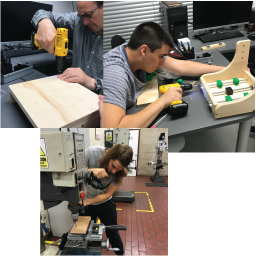

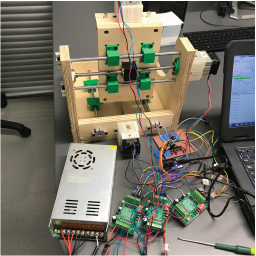

Fabricio, Nicolas and I started building our CNC machine. With the designs I had, Fabricio's electronics expertise and Nicolas' willingness to be of use, we started off quite well. We spent all of our free time building the machine. Here are some pictures:

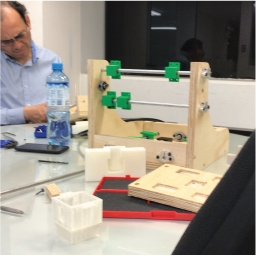

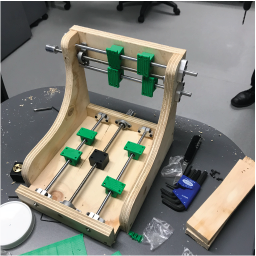

We started assembling the parts we had cut last week. We used the enrouter software to cut the parts in a MultiCAM machine. We decided against designing for pressfit because we felt it would be less stable. So we used nuts and bolts to assemble the machine. In these pictures you can see Fabricio, Nicolas and me, as we assemble the machine. I was mostly in charge of the design of all of the pieces. Including the green hubs for the ball bearings and the hubs for the stepper motors.

We had already considered the electronics when designing the machine, so we had no problem when integrating the pieces.

I left just enough space for the threaded rods to fit into the stepper motors.

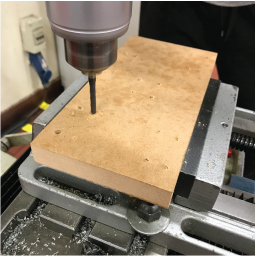

I also drilled some holes into the bed, in order to screw it to the ball bearings attached to the threaded rods. This way the bed would move with stability.

Finally, I helped Fabricio with the electronics. We used a modified satsha kit for controlling the machine, and a TB_6550 V2 driver with 16 microsteps as drivers for the motors.

We had some issues with the CAM softwares, but you can find most of the documentation in the lab's web page. And here you can find my files: