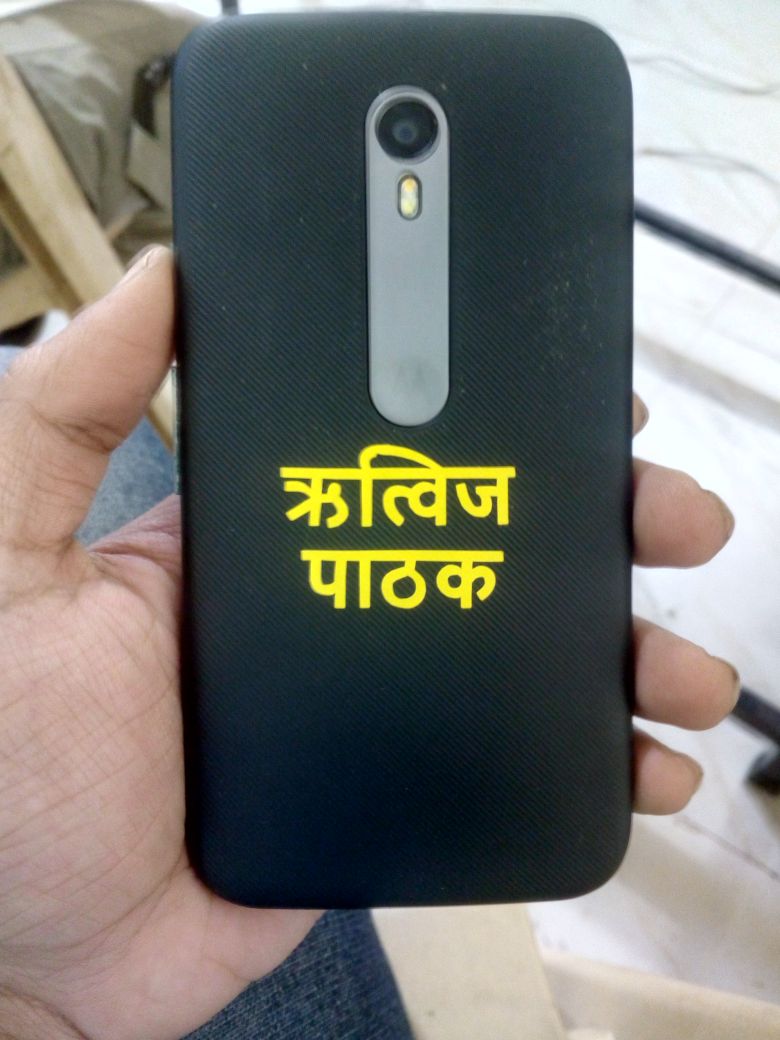

This is my name in devnagari script. This is the same file which i have used for cutting it on the vinyl cutter . As you can see the jagged edges which cause the machine to do a bad job

This week documents chronologically the exploration of cutting tools and materials

