Home

Week Six : 3D Scanning and Printing

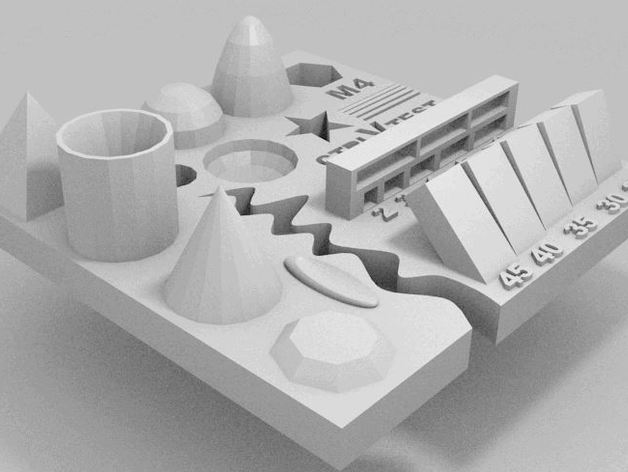

Group Assignment - Testing the design rules for your 3D printer

TEST ONE

I have downloaded STL file From this link. The machine settings are given below with "3D Printer Settings" as heading.

Material Description

Size : 2x50x30mm(Baseplate)

Hole Size : M4 Nut should fit perfectly

Fine Details : Pyramide, Cone, all numbers

Rounded Print : Wave, Half Sphere

Minimum Distance & Walls : 0.1/0.2/0.3/0.4/0.5/0.6/0.7mm

Overhang : 25°/30°/35°/40°/45°

Bridge print : 2/3/4/5/6/mm

Surface : All the flat parts

Settings on CURA

Layer Height : 0.08mm

Shell Thickness : 0.8mm

Bottom / Top Thickness : 0.8mm

Fill Density : 35%

Print Speed : 50mm/s

Support Type : Everywhere

Platform Adhesion Type : None

Nozzle Diameter : 0.4mm

