A. PROBLEM STATEMENT:

“60% of export quality mangoes in Maharashtra go to waste due to improper handling there needs to a tool designed to better harvest the produce so that this percentage can be lowered this will directly increase the profits for the farmers”

B. RESEARCH

- a. Existing Problems of the Current Product:

- B. PROBLEMS ON THE SIDE OF THE USER (HUMAN INTERACTION):

- C. POSSIBLE SOLUTIONS:

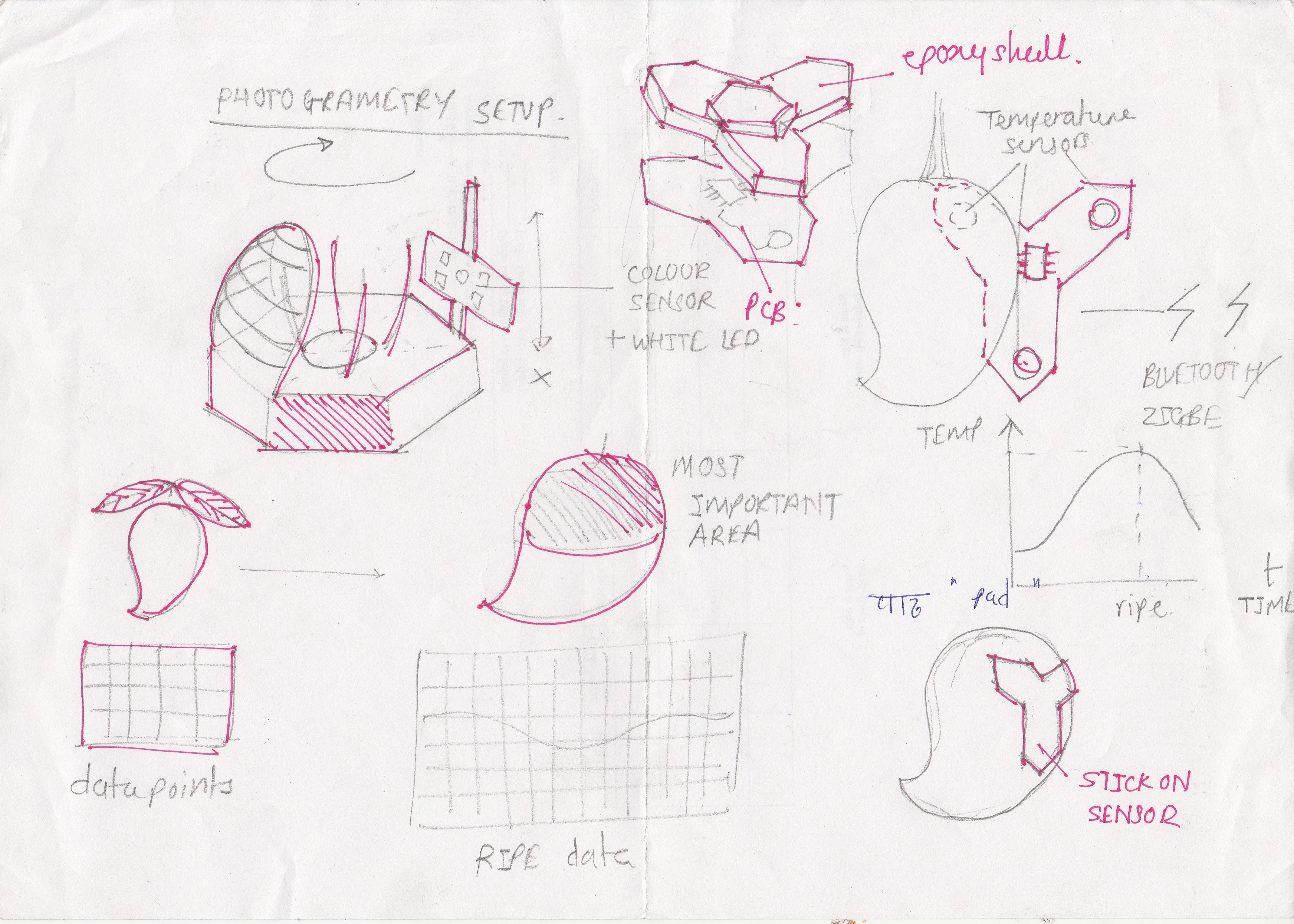

updated project sketck for the final project assignement

UPDATED PROJECT STATEMENT

There are various factors which are going to affect the colour sensor on the stick approach of earlier projects . The earlier work which has been done contains various fallacies where the photographs of certain fruits were taken in non standard way (i.e) in sunlight etc . There doesn’t exist a baseline reading of what is the actual colour of a RGB of the fruit (mango). So went ahead with the idea of a turntable which will be capture the RGB data of a fruit so that It could be studied to better understand the ripening process and also to quantify it . Imagine a matrix of points of rgb data . If we setup a collection algorithm then we can track the colour progression of the fruit . This leads to future applications of it being used as the datahub of drone farming . Where this data will be usefull . or various standalone devices which will help the farmer of the future keep and eye on its produce .

HOW WILL IT BE USED

This project is the data generation unit of the entire experiment . This box will be deployed to various orchards across the state so that the RGB tables of the fruit and its varieties can be catalogued correctly .

Personal Learning Milestones :

Ideated on a project idea . Checked out the feasibility of the project for the duration of the course. Did a need finding and traige of what was the most necessary part of the project and started working on it .