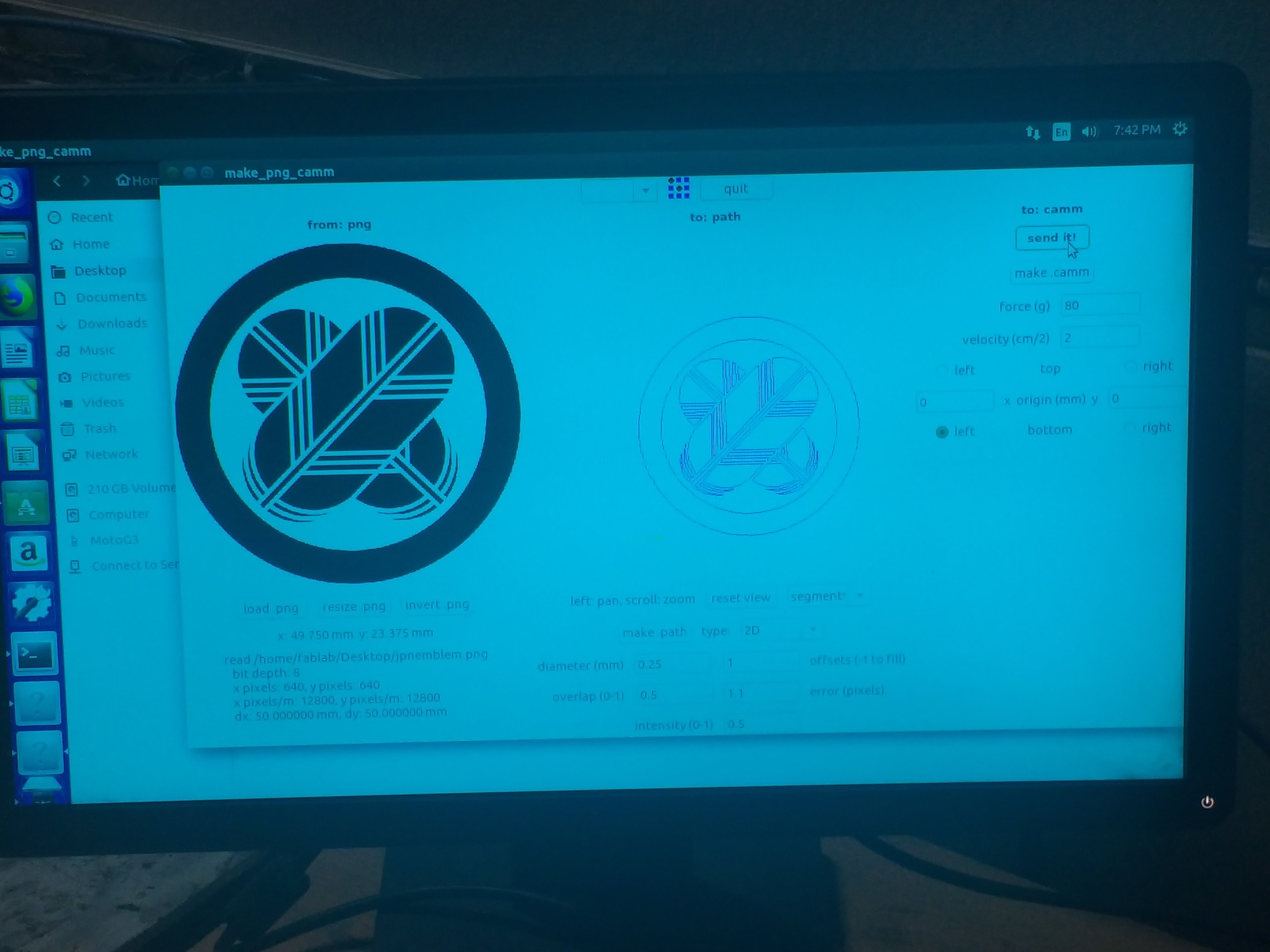

Vinyl Cutter has a pin (drag knife ) which cuts through the vinyl after it presses it down .Written below are some of the things that i have learnt over the course of .The path which is generated after the image is uploaded .Higher the resolution higher the accuracy for the curve . Illustrated below is the difference between the same images but pay close attention to the cut accuracy . Vinyl Cutter is a temperamental peice of eqipment . It will cut the same materaial 80 gms of force and score the other side it will just score it . Weeding is harder than it looks . Tools helpful in soldering are extremely helpful in weeding . Masking tape is helpful but can sometime be ineffective against vinyl . Clear tape is powerfull enough but will leave a residue .

This is my name in devnagari script. This is the same file which i have used for cutting it on the vinyl cutter . As you can see the jagged edges which cause the machine to do a bad job

