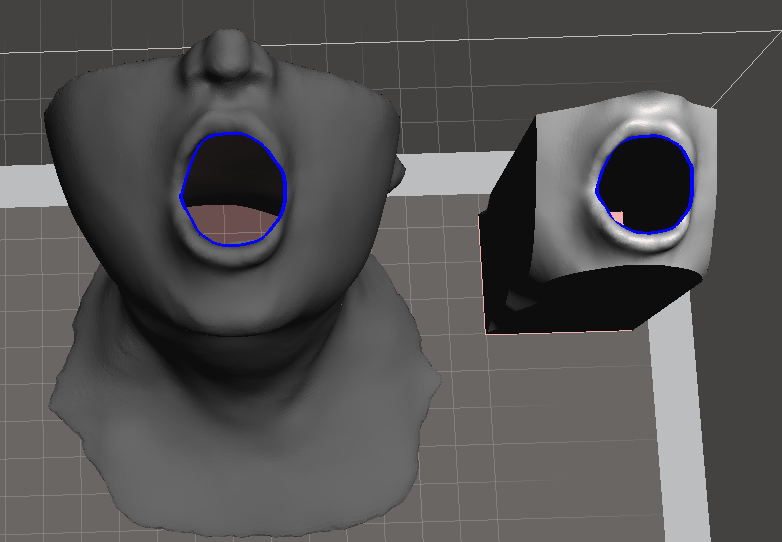

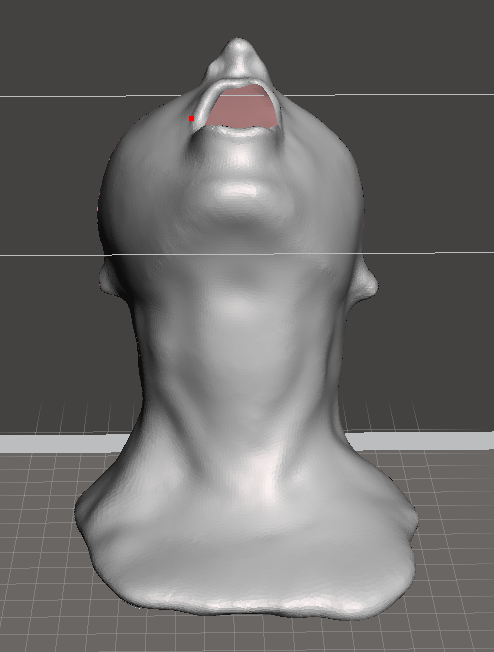

I started out with getting a scan of Anna through the kinect scanner. It didn't catch Annas face at first but we turned of the lights so there was a small lightsource and this worked way better. The scan itself was  pretty scary and didn't resemble the beautiful Anna well at all.

pretty scary and didn't resemble the beautiful Anna well at all.

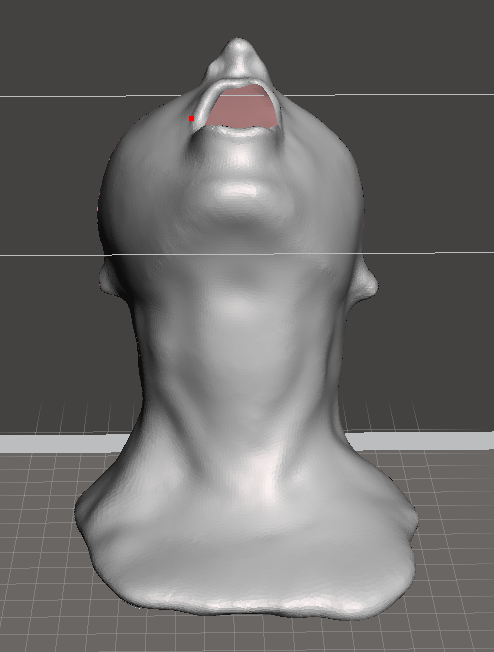

I had been hoping to use the scanning as the foundation for the vase sculpture but ended up re-sculpting it almost from scratch. I did keep the jawbone structure but that was about it. The  Before and

Before and  After shows it pretty clearly, there wasn't much to work with.

After shows it pretty clearly, there wasn't much to work with.

When importing the STL to Meshmixer it rasterized completely (as you can see above) and didn't keep any of the smooth surfaces it had in the beginning. I fixed this by simply using the smooth-surface tools.

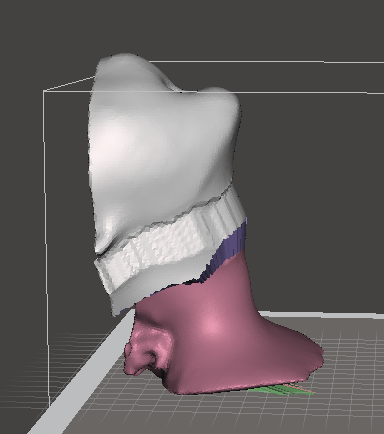

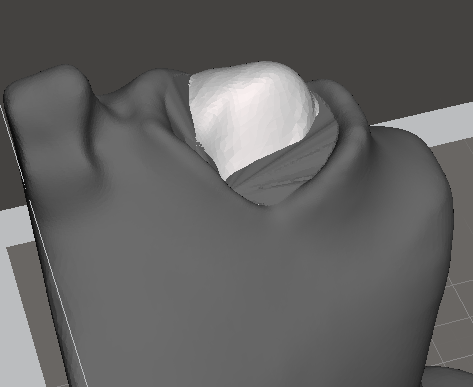

Having to do the structure from scratch wasn't that bad since I had already planned on a few non-human like aspects such as a  overly long neck with an unnatural straightness, see below. I did this by selecting the areas I wanted to keep and simply moving them with the transform tool. This allowed me to create the basic shape I wanted.