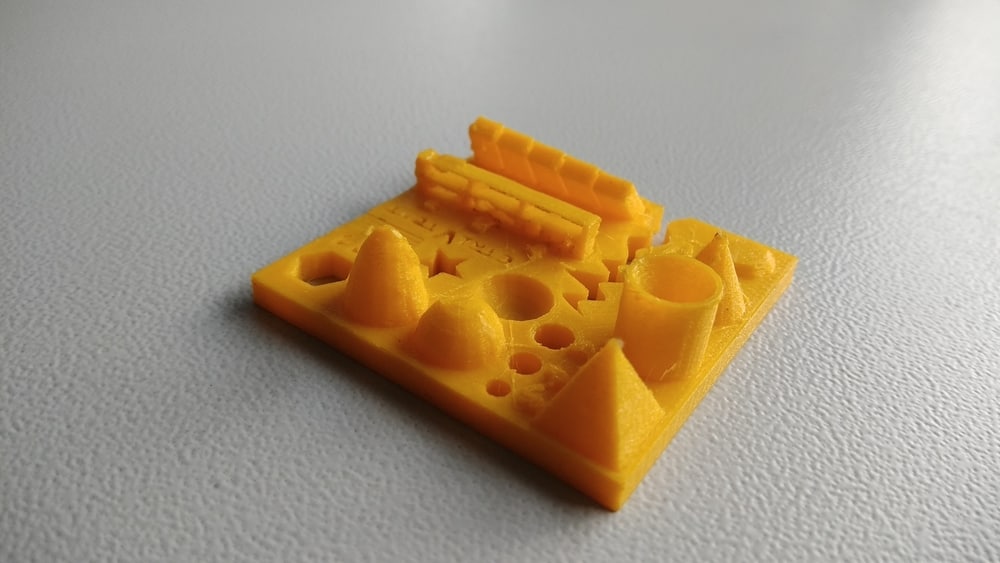

Result

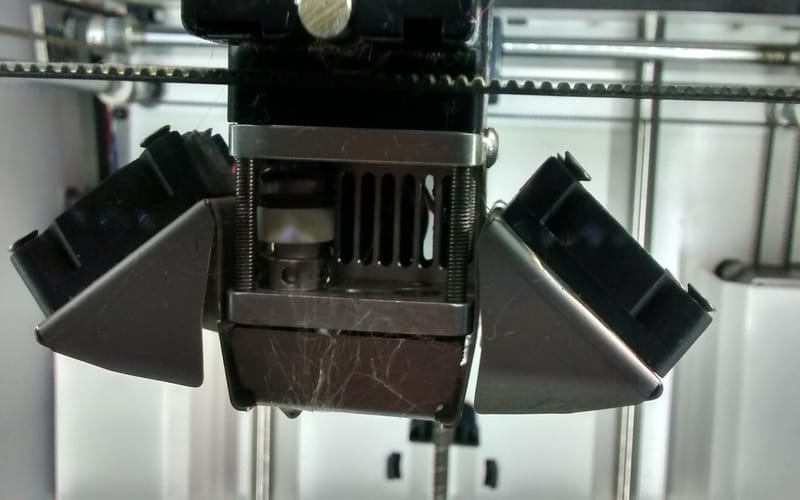

Print was perfect after we cleaned the nozzle. First we heated the nozzle to 240 degree celsius, then saw the Material purging out then we set the temperature to 80 degree celsius and pulled out the material.

Model was used with layer height 0.1 mm

Holes were good measuring 2.8 mm,3.71 mm,4.65mm

M4 nut is fitting perfectly

Pyramid , Cone has good finishing

Wave and Half Sphere is visually good

Overhangs came out well

Bridges were complete apart one side

Fonts were not readable

Walls have some defects

TEST TWO

I have downloaded STL file From this link. The machine settings are given below with "3D Printer Settings" as heading.

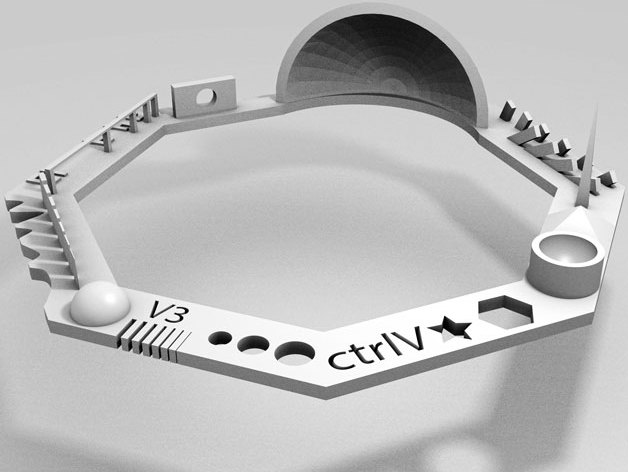

Material Description

Size : 100 x 100mm x 23.83 (10mm width)

Hole Size : Nut should fit perfectly

Fine Details : Pyramide, Sphere

Rounded Print : Wave, Rounded print

Minimum Distance & Walls : 0.1/0.2/0.3/0.4/0.5/0.6/0.7mm

Overhang : 25°/30°/35°/40°/45°/50°/55°/60°/60°/70°

Surface : All the flat parts

Settings on CURA

Layer Height : 0.08mm

Shell Thickness : 0.8mm

Bottom / Top Thickness : 0.8mm

Fill Density : 35%

Print Speed : 50mm/s

Support Type : Everywhere

Platform Adhesion Type : Brim

Nozzle Diameter : 0.4mm

Result

Wall thickness 0.1mm - 0.4 mm was not printed

Bridges except at 2 mm didn't came out well

overhangs at lesser angle need more support

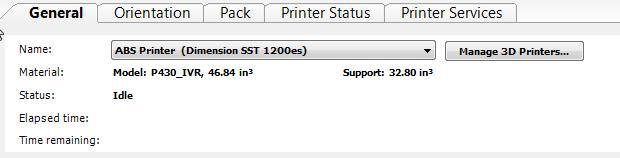

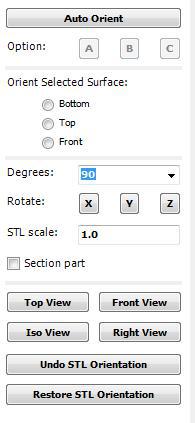

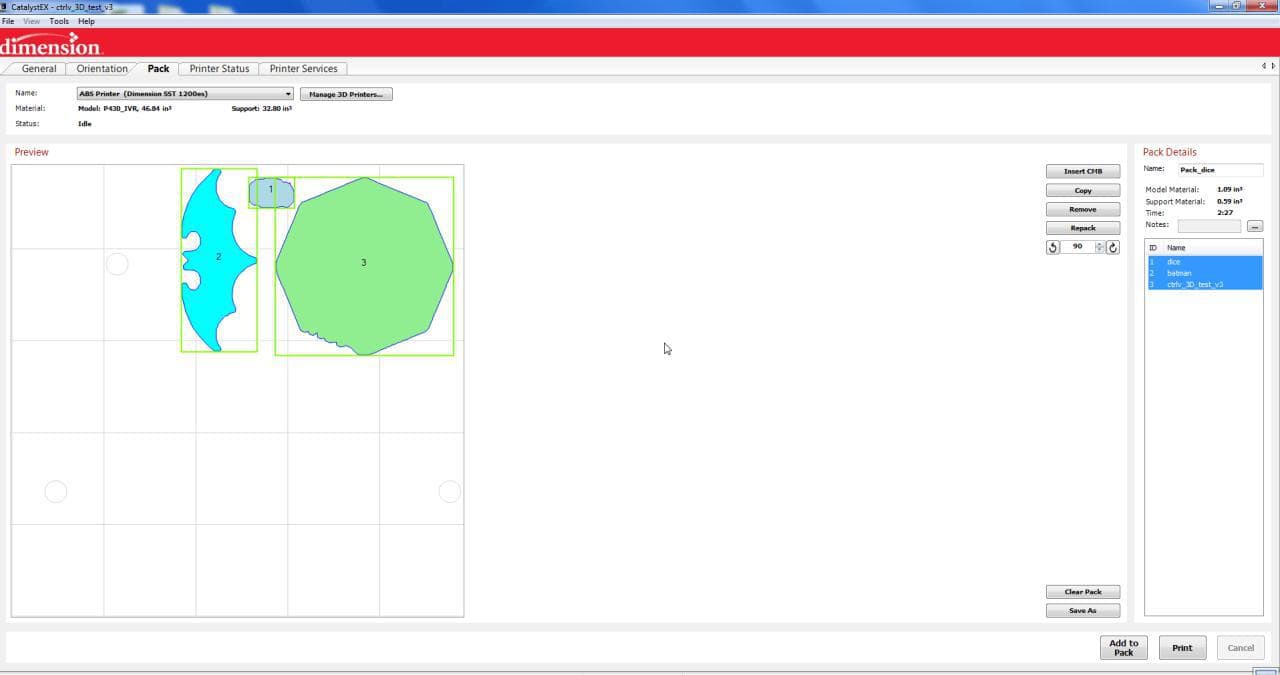

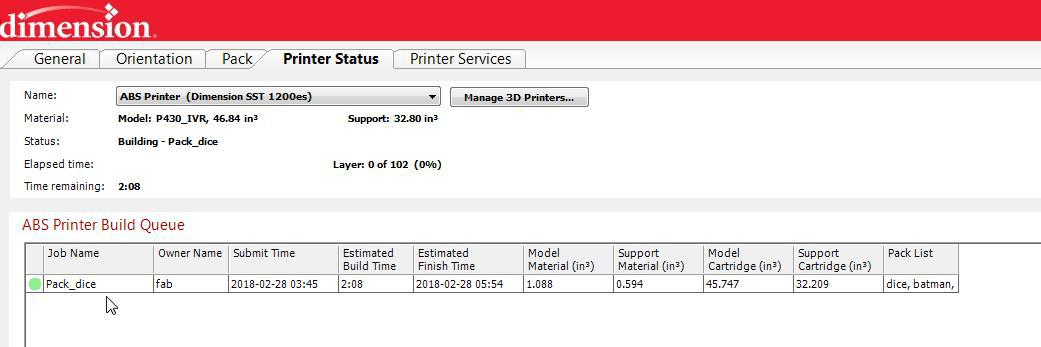

3D Printer

Stratasys Dimension 1200

Unlike Ultimaker, Dimensions set the nozzle axis and bed axis by itself

Separate catridge is used for loading ABS for support material and model material

Calibration on Dimension

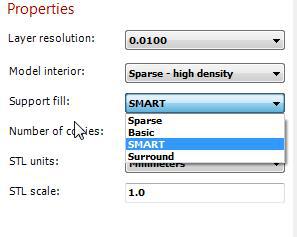

Layer Resolution : 0.0100

Model Interior : Sparse- High Density

Support Fill : Smart

No. of Copies : 1

STL Units : Millimeters

STL Scale : 1.0

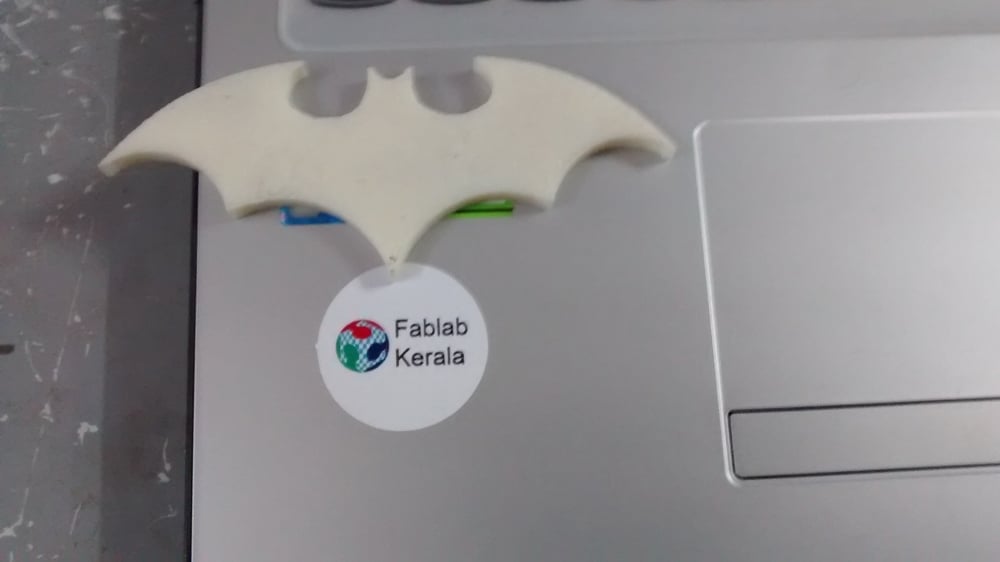

Process STL

Add To Pack

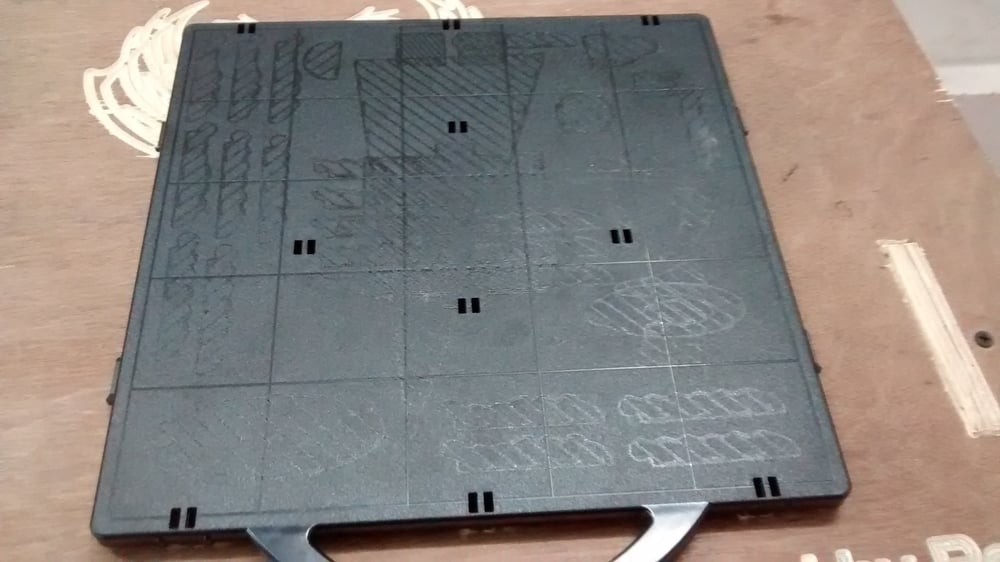

Bed - Dimension

ABS - Acrylonitrile Butadiene Styrene

Model

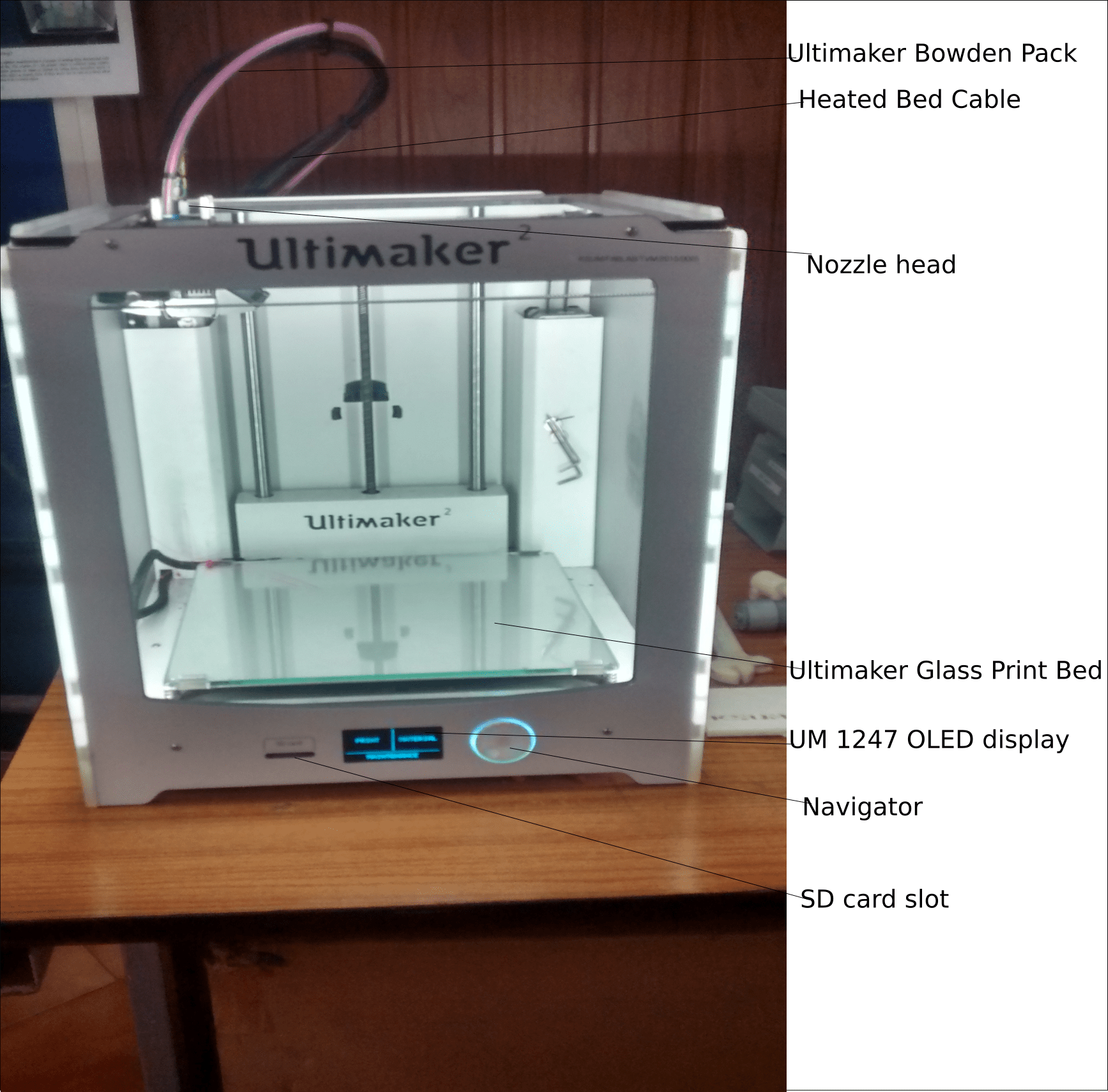

Ultimaker2

Ultimaker2 Nozzle Head

Material is inserted here at the motor on back portion of the ultimaker

Ultimaker 2 Extended AC/DC adapter power supply

Using a fan to keep down the temperature of the adapter

3D Printer Calibration

First I had reset the Ultimaker 2 as guided by our instructor Vinod. From Maintance > Advance Settings > Factory reset, using the navigator from the Ultimaker machine.

The machine itself will guide us what to do at that instance and helps in setting the bed and nozzle axis, as shown in gif below.

1. Created an stl file.

2. Imported the stl file to CURA

3.From Cura, Layer thickness(mm), Shell thickness(mm), Retraction enable / disabel, Bottom/Top Thickness(mm), Fill Density(%), Print speed(mm/s), Support Type(Brim,Raft,None), Platform Adhesion Type and Nozzle size(0.4mm) is set accordingly as needed.

4. Saved and Export above settings to G-code.

5. Copy the G-code to the memory card(which goes into Ultimaker)

6. Rest Ultimaker settings using factory reset and Allign the bed and nozzle

7. Select material type and Load the PLA(polylactic Acid) material in clockwise direction

8. Select the file to print

9. Set nozzle Temperature

10. Print

Material Used - PLA (PolyLactic Acid)

We were provided with many colored PLA. I chose the color - Orange.

