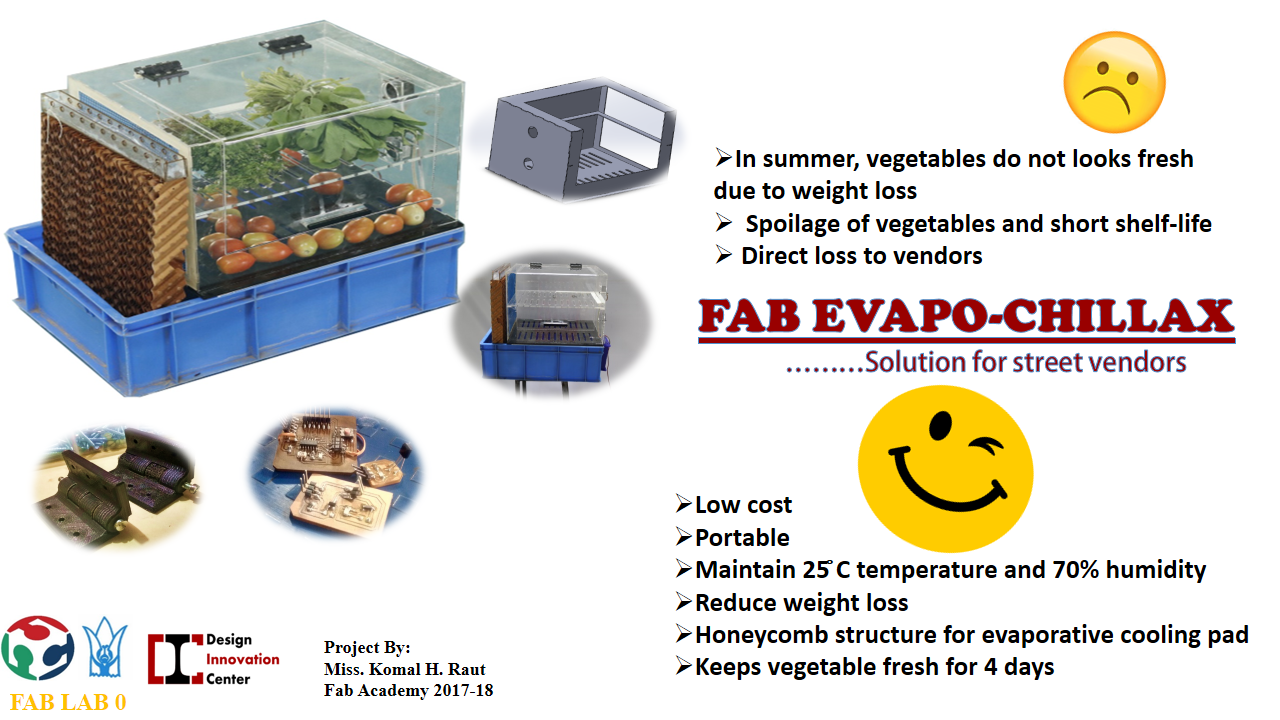

Final Project:- Fab Evapo-chillax

- Need

- Objective

- Ideation/Sketches

- Planning Chart

- CAD model

- Cutting

- Electronics

- Assembly

- Downloads

My final project is to design Fab Evapo-chillax on the principle of evaporative cooling. It is a well-known system and works very efficiently. It is an economical means for reducing the temperature and to increase the relative humidity in an enclosure, such an effect has been extensively used for increasing the shelf life of agricultural produce.

Problem

Cultivating plants and harvesting them is one thing but preserving them for future use is one of the major problem faced by farmers and vegetable vendors. On an average 20-25% Agriculture produce in India is lost, in which major part is the post harvest loss due to improper handling of agriculture produce. In our VA kitchen we brought vegetables from local market in bulk quantity. After 2-3 days, I observed that vegetables did not look fresh, especially the leafy vegetables. I realized that I was not alone facing this problem but also the farmers and vegetable vendors are facing them.

Also, the vendors are uses wet gunny bags and sprinkle water on their produce to keep it fresh. This leads to spoilage of the vegetables, particularly the leafy ones and tomatoes, cucumber, etc. as these veggies have a short shelf life. They get rotten, thus causing loss of income to the vendors as customers refuse to buy these items.

I have decided to make one setup or storage box by using jute bags which locally available.

Working-

The design of the evaporative system was based on the principle of evaporation being always accompanied by a cooling effect to its surrounding. It is a system which (comprises four sides) covers with the jute pads at all the four sides. Air is allowed to pass through jute pads into the system with the help of suction fans. Water drips into the jute pads at a constant rate through a water distribution system. Fans draws air from outside the fridge through the moistened material. As the air passes through the moistened material, it is cooled by evaporation and this cool air spread in the fridge. Evaporation will takes place when humidity is below 100% and the air begins to absorb water.

Data Collection:

Amount of water= 7 liters/day

For this testing, I had taken vegetables from VA kitchen.

Temperature and humidity readings

| Day | Inside Temperature | Inside Humidity | Outside Temperature | Outside Humidity |

|---|---|---|---|---|

| Day 1 | 20 | 58% | 31 | 16.5% |

| Day 2 | 21 | 58% | 34 | 18.5% |

| Day 3 | 20 | 58% | 30 | 18% |

| Day 4 | 21 | 58% | 32 | 15% |

| Day 5 | 22 | 58% | 35 | 19.5% |

| Day 6 | 24 | 62% | 34 | 18% |

| Day 7 | 23.5 | 59% | 31 | 16.5% |

Physiological Weight Loss:

The differences in weight of the vegetables stored in both the ambient and in the evaporative fridge were estimated. The percentage weight loss was estimated using following Equation as given by,

Percentage Weight loss =

| Sr.No. | Vegetables | % weight loss | Store period |

|---|---|---|---|

| 1. | Fenugreek | 1.48% | 3 days |

| 2. | Cabbage | 1.12% | 6 days |

| 3. | Tomato | 2.51% | 8 days |

| 4. | Bottle Guard | 1.34% | 5 days |

| 5. | Coriander | 0.99% | 4 days |

Objective

The challenge is to design a system which prevent the weight loss and maintain the temperature and relative humidity inside the system for preservation purpose.

From this data I decided to divide this project into two parts:

1. Mechanical :

Structure, tray for vegetables, water storing and distribution system, selection of water pump,etc.

2. Electronics :

Selection of fan, Program for motor and fan, Calibration of temperature sensor,etc.

Important Stuff-

Project deadline?

Deadline of the project is 14th June.

completed tasks-

1. Designing and Mechanical Structure

2. Electronics assembly (Project and sensor board is ready)

Remaining Task-

1. Electronics Programming

2. Cable Packaging

WORKING STATUS:

what is working?

