Fabricio, Nicolas and I decided to work on a CNC machine as our group project. We decided to make a Machine with an Interchangeable actuator, so that we could have two different actions performed on the same machine. We're making a CNC LASER engraver and a milling machine. I was tasked with designing the machine and its axis. I got inspiration from a self-made CNC machine made at UTEC.

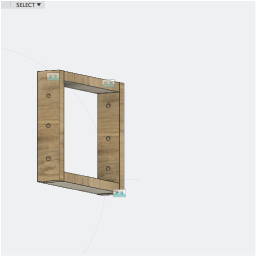

The first thing I did was measure the materials we had available. We had 300 mm long threaded rods, and 19 mm thick Plywood. This dimensions limited my machine to a bed size of roughly 250 x 250 mm. Then, I started sketching in Fusion 360.

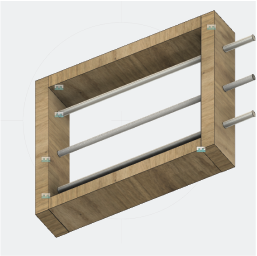

I decided to add the threaded and non-threaded rods, just to verify that mi design was accurate. This would also allow me to check that the distances between the holes were ok.

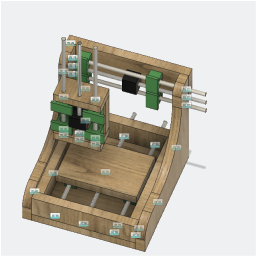

I then continued designing the X Axis, using the available machine as a reference.

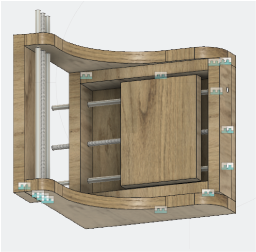

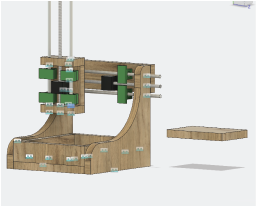

Once this axes were completed, I designed the bed, and placed it as a component on top of the Y axis, just to check whether or not the dimensions were correct.

I then designed the Z_Axis

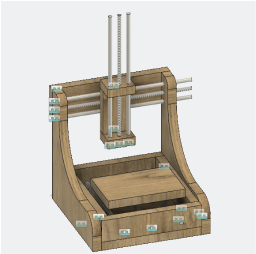

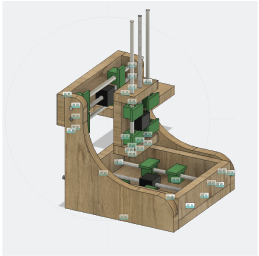

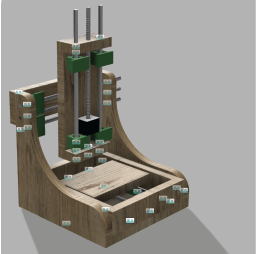

This is the full design of the machine, in which I included the parts which will move the bed and the axes.

I added the Bed to the final design...

And here's the finalized design.

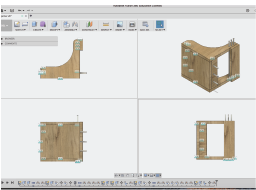

Some extra views...

And a rendered view...

I sent the sketch files as .DXF to the other guys, and then they cut and assembled them.