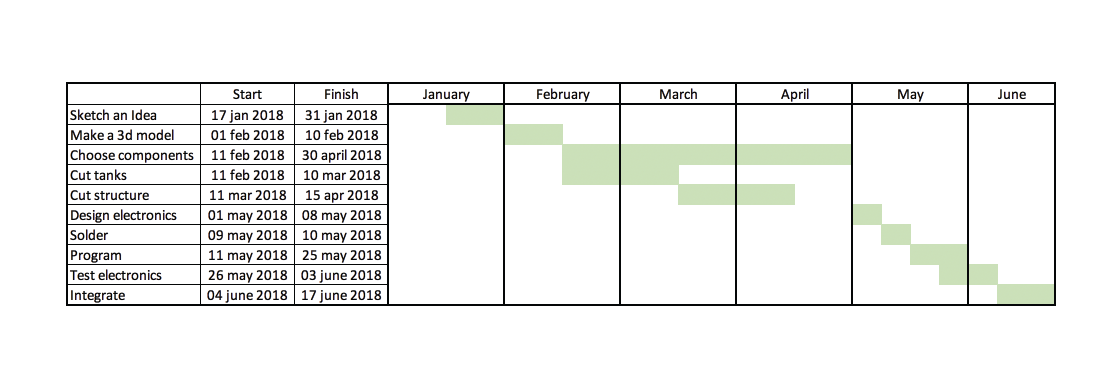

This week was all aout designing our final project and planning for the upcoming weeks. In order to do so, I have answered the following questionaire:

I want to create an automated cold brew machine. This is a slow-dripping method for brewing coffee with ice-cold water. Depending on the likes of the user, the rate at which the droplets are dripped will change, giving the brew a different taste each time.

I have not found a similar project to this one within the fab academy students, but I have taken some inspiration from the Yama towers (which make cold brew). I've done some research regarding the different stages of the process and designed my project accordingly.

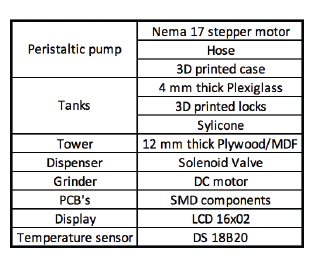

I have constructed a BOM regarding all of the electronic and non-electronic materials I need.

Most of these components can be easily found in Lima. There's a street within the city's historic centre, which sells nothing but electronic components. Acquiring the materials there will be rather easy. Digikey is also an option, but the shipping time might be an inconvinient, specially considering how slos the customs department can be in Peru.

I expect the project to cost no more than 40 bucks, all things considered.

Apart from the actuators, I will be making manufacturing most of the project. I'll use acrylic for the tanks, MDF or Plywood for the Tower, PLA for the peristaltic pump, silicone as an isolating and sealing agent for the tanks, and PCB's.

I'll be using 2D design for the tower and the tanks, cutting them in a shopbot and laser cutter respectively. I'll 3D print my peristaltic pump, and fabricate all of my microcontroller boards.

I have designed the boards and the tanks, but I have yet to cut and assemble them. I still need to program and test the fucntionality of the project.

The main question right now is finding the optimus range for the dripping rate: too fast and the coffee will not be brewed, but too slow and it'll go bad while it's being brewed.

The first thing I've done is plan for my electronics. I've bought most of the components (Solenoid valve, Stepper motor, Power supplier, etc) and I have decided to work with 3 different boards. I've designed and routed all of them, and I'll be soldering them next week. I've also designed the tanks and the grips, and the towers, which I have yet to cut and assemble. I hope this week I'll finish with the assembling and soldering so that I can focus on the code. I'll focus ont he slide and video afterwards.

My main goal is to get to control the dripping with the potentiometer and the peristaltic pump. I'll be happy if there are absolutely no leaks within the tanks, and if the structure is stable. This means the design and integration of the techniques has been adequate. If the machine works properly, then it means my code and electronics are also adequate, and that I've managed to master most of the skills from the academy.