1. The structure or box is fitting. I designed the channel for distributing the water on the honeycomb pad and cut it in the laser cutter.

2. So, Assembly is done.

3. Also My presentation slide is ready.

what is not working?

The project code was not working. I have to work on it.

what questions need to be resolved?

1. Need to work on programming of the project.

2. Need to do electronics packaging.

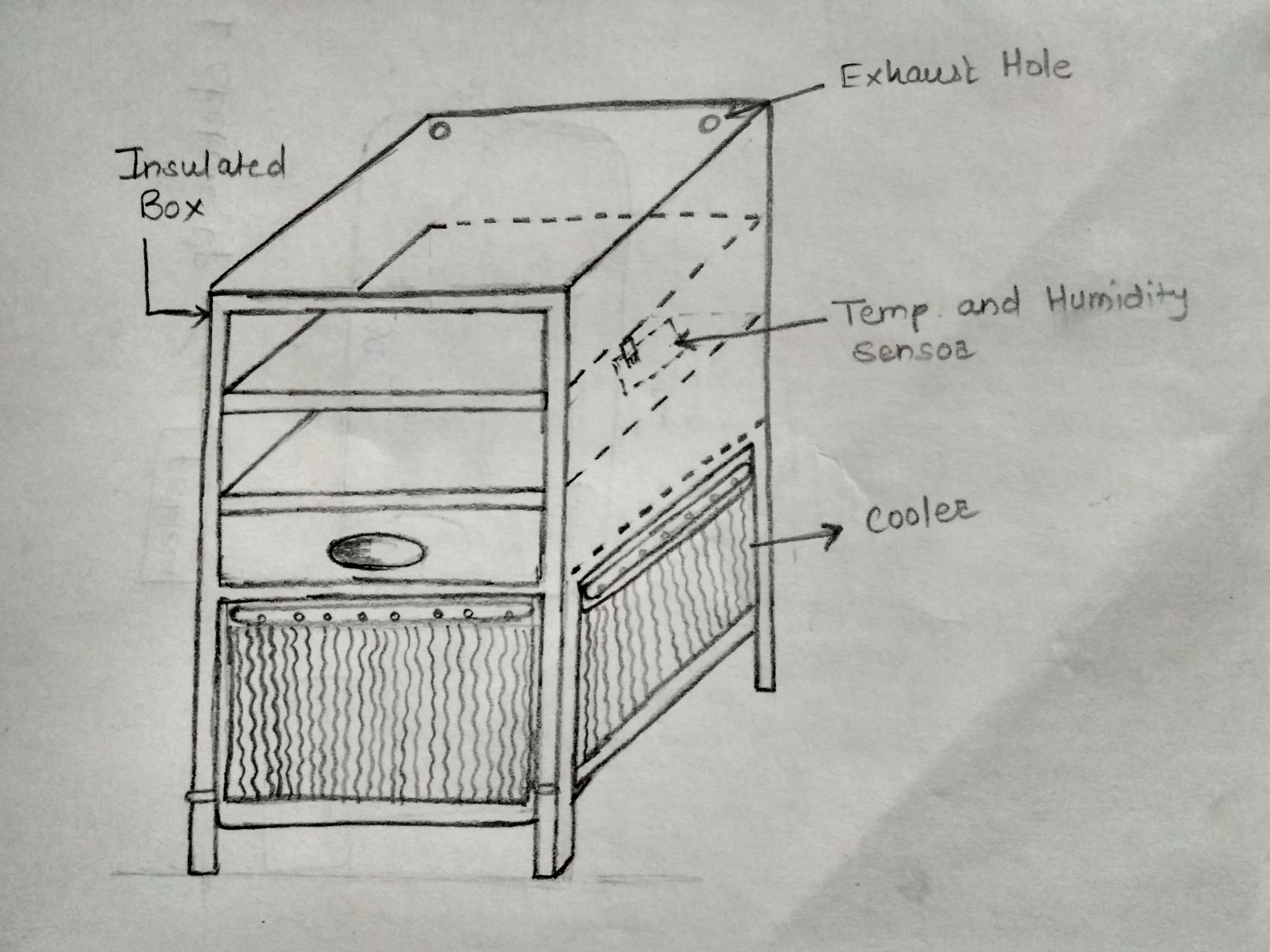

Ideation/Skteches

We need a storage unit for having vegetables fresh. We knew there are already available refrigerators in the market. But refrigerator needs lot of power or electricity. Lack of continuous electricity is one of the major issue. Cold storage are also available in market but all these solutions are not affordable to farmers or vendors.

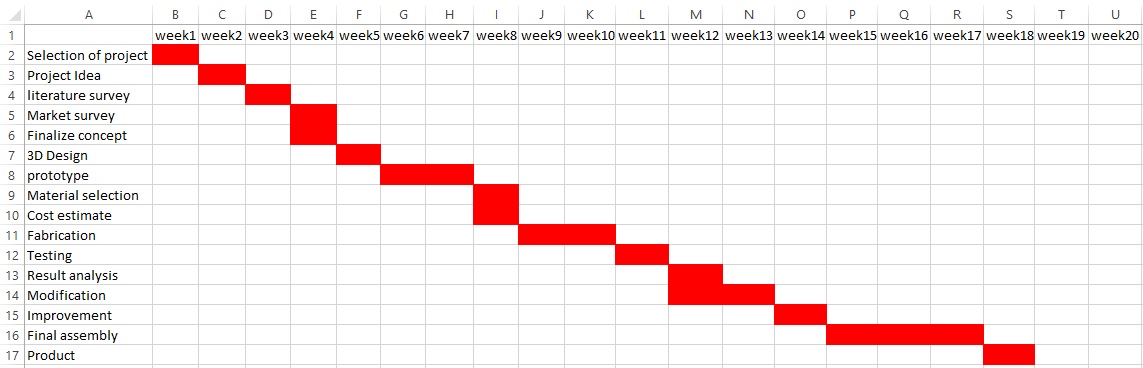

Planning

I have planned my work related to final project. Its really difficult to stick to schedule but I tried my best. Because other than assembly and programming stuff I always stick to my schedule. So, I made Gantt chart to complete my project on time.

I have decided that I will divide my project into parts and try to finish one part in a one week. In each week, I will complete small part of my project. So that I can track my project and try to finish it on time.

I did chart or planning in week 2.

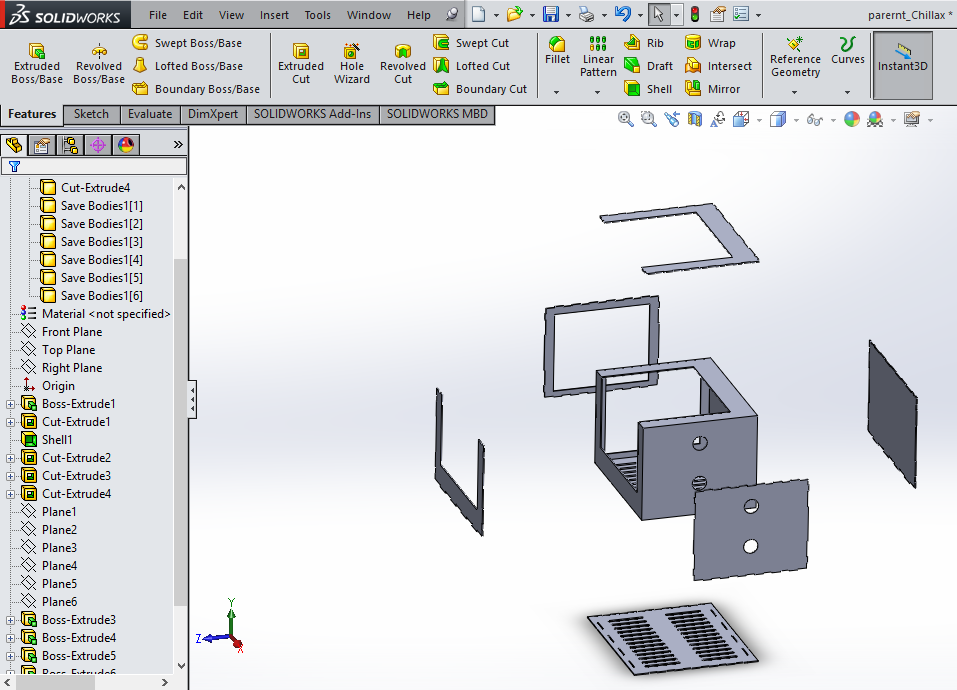

CAD model

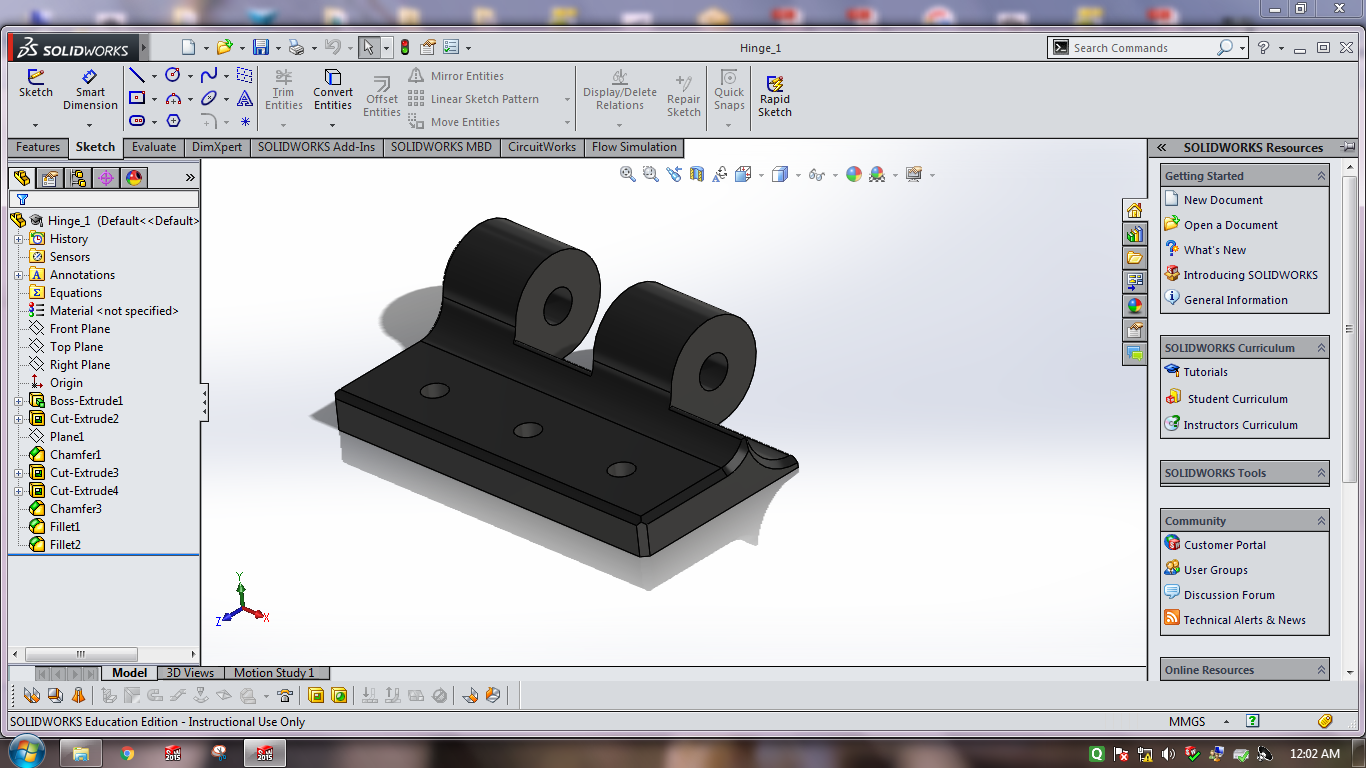

In week 3, I studied various softwares for computer-aided design. I had to select one software which I would use for my all design work of Fabacademy. I selected Solidworks for my 3D designing work.

Here I designed box for my project. Also I designed hinge for my project in solidworks.

This is my 3D designing assignment i.e Week 3

Computer-controlled cutting

In week 4, We have to do laser cutting assignments. I cut all project related parts in SIL LASER.

I explained this cutting part of the project in Week 4

3D printing and scanning

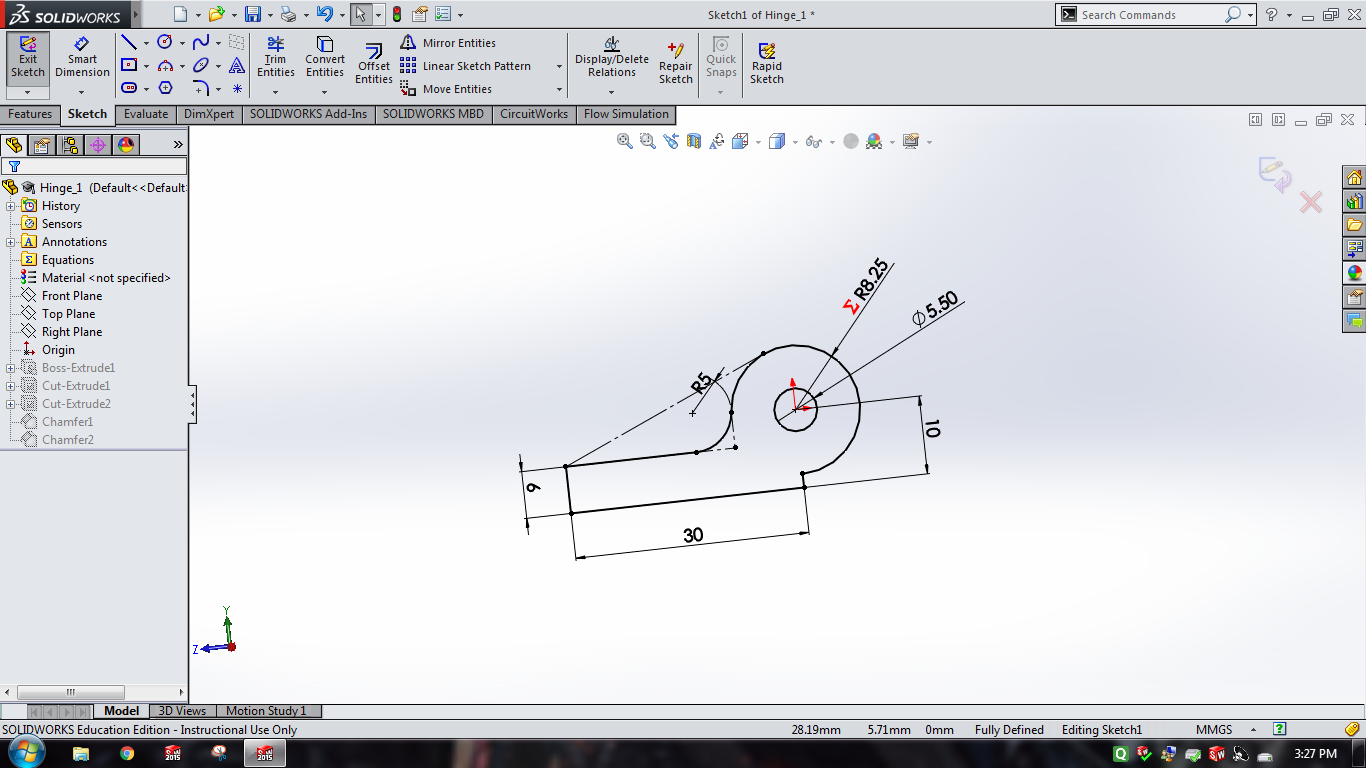

I need hinge for my project. So I decided to make 3D printed hinge for my project. I designed the hinge as I want. I made design in solidworks and save file in .stl format.

For this it was actually possible to make a hinge that includes no external parts, such as studs or a steady axis.

Hinges like pin barrel hinge, where it has a pin that is guided motion into a barrel.

But I had realized an issue about printing this kind of hinge was the printed part consists of a rough surface that might generate higher grade of friction between the moving components, These rough lines are seen on our printer.

Hence I preferred to have the moving axis out of metal to avoid surface friction to have smooth motion.

You can see more about 3D printing in week 6

Mechanical Part:

Already I have done some parts like storage box, water distribution system, tray for vegetables,etc.

So, Its time to assemble everything and complete the mechanical part.

So, structure of the project is ready.....

