Wheek 4:Computer Controlled

Cutting

In this week, we have learned how to use the computer cutting machinery, laser cutter and vinyl cutter.

Laser Cutting.

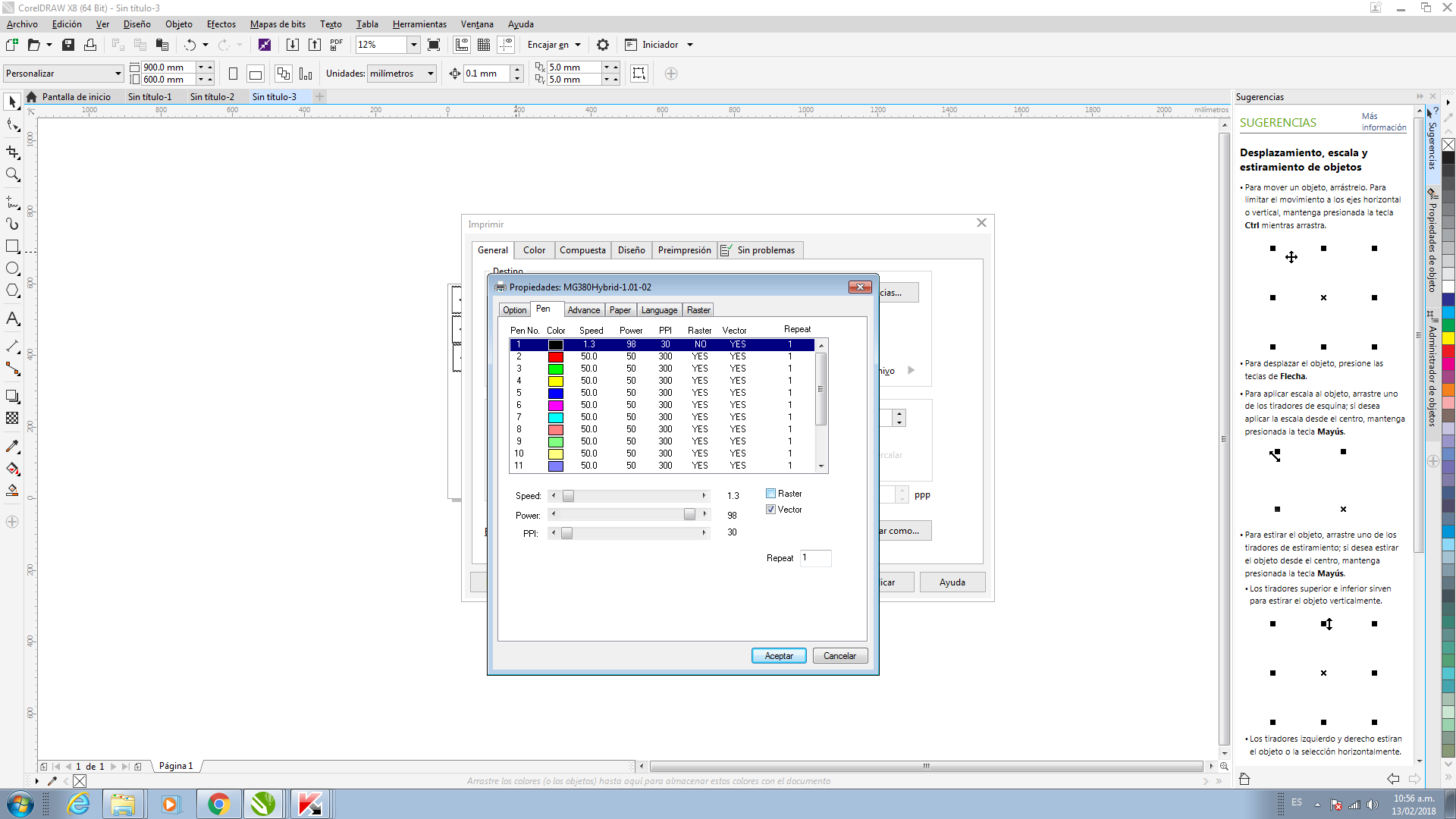

The laser cutter uses Corel Draw to input cutting parameters, and imports the image from inventor. The extensions used were dxf from Inventor and import to Corel. Provided all these tools, it was very hard to decide which one would suit me the best. I used Inventor from Autodesk on 2D or 3D I generated the 3D sheets and exported the file.