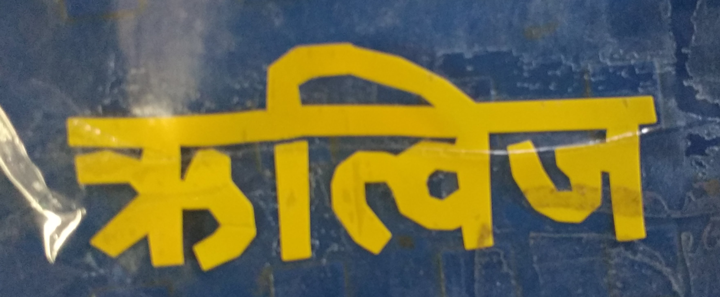

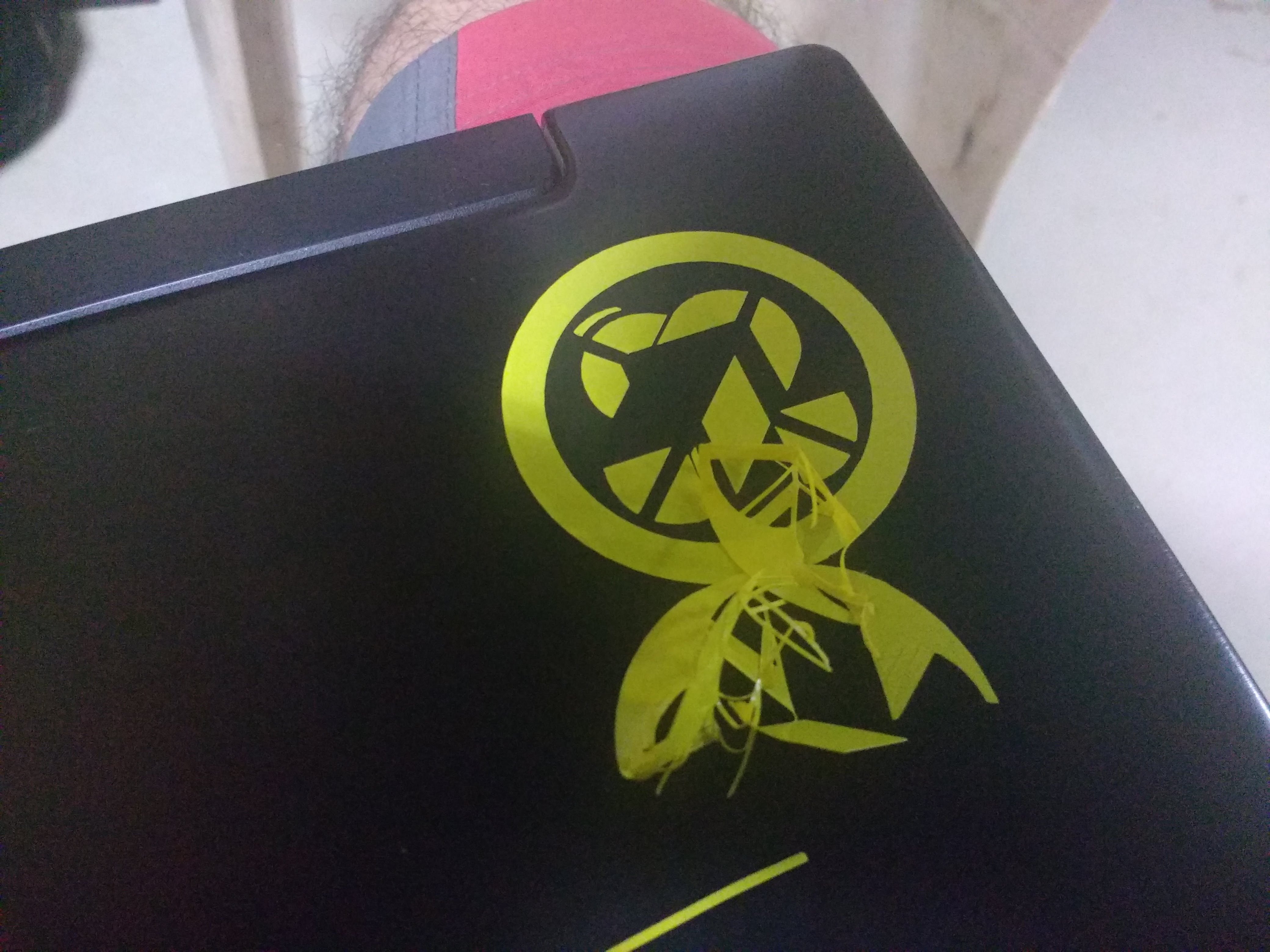

This is the first cut on the printer .Notice the jagged path.This was due to low resolution. My weeding technique was horrible . I used the transparent tape . It left a sticky residue. and it was not properly placed .

Cutting the vinyl using the vinyl cutter.

I choose to cut this Japanese Emblem(). This is the old symbol for Samurai. I chose this symbol as it offered some complexity to push the limits of the machine.