overly long neck with an unnatural straightness, see below. I did this by selecting the areas I wanted to keep and simply moving them with the transform tool. This allowed me to create the basic shape I wanted.

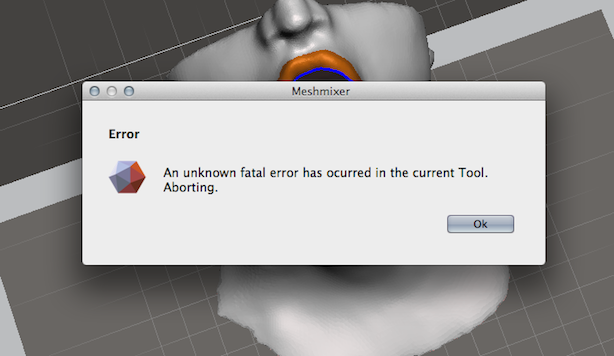

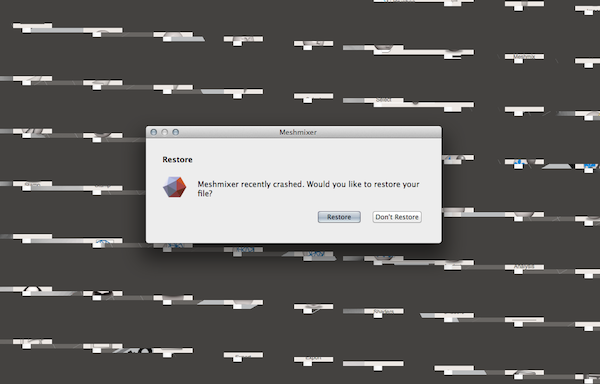

Sculpting the actuall shape was a straight forward process which I enjoyed. If it hadn't been for Meshmixer insisting on crashing regularily it would've been no problem, but no, Meshmixer seemed to enjoy crashing and giving me  cute error messages. It would freeze up and I'd restart it, solving nothing, sometimes when it had crached and I'd restarted Meshmixer it would give me

cute error messages. It would freeze up and I'd restart it, solving nothing, sometimes when it had crached and I'd restarted Meshmixer it would give me  beautiful glitches while reminding me it just crached. I believe this might have something to do with the model being constructed by aprox. 2 000 000 triangles.

beautiful glitches while reminding me it just crached. I believe this might have something to do with the model being constructed by aprox. 2 000 000 triangles.

But there were issues...

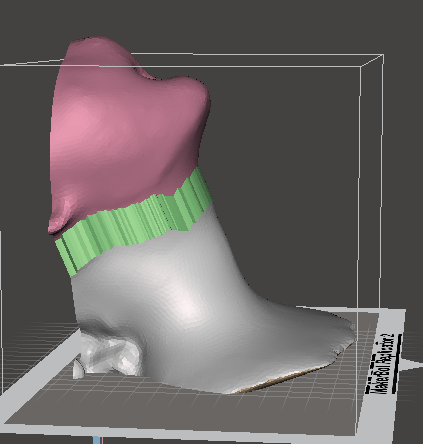

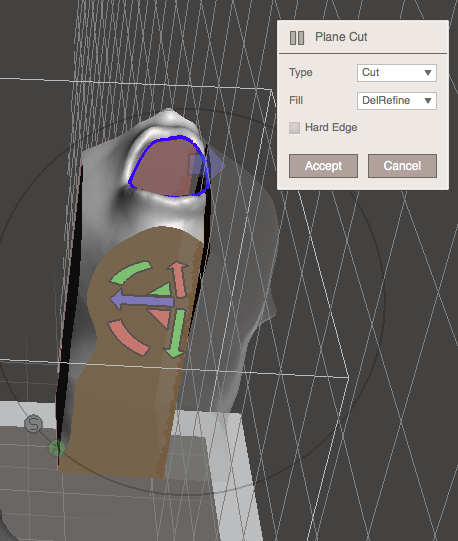

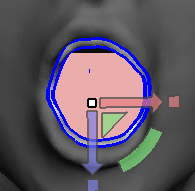

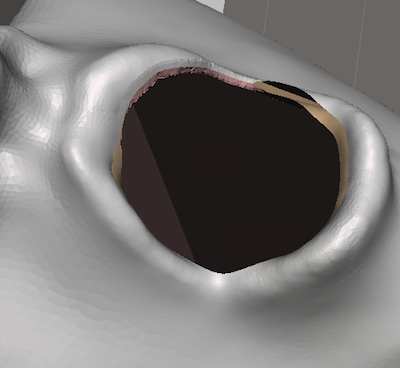

What would seem to be the most difficult part, actually shaping something into a nice human-like shape was, as previously mentioned, easy. The difficult part came about when I needed to make it printable. In order to create the inside without having a lot of extra free space I made a copy of the original and used  plane cut to make the smaller space. Afterwards I placed the smaller copy

plane cut to make the smaller space. Afterwards I placed the smaller copy  on the inside. The first time I did this I used the

on the inside. The first time I did this I used the  zipping tool to merge the layers but this time I didn't want any chance of leaving only a shell but a full solid except for the opening of the vase and the space. I did this by using the boolean tool and then the inflate tool to drag the inside out. This ended up

zipping tool to merge the layers but this time I didn't want any chance of leaving only a shell but a full solid except for the opening of the vase and the space. I did this by using the boolean tool and then the inflate tool to drag the inside out. This ended up  looking pretty gross.

looking pretty gross.

Printing was pressuring my patience

The final issue I had was making it a printable shape which netfabb would embrace without any exclamations. I thought I had this solved by, when making the shape hollow, giving it a 2 mm thickness. I believe the problems came about when I created the holes for the mouth by using Extract instead of some other tool which would still leave an unbroken object.

Whatever the issue was, when I scaled it down (since we didn't have a printer which could produce such a large object) I ended up having a wall thickness which was below the resultion it printed in and thus it didn't print. In frustration I threw this first print away and unfortunately didn't get any pictures.

More failed prints.

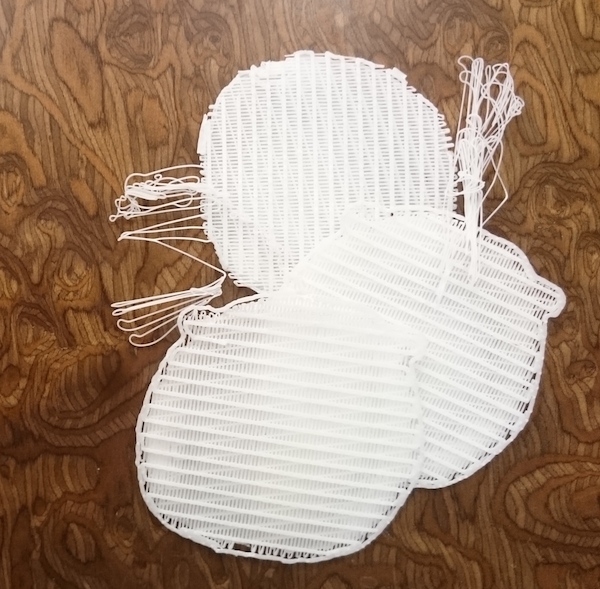

But no worries! I had so many other failed prints I've got a few left over to show. It wasn't until my sixed or seventh print (I lost count) that I actually managed to print something closely resembling my 3d design.

The biggest bach of failed prints produced the same poor results. The first two times it did this I had let the prints go over night and didn't look at it until the next morning. At first I thought the printer was broken and decided to use the same settings but this time stare at it as though it was Schrödinger's cat. It helped because Stuart noticed that the layers might've been pulling the edges up by creating a tension towards the inside since the filling pattern  focused on the center which lifted the side and eventually blocked the nozzle.The settings were the issue.

focused on the center which lifted the side and eventually blocked the nozzle.The settings were the issue.

I changed the settings by lowering the amount of raft support and eventually got a pretty nice print (se above). The only issue was the  corner of the mouth. I believe the issue with the mouth was the same as in the first print, since the walls were pretty thin.

corner of the mouth. I believe the issue with the mouth was the same as in the first print, since the walls were pretty thin.

In general I'm pretty satisfied with the result, the resolution was beyond what I expected and the  shapes of the neck came out nicely even though I could've accentuated them a bit more so it would look more like it did

shapes of the neck came out nicely even though I could've accentuated them a bit more so it would look more like it did  in Meshmixer.

in Meshmixer.

"This Could Not Be Made Subtractively!"

Yeah. What that says. No but honestly, most things can be made subractively, they would just be a bajillion times more complicated to make that way. Since if we would be using a milling machine for this the inside would be quite difficult and we'd have to mill it out in two separate pieces (at least); those two pieces would then have to be double sidedly milled too. A hassle I tell you. Let's 3D print.

Plug it!

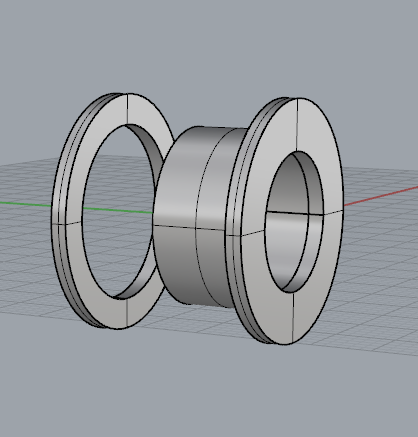

I also made a quick design of a plug earing since mine broke at the time. I stopped since I thought the resolution for the screw on mechanism would be too low.