Parametric Design.

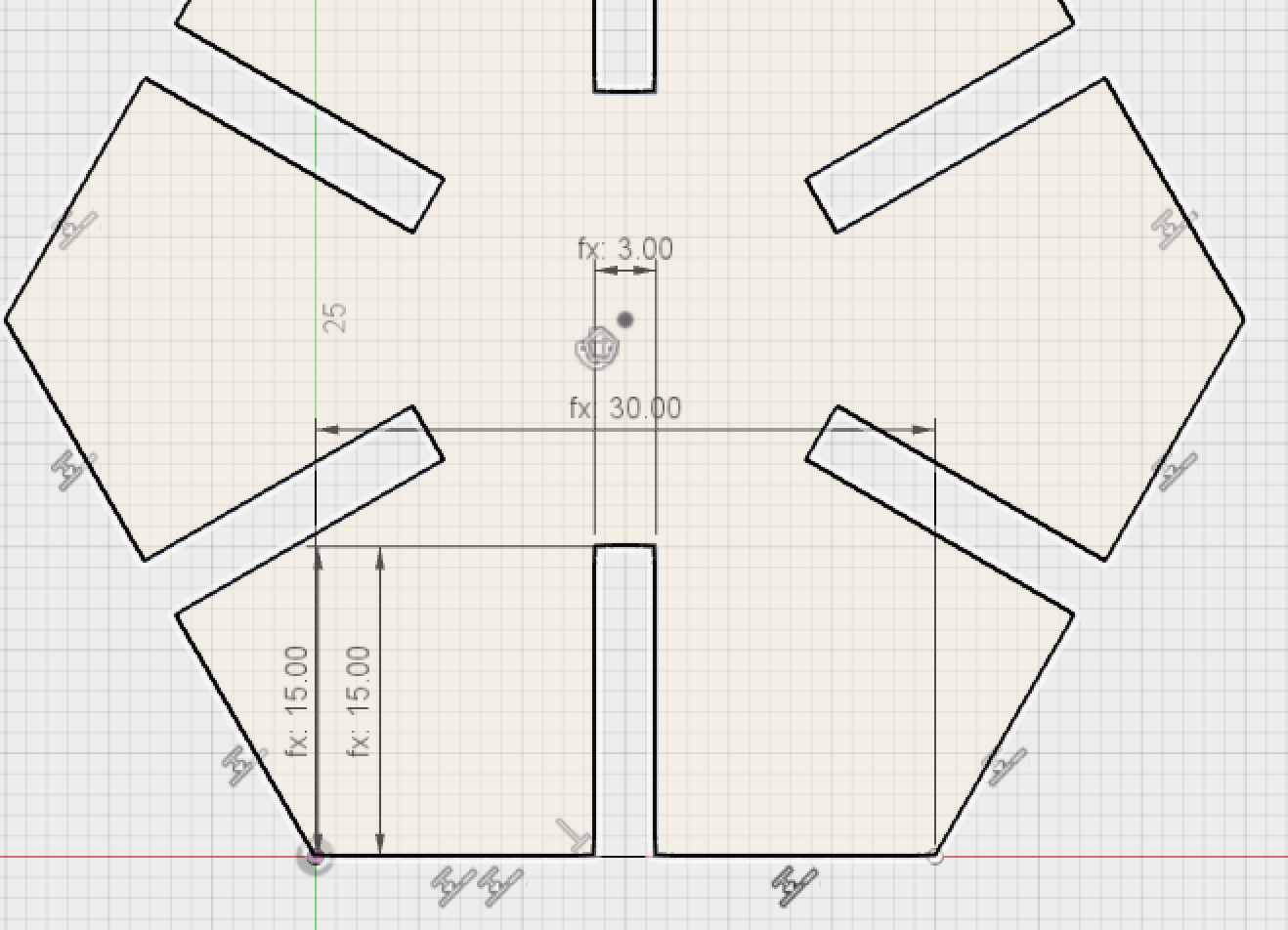

During thid week I designed a simple support for my phone with press fit.For the process I used fusion 360 with parametric design.