Electronics

Electronics Design and production

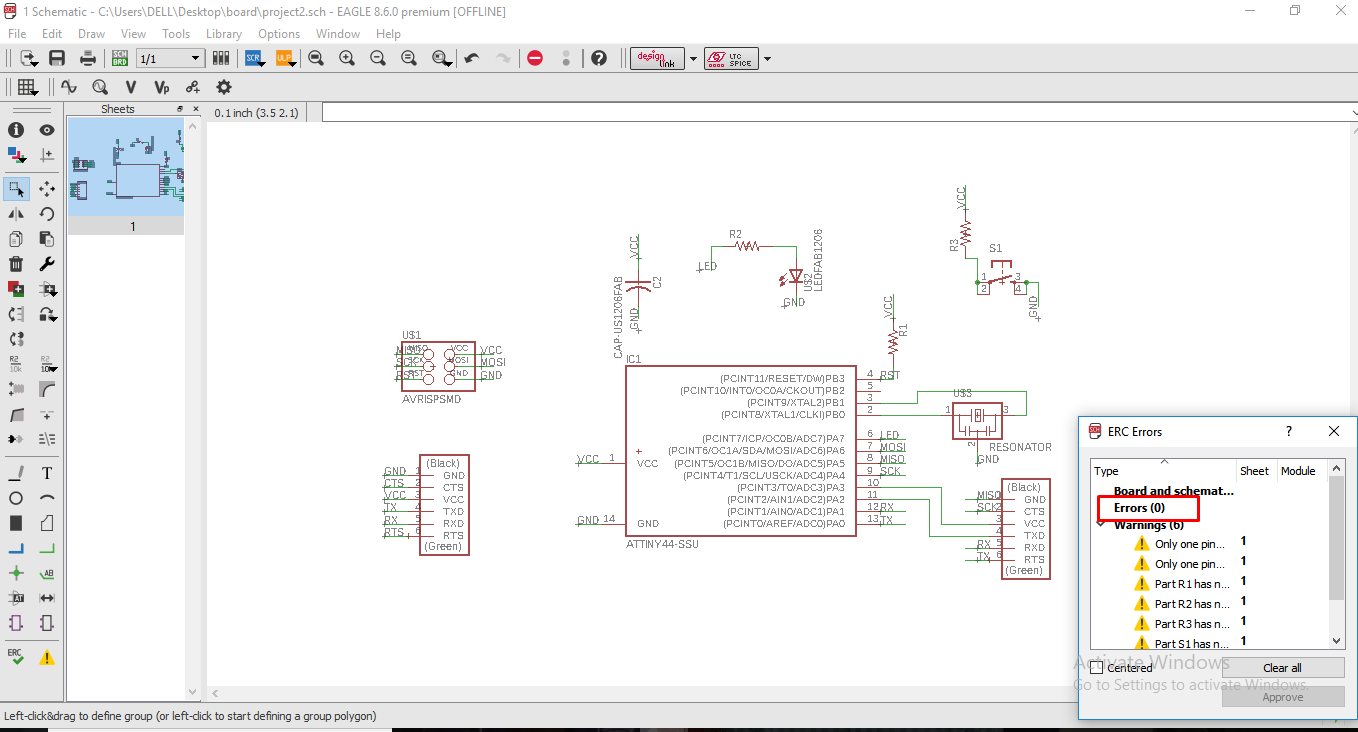

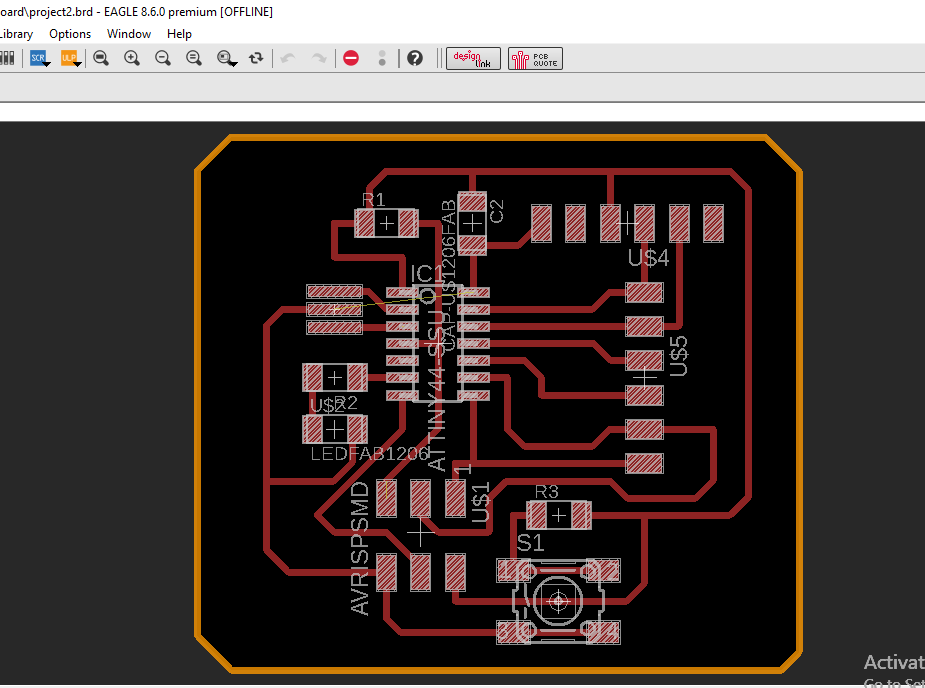

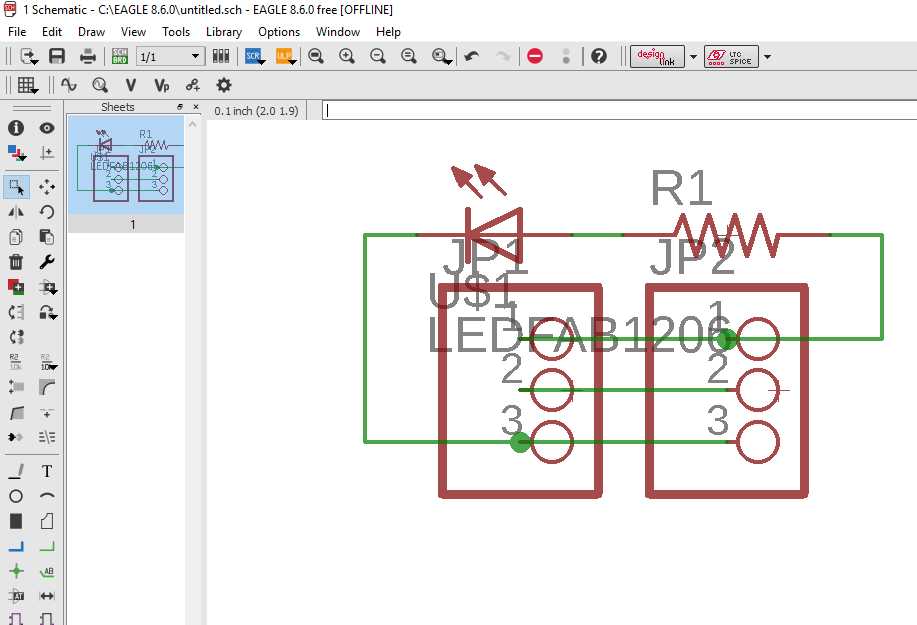

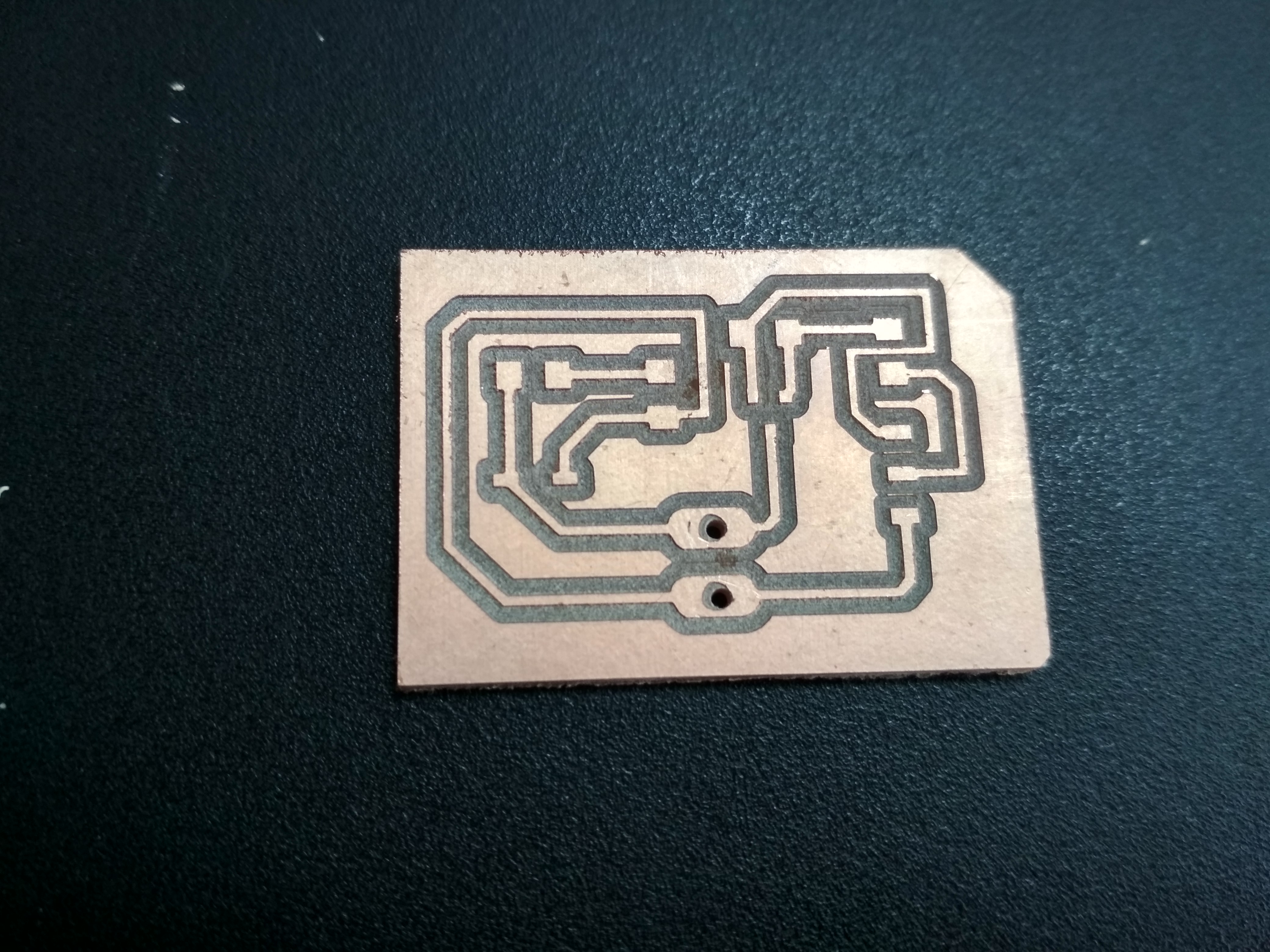

I learned how to design the PCB. I used Eagle for designing the PCB of the final project. For designing, used Attiny44A IC which has 10 input or output pins fixed on my final board.