CURA Settings

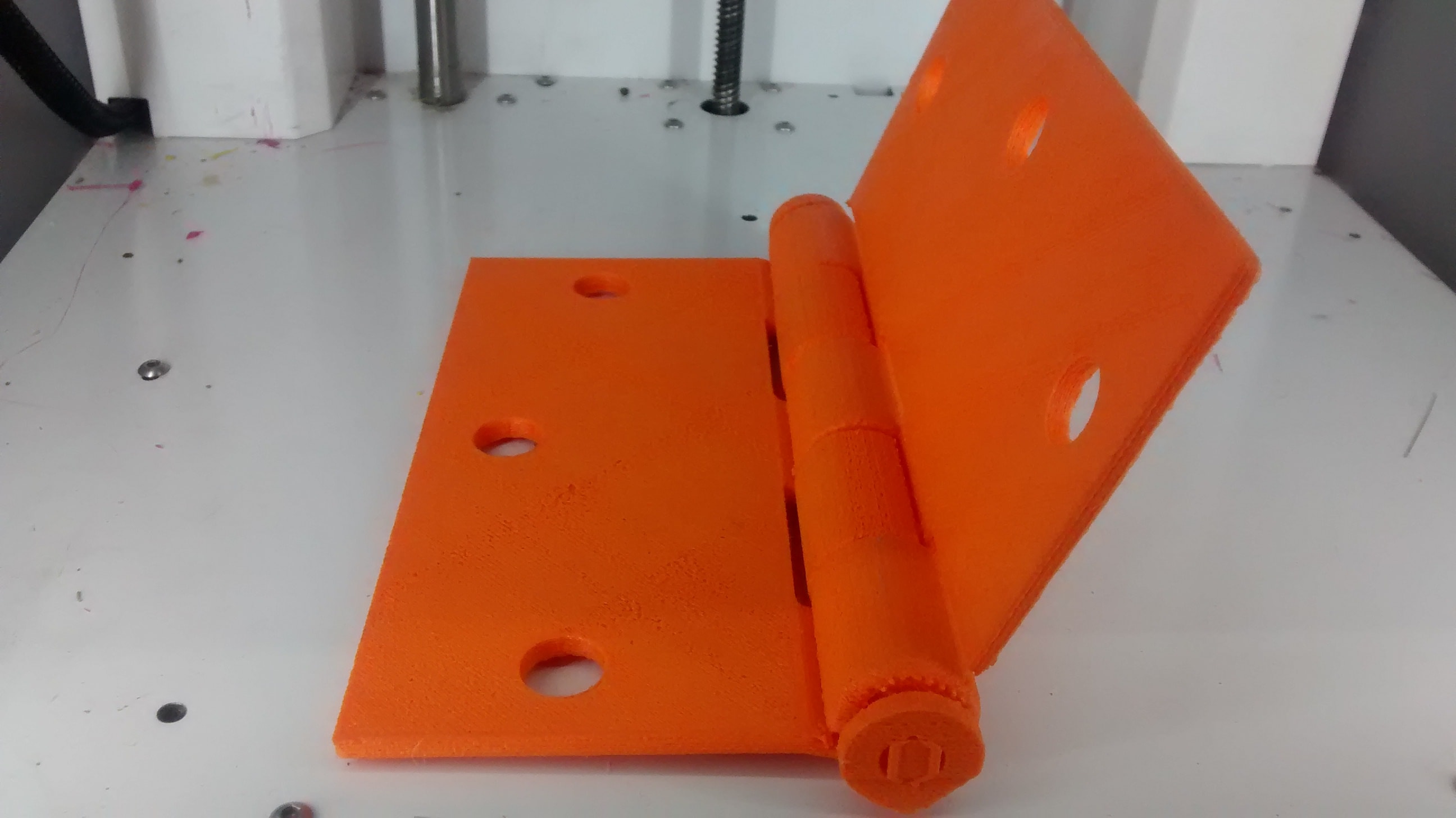

My 3D Model - Hinge

I used Fusion 360 to design a hinge. I faced a problem while printing because my design was so small, that it was not able to act as a hinge but just a model. So i scaled it. After removing the support I finally printed a Hinge using ultimaker2. Works perfectly.