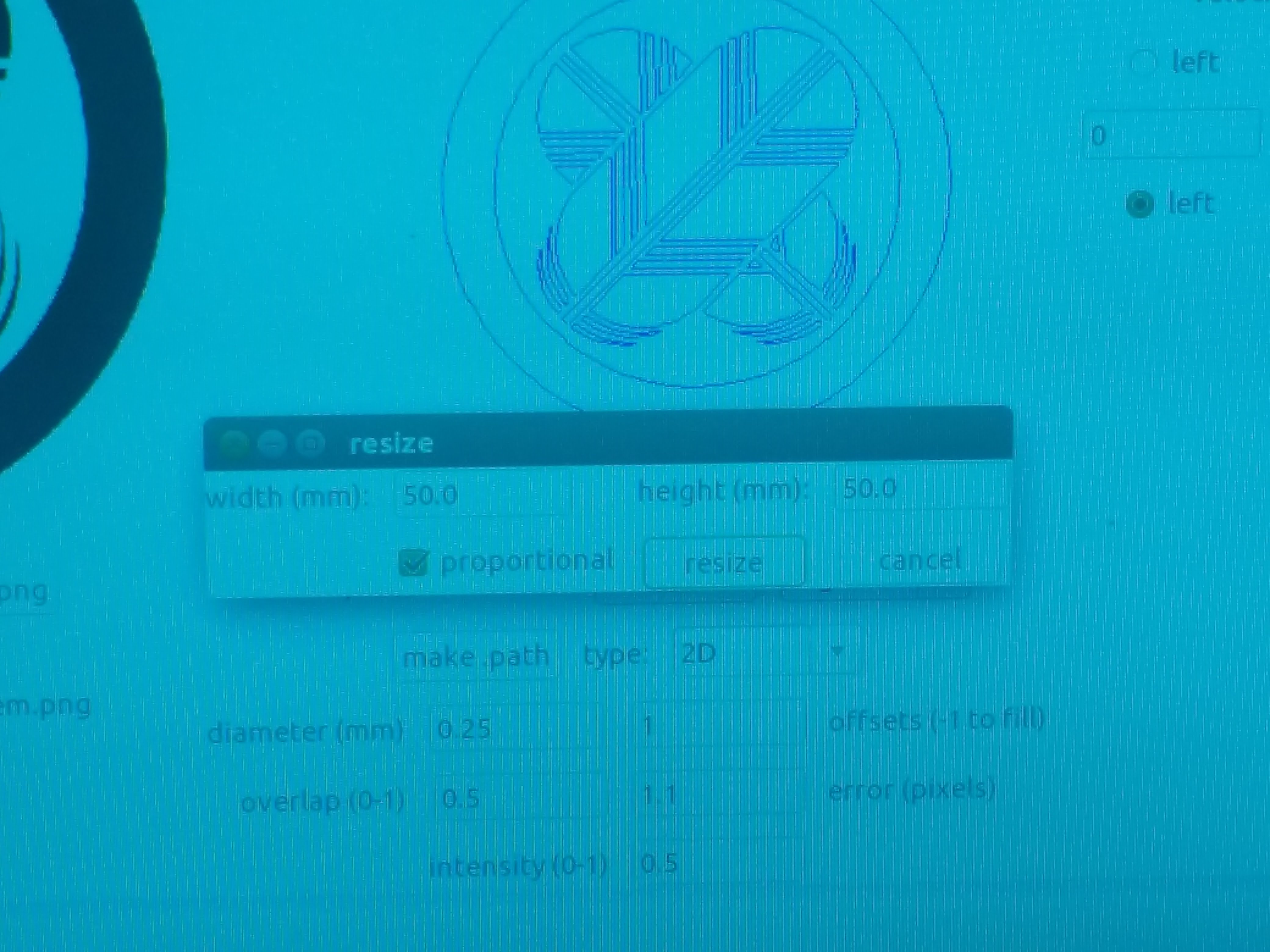

Rescaling the image

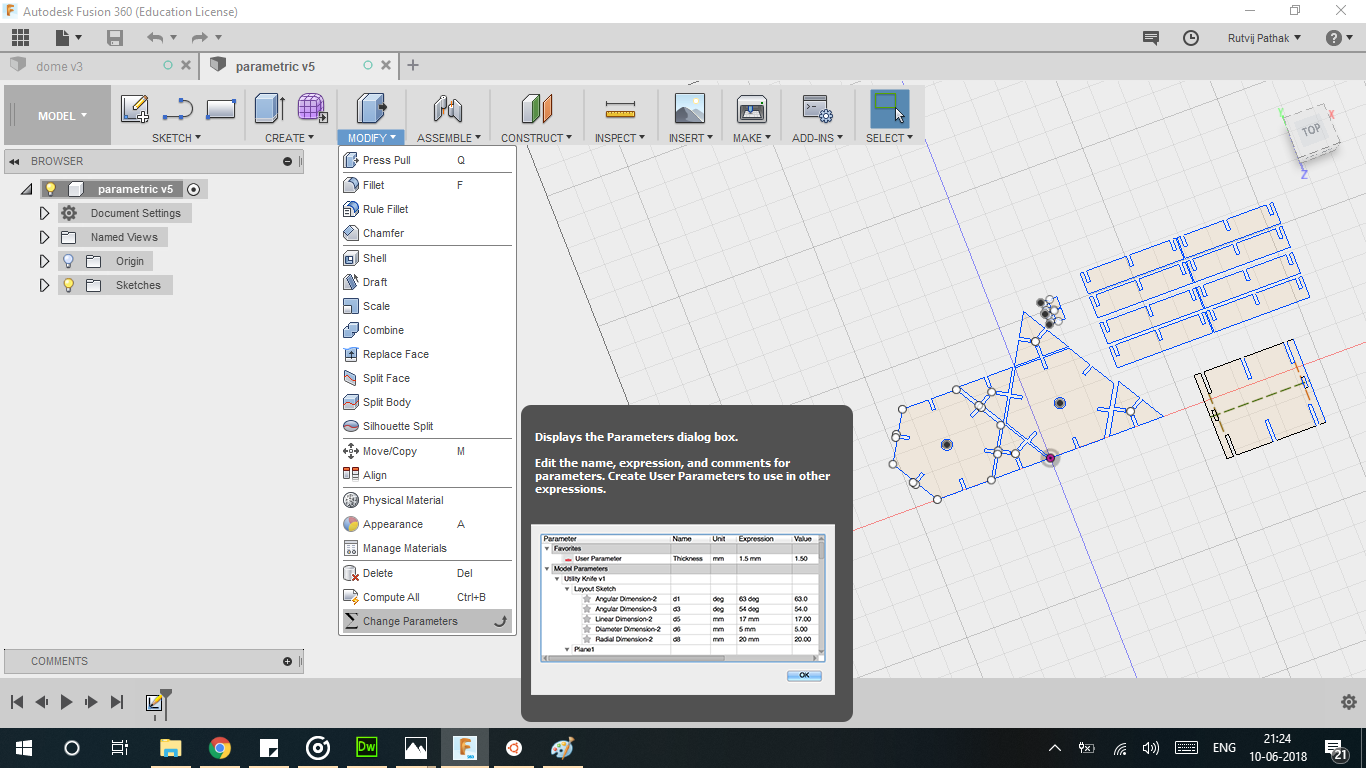

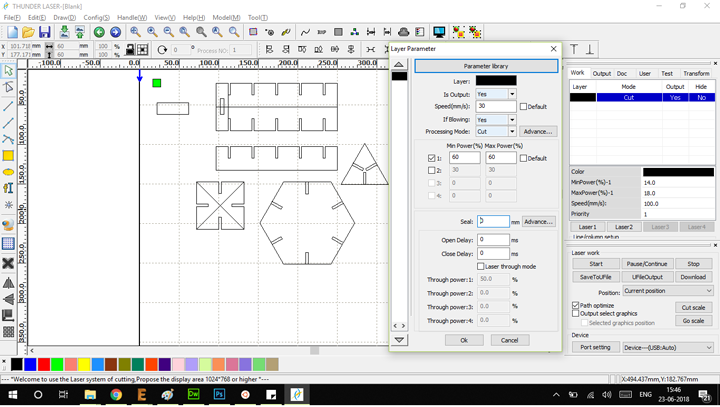

One of the problems is faced was the parameter window was not opening. Due to this i couldnt edit the parameters after editing . I looked on the internet to find the clearing user cache date will help . So I cleared the user data sure enought the parameter came up.

This is the SIL cutter which is availabe in Vigyan Ashram

The kerf is the burn of the material between cuts . This can be lead to differences in the measurements i.e in measuring the kerf for the machine we designed a 40mm x 40 mm square to be cut . After the cut the measurement of square as follows.