This is schematic diagram of my project board in this I have given two 6 pin header i.e 12 pins in which one for VCC and One for GND. So, total 10 pins for input and output. I have given 1 pin for input sensor and 1 for output relay circuit. In this board I have given the extra pins considering future scope.

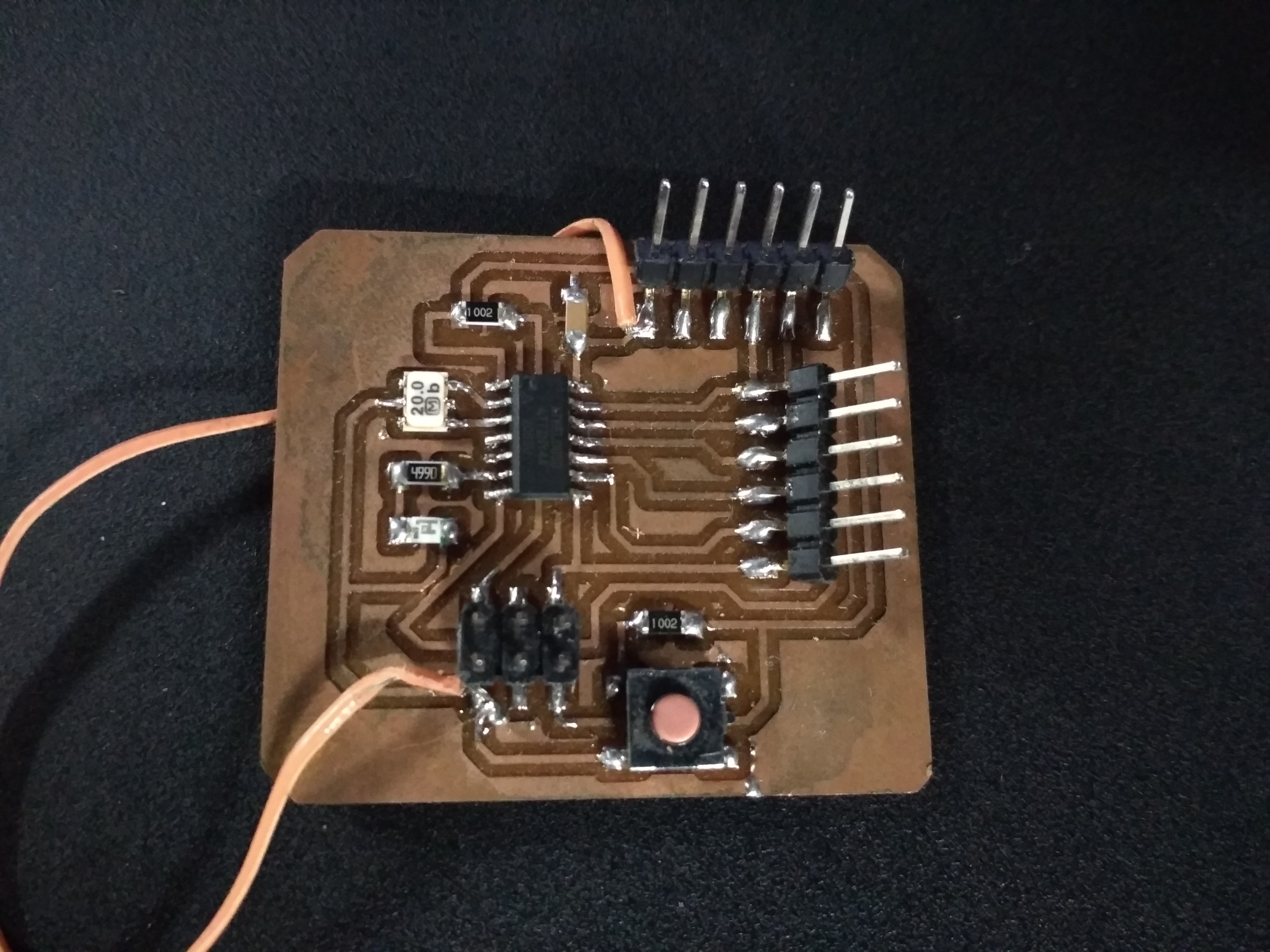

I also learned all the skills i.e milling, soldering and debugging. I made my final project board using all the skills.