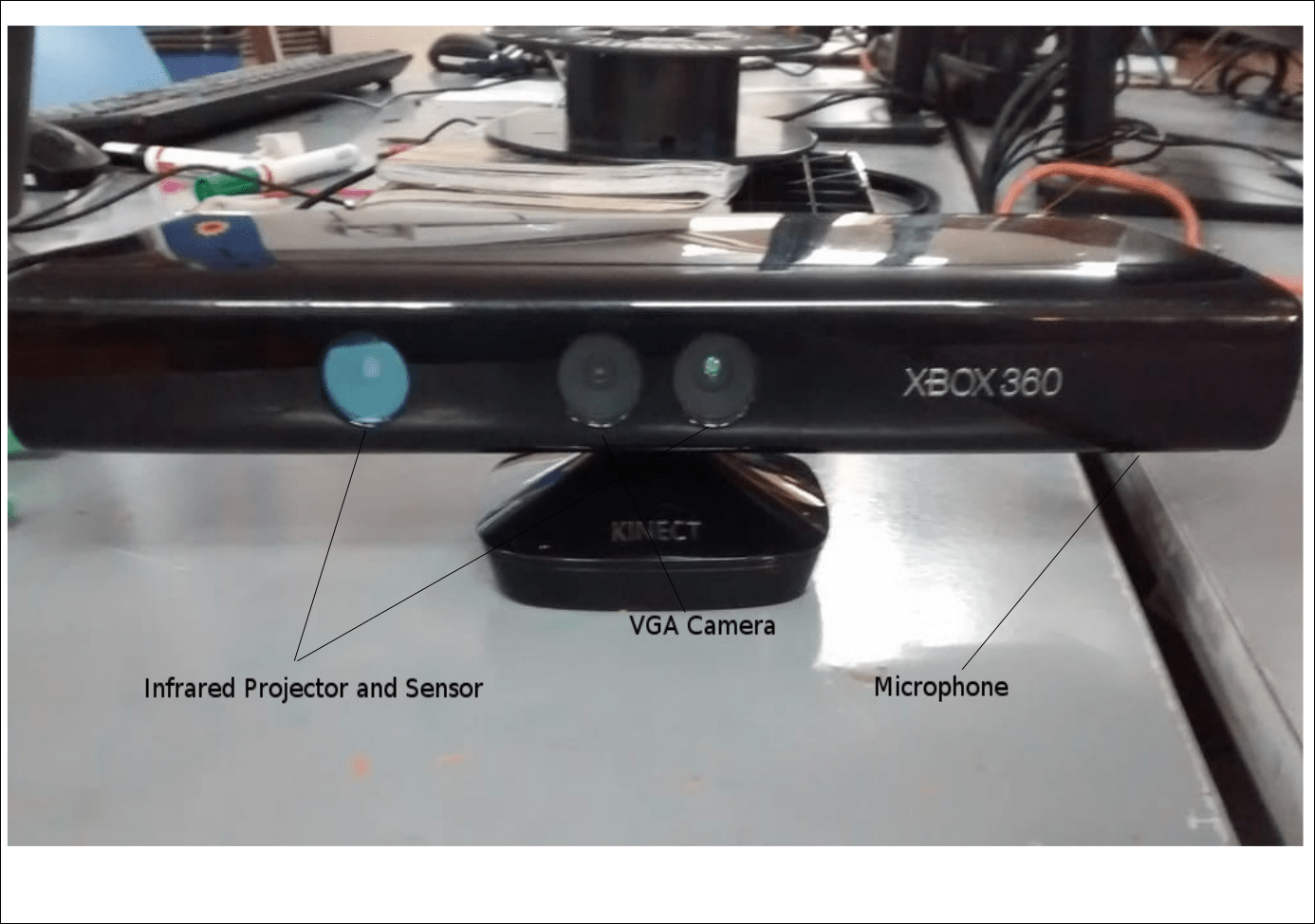

3D Scanner

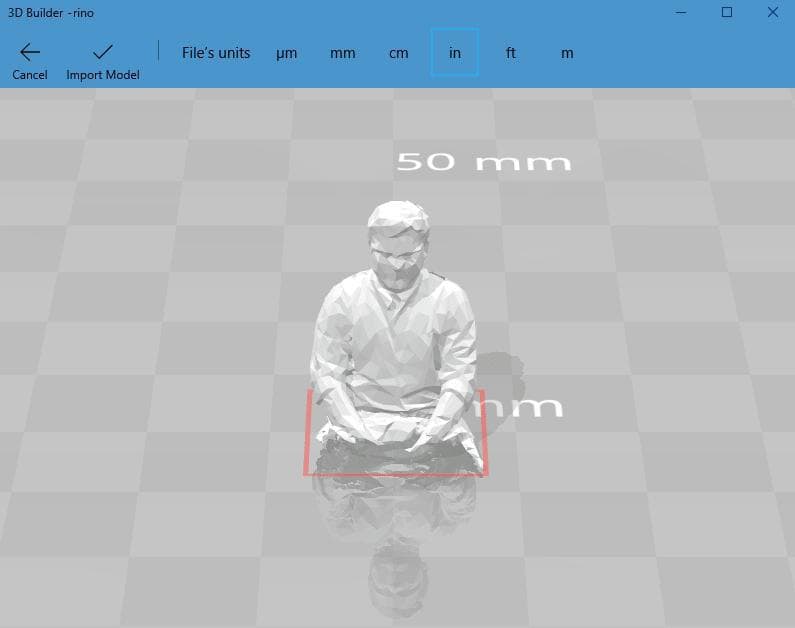

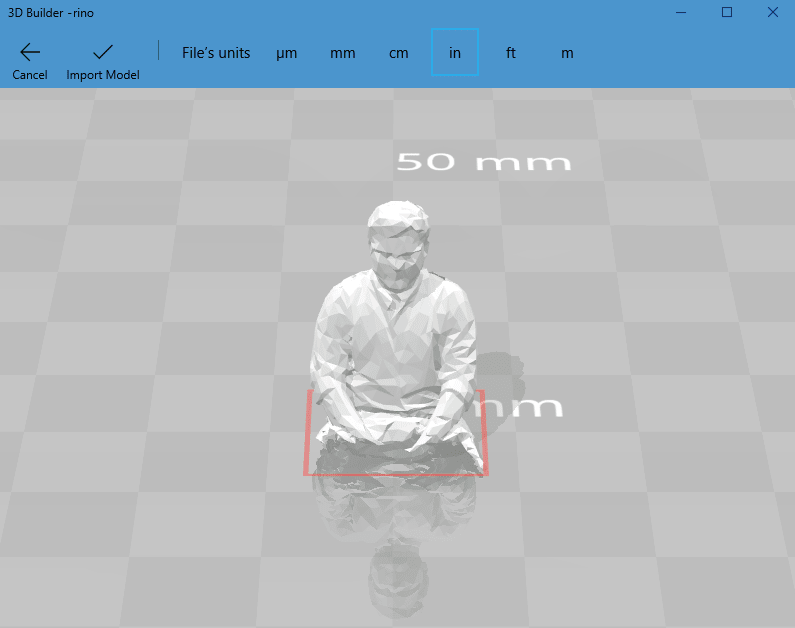

3D Scanned Image

First time seeing the scanner and I was surprised when our instructor told me to scan myself. I was wondering how it will work, then he showed me how its