The kerf of this machine is 0.13 mm

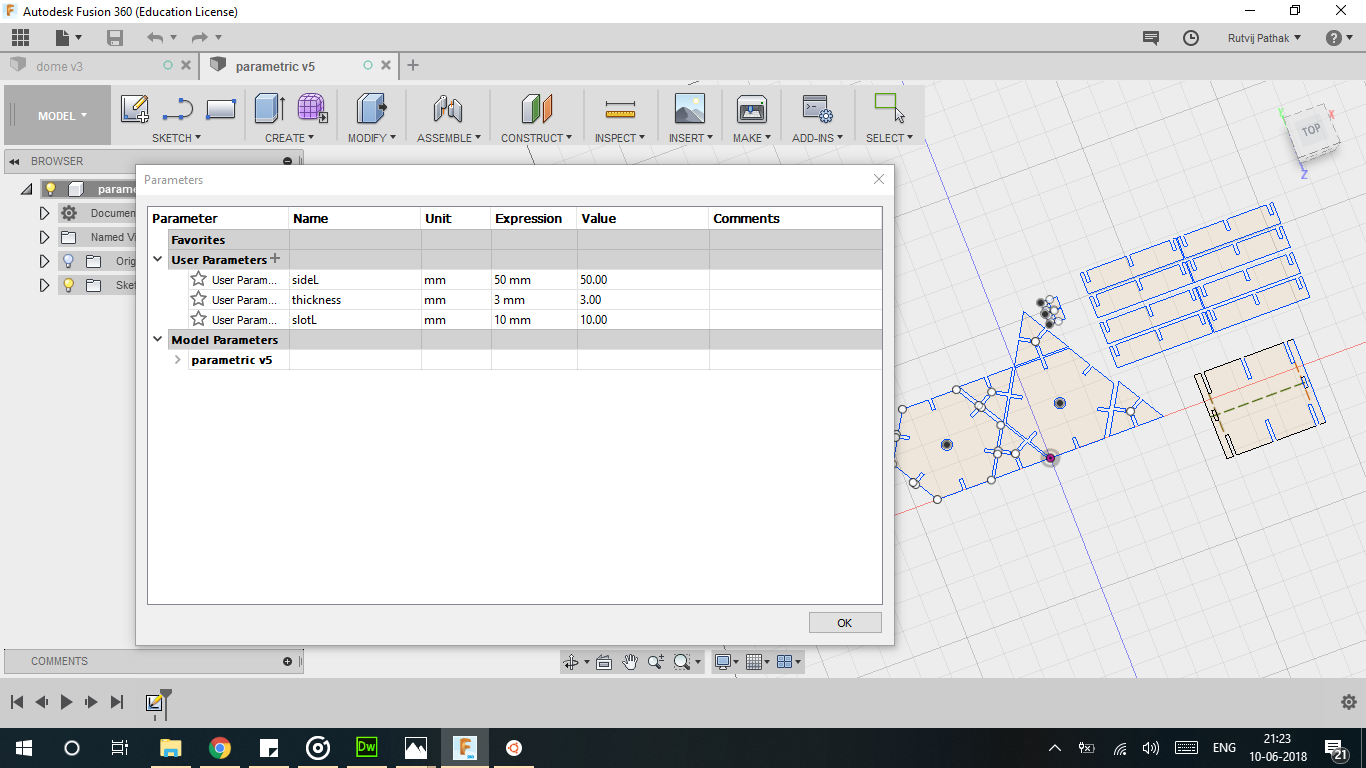

This is how you open the parameter window in Fusion 360 .

This image illustrates the parameters which i have used and defined . in the my parmetric construction set .