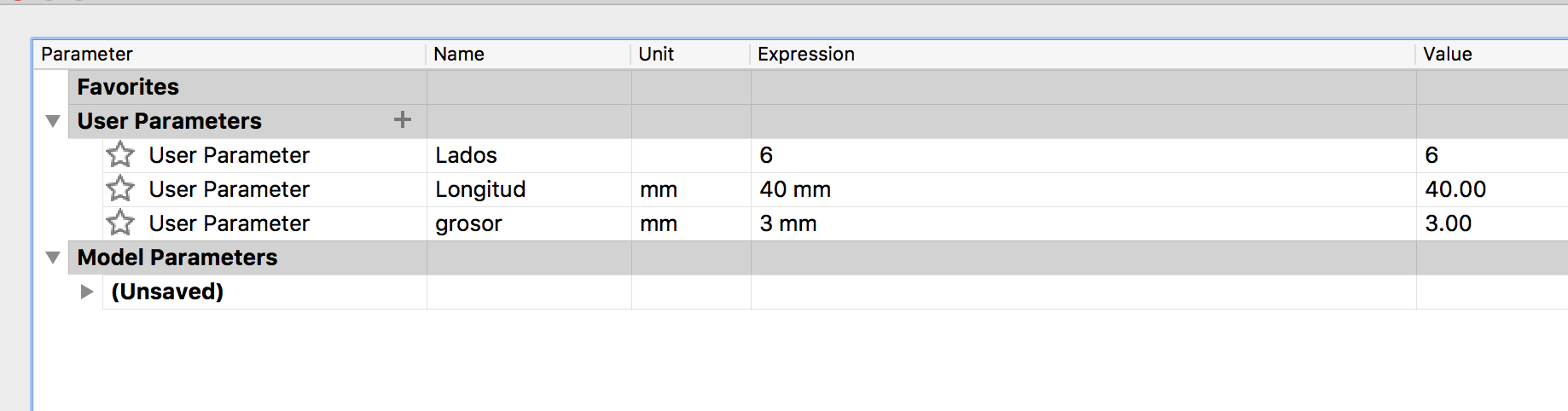

Fig 1. Parameter on fusion 360.

Fig 2. The parametric draw on fusion.

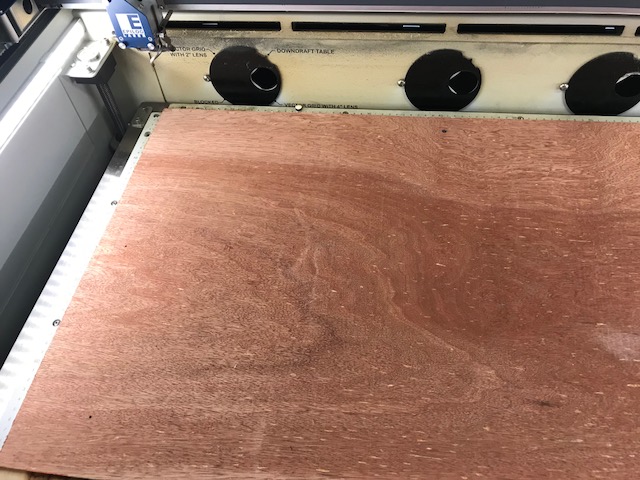

Fig 3. The plywood’s thickness is 3mm.

Fig 4. The filter renews air on the room.

Fig 5. The air outlet for the epilog 30 w. It prevents the material from catching on fire

Fig 6. Set the cero point on the machine.