You can see whole procedure in Week 5

Input devices-

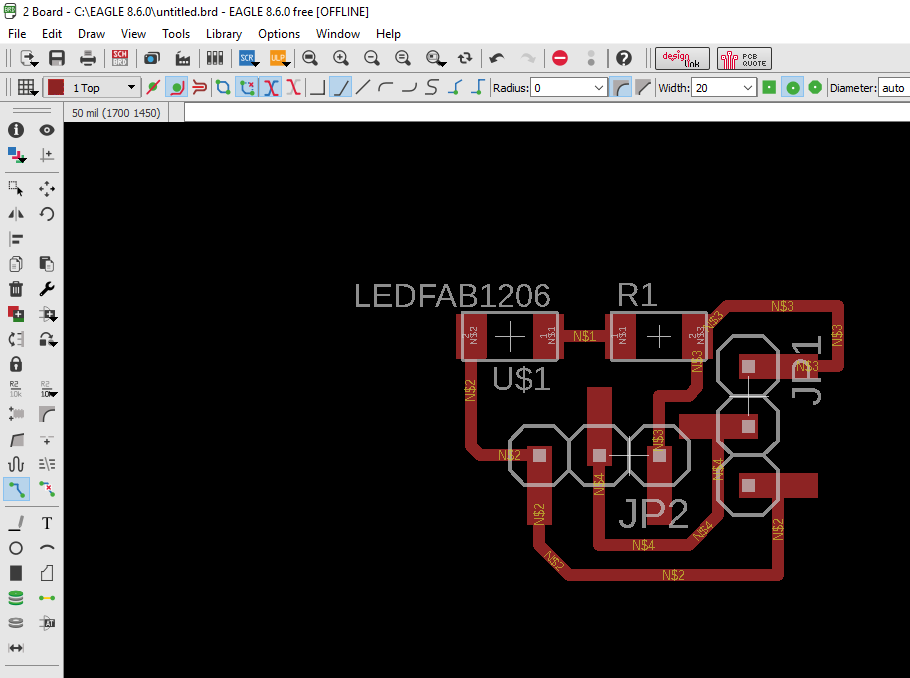

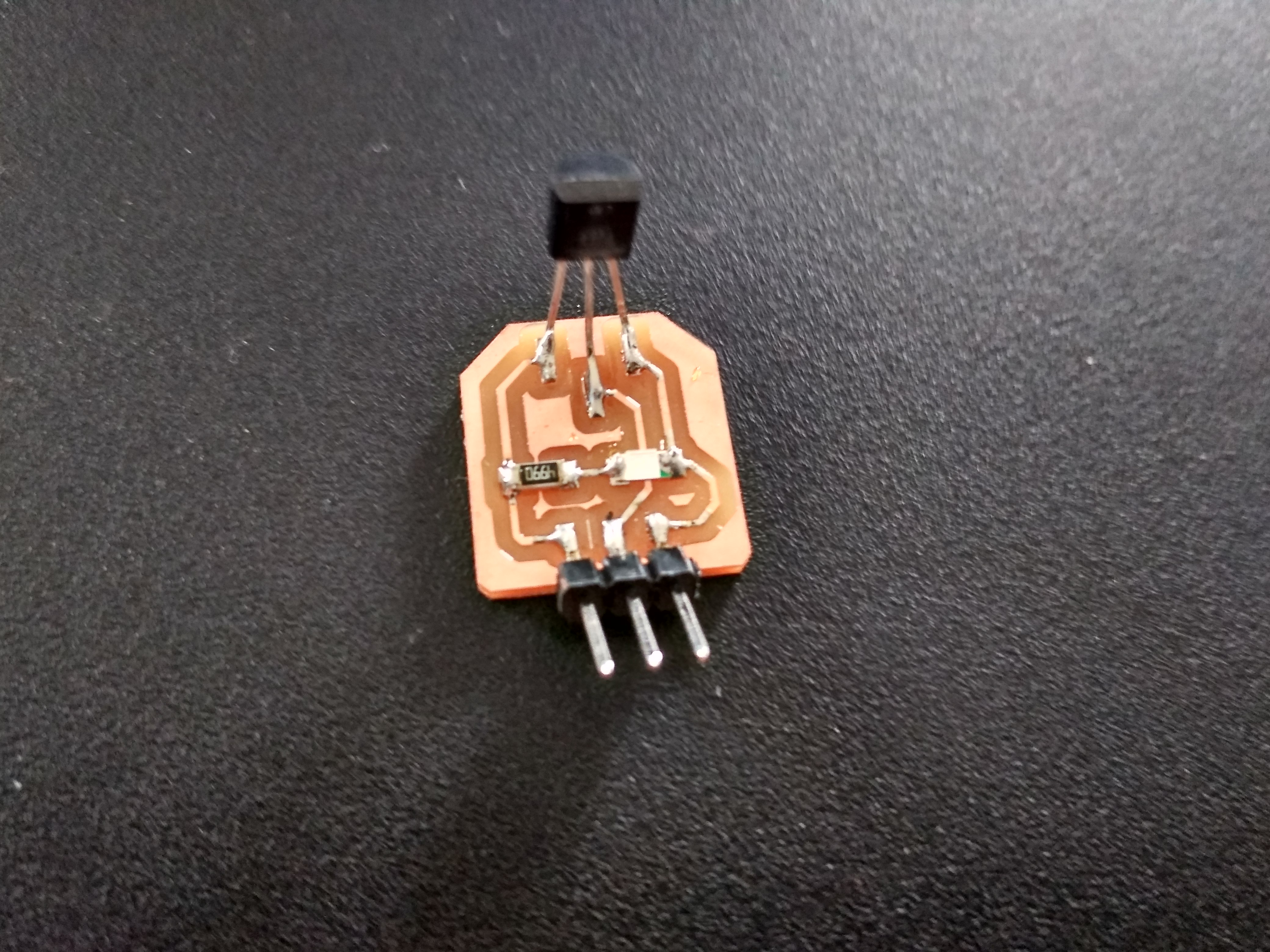

By using Eagle and Rolland Modella, I made PCB for temperature sensor.

I want to measure temperature in my project so I decided to make temperature sensor in this assignment.

I added two 3 pin header, one LED and resistor in eagle for schematic. Join them and check the erc which is best feature of eagle. After schematic I routed the board.