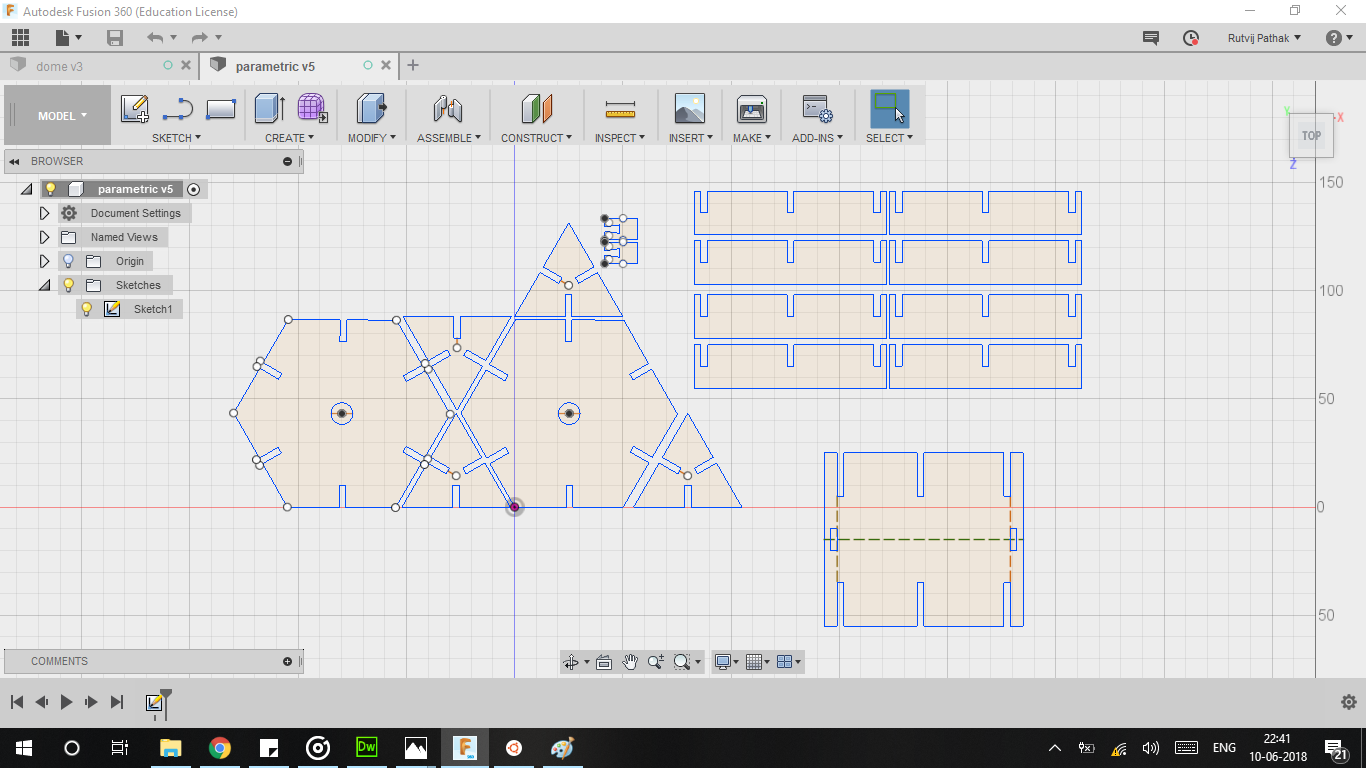

This the final pressfit construction file .