done. Tada theres myself scanned and I'm seriously looking forward to print or mold it anytime within the academic period.

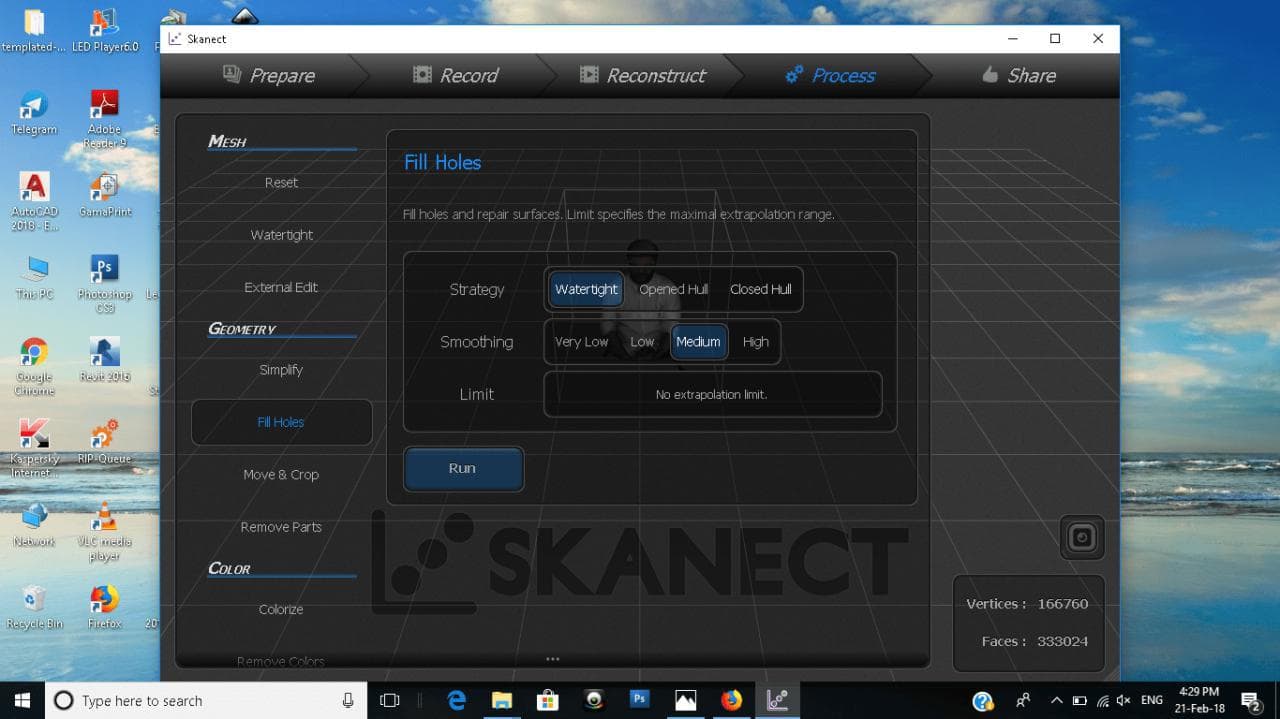

Using Skanect Software, I was able to scan myself. The problem faced here is, if you want high resolution scan, You should buy the original licence.