I made this assignment in Week 11

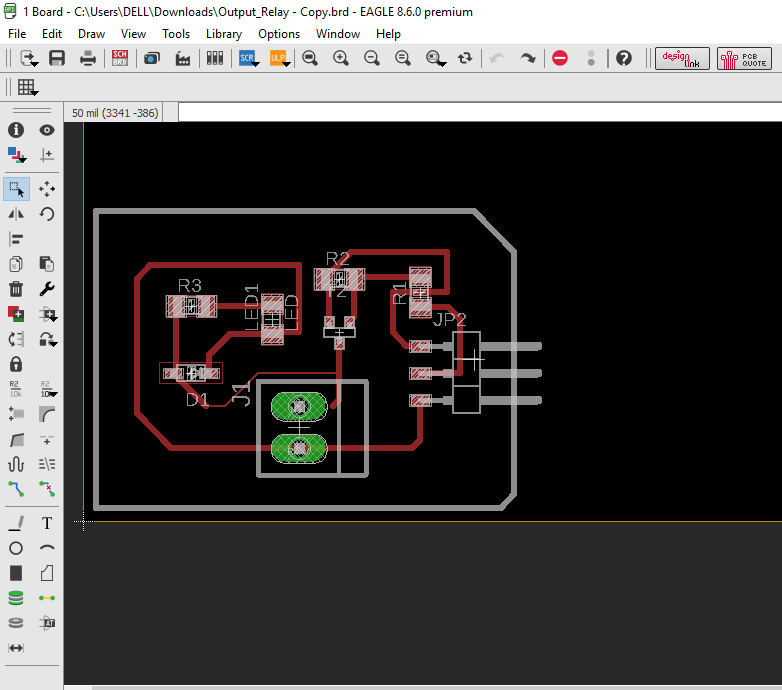

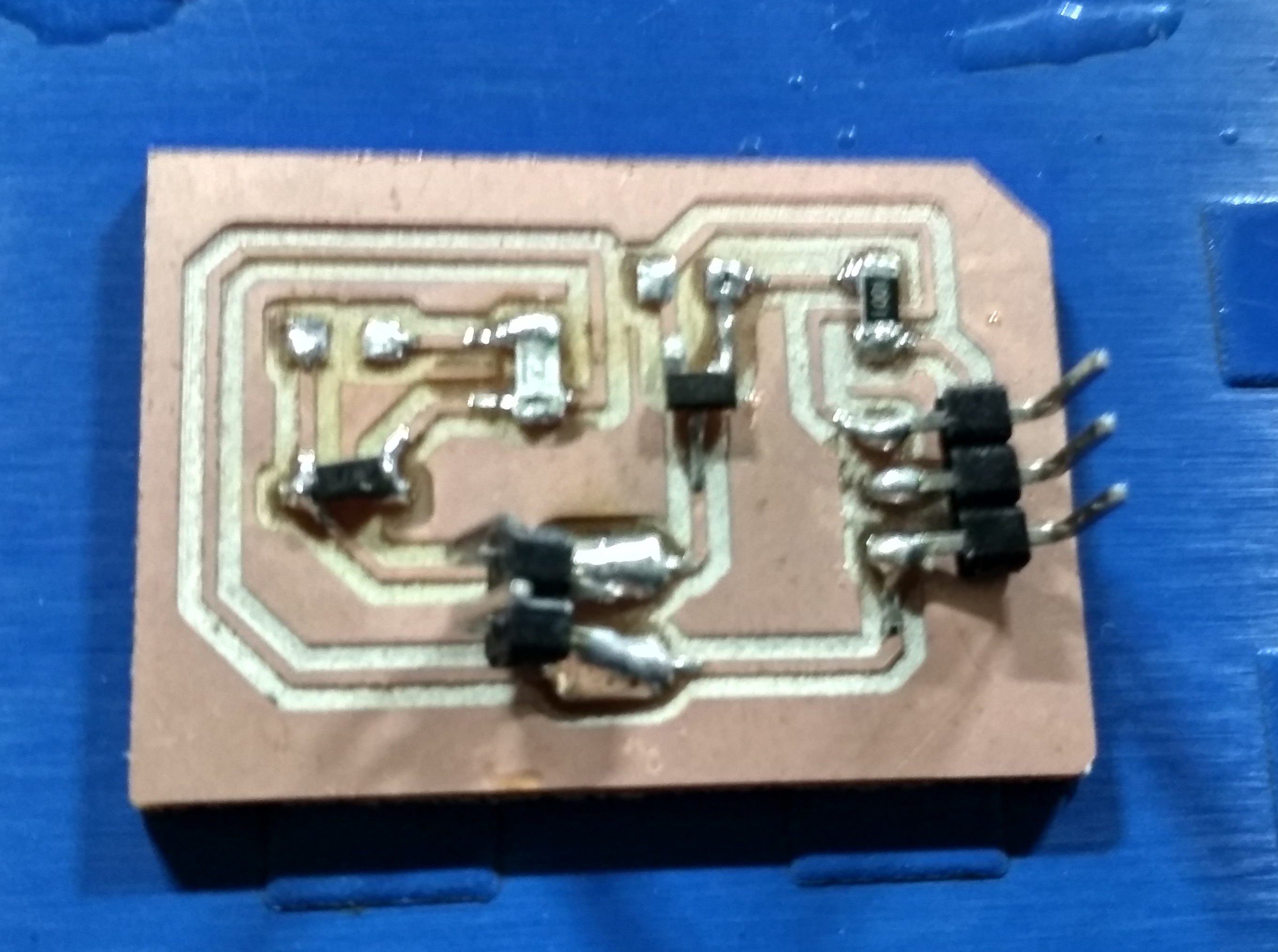

Output Devices-

In this week we have to make board with output device. So, I decided to do this assignment related to my final project. There is a need to make ON and Off water pump. So I decided to make board for water pump.

I milled the output board by using modela 3axis milling machine.

I made this assignment in Week 12

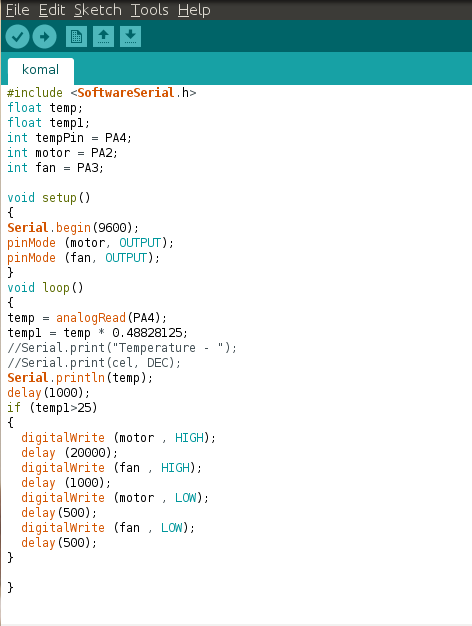

Embedded programming

In my project, the input is a temperature sensor and the output is a relay driving board which is going to switch on/off as it receives signal from the temperature. Here I learn to code, I am new to coding and arduino is easy to learn. hence I have write the code for my board using arduino IDE. It is a simple code which receives the signal from input board and switches on and off the water pump as the senses the temperature.

Original code :

Electronics Part:

For the electronics part, I get my programmed PCB's (micro-controller, temperature sensor), relay , DC fan, 5volt and 12 volt DC supply,etc. I have managed all wiring part neatly and made one box for electronics stuff.

Bill of material:

1. water pump - 70/-

2. Plastic tray- 300/-

3. Acrylic sheet- 600/-

4. DC fan(40*40mm)- 400/-

5. Honeycomb evaporative cooling pads- 250/-(30*50cm)

6. DC power adapter- 70/-

Total cost= 1600/-(INR)

Project License Information-

I have chosen GNU GPLv3 for my project.

Anyone can studied it and can modify it. Copyright and license notices must be preserved.

You can get more information Here.

All tasks are completed and my product looks like this......

In this system, water falls on the Honeycomb structure evaporative pads (which is fixed at the one side of the box)after some interval and then fan (which is fixed at the opposite side of the evaporative pad) sucks the dry air from outside which becomes wet air after passing from moistened material i.e evaporative pad. By using this evaporative principle we can maintain 20-25 degree celcius and 60-70% humidity inside the storage box. When the inside temperature is more than 23 degree celcius, Water and fan turn on automatically.

Presentation Slide:

This slide made for presentation and the original slide you can see Here.

Presentation Video:

This video made for presentation and the original video you can see Here.

Download all the files are related to project

1. Project Design- Original files and .DXF files.

2. 3D design (Hinge)- Original and .STL files

3. Project board -

Download the board and PNG file from here.

4. Input sensor board -

Download the board file from here. and

Download the PNG file from here.

5. Output board-

Download the board and PNG file from here.

6. Code for the project- Original code

7. Electronics box Design- Original files and .DXF files.