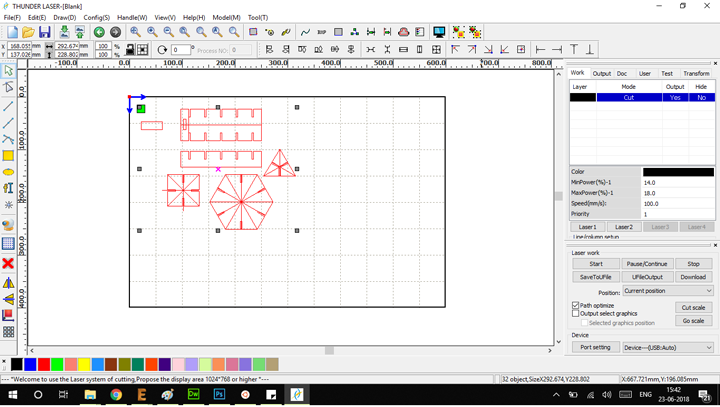

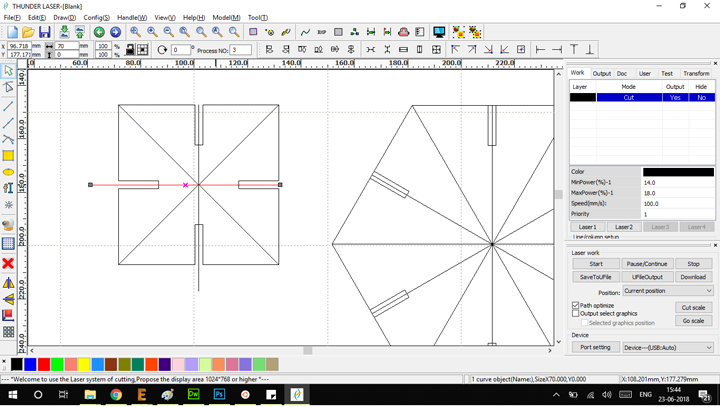

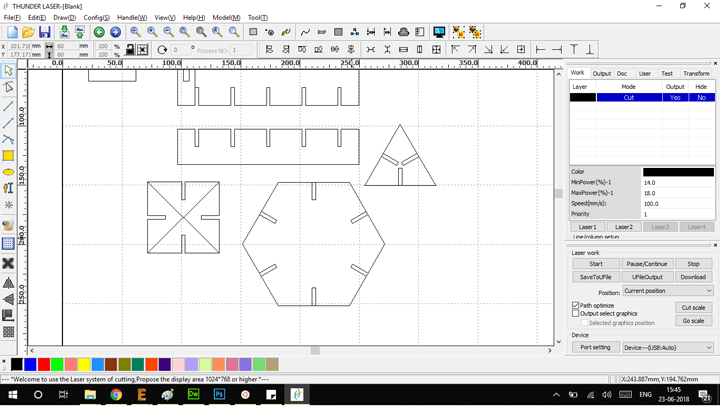

Importing the dxf file generated by Fusion 360 in RDworks . Notice this dxf also contains the construction lines in the sketch

Cleaning the construction lines from the part of the sketch which shouldnt be cut

Setting the power and speed of the laser cut for the acryllic . Power = 60 % and Speed = 30 % for cutting acryllic

This is the basic interface of the Laser Cutter .

To cut a file from the dxf this is the sequence which is used . .

Setting the height of the laser for the proper cutting .

.

This is the display of the screen when changing the z height of the bed .

.

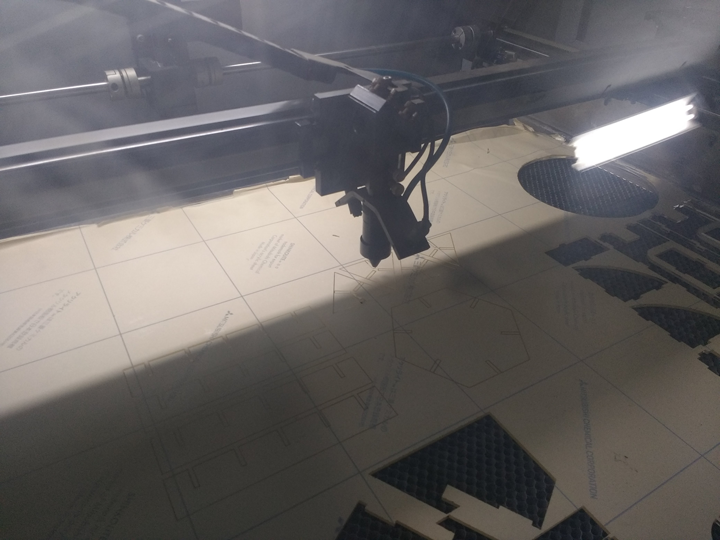

This photos illustrate the cutting process for the acryllic

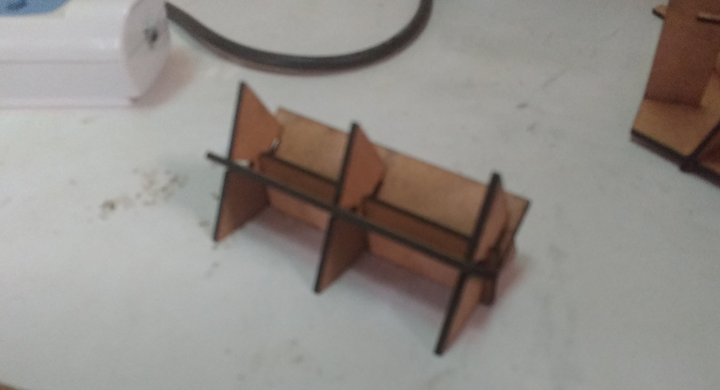

This the final pressfit construction file which was generated , laser cut , and assembled.

Learing parametric construction set . Learning to identify the most basic of the shapes which will be used for construction . Learnt how to use a Vinyl Cutter and Various Laser Cutters . BIG SIL machine is good for quick prototyping . SIL has difficulty in processing precise small cuts.Epilog is good for extremely precise work .

Speed is one of the disadvantages of this type of the machine .

The orignal files can be found here