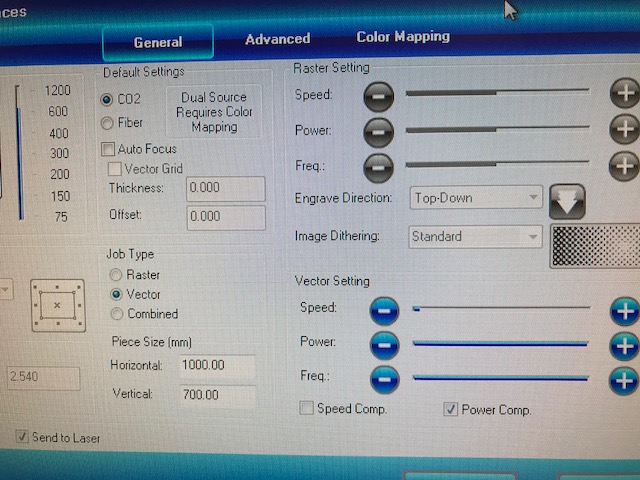

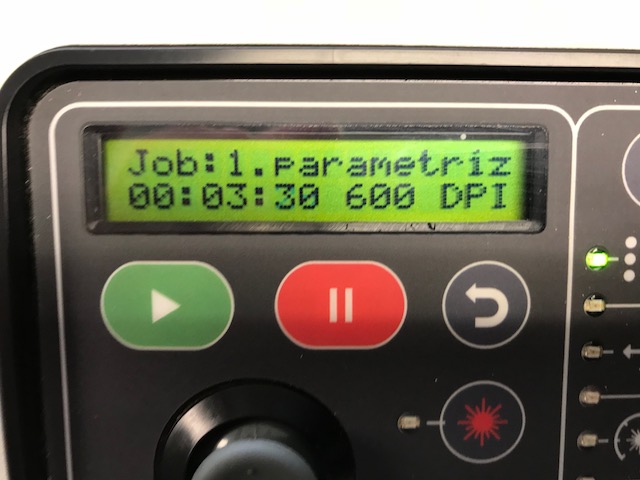

Fig 7.The printer settings, speed 4%, Power 100, Frequency 100 and job types Vector and 600 DPI.

Fig 8. The job lasts 6 minutes.

Fig 9. The pieces on the laser cutting machine.

Fig 10. The emergency stop and turn on botton.

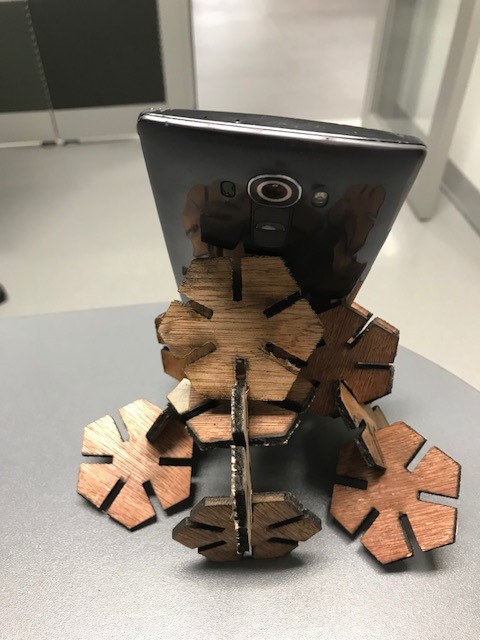

Fig 11. The model with the telephone.

Fig 12. The model from the back. The file was exported as DXF to Ilustrator and then sent to the epilog 30 printer settings. The pieces have multiple ways of being assembled with press fit.

The Design.

Fig13. Inventor Software. Fig 14. The plate design on Inventor. Fig 15. The support part (2 pieces) design on Inventor. Fig 16. Ribs Support (2 pieces) design on Inventor. In the assembly model shows that. Fig 17. Final support (Isometric) design on Inventor. Fig 18. Assemble model design on Inventor.

In the assembly model show that. Fig 19. Inside the laser cutter GCC Laser Pro Fig 20. The machine cutting the design. Fig 21. The parameter on the machine. Speed 1.3/Power 90 / PPI 30 /Vector. Fig 22. The final pieces assembled as the support for the DC motor.

The other part of the assignment with the laser machine consists in designing the flexible guard on Inventor. Fig 23. Flexible guard design on Inventor. Fig 24. Flexible guard on laser cutter.

The next pictures show the assembled flexible guard. This is used for the lemon hopper.

Fig 26 Example of guard flexible.

Fig 27. Other view, Example flexible guard.

The kerf in my asigment was 0.2mm. I used plywwod.

Link for the kerf:

http://www.cutlasercut.com/resources/tips-and-advice/what-is-laser-kerf

Vynil Cutting.

Ready to be sent.

Ribs

Safe guard.

Plate

Support part.

New archive pressfit.